Construction method of drainage pipeline

A construction method and technology of drainage pipes, which are applied in sewer pipe systems, waterway systems, water supply devices, etc., can solve problems such as pipes are easy to float, and achieve the effects of improving compression resistance, backfilling symmetry, and preventing movement and deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in further detail below in conjunction with the accompanying drawings.

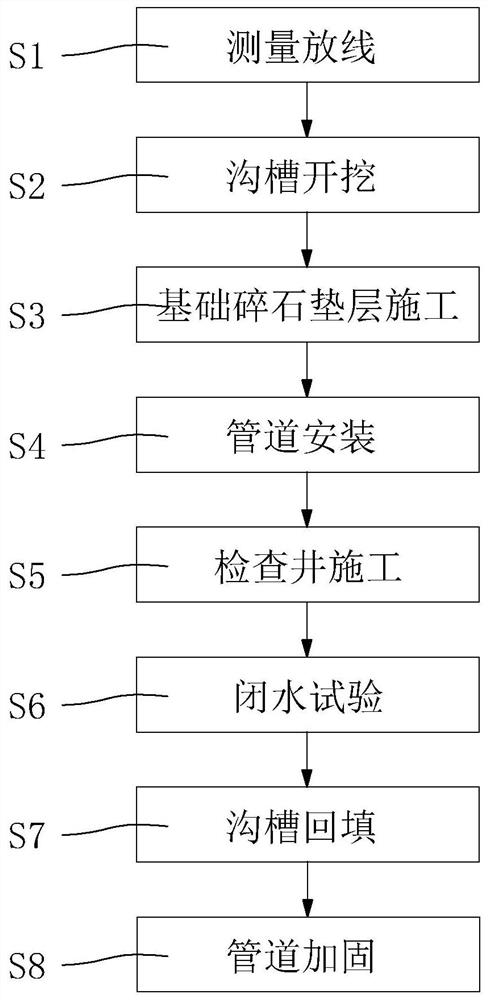

[0063] Such as figure 1 As shown, it is a construction method of a drainage pipeline disclosed by the present invention, including S1 measurement setting out, S2 trench excavation, S3 foundation crushed stone cushion layer construction, S4 pipeline installation, S5 inspection well construction, S6 closed water test, S7 trench backfilling, S8 pipeline 2 reinforcement and other construction steps.

[0064] S1 measuring and setting out, release the pipe centerline and well position through the coordinate points and road centerline mileage piles, draw out the benchmark point, determine the excavation sideline of the foundation pit in the longitudinal direction of the pipeline, and measure the excavation depth to strengthen the maintenance of pile points; construction process Care should be taken to protect the measurement control points.

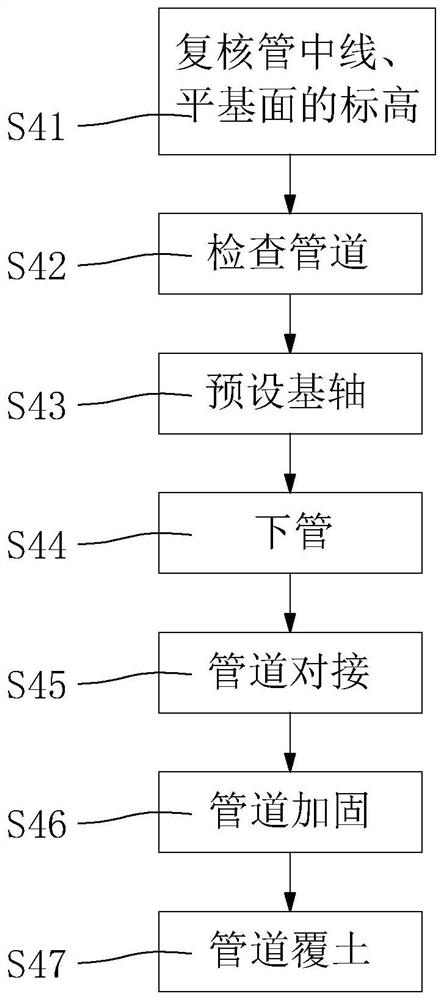

[0065] Such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com