A hysteresis driven damper

A driving and hysteresis technology, which is applied in the direction of lifting valves, valve devices, engine components, etc., can solve the problems of no sealing protection structure and hidden dangers in the sealing effect, and achieve the effect of avoiding accidental rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

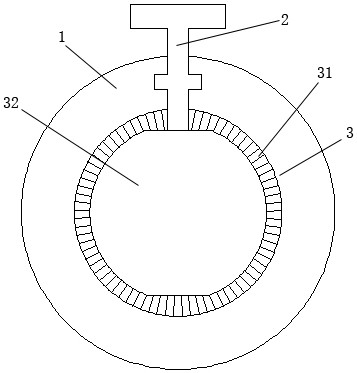

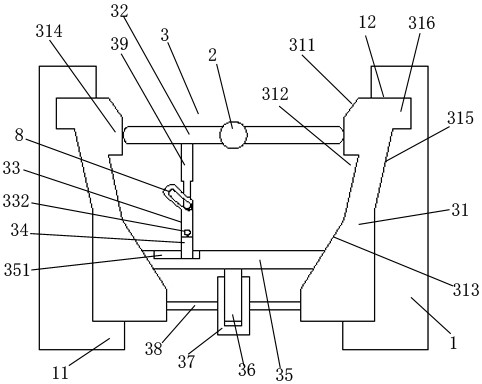

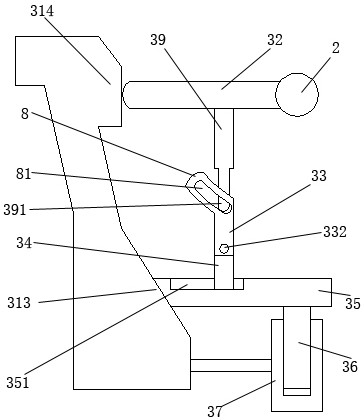

[0023] Such as Figures 1 to 7 As shown, a hysteresis-driven air valve includes a valve body 1, a drive rod 2, and a hysteresis-response sealing mechanism 3; 35. Rotating rod 39, sliding telescopic rod 34, guide column 36, guide cylinder 37, connecting rod 38, arc-shaped block 8; the sealing ring 31 is installed inside the valve body 1; the inner end of the sealing ring 31 is surrounded by The inside is provided with an inner sealing convex ring 314; the inner side of the outer end of the sealing ring 31 is provided with a tapered sealing ring surface 313; the tapered sealing ring surface 313 is a conical structure with a large inner end and a small outer end; The outer end closure plate 35 is a flat conical structure; the inner end closure plate 32 is installed inside the inner sealing convex ring 314 at the inner end of the sealing ring 31; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com