Selective vacuum resin hole plugging machine

A resin plug hole and selective technology, which is applied to the formation of electrical connection of printed components, electrical components, printed circuits, etc., can solve problems such as poor effect, and achieve the effects of convenient use, good foam breaking effect, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

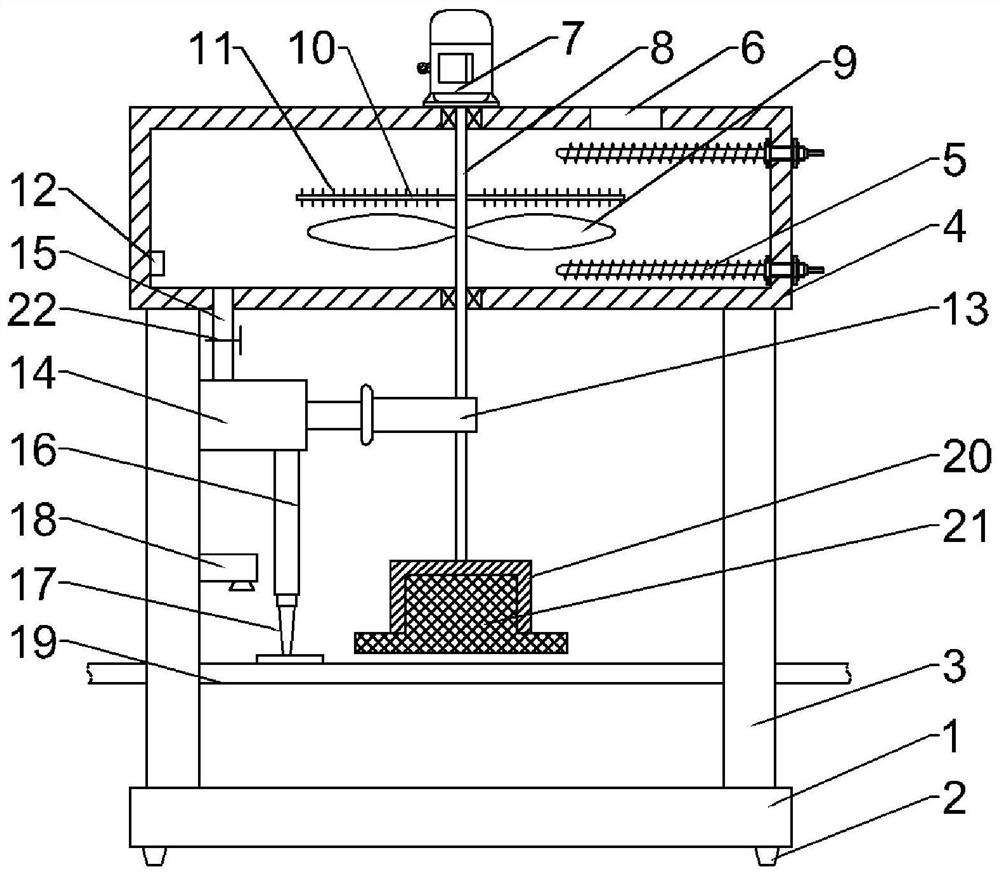

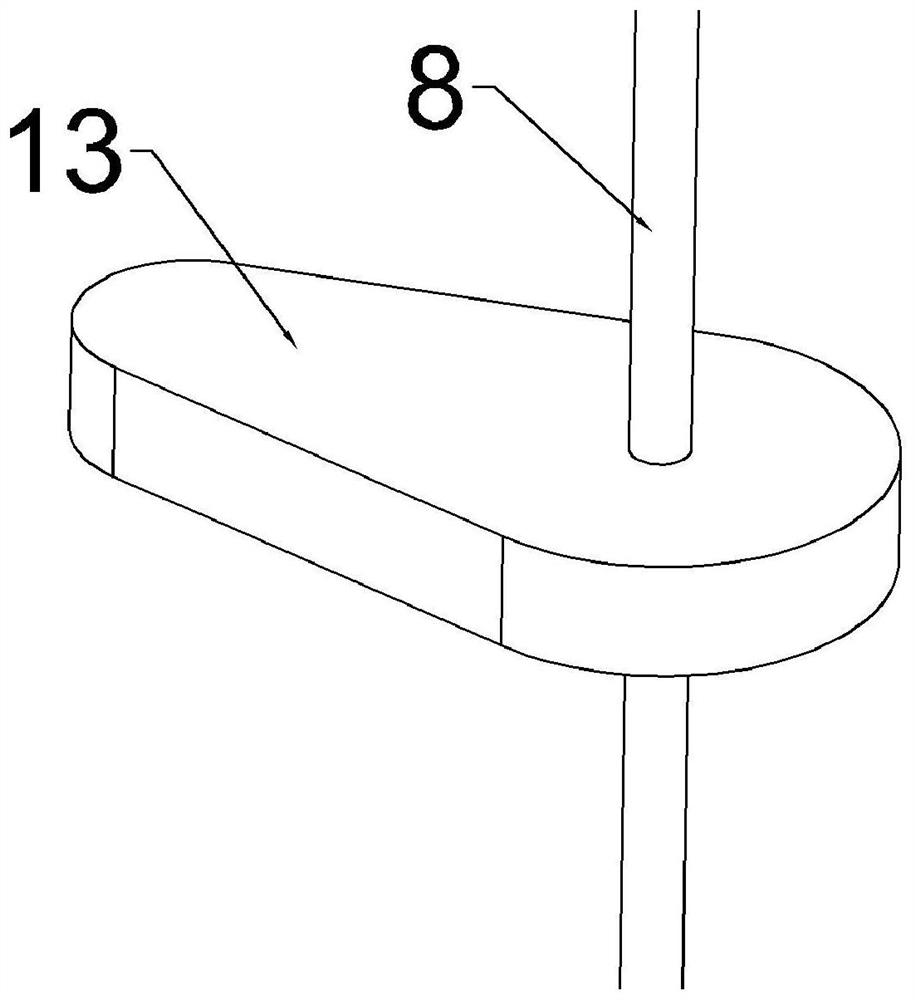

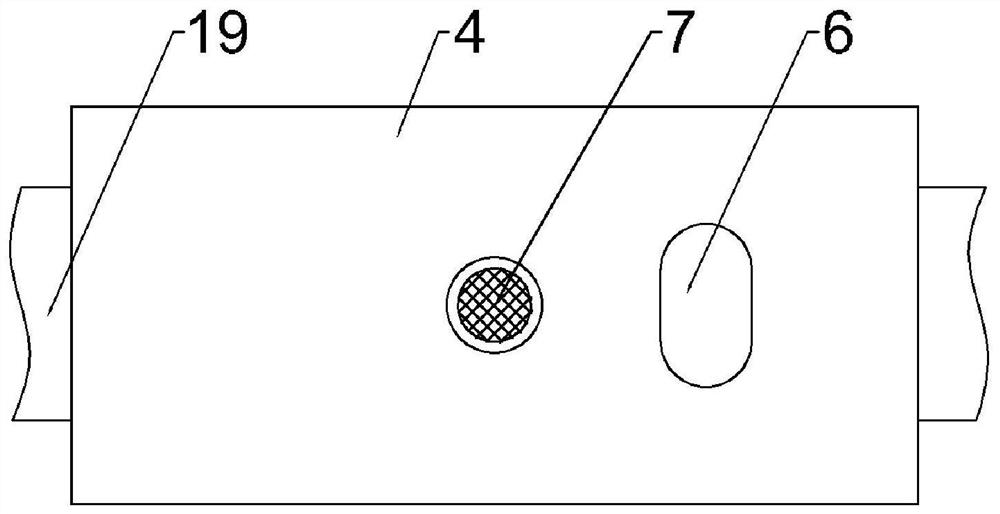

[0021] Example 1: Please refer to Figure 1-3 , a selective vacuum resin plugging machine, comprising a base 1, a support column 3 is fixedly connected symmetrically to the left and right above the base 1, a melting box 4 is fixedly connected to the top of the support column 3, and a plurality of electric heating tubes 5 are fixedly connected to the side wall of the melting box 4 , the top of the melting box 4 is fixedly connected with a motor 7, the output end of the motor 7 is fixedly connected with a longitudinal shaft 8, and the outer side of the longitudinal shaft 8 is fixedly connected with a stirring blade 9, and the stirring blade 9 is located in the melting box 4, above the stirring blade 9 A rotating breaking rod 10 is fixedly connected, and a plurality of defoaming needles 11 are fixedly connected to the outside of the rotating breaking rod 10, and a bubble detector 12 is fixedly connected to the left side of the bottom of the melting tank 4;

[0022] When in use, p...

Embodiment 2

[0030] Embodiment 2: This embodiment is a further improvement of the previous embodiment: the bottom of the longitudinal shaft 8 is fixedly connected with a connecting seat 20, and the bottom of the connecting seat 20 is fixedly connected with a sponge 21. The sponge 21 is located above the conveyor belt 19 and is completed in the plug hole. The workpiece that has plugged the hole in the back moves to the right along the conveyor belt 19, and contacts with the sponge 21, which will absorb excess resin to avoid excessive resin filling.

[0031] The working principle of the present invention is: when the present invention is in use, the resin material required for the plug hole is placed in the melting box 4, and then the electric heating tube 5 and the motor 7 are turned on and the solenoid valve 22 is closed, and the electric heating tube 5 heats the resin to melt it At the same time, the motor 7 rotates to drive the vertical shaft 8 to rotate, and the rotation of the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com