Arc roller set with adjustable radian

A technology of arc-shaped rolls and arcs, which is applied in the field of adjustable arc-shaped rolls, can solve the problems of prolonging the production cycle, increasing the workload of workers, increasing the cost of equipment investment, etc., and achieving the effect of facilitating the adjustment of curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

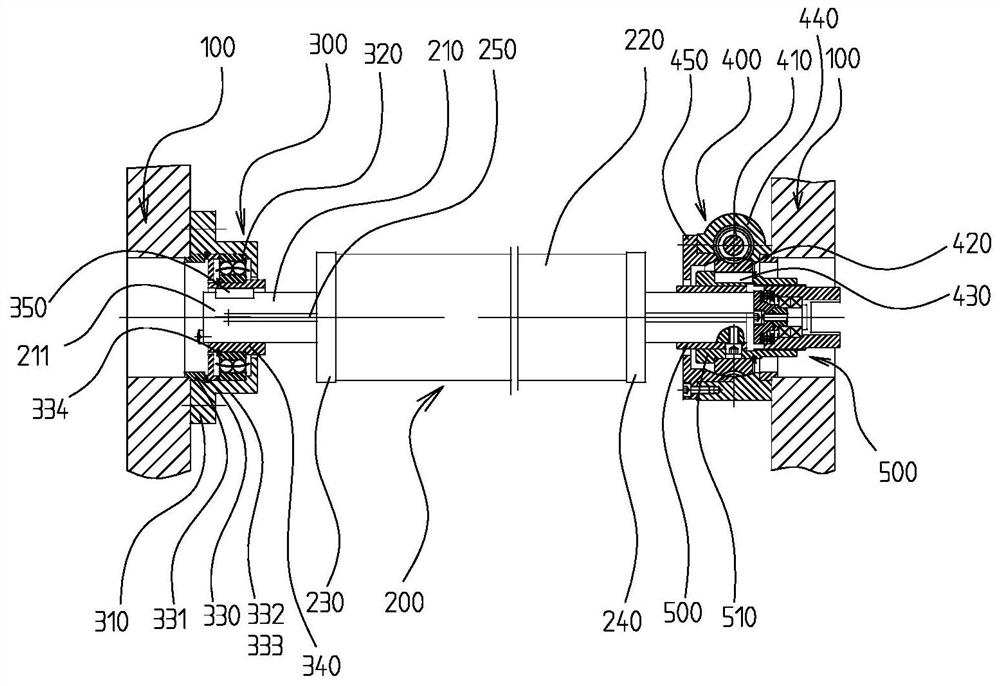

[0031] An adjustable arc arc roller group, including

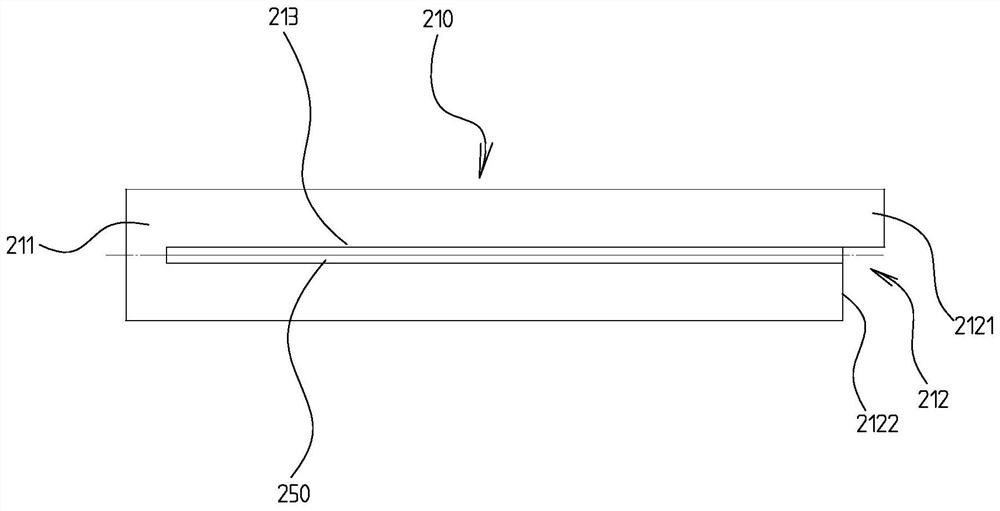

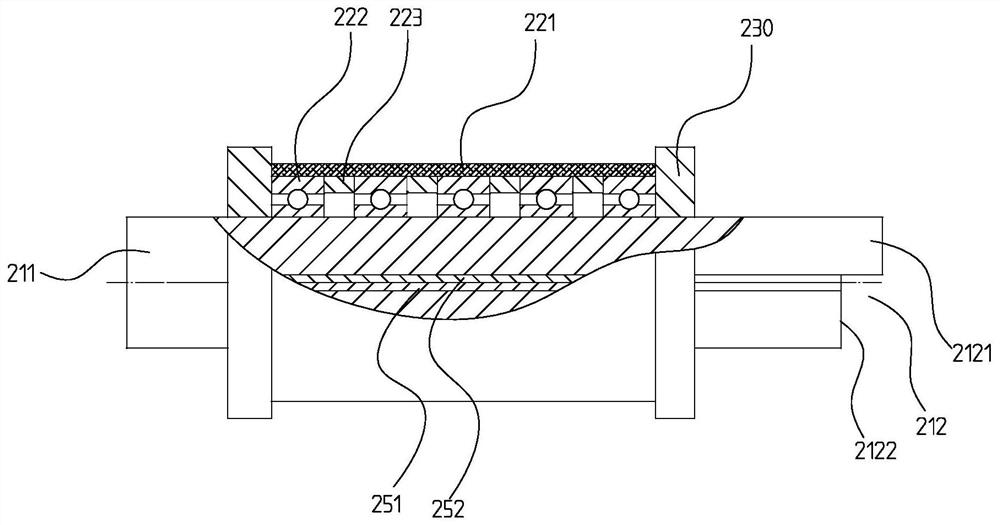

[0032] The arc-shaped stick 200, the arc-shaped stick includes a rotating shaft 210, and the rotating shaft 210 is provided with a through groove 213, and the through groove 213 divides the rotating shaft into an upper half shaft 2121 and a lower half shaft 2122, and the upper half shaft 2121 and the lower half shaft 2122 only The first end 211 of the rotating shaft is fixedly connected, and the length of the upper half shaft 2121 at the second end of the rotating shaft 210 is longer than the length of the lower half shaft 2122 at the second end of the rotating shaft 210; Cut to the first end 211 of the rotating shaft until the distance from the first end 211 of the rotating shaft is set to a length and then stop, thereby dividing the upper half shaft 2121 and the lower half shaft 2122 while making the upper half shaft 2121 and the lower half shaft 2122 on the rotating shaft The first end 211 is fixedly connected, and the ...

Embodiment 2

[0038] In actual use, in order to achieve a better stretching effect, it is also necessary to adjust the positions of the convex and concave points of the rotating shaft 210 relative to the paper, so as to achieve the best stretching effect. On the basis of Example 1, an angle adjustment assembly 400 is also included, and the angle adjustment assembly 100 can drive the rotating shaft 210 to rotate. Specifically, the angle adjustment assembly 400 includes a housing 440, a worm 410, a worm wheel 420, a transmission flat key 430, and an end cover 450. The worm 410 is engaged with the worm wheel 420. 510 is provided with a keyway, and the transmission flat key 430 is installed in the keyway, so that when the worm 410 is rotated, the worm wheel 420 will also rotate synchronously, and the adjustment nut 510 is driven by the transmission flat key 430 to rotate, because the adjustment nut 510 passes through the screw 530 below The half shaft 2122 is fixedly connected, so when the adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com