pipe cleaning robot

A pipeline cleaning and robot technology, applied in the direction of instruments, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of affecting the working distance, insufficient traction, hindering the smooth passage of transport materials, etc., and achieve the effect of rapid cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

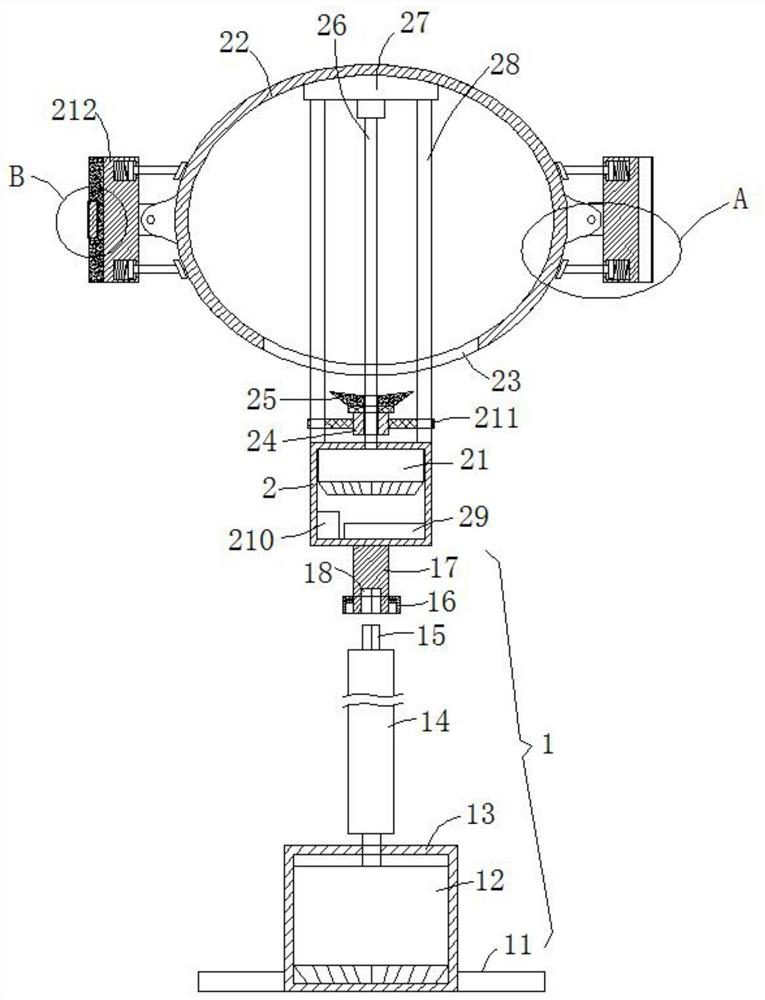

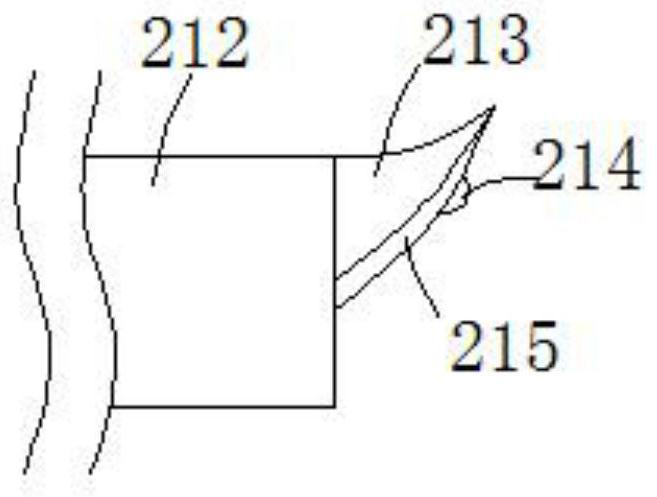

[0026] see Figure 1-4 , this embodiment provides a pipe cleaning robot, including a power mechanism 1, a mounting seat 2, an oval adjustment steel ring 22 and a data processing module 29, the inner cavity of the mounting seat 2 is a hollow structure, and the inner cavity of the mounting seat 2 is The side is provided with a servo motor 21, the servo motor 21 runs through the rear end surface of the mounting seat 2 through the rotation of the power shaft, and is connected with a threaded transmission rod 26, and the inner rear end side wall of the elliptical adjusting steel ring 22 is fixedly welded with a connecting seat 27, the elliptical The front end of the shape adjusting steel ring 22 is provided with an adapter hole 23, the tip of the threaded transmission rod 26 rotates through the adapter hole 23, and is connected to the center of the front end surface of the connecting seat 27 through the rotating disk, and the outer wall of the threaded transmission rod 26 is passed ...

Embodiment 2

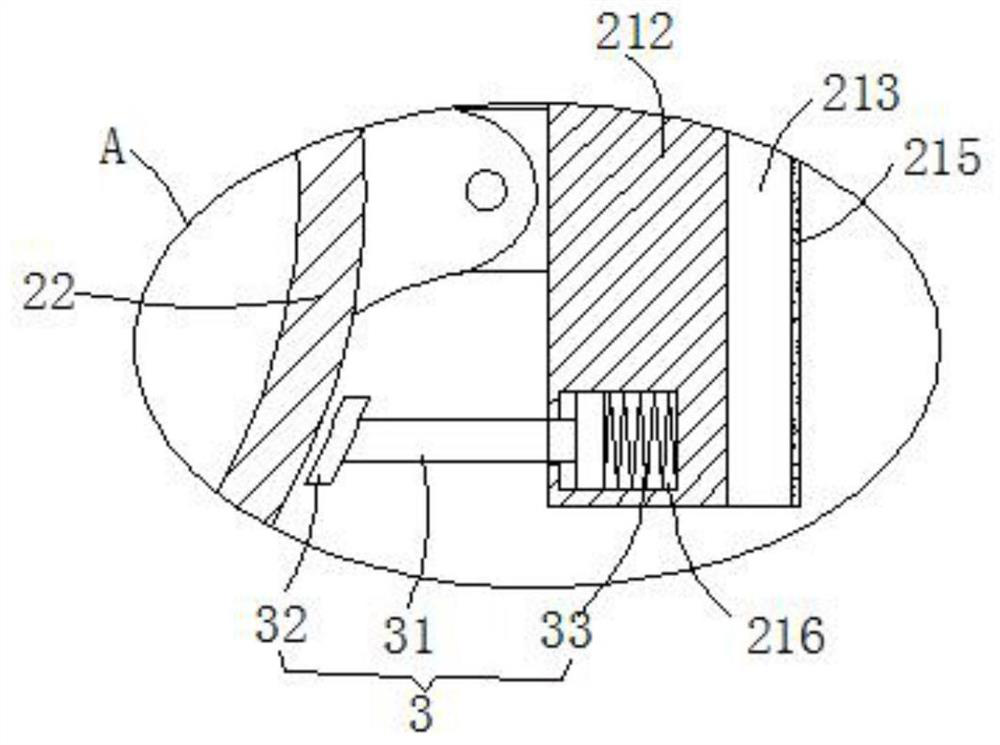

[0034] see Figure 1-4 , further improvements have been made on the basis of Example 1:

[0035] The side of the two connecting plates 212 close to the elliptical adjustment steel ring 22 is provided with two front and back symmetrical buffer mechanisms 3, each buffer mechanism 3 includes a T-shaped bar 31 and an arc-shaped rubber adapter block 32, two The side of the connecting plate 212 close to the elliptical adjusting steel ring 22 is provided with two T-shaped chute 216 distributed front and rear. The arc-shaped rubber adapter block 32 is fixedly connected with the tip of each T-shaped bar 31, and each arc-shaped rubber adapter block 32 is matched with the outer wall of the oval-shaped adjusting steel ring 22, and each T-shaped bar 31 is connected with the Springs 33 are connected between the inner cavities of each T-shaped chute 216. When the oval adjustment steel ring 22 is adjusted and the oval adjustment steel ring 22 is deformed, the position of the connecting plate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap