Automatic rack drilling equipment

A drilling equipment and rack technology, which is applied in drilling/drilling equipment, boring/drilling, metal processing equipment, etc., can solve problems such as low drilling efficiency, save manpower, improve drilling quality, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

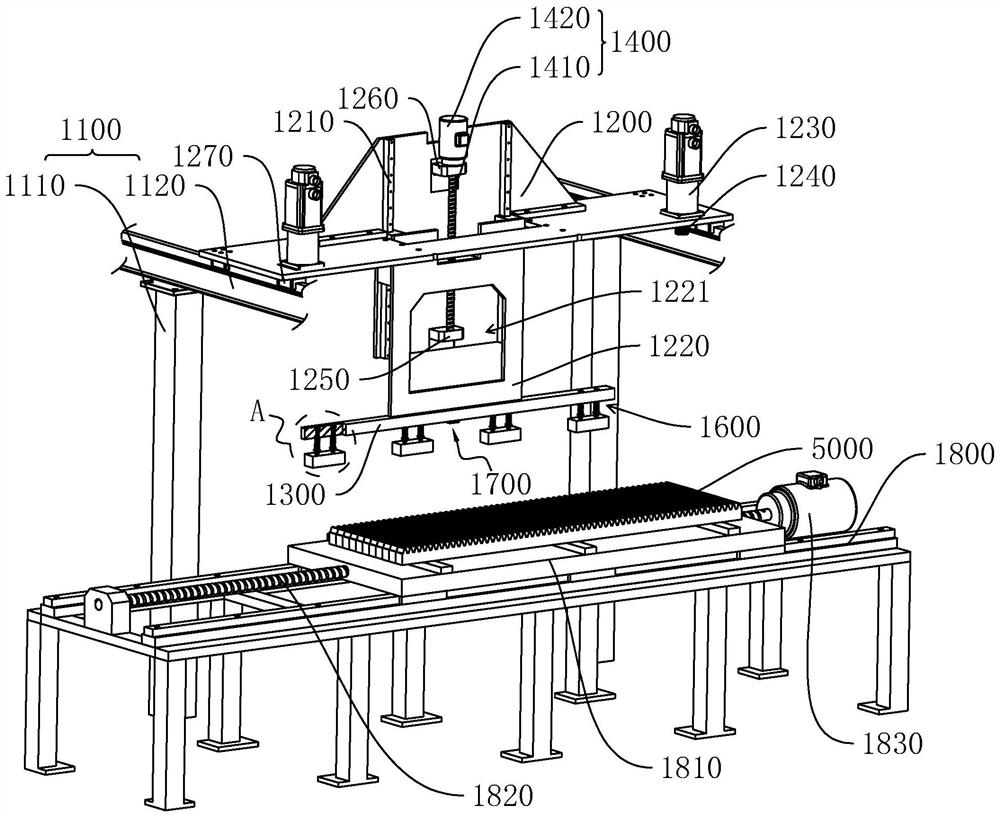

[0051] The following is attached Figure 1-9 The application is described in further detail.

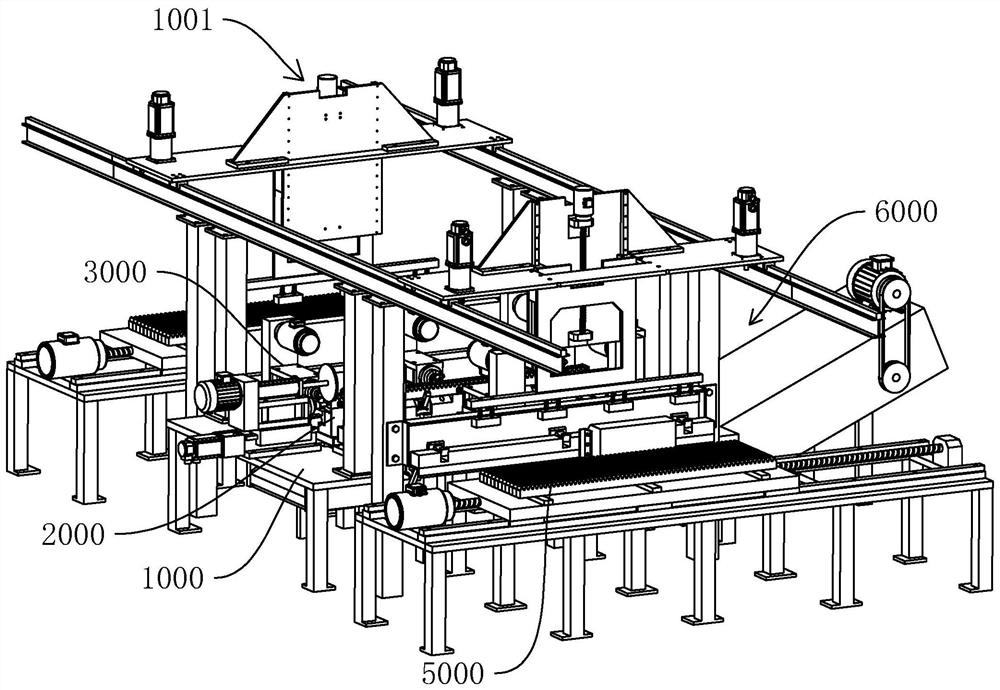

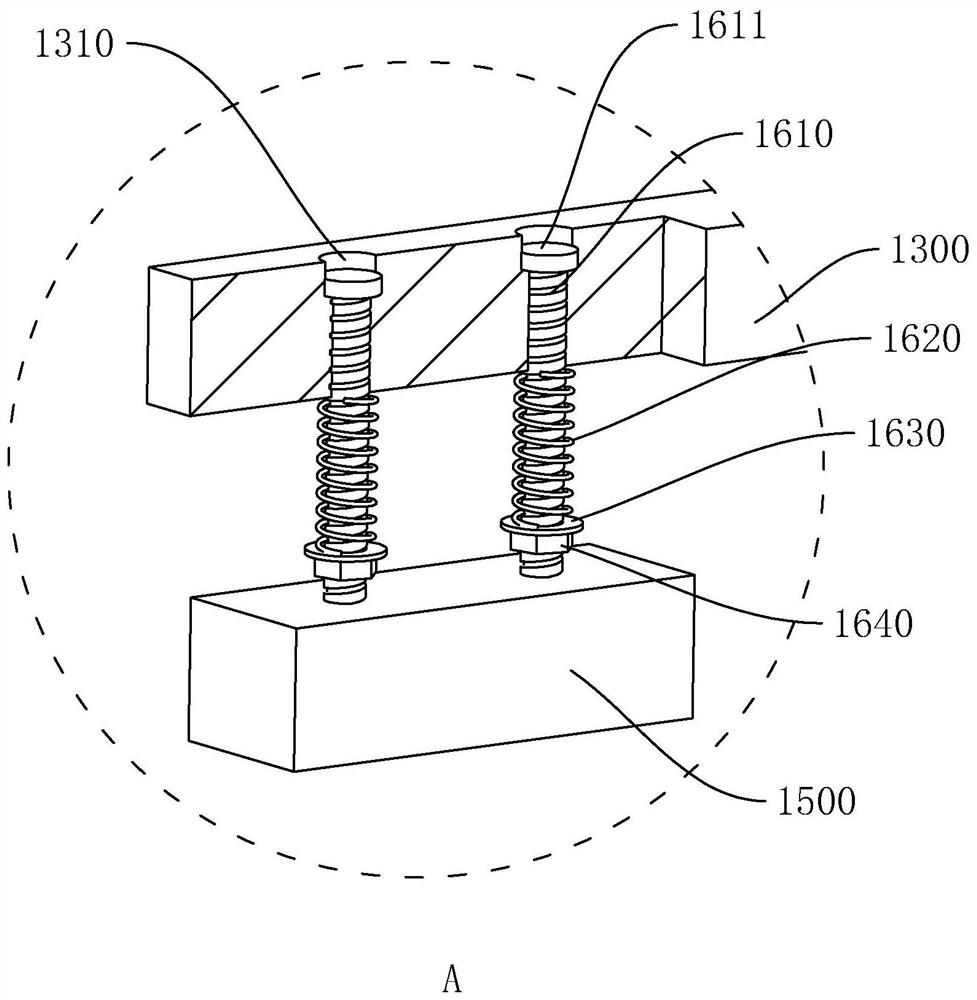

[0052] The embodiment of the present application discloses a rack automatic drilling device. refer to figure 1 , including workbench 1000, workbench 1000 is provided with tooling 2000 for clamping rack 5000, and drill bit 3000 is arranged on the side of tooling 2000, and the position of drill bit 3000 corresponds to the drilling position of rack 5000. Both sides of the workbench 1000 are provided with automatic loading and unloading devices 1001 . The workbench 1000 is provided with a water outlet device on one side of the tooling 2000, and the water outlet of the water outlet device faces the tooling 2000 or the rack 5000, and the workbench 1000 is provided with a communication hole. A chip removal device 6000 is provided below the workbench 1000, and the chip removal device 6000 is located directly below the communication hole.

[0053] Utilize the automatic loading and unloadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com