Bending part dual-face punching mold

A bending and punching technology, which is applied in the field of double-sided punching molds for bending parts, can solve problems such as inability to punch holes, achieve the effect of ensuring punching quality and improving punching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

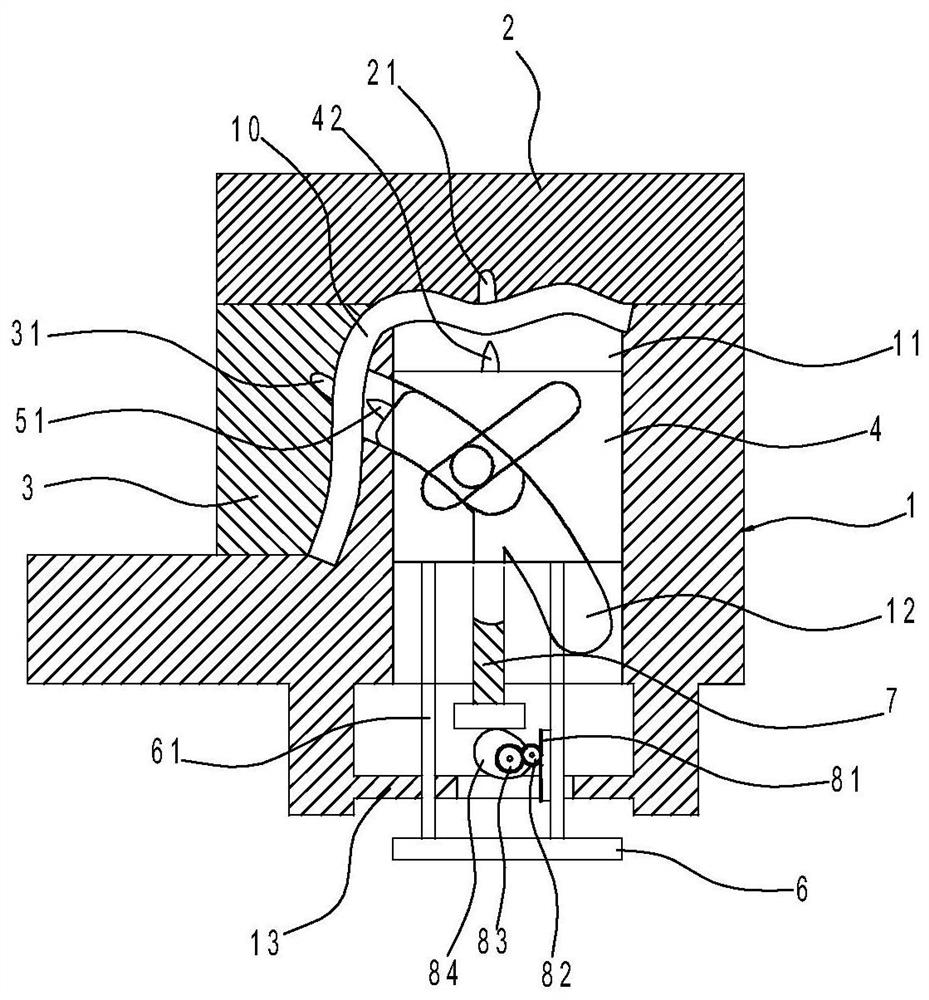

[0019] Such as Figures 1 to 5 As shown, the double-sided punching die for curved parts in this implementation includes a bottom mold 1, a top mold 2, a side mold 3, a vertical slider 4, a curved slider 5, a push plate 6 and a push rod 61.

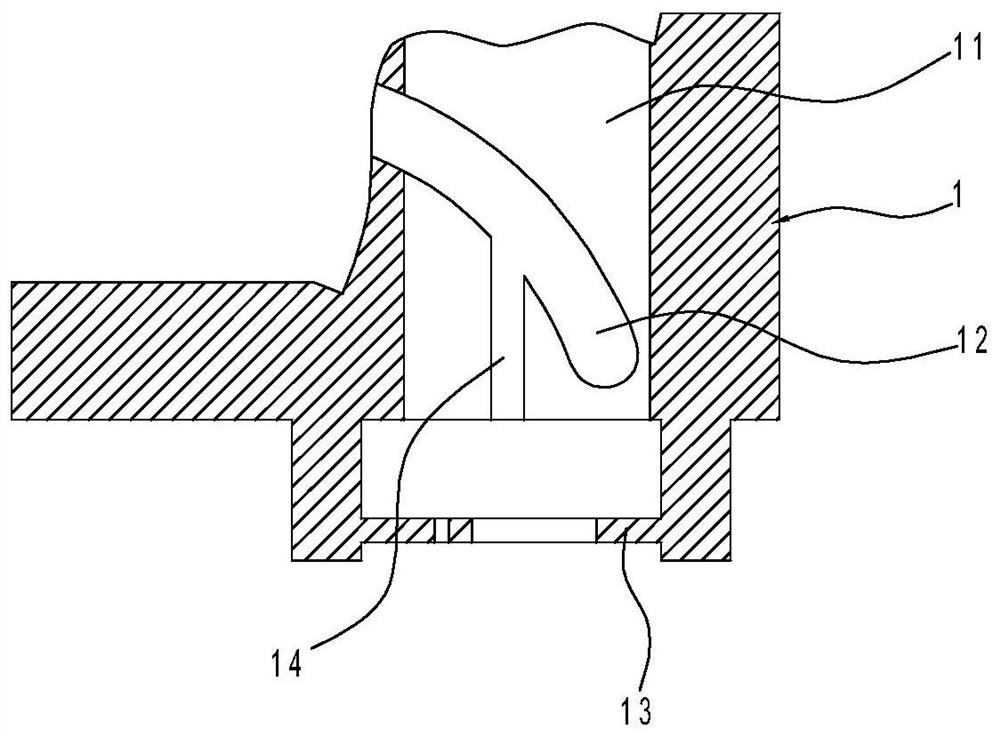

[0020] Among them, when the bottom mold 1, the top mold 2 and the side mold 3 are closed, a cavity 10 matching the external shape of the curved part is formed inside, and an upper punching hole 21 is opened in the cavity of the top mold 2. A side punching hole 31 is provided in the cavity, a push plate 6 is arranged under the bottom mold 1, a push rod 61 is arranged on the push plate 6, a vertical slideway 11 arranged vertically is provided in the bottom mold 1, and the bottom mold 1 is provided with an arc-shaped slideway 12 opposite to the side punching hole 31, and a vertical slider 4 is slidably arranged in the vertical slideway 11, and an inclined slideway 41 is provided on the vertical slideway 4. On the arc-shaped slideway 12 The i...

Embodiment 2

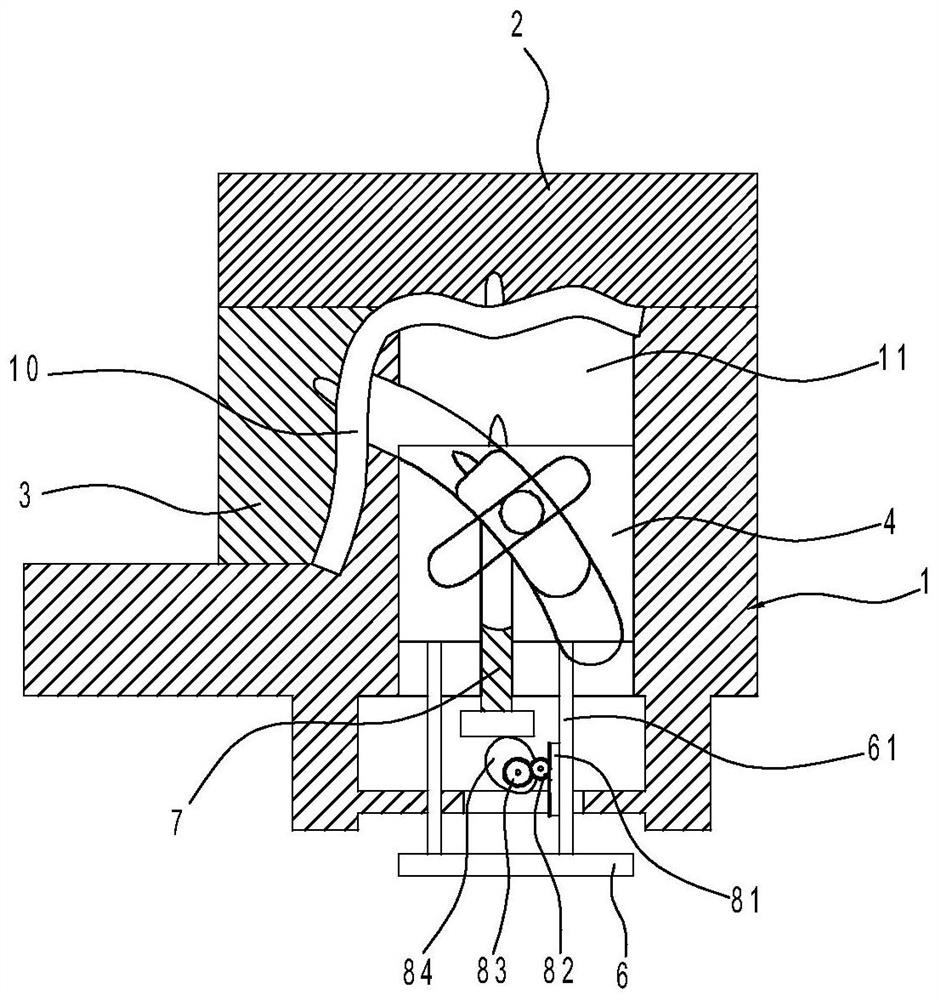

[0027] Such as Figure 6 and 7 As shown, the difference technical feature of embodiment 2 relative to embodiment 1 is that the ejector mechanism is different. The ejector mechanism in embodiment 2 is that a spacer 91 is arranged on the push plate 6, and a spacer 91 is set in the vertical slider 4. There is a sliding hole 14 communicating with the curved slider 5, and a push rod 7 is slidably arranged in the sliding hole 14, and the top of the push rod 7 is formed with a shape that is adapted to the bottom of the curved slider 5, and the bottom of the push rod 7 is provided with a The base plate 93 is provided with a bent rod 92 above the push plate 6 , one end of the bent rod 92 is hinged on the bottom mold 1 , and the other end of the bent rod 92 is located below the base plate 93 .

[0028] When the push plate 6 pushes the vertical slider 4 upward, the other end of the curved rod 92 pushes the base plate 93 to move upward. When the vertical slider 4 and the curved slider 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com