Photovoltaic encapsulation material poe film with resistance to potential-induced attenuation

A potential-induced decay, packaging material technology, used in films/sheets without carriers, adhesives, adhesive additives, etc., which can solve the problems of easy diffusion of positive ions, large charge relationship, and PID failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

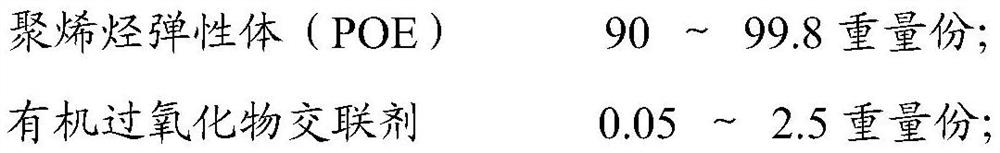

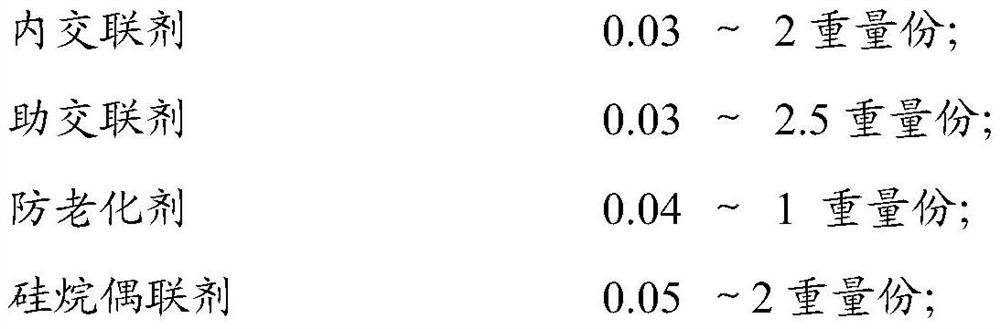

Embodiment 1

[0018]

[0019] The above components are fully mixed and then added to the extruder. The extrusion temperature is 90°C. Extrude through a T-shaped flat die to form a film, or directly pass through two calender rolls to form a film and wind it up. Cut the rolled anti-PID POE film to the size of the solar photovoltaic module, and stack it according to the structural order of glass / anti-PID POE film / P-type PERC single crystal double-sided cell / anti-PID POE film / glass And evacuated and laminated at 150°C, the vacuuming time was 5 minutes, and the lamination time was 12 minutes. The power attenuation is 1.1%, and the power attenuation at the back of the module is 1.5%. Under the same conditions, the power attenuation at the front of the module with the upper and lower layers of ordinary POE film is 5%, and the power attenuation at the back of the module is 16%. After lamination under the same conditions, the cross-linking degree of the film measured by xylene extraction method i...

Embodiment 2

[0021]

[0022]

[0023] The above components are fully mixed and then added to the extruder. The extrusion temperature is 90°C. Extrude through a T-shaped flat die to form a film, or directly pass through two calender rolls to form a film and wind it up. Cut the rolled anti-PID POE film into the same size as the solar photovoltaic module, stack and Vacuumize and laminate at 150°C, the vacuum time is 5 minutes, and the lamination time is 20 minutes. In the PID experiment (85% humidity and 85°C, -1000V, 192hr) of the obtained laminate, the component power decays 1.1%, under the same conditions, the attenuation of the module with ordinary POE film on the upper and lower layers is 9.6%. After lamination under the same conditions, the cross-linking degree of the film measured by xylene extraction method is 80%, and the residual enthalpy value of the film after cross-linking measured by DSC is 0.001J / g.

Embodiment 3

[0025] Element parts by weight POE (1:1 mixture of ethylene-butene copolymer and ethylene-octene copolymer) 96 Hydroxyethylacrylamide 0.5 Triallyl isocyanurate (TAIC) 1 3-aminopropyltriethoxysilane (silane coupling agent KH550) 1 Dicumyl peroxide (peroxide crosslinker DCP) 1 N,N'-di-sec-butyl-p-phenylenediamine (Antioxidant 4720) 0.5

[0026] The above components are fully mixed and then added to the extruder. The extrusion temperature is 90°C. Extrude through a T-shaped flat die to form a film, or directly pass through two calender rolls to form a film and wind it up. Cut the rolled anti-PID POE adhesive film to the size of the solar photovoltaic module, stack it in the order of glass / anti-PID POE adhesive film / N-type high-efficiency battery sheet / anti-PID POE adhesive film / backsheet and in 150 Vacuumize and laminate at ℃, the vacuum time is 5 minutes, and the lamination time is 15 minutes. In the PID experiment (85% humidity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com