Multifunctional small rotary shaving assembly

A multifunctional and small technology, applied in metal processing and other directions, can solve the problems of high mold production cost, complex connection and installation structure, occupation of living space, etc., to save living space, improve wool feeding efficiency, and reduce living costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with accompanying drawing:

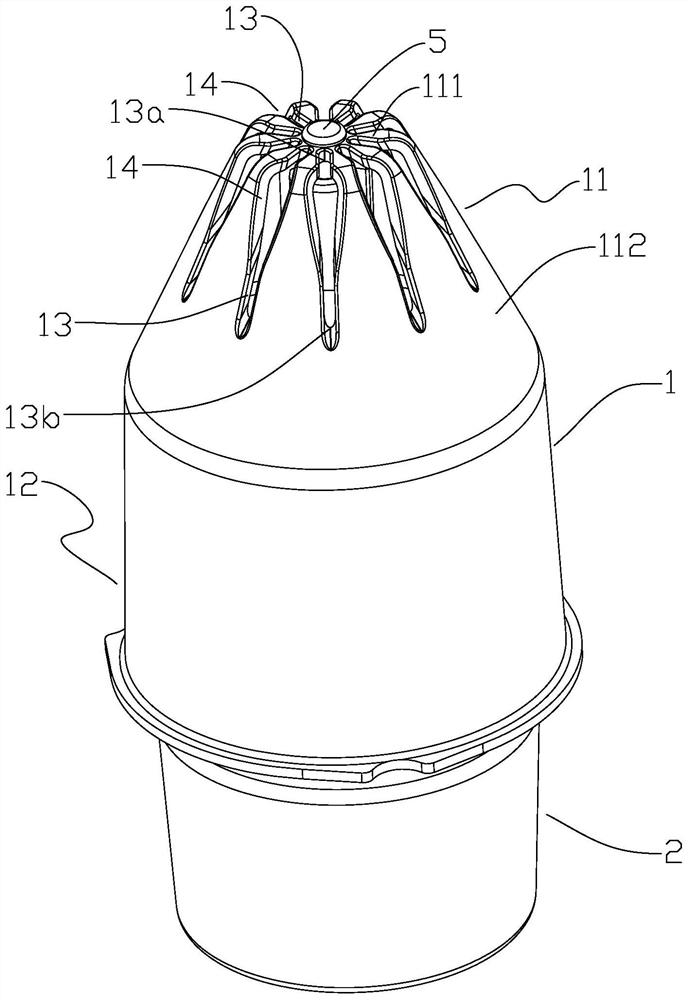

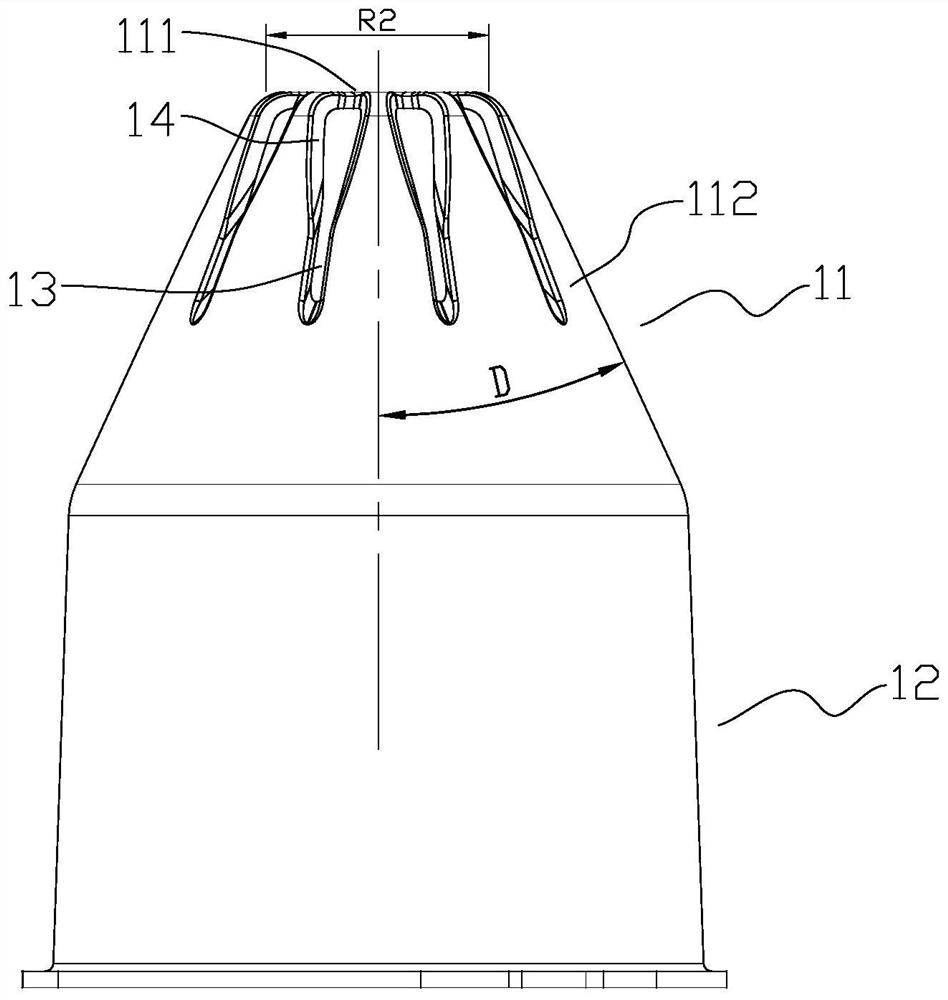

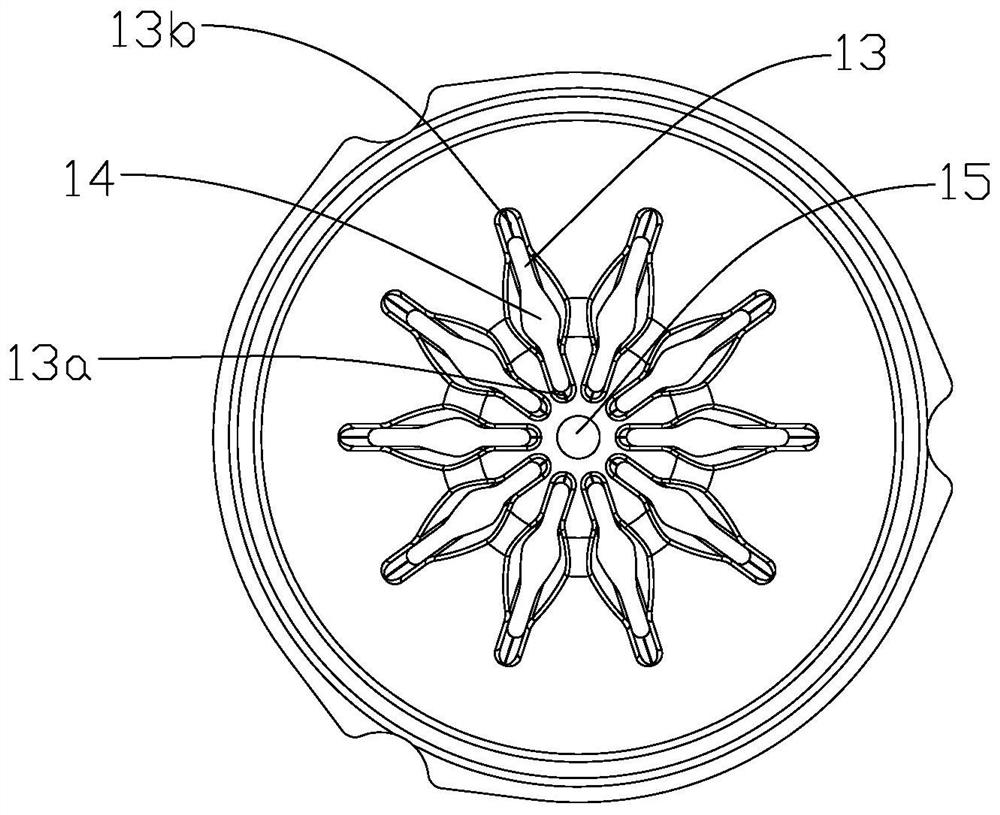

[0058] Such as Figures 1 to 15 As shown, a multifunctional small rotary shaving assembly includes a cutter head cover 1 and a moving knife assembly 2, the moving knife assembly 2 includes a moving knife 3 and a bracket 4 for holding the moving knife 3, and the cutter head cover 1 includes a cover head 11 and a cover body 12 integrated up and down. The cover head 11 includes a cover top 111 and a cover wall 112 connected to the outside of the cover top 111. The cover top 111 and the cover wall 112 enclose a power knife 3 In the cutting cavity 110 that rotates inside, the cover head 11 is provided with a plurality of hair feeding grooves 13 that communicate with the inside and outside of the cover head 11 along the circumferential direction, and the multiple hair feeding grooves 13 are independent and not connected to each other. 13 spans from the cover top 111 to the cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com