Thick plate forming drawing die

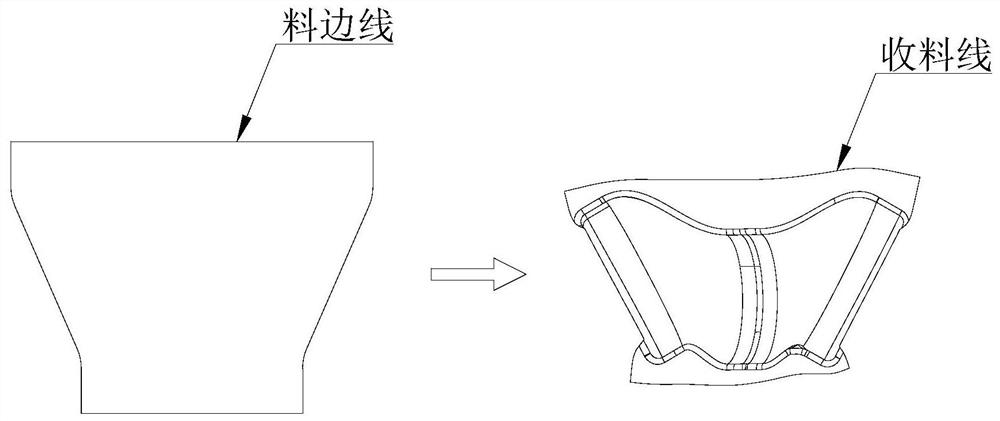

A drawing die and die holder technology, applied in the field of thick plate forming drawing die, can solve the problems affecting the overall progress of the product, unbalanced drawing force, low processing efficiency, etc., so as to control the wrinkling and cracking phenomenon, and achieve the same finished product. The effect of good performance, convenient debugging and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

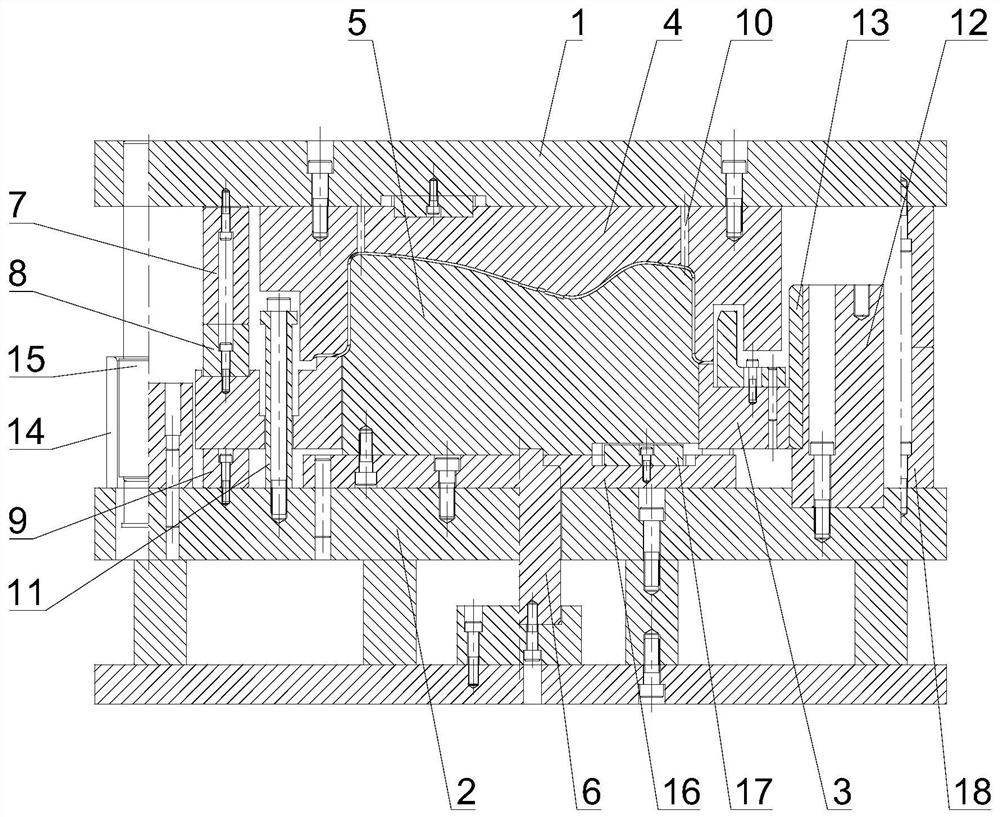

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0021] see figure 1 and 2 As shown, this embodiment provides a thick plate forming drawing die, which includes an upper mold base 1 , a lower mold base 2 and a binder ring 3 .

[0022] The upper die base 1 is set on the die base 4, the lower die base 2 is provided with a punch 5 corresponding to the die base 4, and the binder ring 3 floats between the upper die base 1 and the lower die base 2 through the action of the nitrogen spring 6. In between, the binder ring 3 is provided with a through hole allowing the punch 5 to pass through freely.

[0023] The lower surface of the upper mold base 1 is provided with a first limiting block 7, and the upper surface of the binder ring 3 is provided with a pressure regulating block 8 corresponding to the first limiting block 7, and the height of the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com