Camera lifting system for cable trench inspection robot

A technology of inspection robot and lifting system, which is applied in the installation of closed-circuit television system, TV system components, cables, etc. It can solve the problems of inspection loopholes, poor monitoring effect of cable temperature change, and complicated operation, so as to ensure that the rod body is straight Straightness, reliable protection effect, and placement reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

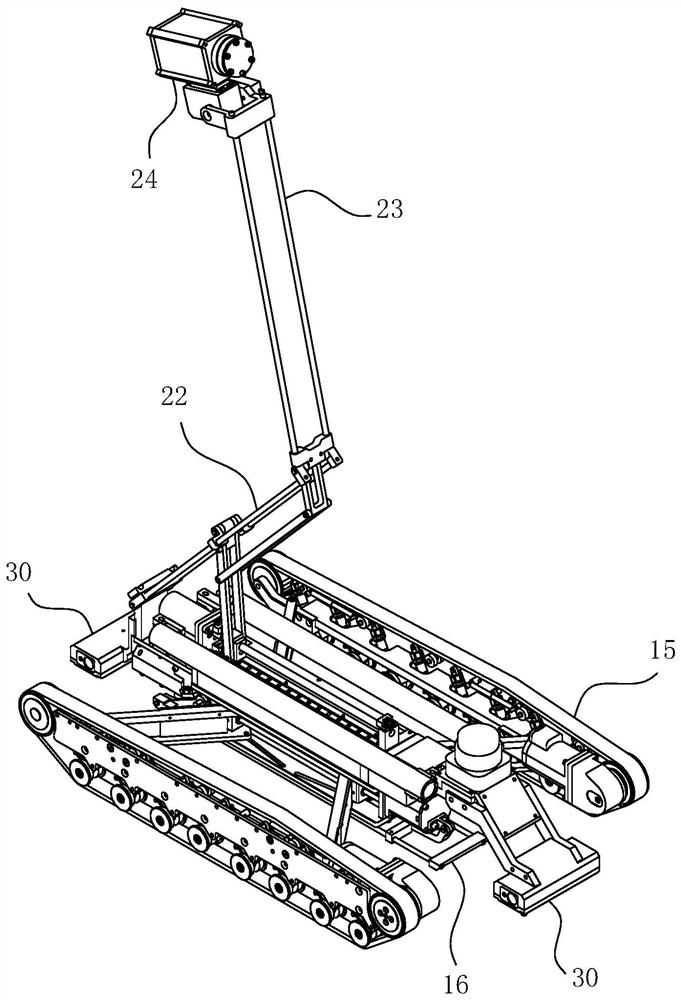

[0045] When the present invention is implemented, it exists as a part of the cable trench inspection robot. Therefore, for the convenience of overall understanding, the structure and working method of the specific embodiment of the entire cable trench inspection robot are described as follows:

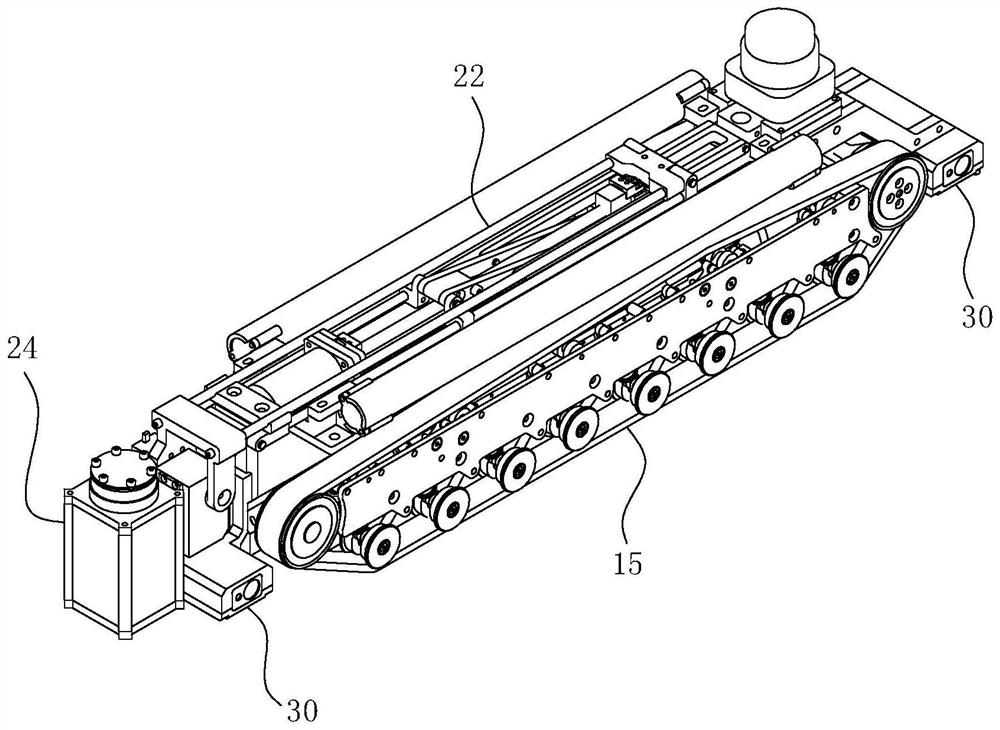

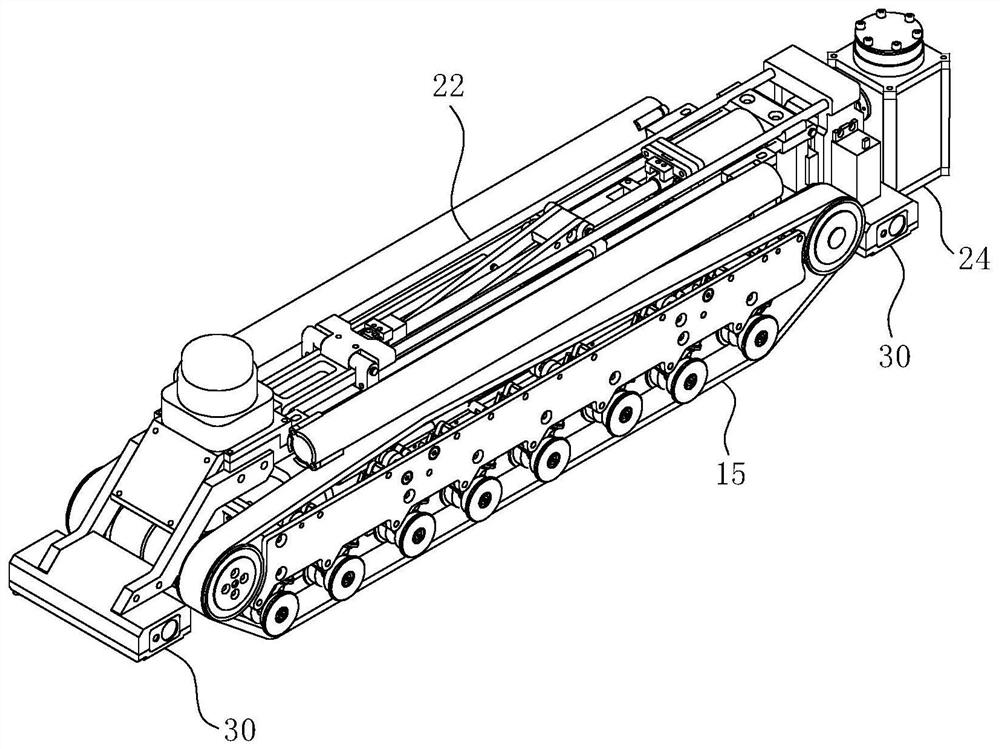

[0046] Cable trench inspection robot, such as Figure 1-17 As shown, its main body includes a base deployment system and a camera lifting system arranged on the base deployment system. in:

[0047] 1. Base expansion system

[0048] Base deployment systems such as Figure 1-12 As shown, it includes an expansion assembly for driving the walking assembly 15 to be extended so as to walk on the ground of the cable tunnel with a traveling posture, and driving the walking assembly 15 to return to the walking state so as to retract the width of the cable trench, and for driving the entire system to lift so that The jacking assembly 16 that is higher than the cable trench and descends so as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com