Self-locking plug and installation method thereof

A plug and self-locking technology, which is applied in transportation and packaging, vehicle seats, special positions of vehicles, etc., can solve the problem of plug frame falling off, prevent accidental falling off, and ensure stable installation and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

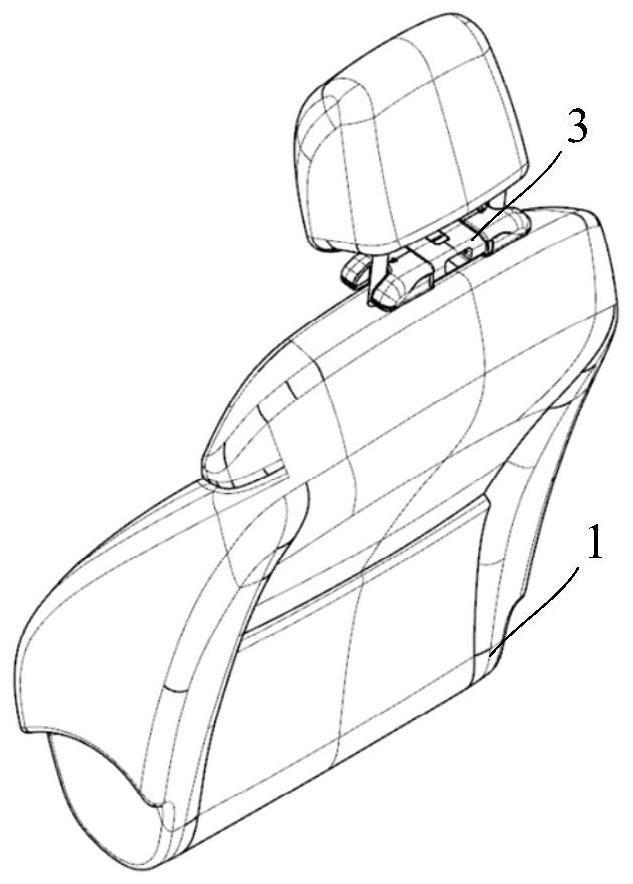

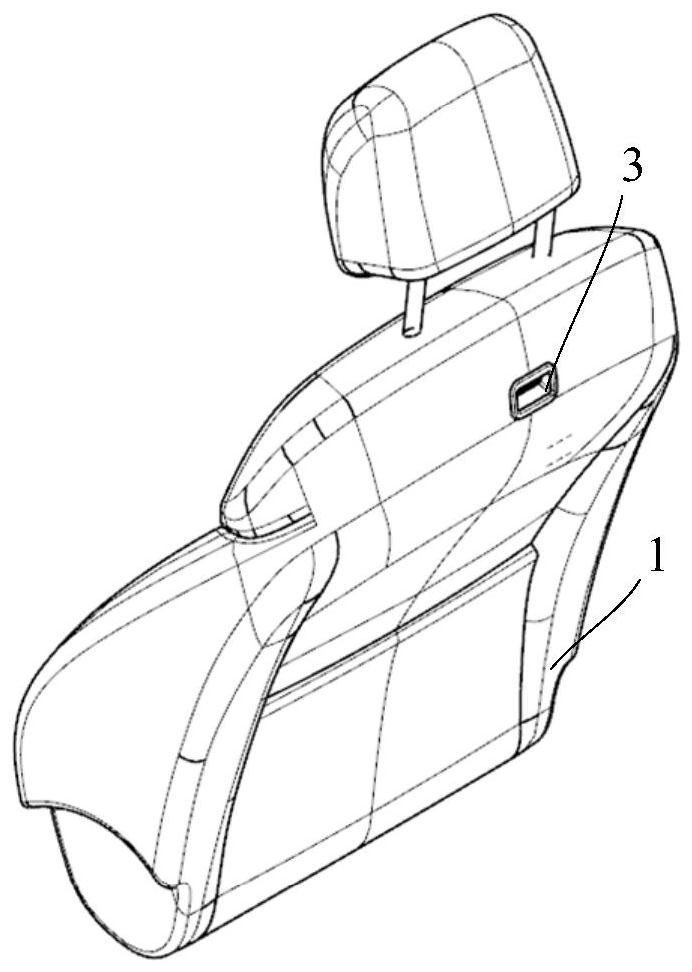

[0056] refer to figure 2 and image 3 , shows schematic diagrams of two embodiments of socket brackets for car seats. Figure 4 and Figure 5 It is a schematic diagram of two embodiments of the installation state of the self-locking plug of the car seat. structure Figure 2 to Figure 5As shown, the seat back of the car seat 1 is generally provided with a socket frame 3 adapted to the self-locking plug 2, and the self-locking plug is installed by inserting and fixing the self-locking plug 2 into the socket frame 3 of the seat back 1 2. The position of socket frame 3 can be positioned at the top or the rear portion of the chair back. In this embodiment, the self-locking plug 2 is connected to the neck bracket for installing the neck bracket on the back of the car seat.

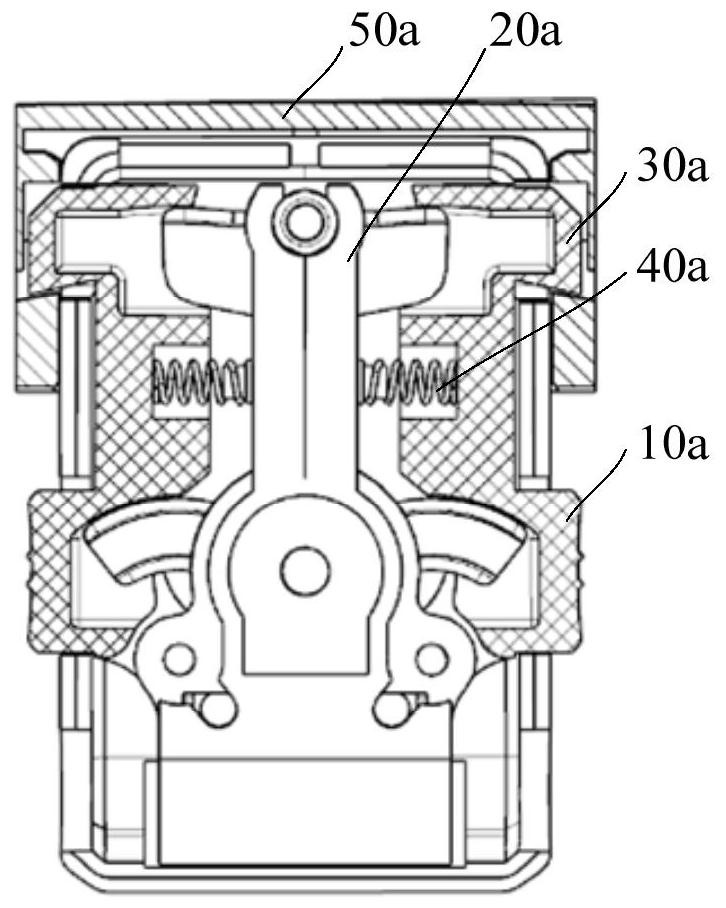

[0057] refer to Figure 6 to Figure 8 , shows a sectional view of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com