Recording head maintenance device and inkjet recording apparatus therewith

A technology for maintaining devices and recording heads, which is applied to power transmission devices, printing, transfer materials, etc., and can solve problems such as uneven wiping and difficulty in stabilizing the posture of the wiping blade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

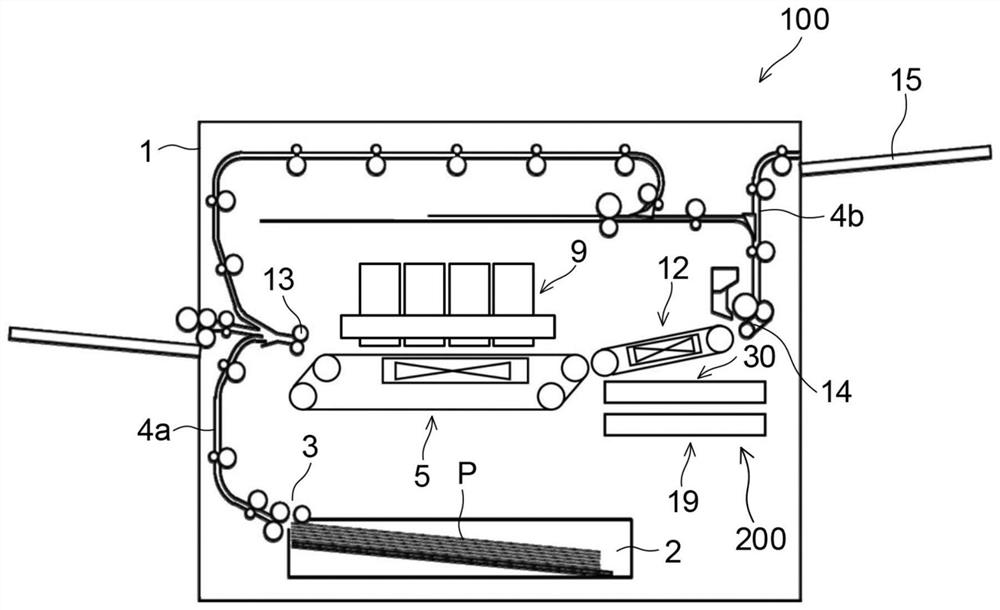

[0046] [Structure of Inkjet Recording Apparatus]

[0047] Hereinafter, the printer 100 as an inkjet recording device equipped with the maintenance device 200 of the present invention will be described with reference to the drawings. Such as figure 1As shown, the printer 100 has a paper feed cassette 2 as a paper storage portion arranged below the inside of the printer main body 1 . Paper P, which is an example of a recording medium, is housed inside the paper feeding cassette 2 . Downstream in the paper feeding direction of the paper feeding cassette 2, i.e. figure 1 The paper feeding device 3 is disposed above the left side of the paper feeding cassette 2 in the drawing. Through this paper feeding device 3, the paper P is figure 1 The sheets are separated and sent out one by one toward the upper left of the paper feeder 2.

[0048] In addition, in the printer 100, a first paper conveyance path 4a is provided inside. The first paper conveying path 4 a is located at the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com