Knife net structure of rotary shaver and machining method thereof

A shaver and knife net technology, which is applied in the processing field of knife net structure, can solve problems affecting shaving efficiency, painful skin, running out, etc., to improve shaving efficiency, increase hair feeding efficiency, and improve comfort Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with accompanying drawing:

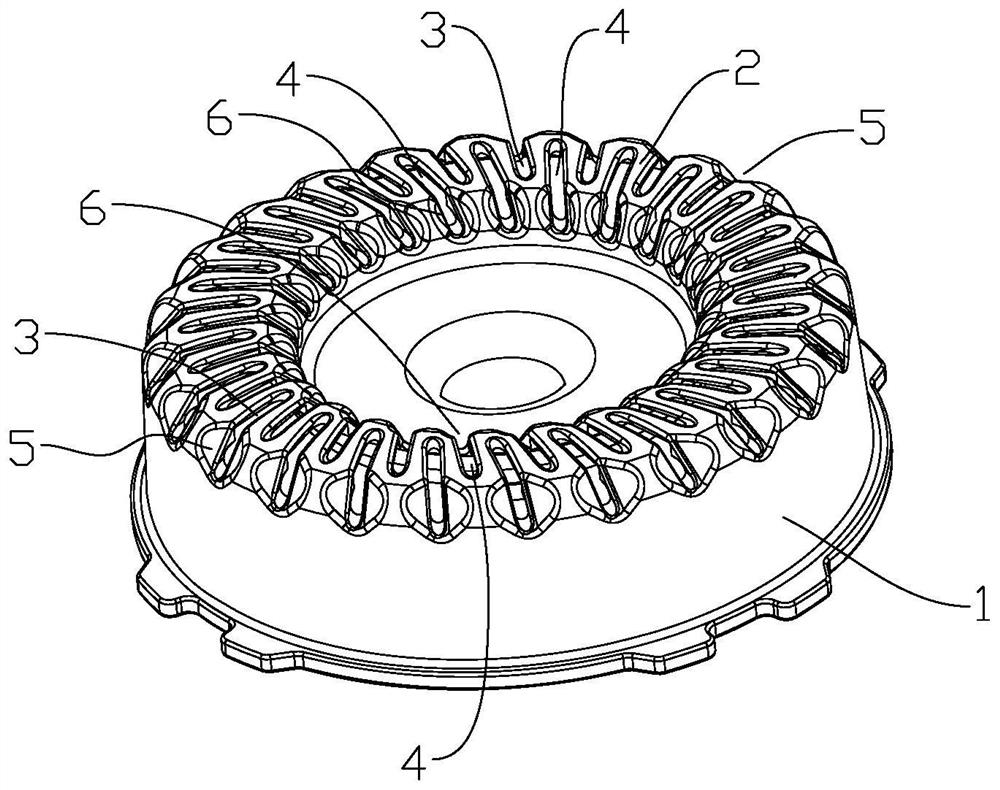

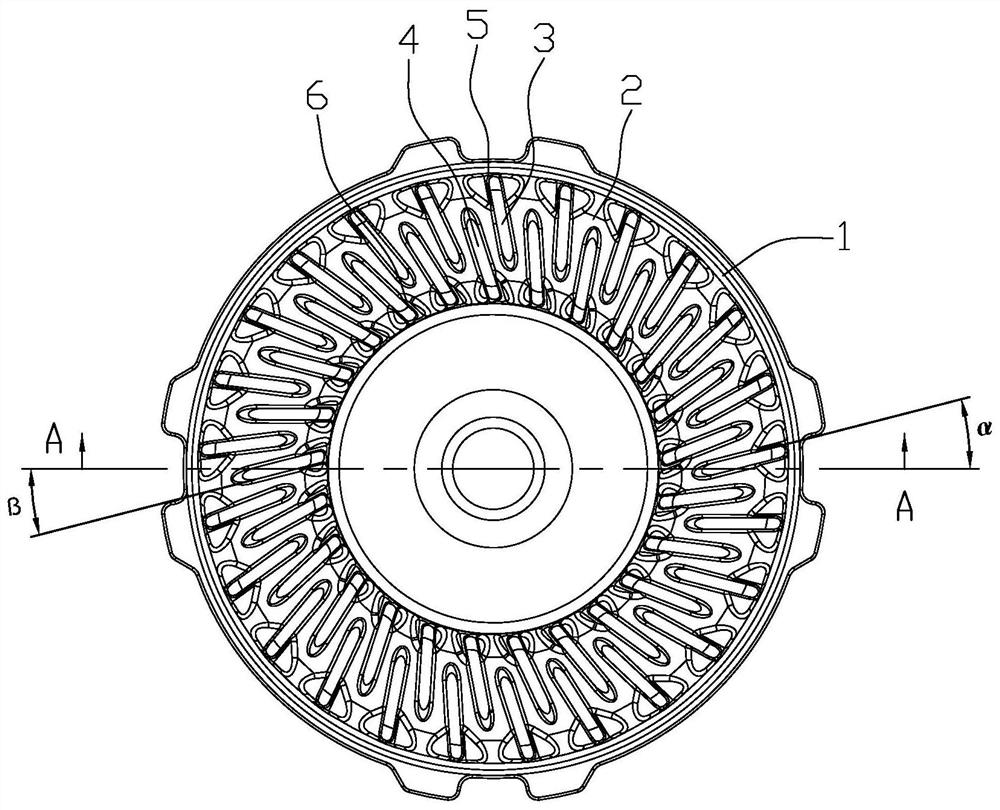

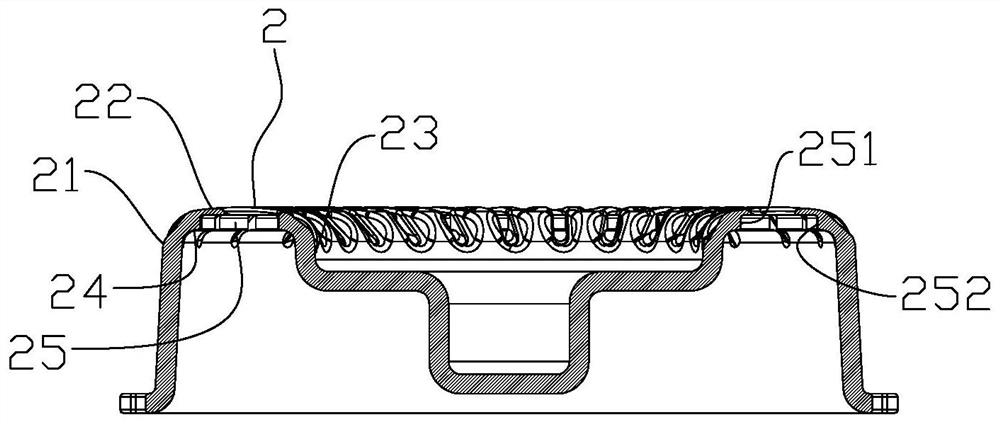

[0049] like Figures 1 to 6 As shown, a knife net structure of a rotary shaver includes a knife net body 1, and the knife net body 1 is provided with a raised annular shaving track 2, and the shaving track 2 includes an outer ring side 21, The inner ring side 23 and the track top surface 22 connecting the outer ring side 21 and the inner ring side 23, the shaving track 2 is provided with an outer hair feeding groove 3 and an inner hair feeding groove 4 separated from each other, and the outer feeding groove 4 Groove 3 extends from the side 21 of the outer ring to the middle of the shaving track 2, preferably at a position in the middle of the shaving track 2, and the inner hair groove 4 extends from the side 23 of the inner ring to the middle of the shaving track 2, preferably At the position outside the middle of the shaving track 2, there are multiple outer hair feed gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com