EVA adhesive film, preparation method and application thereof in photovoltaic assembly

A film and liquid technology, which is applied in the field of packaging materials for photovoltaic modules, can solve the problems of EVA film, such as reduced light transmittance and cross-linking degree, and easy conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

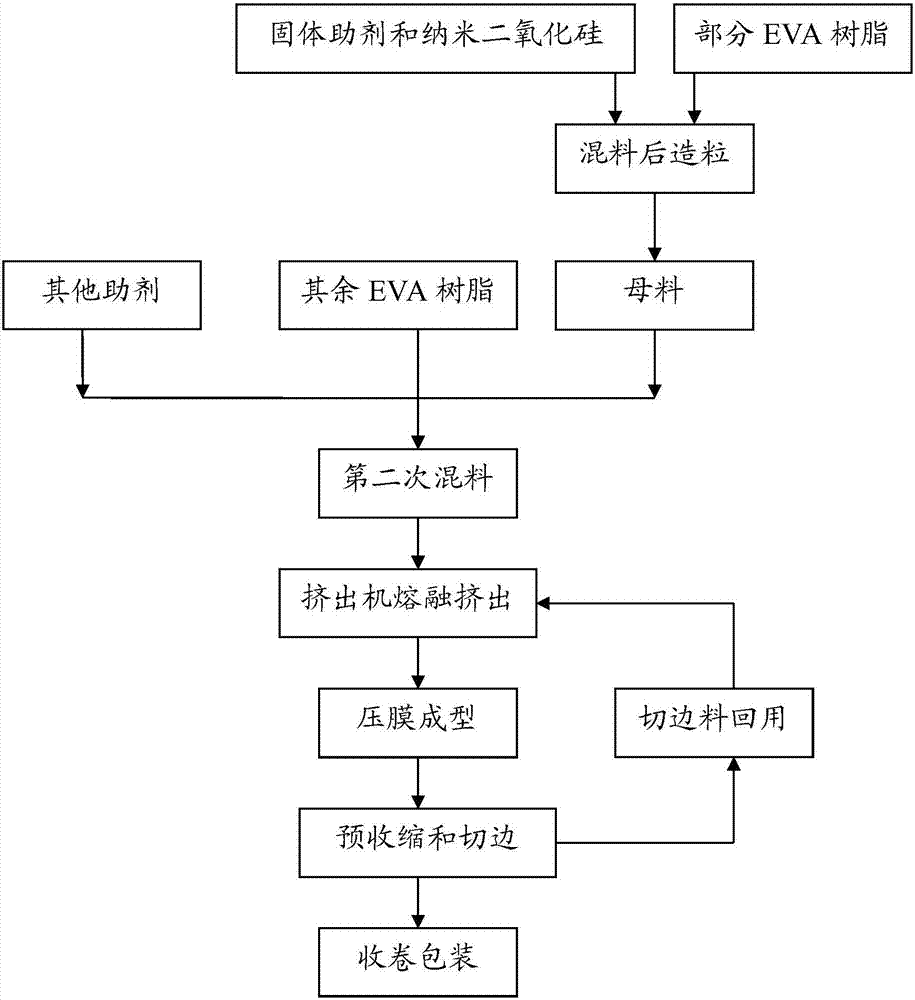

[0051] The present invention also provides the preparation method of the EVA adhesive film described in above-mentioned technical scheme, comprises the following steps:

[0052] (1) will account for total EVA resin quality 1~8% EVA resin, nano silicon dioxide and anti-ultraviolet aging auxiliary agent mix rear granulation, obtain molding particle;

[0053] (2) the molded particle that described step (1) obtains is mixed with the EVA resin of peroxide initiator, liquid silane coupling agent, liquid crosslinking agent and surplus, obtains mixed material;

[0054] (3) extrude into thin film after the mixed material melting that described step (2) obtains, obtains EVA film.

[0055] The invention mixes 1-8% of the mass content of the EVA resin, nano-silicon dioxide and an anti-ultraviolet aging additive, and then granulates to obtain shaped particles.

[0056] In the present invention, the mixing mode of described EVA resin, nano silicon dioxide and anti-ultraviolet aging additiv...

Embodiment 1

[0069] 40kg of EVA resin, 3kg of silicon dioxide with a particle size of 50nm and 2kg of benzophenone compounds are stirred and mixed in a mixer, and then granulated in a granulator to obtain shaped particles with a particle size of 2mm, and then shaped particles With peroxide 2-ethylhexyl tert-butyl carbonate 7kg, triallyl isocyanurate 6kg, 3-(methacryloyl oxygen) propyltrimethoxysilane 2kg and surplus EVA resin 940kg Mixing to obtain a mixed material, which is melted at 80°C and extruded into a film, and then processed by compression molding, pre-shrinking, edge trimming and winding packaging to obtain an EVA film.

[0070] The performance of the EVA adhesive film that present embodiment is made is measured, and the result is as shown in table 1.

[0071] The EVA resin produced in this embodiment is used for photovoltaic module encapsulation, and a PID test is carried out on the photovoltaic module. During the PID test, a reverse voltage of -1000V is input to the photovoltai...

Embodiment 2

[0073] 70kg of EVA resin, 10kg of silicon dioxide with a particle diameter of 100nm and 4kg of hindered amine compounds were stirred and mixed in a mixer, and then granulated in a granulator to obtain shaped particles with a particle diameter of 8mm, and then the shaped particles were mixed with 2, 5-dimethyl-2,5-di-tert-butylperoxyhexane 10kg, trimethylolpropane trimethacrylate 10kg, 3-(methacryloyloxy)propyltrimethoxysilane 5kg and remaining A certain amount of EVA resin 891kg is mixed to obtain a mixed material, and the mixed material is extruded into a film after being melted at 100° C., and the EVA film is obtained through compression film molding, pre-shrinkage, edge trimming and winding packaging.

[0074] The performance of the EVA adhesive film that present embodiment is made is measured, and the result is as shown in table 1.

[0075] The EVA resin produced in this embodiment is used for photovoltaic module encapsulation, and a PID test is carried out on the photovol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com