Clamp for automatic disassembly and assembly of container deck lock

A technology of automatic disassembly and assembly of container cabins, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve problems such as personal safety hazards, production efficiency blockages, traffic safety hazards, etc., to reduce personal safety hazards and facilitate storage and grasping, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the embodiments of the accompanying drawings.

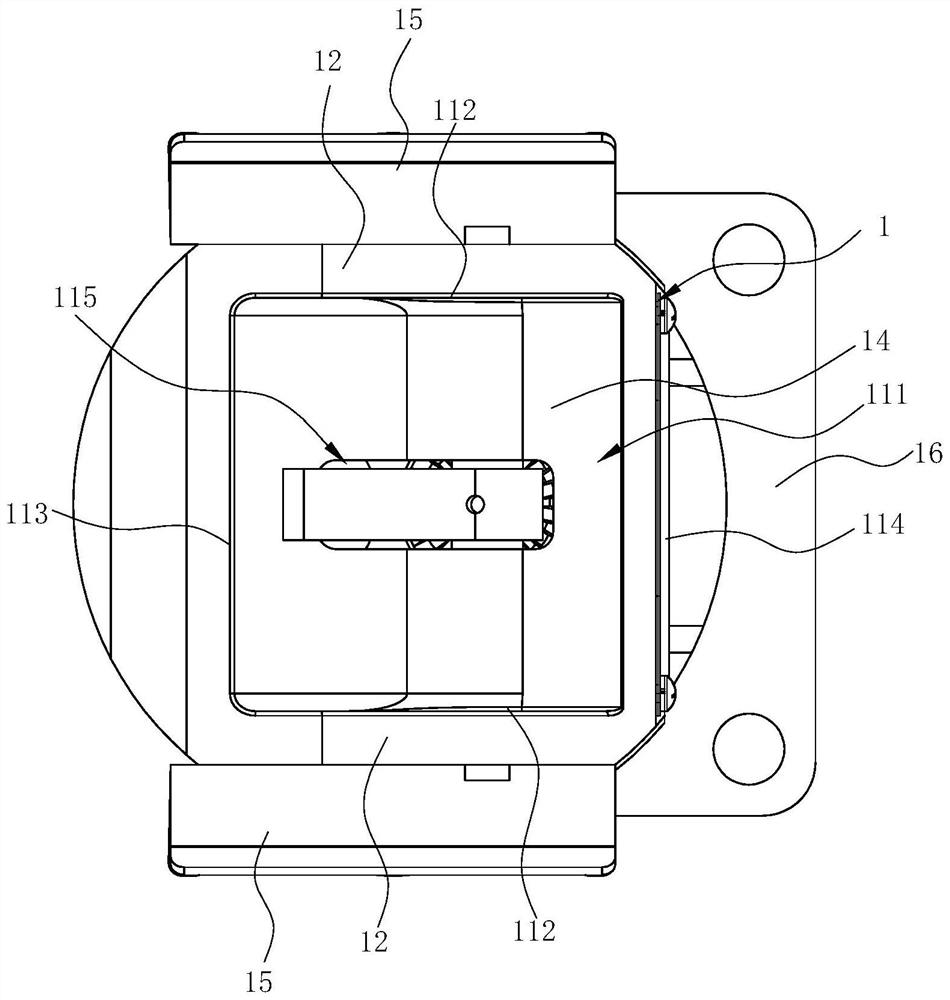

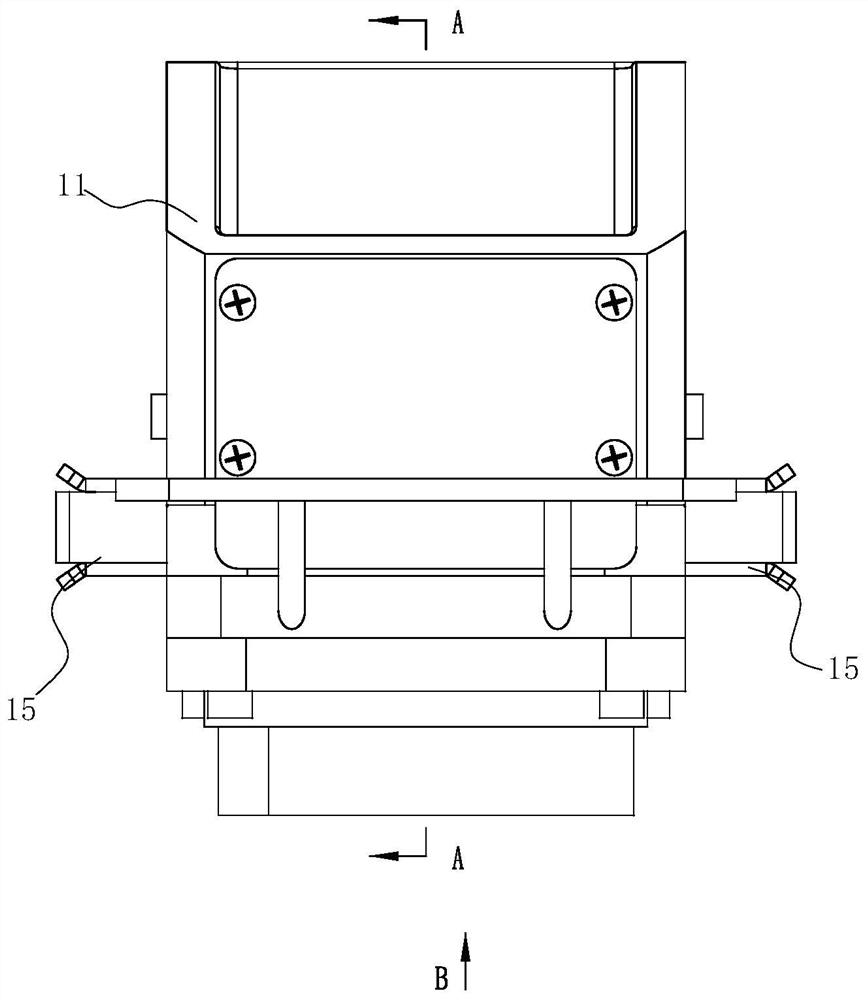

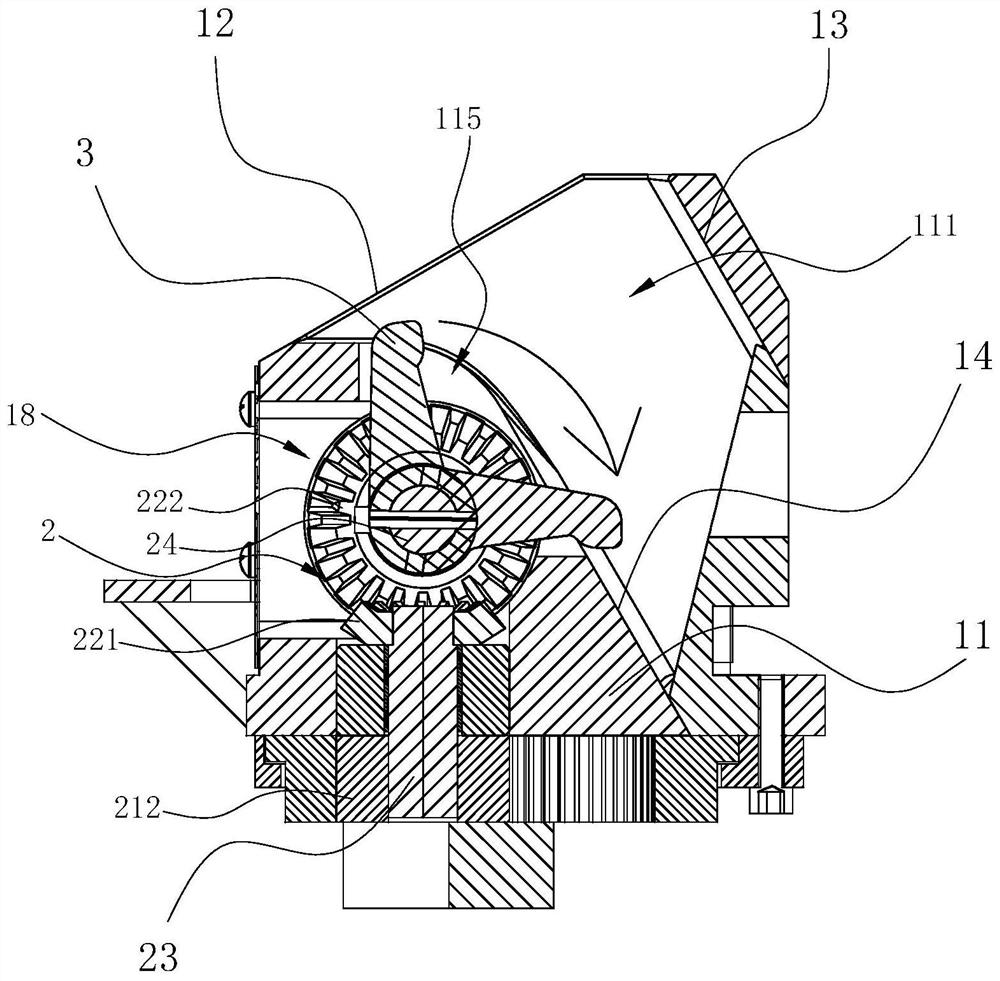

[0025] see figure 1 and figure 2 , a fixture for automatic disassembly and assembly of container deck locks, suitable for TL-FA / G container deck locks of SEC Company, including a clamp body 1, a transmission mechanism 2 and a shift fork 3.

[0026] see Figure 1 to Figure 6 , The clip body 1 includes a seat body 11 , a first limiting surface 12 , a second limiting surface 13 , a third limiting surface 14 , a clamping portion 15 and a guiding portion 16 . The seat body 11 is approximately cylindrical, and its top surface is recessed downward to form a groove 111 for the lower part of the deck lock 300 to be put into. The groove 111 has two opposite first side walls 112, and a second side wall 113 and a third side wall 114 respectively connected between the two ends of the first side wall 112, the second side wall 113 and the third side w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com