High slope bolt and cable operation platform and construction method

A technology for working platforms and slopes, applied in excavation, foundation structure engineering, sheet pile walls, etc., can solve problems such as difficult hole positions, and achieve time-consuming, labor-intensive, simple and economical results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

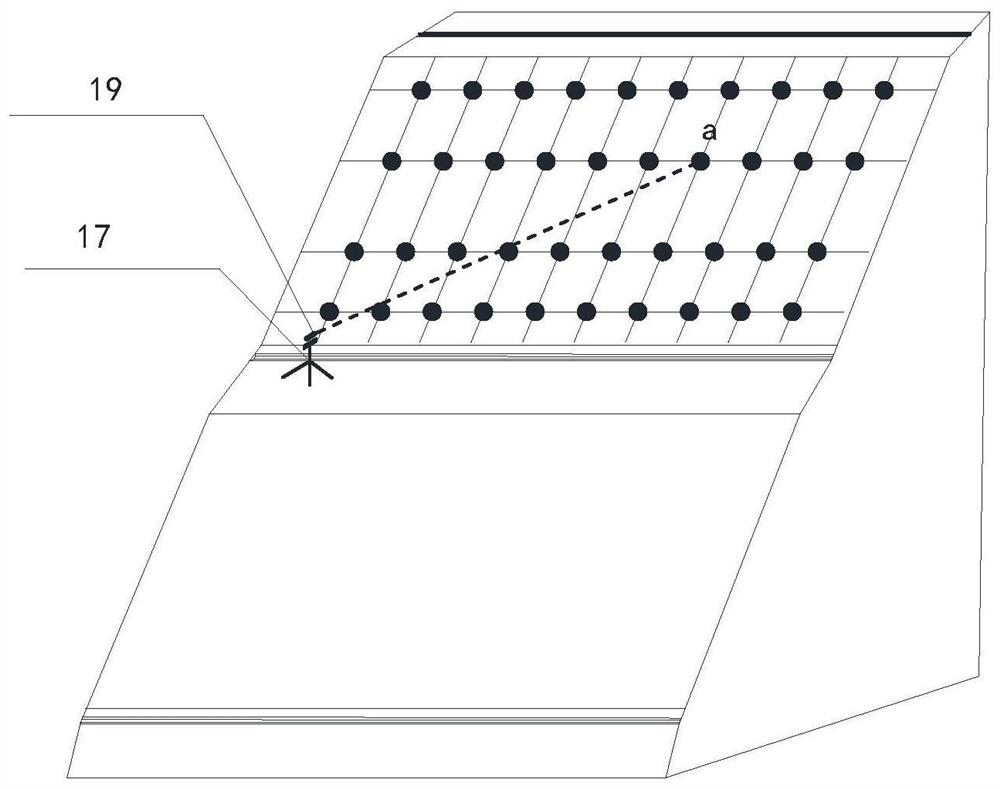

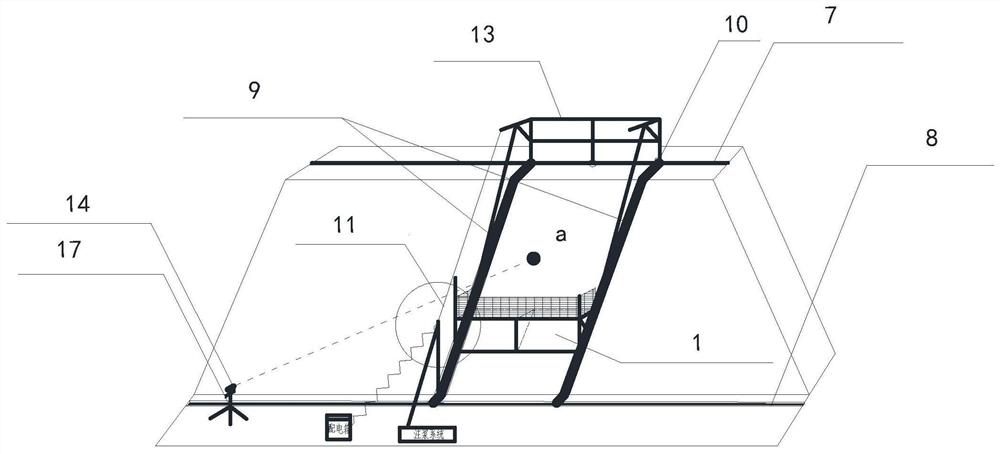

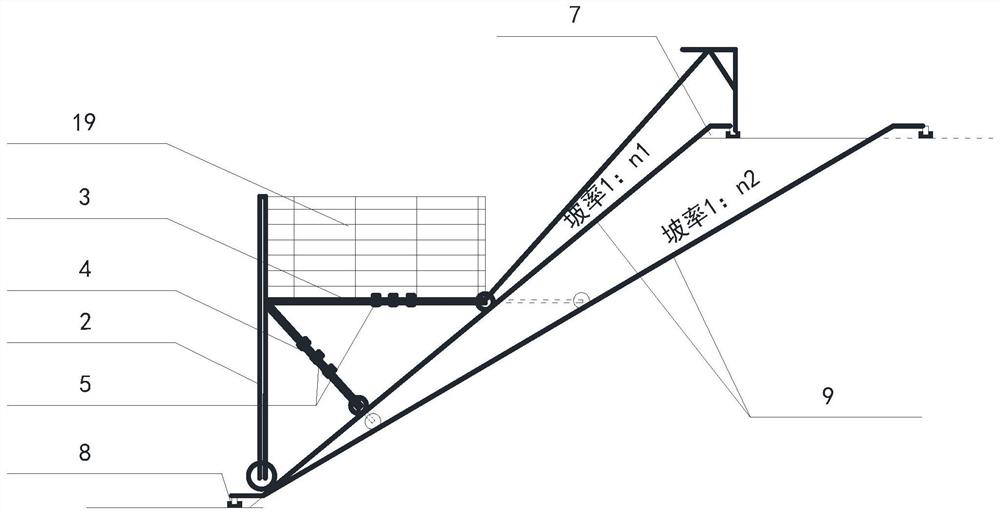

[0035] As shown in the figure, the high slope bolt and cable work platform includes a lifting operation platform. The lifting operation platform is composed of a platform frame and two "K" type lifting frames 1. The two "K" type lifting frames 1 are respectively The sides symmetrical to the bottom surface of the platform frame are connected; the "K" type lifting frame 1 is composed of a vertical arm 2, a horizontal telescopic arm 3 and an oblique telescopic arm 4; the oblique telescopic arm 4 is provided with three telescopic fixed nuts 5, According to different grades, through the telescopic rods of the oblique telescopic arm 4 and the horizontal telescopic arm 3, effective contact with high slopes with different grades can be achieved; the top of the "K" erecting arm 1 is provided with a roller 6;

[0036]It also includes the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com