Punching machine

A punching machine and frame technology, applied in punching tools, metal processing, metal processing equipment, etc., can solve the problems of reducing punching speed, easy damage of punching machines, and difficulty in ensuring punching quality, so as to ensure punching. Quality, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present technology will be further described below through the embodiments in conjunction with the accompanying drawings.

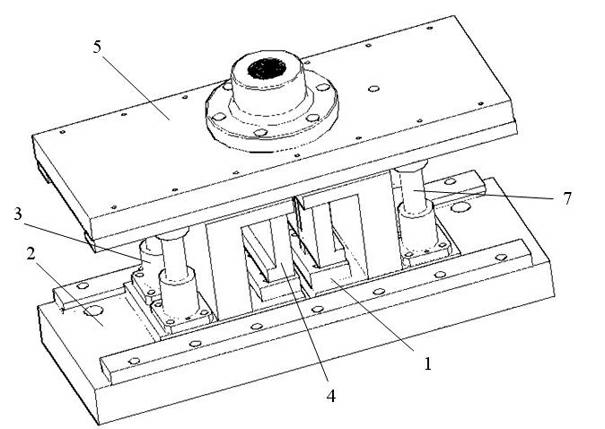

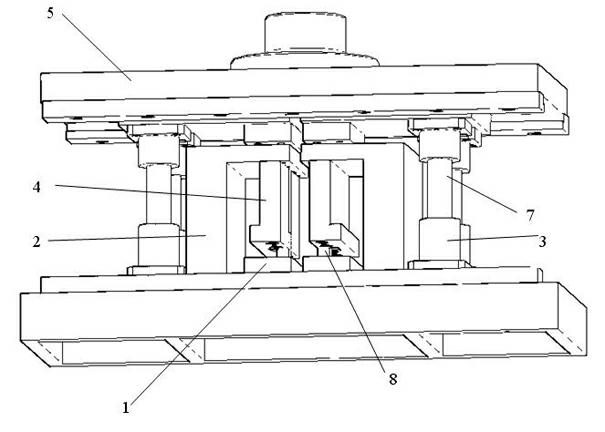

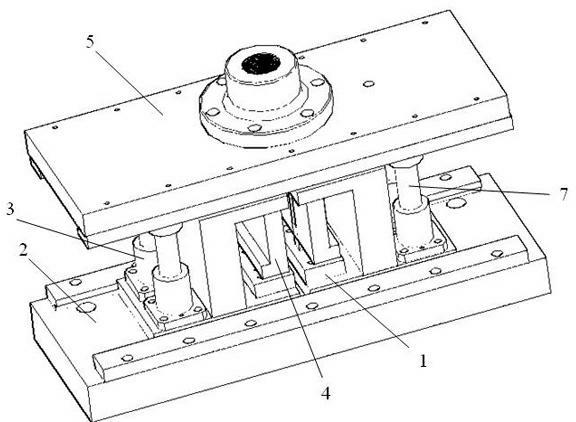

[0012] Such as figure 1 , 2 In the shown punching machine, two dies 1, two punch sleeves 4 and four guide sleeves 3 are all fixed on the frame 2. The upper end of the upper template 5 is connected with the piston rod of an oil cylinder or an air cylinder that drives it to move up and down. The lower part of the upper template 5 is connected with four guide pillars 7 extending into the guide sleeve and two punches 8 corresponding to the die through the punch sleeve. The guide post 7 and the guide sleeve 3 form an up and down sliding pair; the punch 8 and the punch sleeve 4 form an up and down sliding pair.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com