Uncoiling device for relief three-dimensional holographic image thermal shrinkage film production

A three-dimensional holographic, heat-shrinkable film technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of inability to adjust the size, easy sliding of the device, etc., to avoid rolling and improve practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

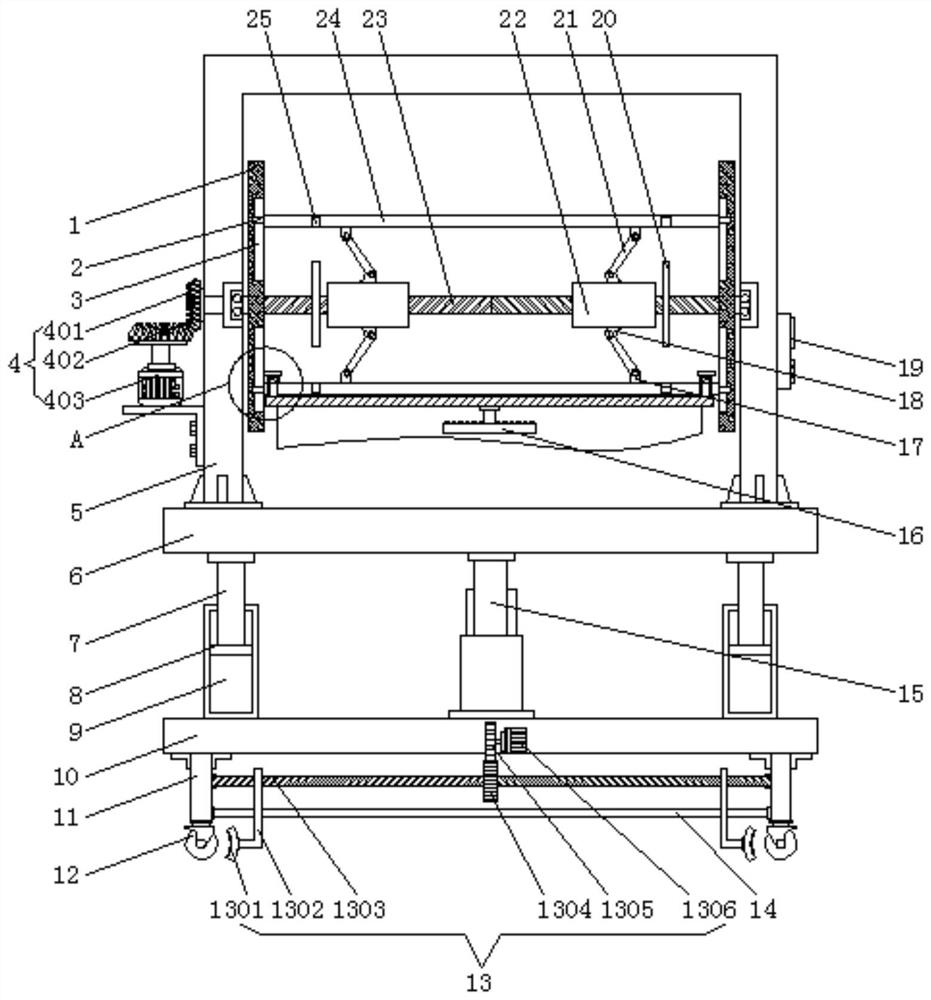

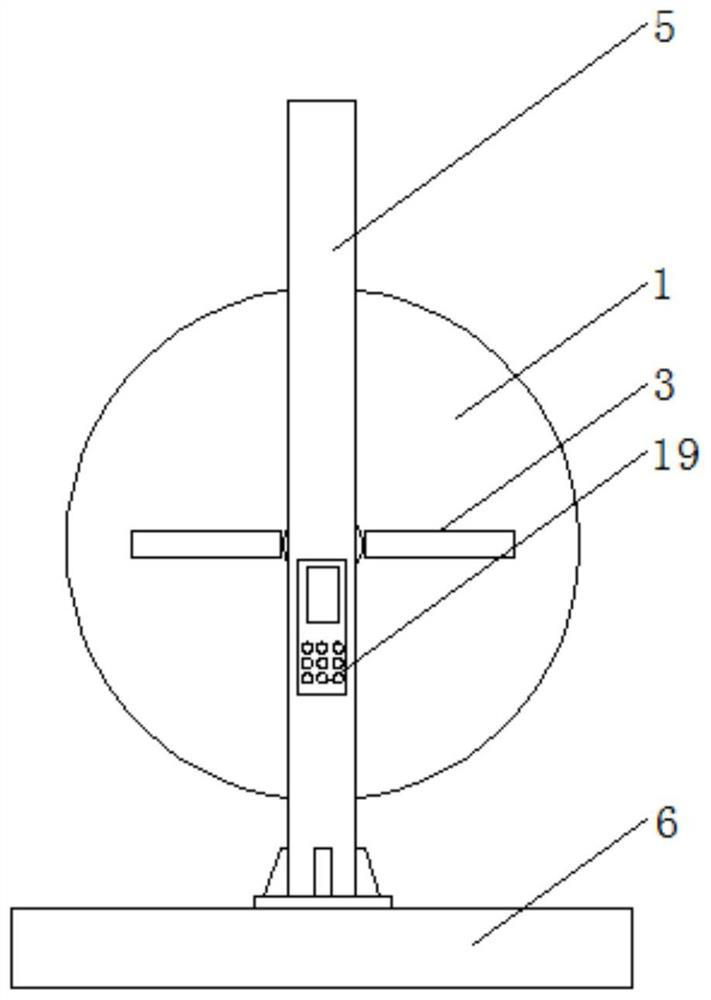

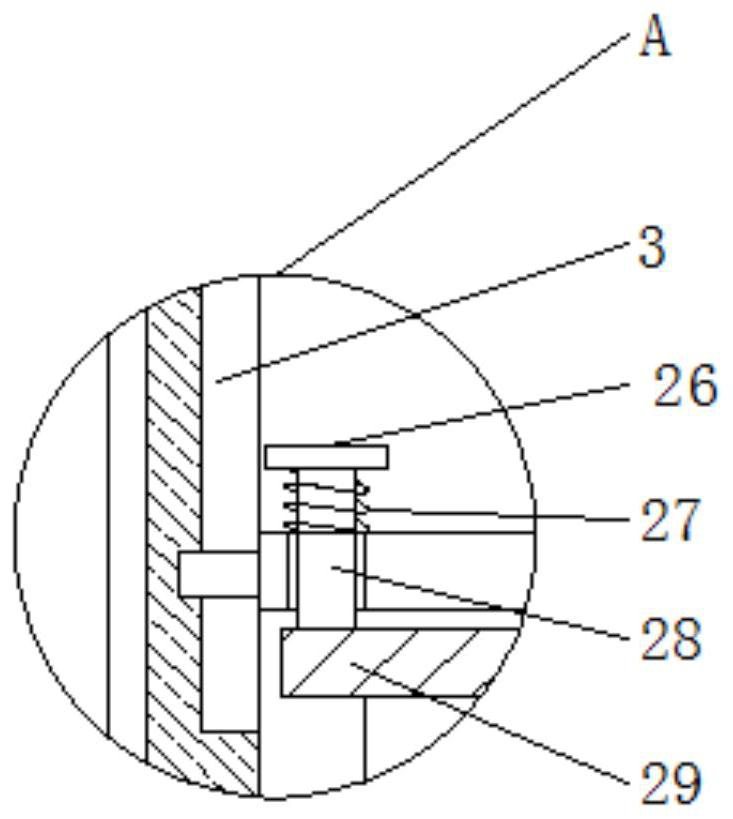

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0031] The present invention provides a technical solution: an unwinding device for producing heat-shrinkable films with embossed three-dimensional holographic images, including a bottom plate 10, four corners of the bottom of the bottom plate 10 are equipped with support columns 11, and the bottom of the support column 11 is equipped with rollers 12 A locking mechanism 13 is installed between the inner sides of the support columns 11, and the locking mechanism 13 includes a locking block 1301, an L-shaped rod 1302, a first two-way screw rod 1303, a first gear 1304, a second gear 1305 and a servo motor 1306 , the first two-way screw rod 1303 of the locking mechanism 13 is located between the inner sides of the support columns 11, the center of the outer wall of the first two-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com