Thin film generation method

A thin film and precursor technology, applied in the field of solar photovoltaic, can solve the problems of deterioration of the electrical performance of photovoltaic modules, and achieve the effect of high bond energy and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

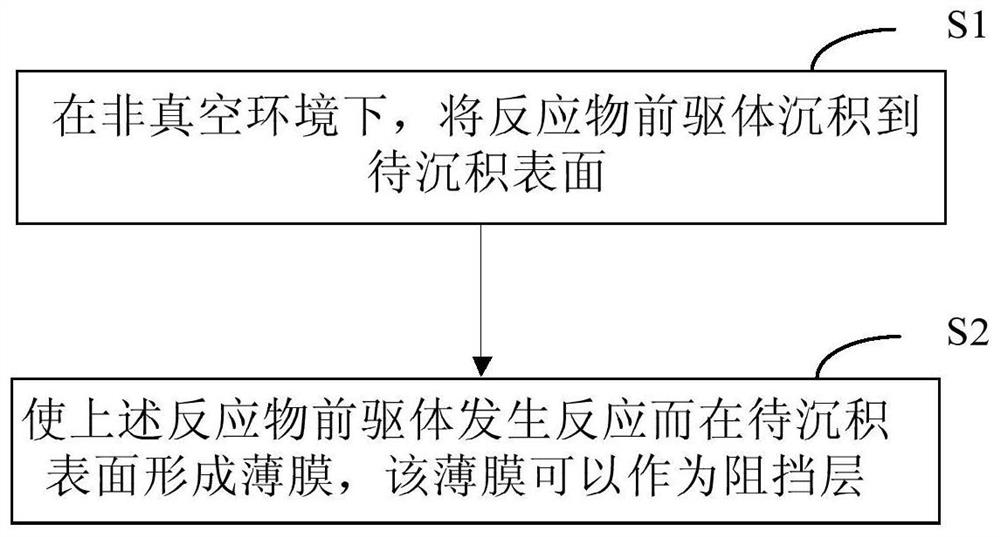

Method used

Image

Examples

Embodiment 1

[0079] Use the spray pyrolysis method to generate a thin film (alumina thin film) for ultra-clear glass. The steps are as follows:

[0080] A1: Prepare the surface to be deposited. Select ultra-clear glass for photovoltaic modules that have been cut, and clean the surface to be deposited.

[0081] A2: Spray solution preparation. Aluminum acetylacetonate is selected as the thermal decomposition substance, methanol and water are selected as solvents, and the concentration of the prepared aluminum acetylacetonate solution is 0.08mol / L.

[0082] A3: Deposit aluminum oxide film. Place the surface of the ultra-clear glass to be deposited (coated surface of the ultra-clear glass) on the carrier plate of the machine, control the reaction temperature to 400 degrees, turn on the ultrasonic wave with a frequency of 20MHz to generate a spray, and introduce the spray into the deposition chamber to contain the reaction precursor The droplets of the body evenly cover the surface of the gl...

Embodiment 2

[0087] Use the spray pyrolysis method to generate a thin film (titanium oxide thin film) for ultra-white glass. The steps are as follows:

[0088] B1. Prepare the surface to be deposited. Select ultra-clear glass for the photovoltaic field that has been cut, and clean the surface to be deposited.

[0089] B2, spray solution preparation. Titanium acetate is selected as the thermal decomposition substance, and ethanol or water is selected as the solvent. The concentration of the prepared titanium acetate solution is 0.06mol / L.

[0090] B3. Depositing a titanium oxide film. Place the glass coating surface on the carrier plate of the machine, the reaction temperature is 400 degrees, turn on the ultrasonic to generate spray and introduce the spray into the deposition chamber, so that the spray droplets containing the reaction precursor evenly cover the surface of the glass to be deposited. Under the condition of heating, the solvent gradually volatilizes, and after the titanium...

Embodiment 3

[0092] Use the spray pyrolysis method to generate a thin film (zirconia thin film) on the anti-reflection layer of the battery sheet, the steps are as follows:

[0093] C1: Prepared as a solution for spraying. Zirconium acetate is selected as the thermally decomposed substance, a mixture of methanol and water is selected as the solvent, and the concentration of the prepared zirconium acetate solution is 0.5 mol / L.

[0094]C2: deposition of zirconia thin film. Place the battery on the carrier plate of the machine (the anti-reflection layer of the battery is used as the surface to be treated to receive the atomized droplets), control the reaction temperature to 400 degrees, turn on the ultrasonic frequency of 800MHz to generate spray, and introduce the spray into the deposition chamber The chamber makes the mist containing the reaction precursor evenly cover the surface of the glass to be deposited; the mist gradually volatilizes under the action of heat, and at the same time, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com