Flue-cured tobacco flavored electronic cigarette liquid and preparation method thereof

A technology of electronic cigarettes and flue-cured tobacco, which is applied in the fields of tobacco, tobacco processing, application, etc., can solve the problems of food safety, deep color, easy turbidity, etc., and achieve the effect of mature and stable processing technology, simple processing process and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

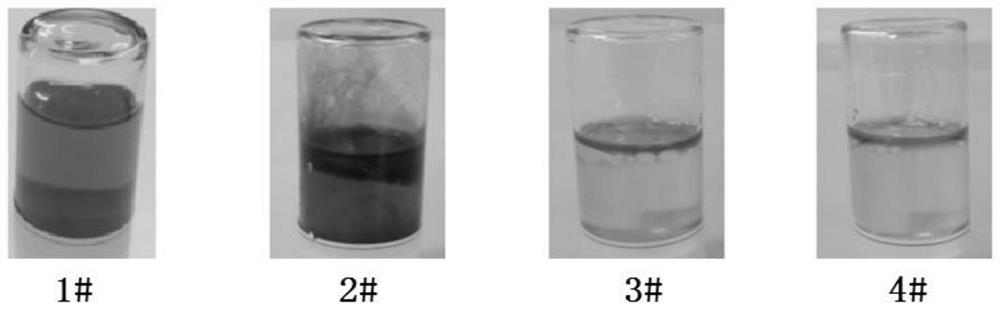

[0219] Embodiment one tobacco extract used in the present invention is compared with other tobacco extract application properties

[0220]According to the formulations in Table 1-1 and Table 1-2, the components were mixed evenly to prepare 1# to 4# e-cigarette liquids with flue-cured tobacco taste, and 1# was the preferred e-cigarette liquid formula of the present invention. (by mass percentage)

[0221] Among them, the flue-cured tobacco is prepared by mixing the middle and upper flue-cured tobacco sheets produced in Fujian, Yunnan, and Guizhou in a mass ratio of 1:1:1.

[0222] (1) Flue-cured tobacco water extract, mix flue-cured tobacco and distilled water at a mass percentage of 1:9, soak for 1h, heat and boil under standard atmospheric pressure for reflux for 1h, filter through a 300-mesh filter, and concentrate the obtained extract under reduced pressure to relative density Prepared after 1.100-1.150.

[0223] (2) The ethanol extract of flue-cured tobacco is made of fl...

Embodiment 2

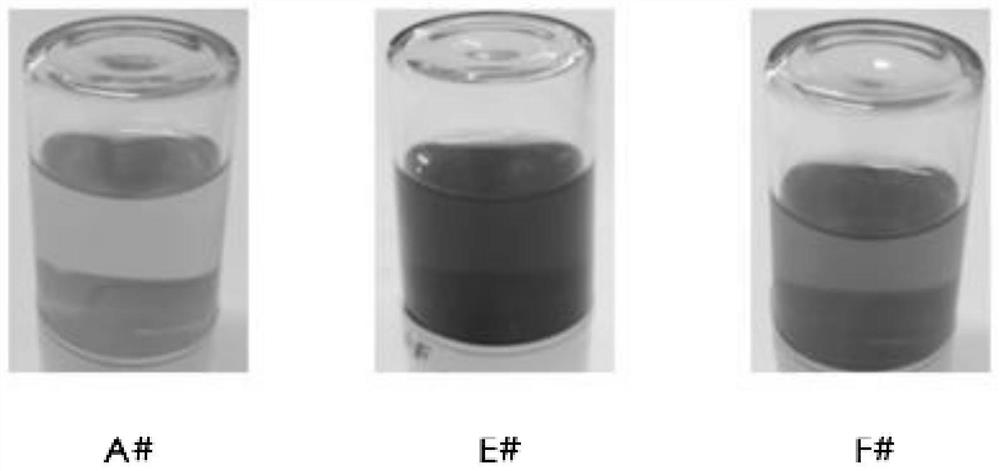

[0237] Example 2 Comparison of the application performance of the composite tobacco extract used in the present invention and that of a single variety of tobacco extract in the preparation of e-cigarette liquid

[0238] According to the formulations in Table 1-2 and Table 2-1, mix each component (the preparation or source of each component is the same as in Example 1) to prepare 5#~7# electronic cigarette liquid with flue-cured tobacco flavor. Among them, 1# is the preferred e-smog liquid formulation of the present invention. (by mass percentage)

[0239] Table 2-1 Flue-cured Tobacco Flavored Electronic Cigarette Liquid

[0240] component name 1# 5# 6# 7# Flue-cured tobacco water extract 1% 7.5% / / Flue-cured Tobacco Ethanol Extract 2% / 7.5% / flue-cured tobacco maillard reactant 4% / / 7.5% Flue-cured Tobacco Molecular Distillation Light Components 0.5% / / / other additives 92.5% 92.5% 92.5% 92.5% total 100%...

Embodiment 3

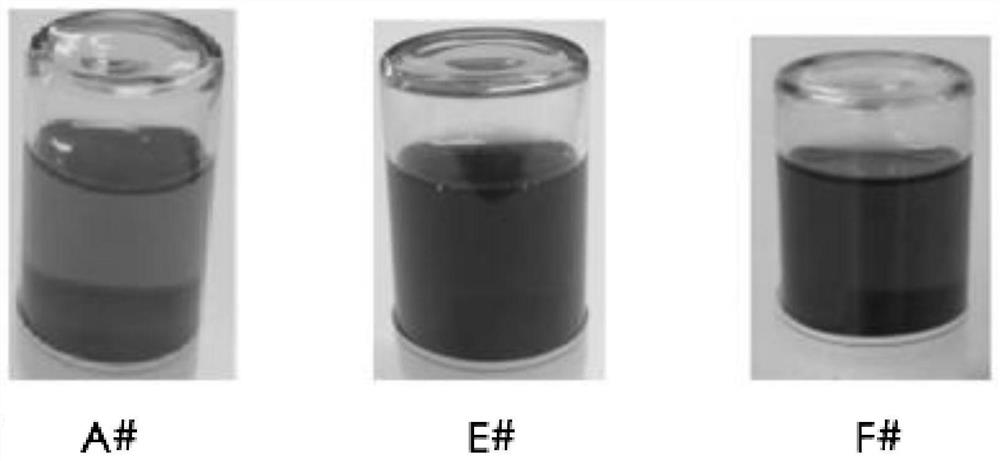

[0252] Example 3 Tobacco Extract Blending Ratio Application Comparison

[0253] According to the formulations in Table 3-1 and Table 1-2, mix each component (the preparation or source of each component is the same as in Example 1) to prepare 8#~13# electronic cigarette liquid with flue-cured tobacco taste. Among them, 1#, 8#, and 9# are the formulations of electronic cigarette liquids within the scope of the present invention. (by mass percentage)

[0254] Table 3-1 Flue-cured Tobacco Flavored Electronic Cigarette Liquid

[0255]

[0256] The atomized liquid prepared above was put into the electronic cigarette appliance respectively for smoking. The atomizer of the electronic cigarette appliance used a heating wire with a resistance value of 1.6Ω and an atomization voltage of 3.8V. The specific evaluation method is the same as above, and the evaluation results are shown in Table 3-2:

[0257] Table 3-2 Evaluation results of flue-cured tobacco flavor e-cigarette liquid in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com