Process control valve

A process control, valve body technology, applied in lift valves, valve assemblies, valve details, etc., to solve problems such as valve 10 not functioning properly, lengthy operation shutdown and maintenance procedures, plug 16 stuck in one position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

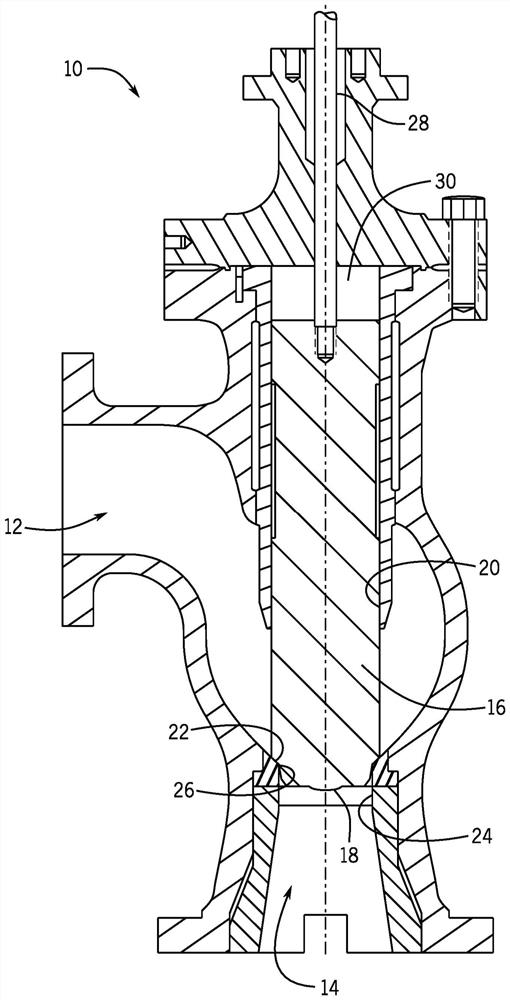

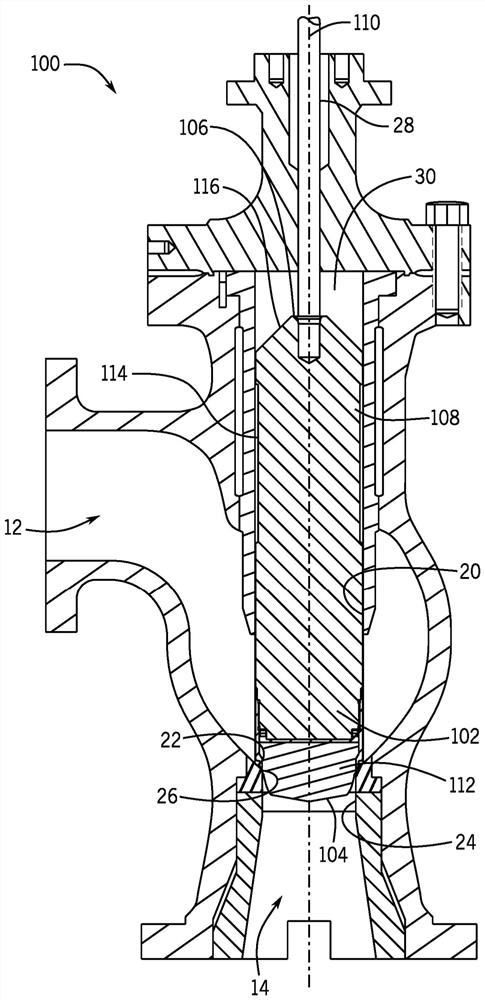

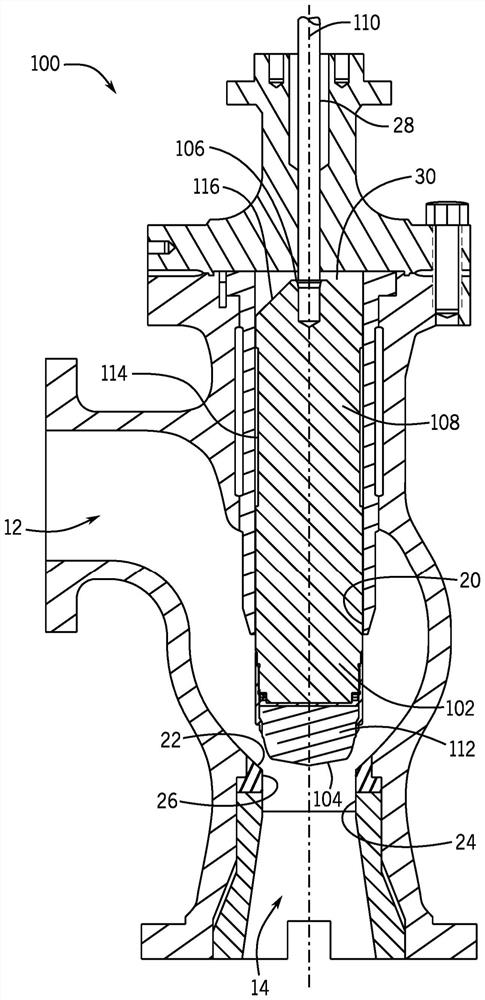

[0013] Before any embodiment of the invention is explained in detail, it is to be understood that the invention is not limited in its application to the details of construction and the arrangements of components set forth in the following description or shown in the following drawings detail. The invention is capable of other embodiments and of being practiced or carried out in various ways. Also, it is to be understood that the phraseology and terminology used herein are for the purpose of description and should not be regarded as limiting. The use of the terms "comprising", "including" or "having" and variations thereof herein is intended to cover the items listed thereafter and equivalents thereof as well as additional items. Unless otherwise stated or limited, the terms "mount", "connect", "support" and "coupling" and variations thereof are used broadly and encompass direct and indirect mounting, connecting, supporting and coupling. Further, "connected" and "coupled" are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com