Coal mine rail sorting car

A technology for coal mines and rails, applied in the field of coal mine rail sorting vehicles, can solve problems such as the inability to deal with the cleaning of dangerous places, and achieve the effects of avoiding impossible picking, improving efficiency, and ensuring safety problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

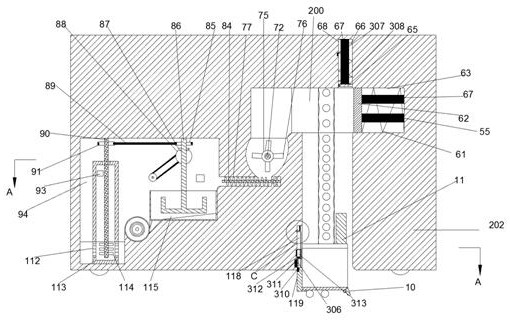

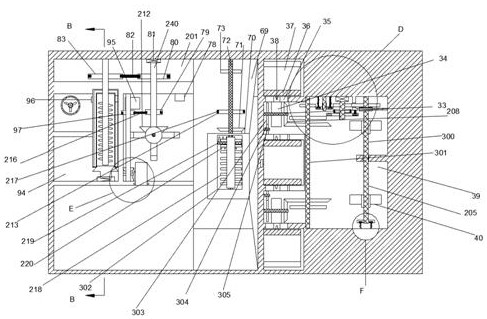

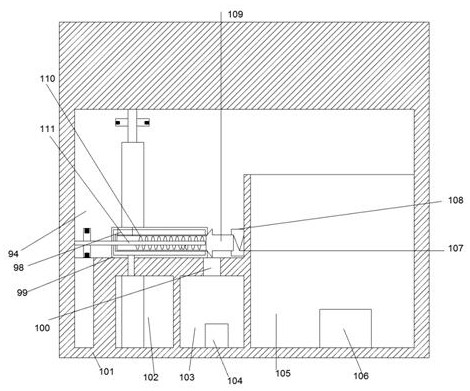

[0026] Combine below Figure 1-11 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0027] combined with Figure 1-11 The coal mine rail sorting car includes a car shell 202, a transmission chamber 39 is provided inside the car shell 202, a switch control chamber 118 is provided on the left side of the transmission chamber 39, and a switch control chamber 118 is provided above the transmission chamber 39. Pushing chamber 200, the lower left side of the pushing chamber 200 is provided with a crushing chamber 69, the left side of the crushing chamber 69 is provided with a driven chamber 94, and the top of the driven chamber 94 is provided with a stirring and separating mechanism 212. A solution chamber 102 and a stirring chamber 115 are provided below the moving chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com