Rigid sail for vessels, in particular large ships, and vessel with a rigid sail

A rigid and large-scale technology, applied in the field of rigid sails, can solve the problems of being unable to go under the bridge and high total weight of rigid sails, and achieve the effects of reducing total weight, cheap production, and reducing bending pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

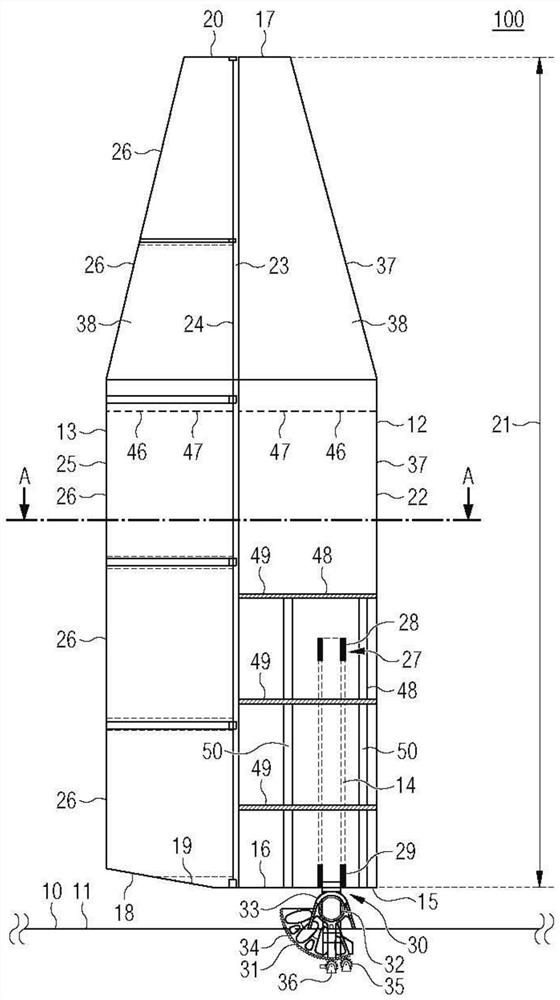

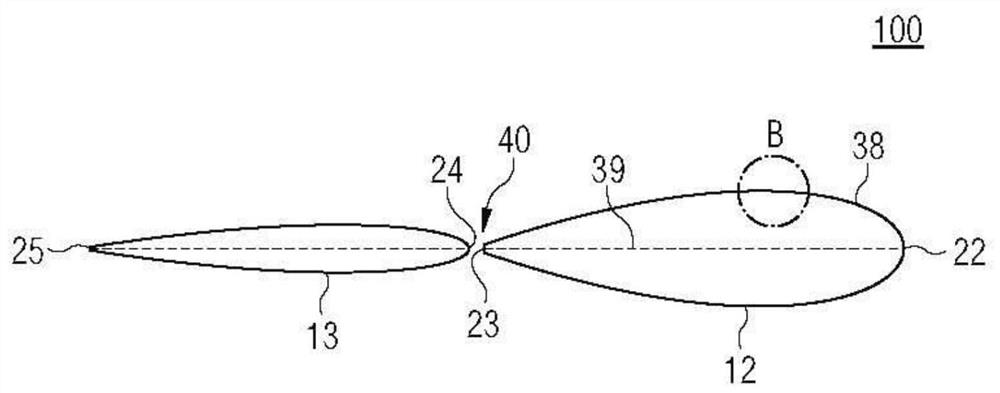

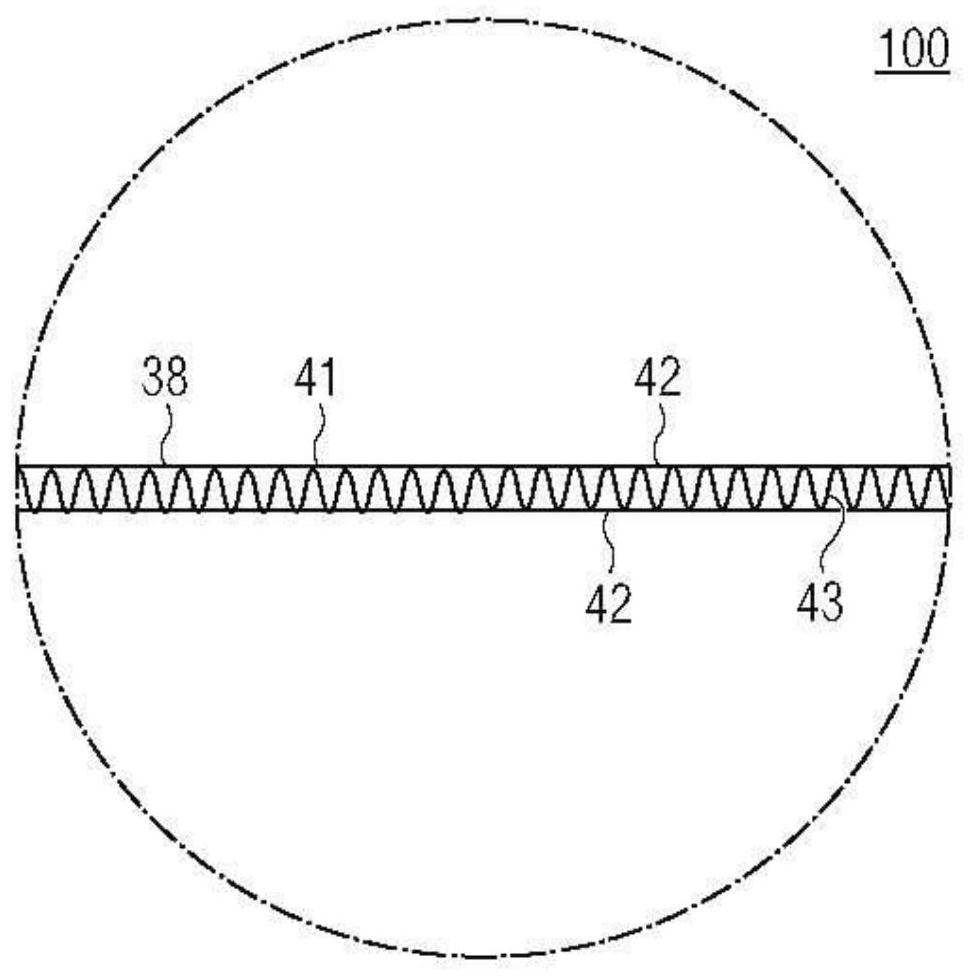

[0092] figure 1 A rigid sail 100 is shown, arranged on a boat 10 . In a ship, only the deck 11 of the ship is shown. The rigid sail 100 is shown in side view and includes a first wing body 12 and a second wing body 13 . The first wing body 12 is connected to the deck 11 of the vessel via a mast 14 . The first wing body 12 has a first base 15 and a first head 17 , and the first base 15 has a first bottom plate 16 . Similarly, the second wing body 13 includes a second base 18 with a second base 19 and a second head 20 . The mast 14 is introduced into the first wing main body 12 through the first base 15 or the first bottom plate 16 and arranged inside the first wing main body 12 . From the first base 15 the mast 14 extends across a third of the maximum height 21 measured between the first base 15 and the first head 17 . Furthermore, the first wing body 12 and the second wing body 13 have leading edges 22 , 24 and trailing edges 23 , 25 , respectively. The second wing body ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap