Exposure machine adjusting method and device

An adjustment method and technology of an exposure machine, which are applied to exposure devices in photo-engraving process, optomechanical equipment, microlithography exposure equipment, etc., can solve problems such as affecting the quality of exposure imaging, manual installation errors, not necessarily completely parallel, etc., to avoid The effect of uneven exposure imaging and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

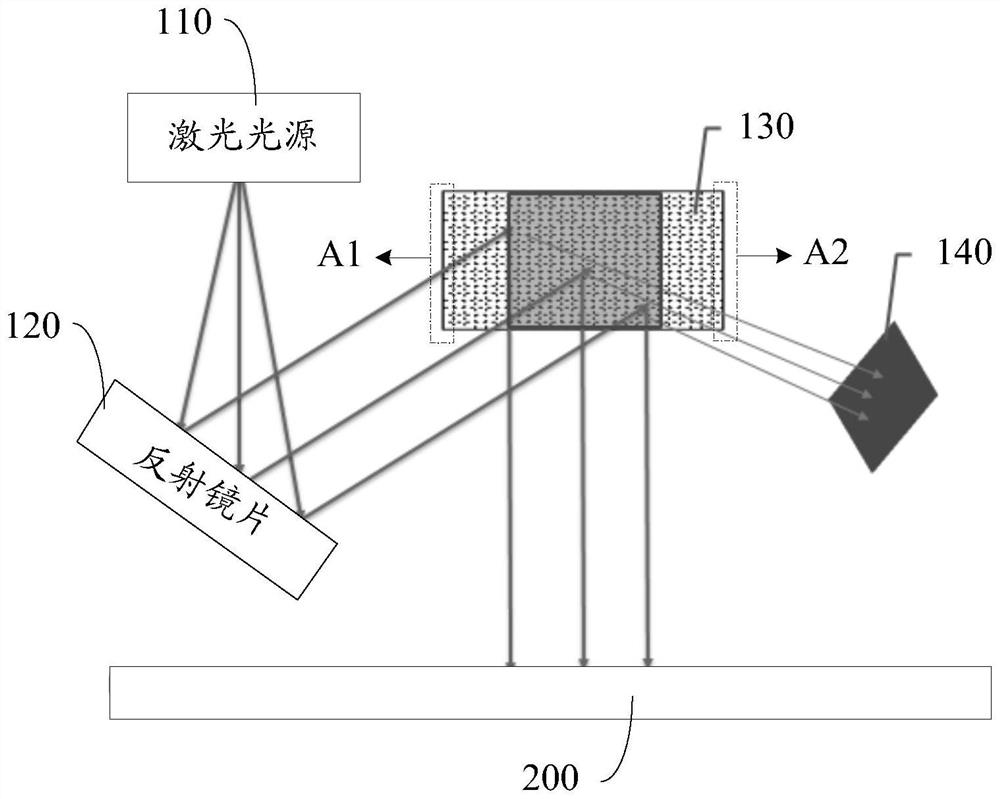

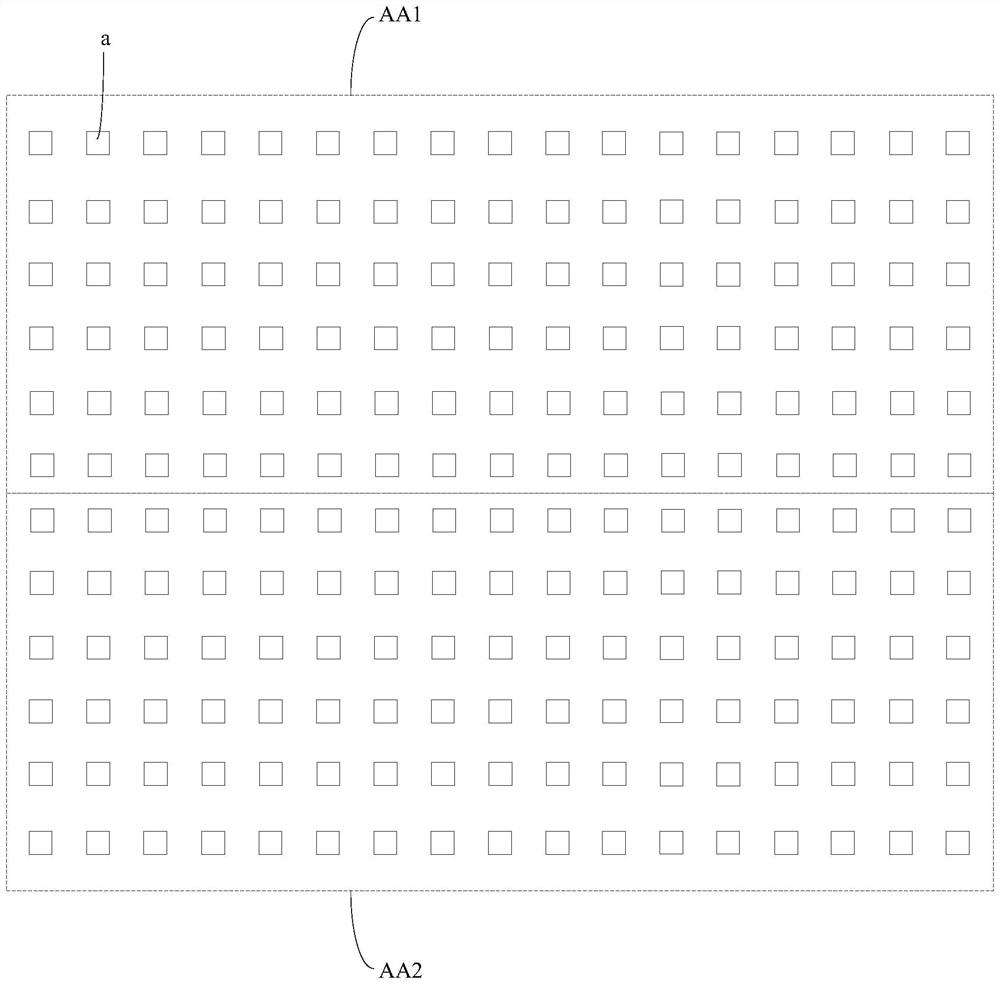

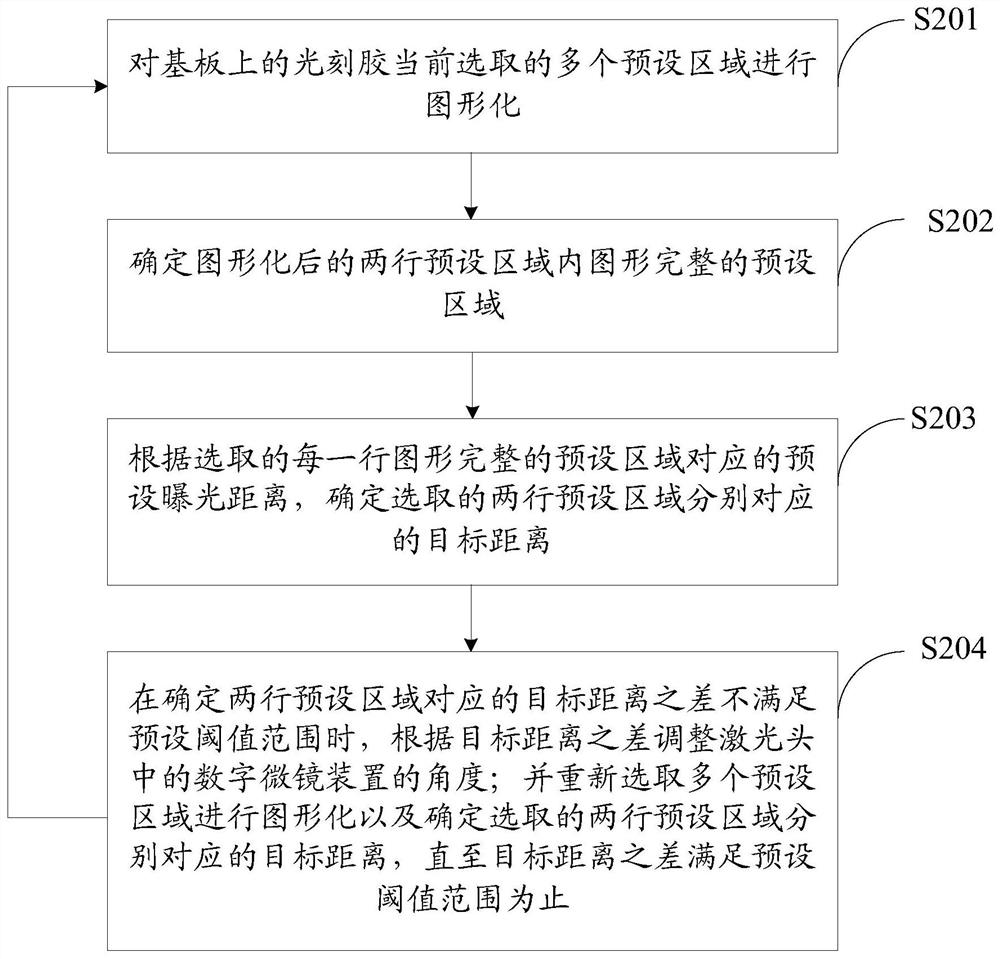

[0069] During specific implementation, the exposure machine in the embodiment of the present invention may be an LDI exposure machine. Generally, the scanning exposure process of the LDI exposure machine is: control the movement of the platform used to carry the substrate in the exposure machine, and feed back the position signal to the data processing module while the platform is moving. The data processing module generates the position signal according to the position signal fed back by the platform. The image is projected on the DMD, and the DMD reflects the light beam to the substrate to complete the exposure work at this position. combine Figure 1b As mentioned above, in this manner, one scanning exposure can form a striped scanning band, that is, the first scanning exposure can form a striped scanning band AA1, and the second scanning exposure can form a striped scanning band AA2. In addition, there may be a plurality of exposure areas a in the strips AA1 and AA2. Aft...

Embodiment 2

[0113] This embodiment is a modification of some of the implementation manners in the first embodiment. The following only describes the differences between this embodiment and the first embodiment, and the similarities will not be repeated here.

[0114] In specific implementation, in the embodiment of the present invention, an exposure machine is used to expose multiple preset regions of the photoresist, which may specifically include:

[0115] Control the exposure machine to perform a scanning exposure to expose the two rows of preset areas corresponding to the photoresist in the third scanning area; wherein, the first row of the two rows of preset areas in the third scanning area is close to the first row The upper boundary of the third scan area, the second row is close to the lower boundary of the third scan area. In this way, only one exposure can be used, thereby reducing power consumption. Taking N=17 as an example, combine Figure 7 As shown, a row of preset areas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com