Patents

Literature

30results about How to "Good foam breaking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

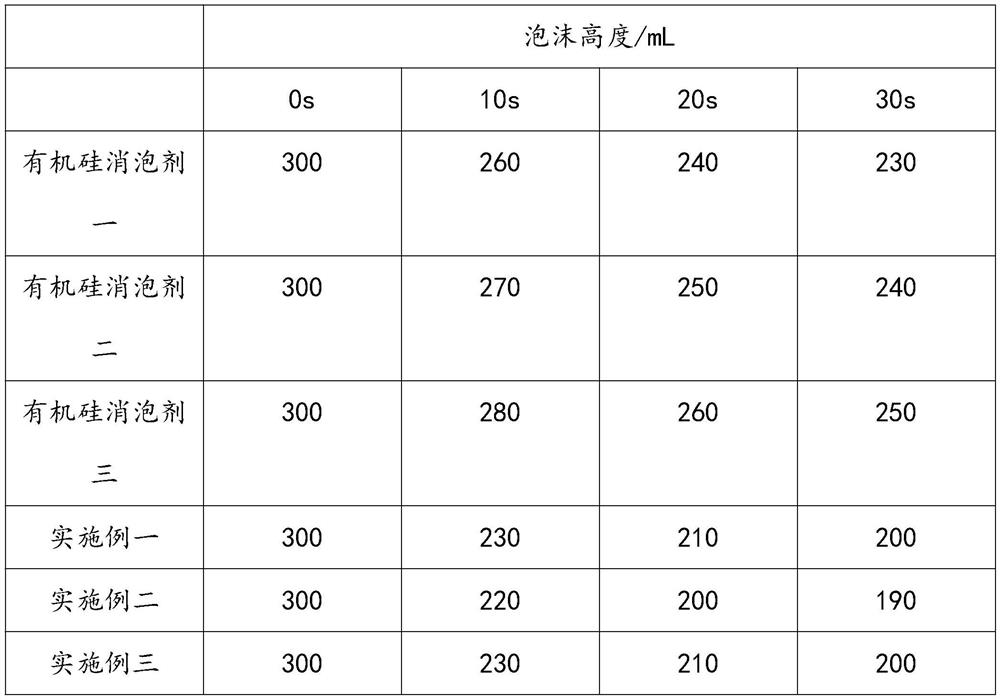

Defoaming agent composition

ActiveCN103768834ALarge specific surface areaStrong Hydrophilic PropertiesFoam dispersion/preventionSolventDefoaming Agents

The invention relates to a defoaming agent composition which is prepared by compounding 20-30 parts by mass of branched polyether, 10-20 parts by mass of modified nano silica, 20-30 parts by mass of polyorganosiloxane and 20-30 parts by mass of a solvent. The defoaming agent composition combines the hyperbranched polyether and the modified nano silica together, has an obvious synergistic effect, so that the hyperbranched polyether and the modified nano silica can be more compatible, defoaming properties of the hyperbranched polyether and the modified nano silica in high temperature environment can be increased, when the adding amount is about 30 mug / g, the defoaming rate can reach more than 90%, and the defoaming performance is strong.

Owner:CHINA PETROLEUM & CHEM CORP +1

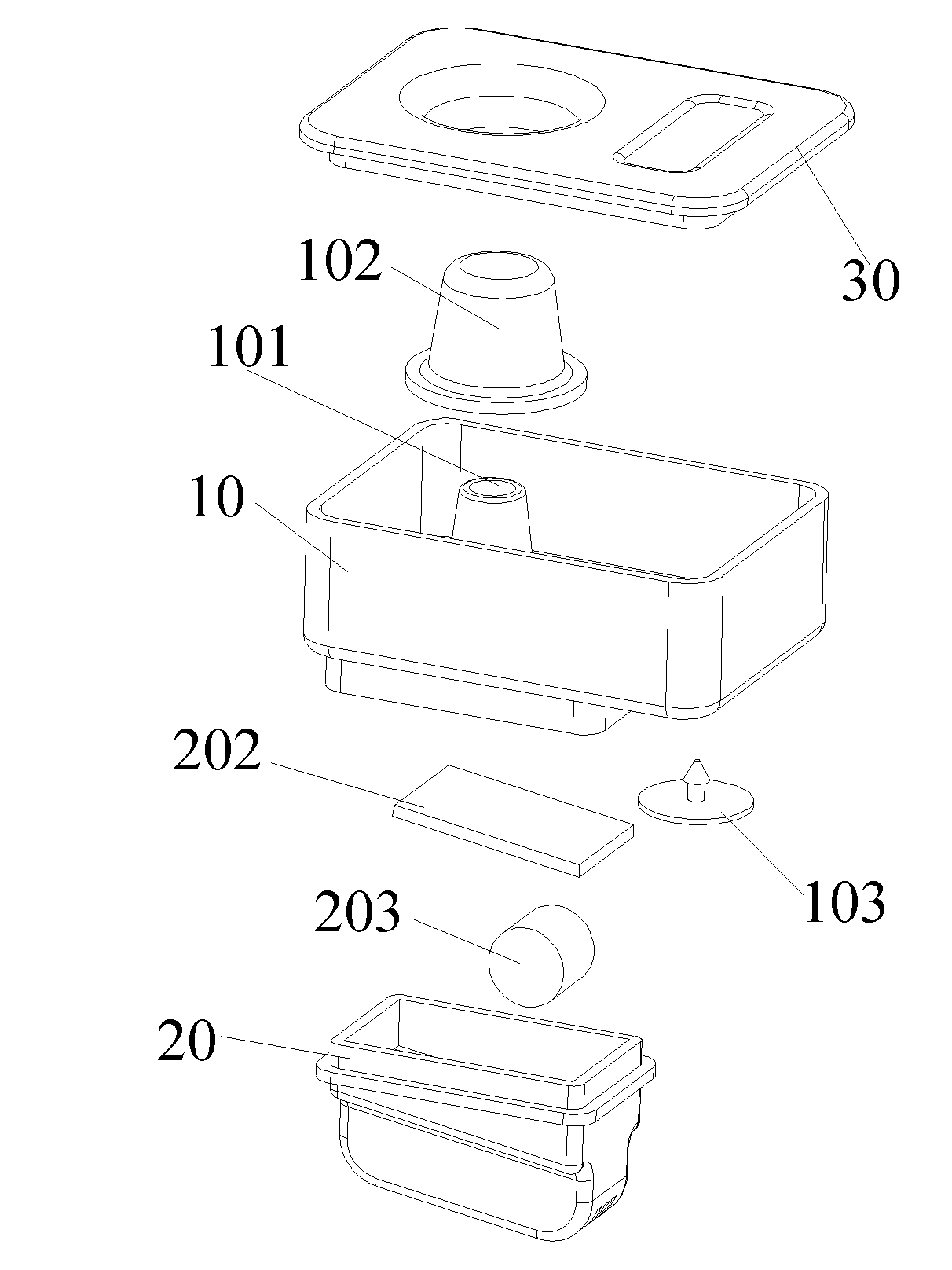

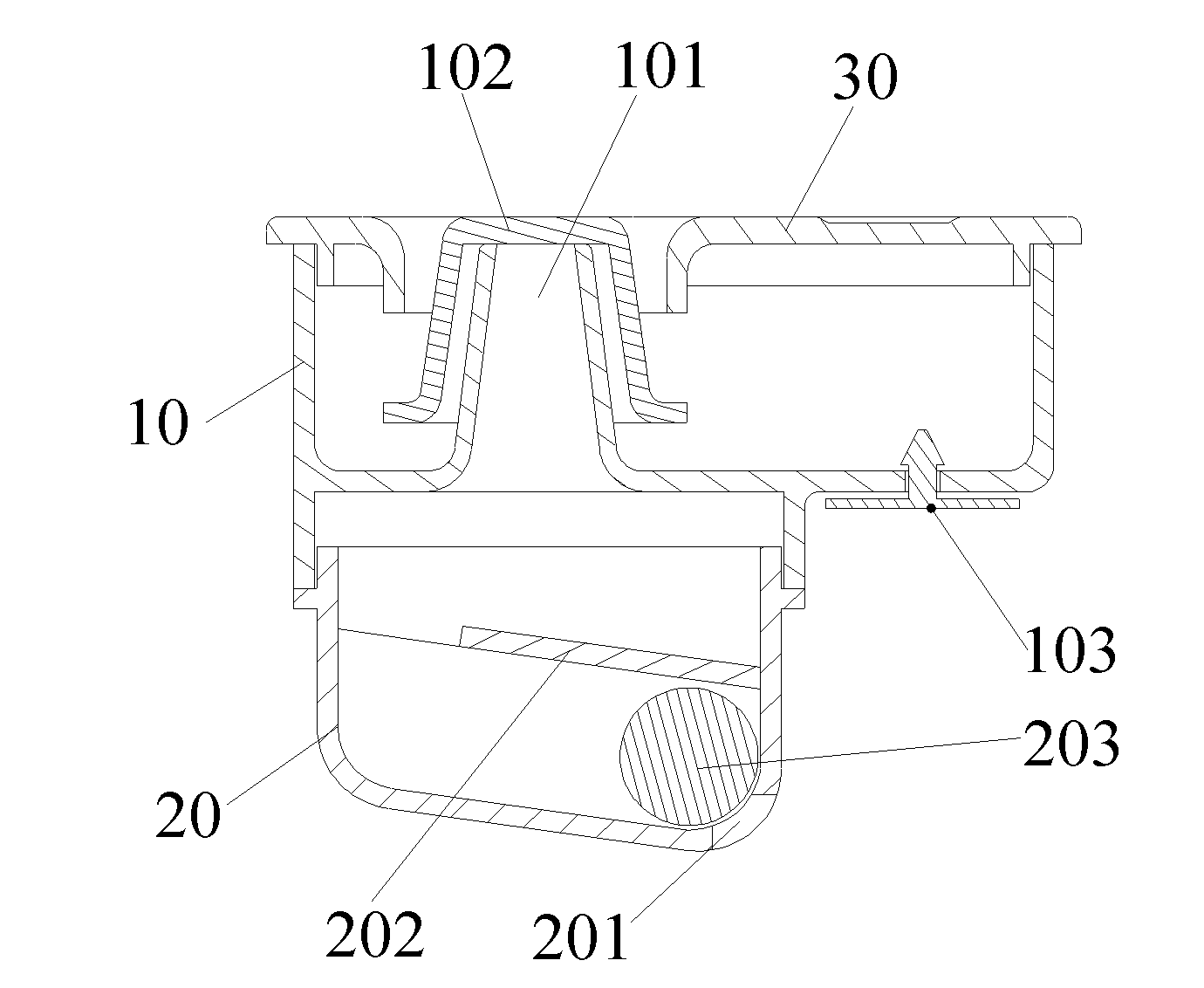

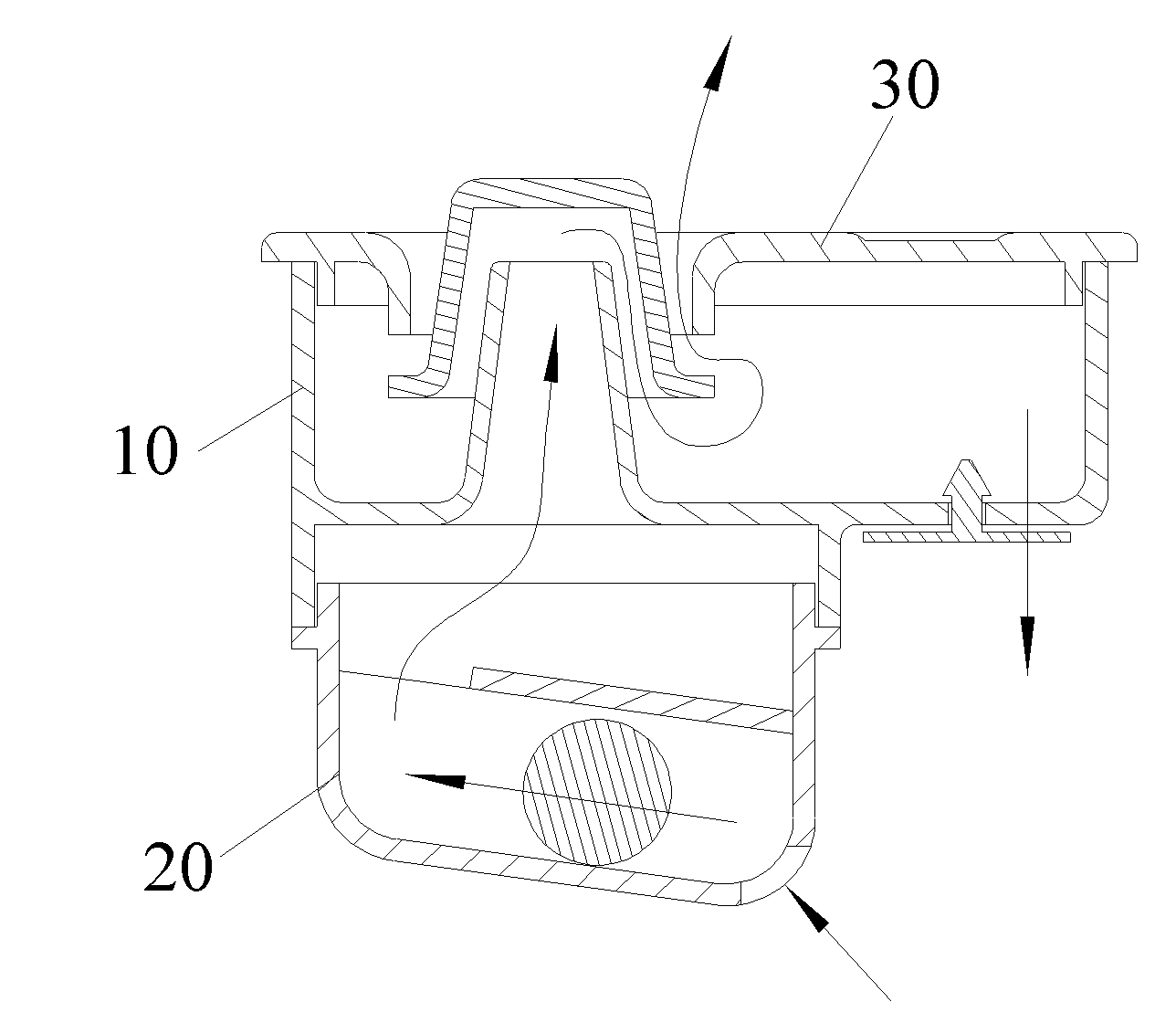

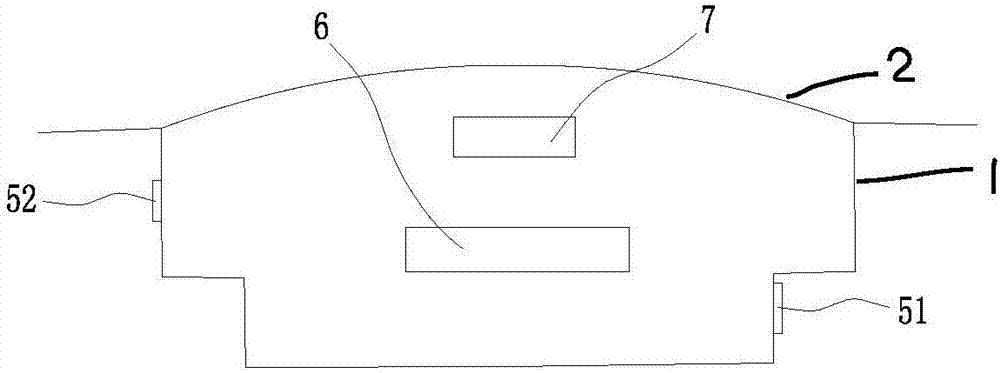

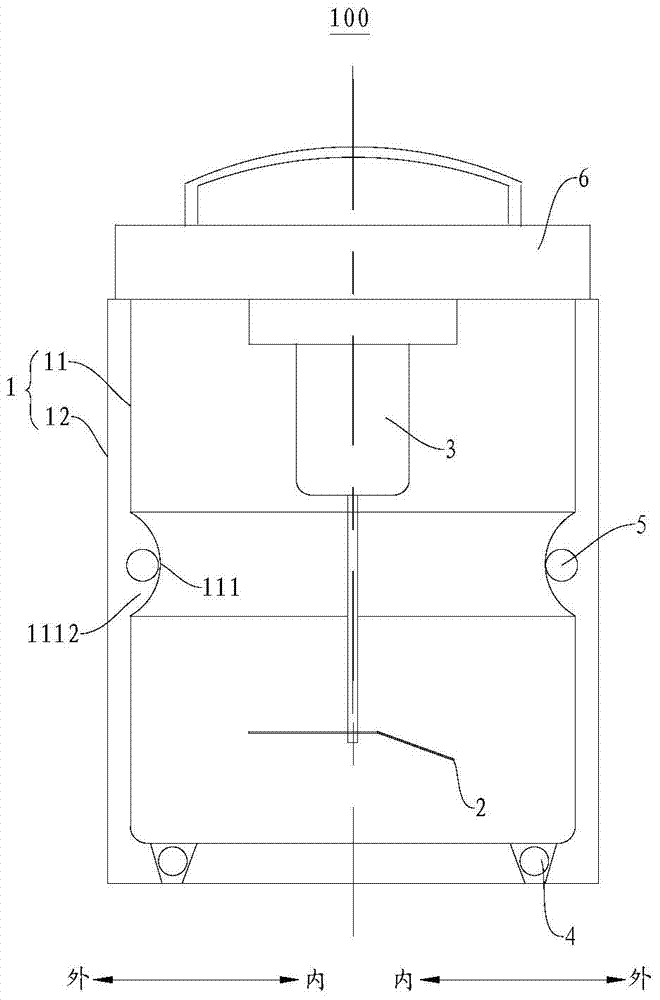

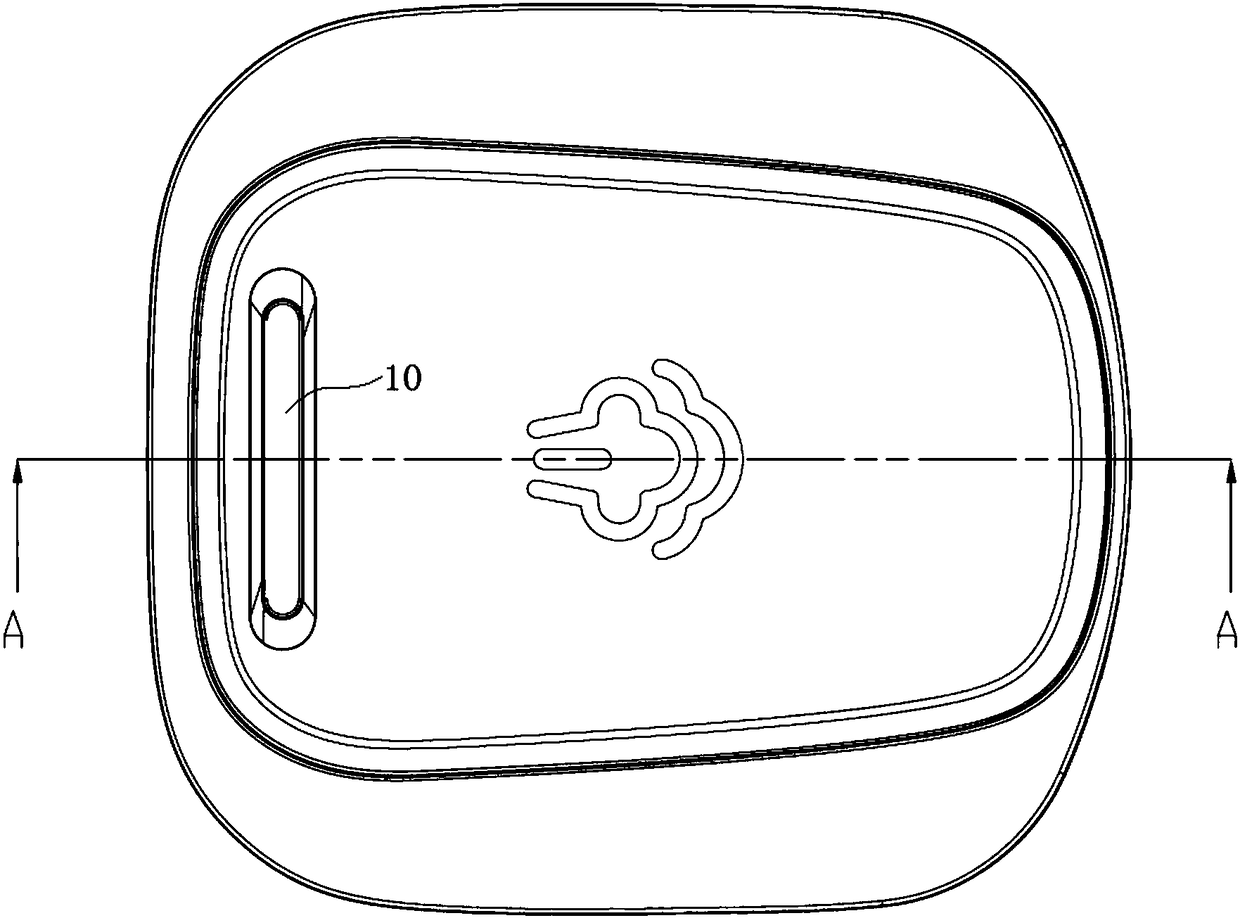

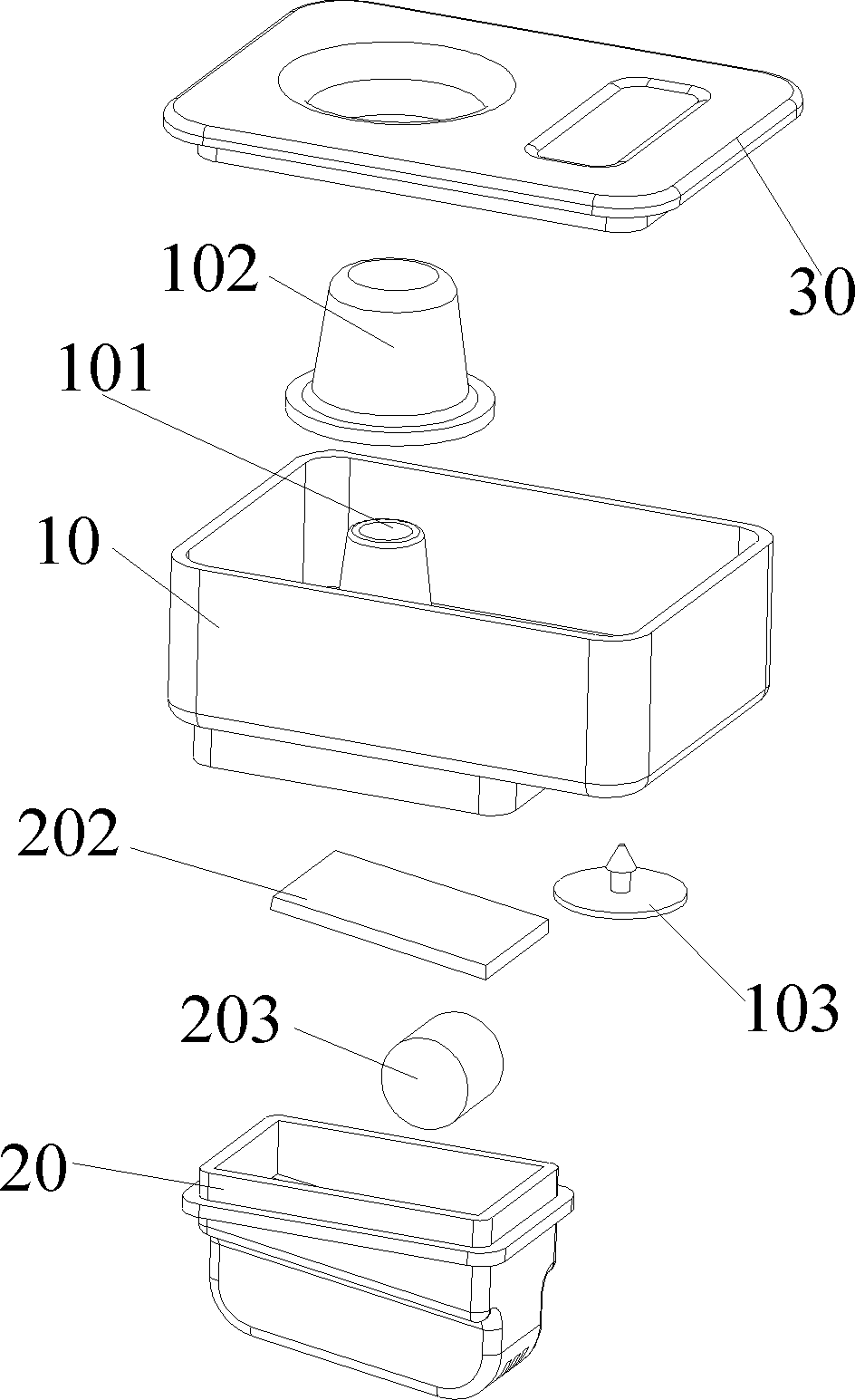

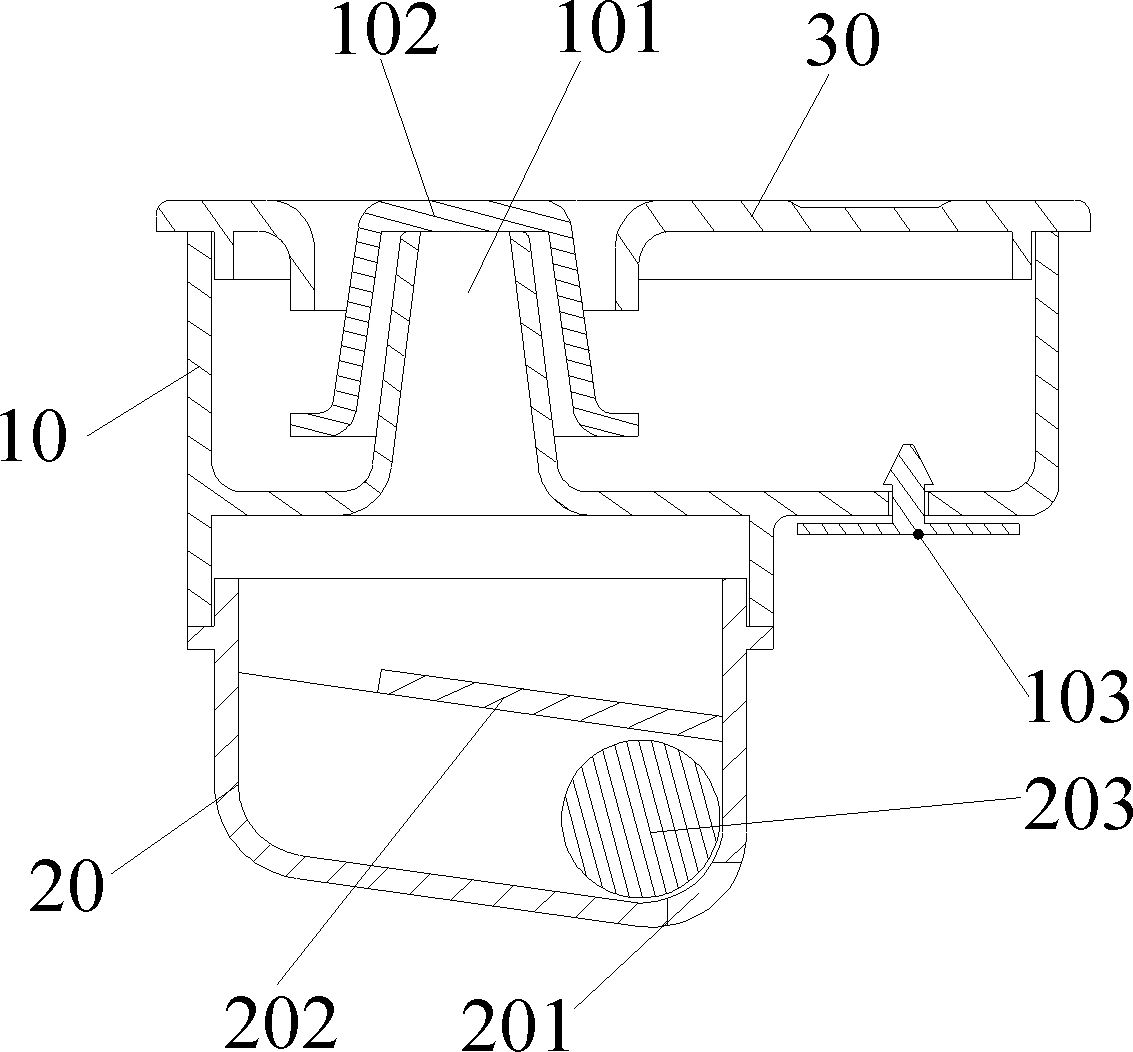

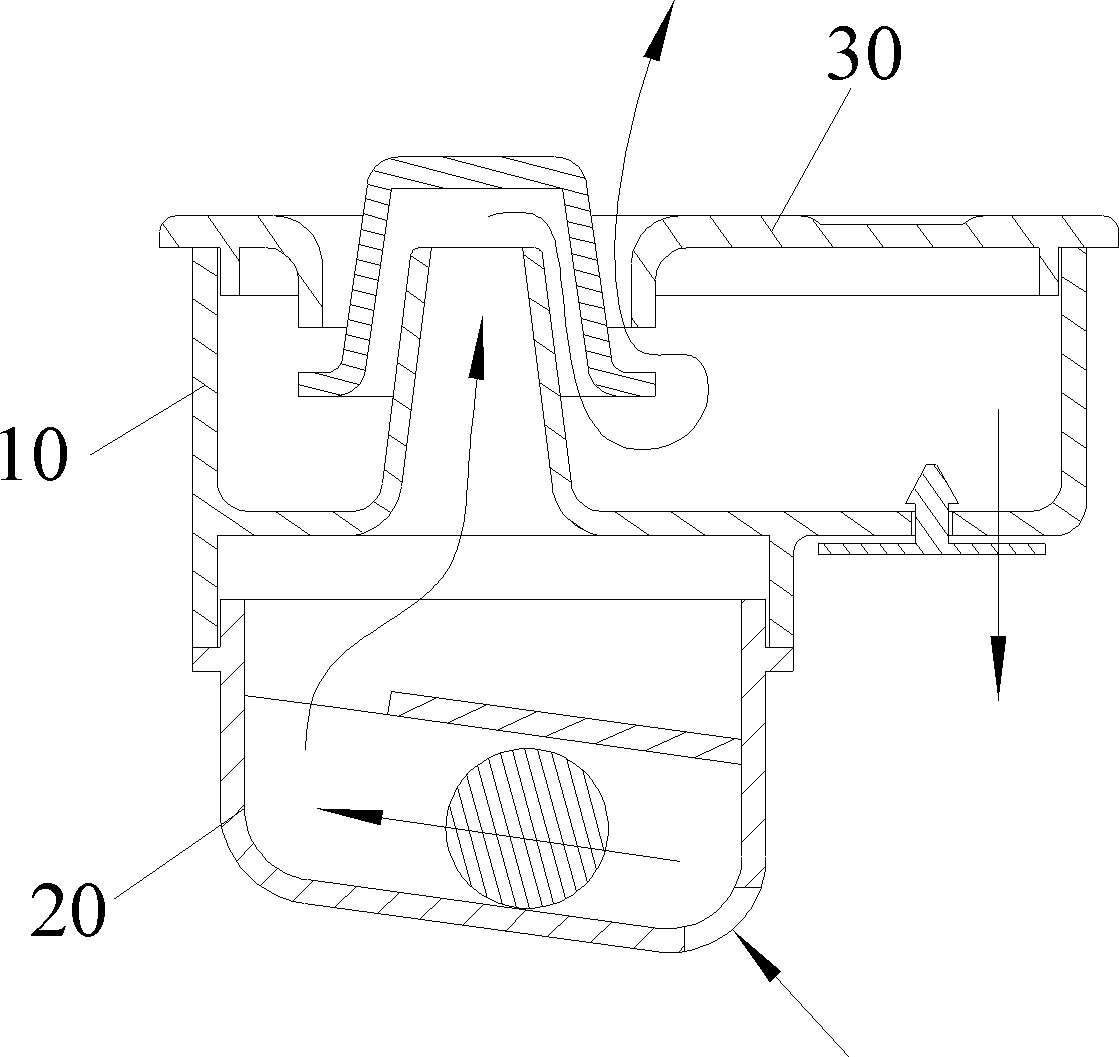

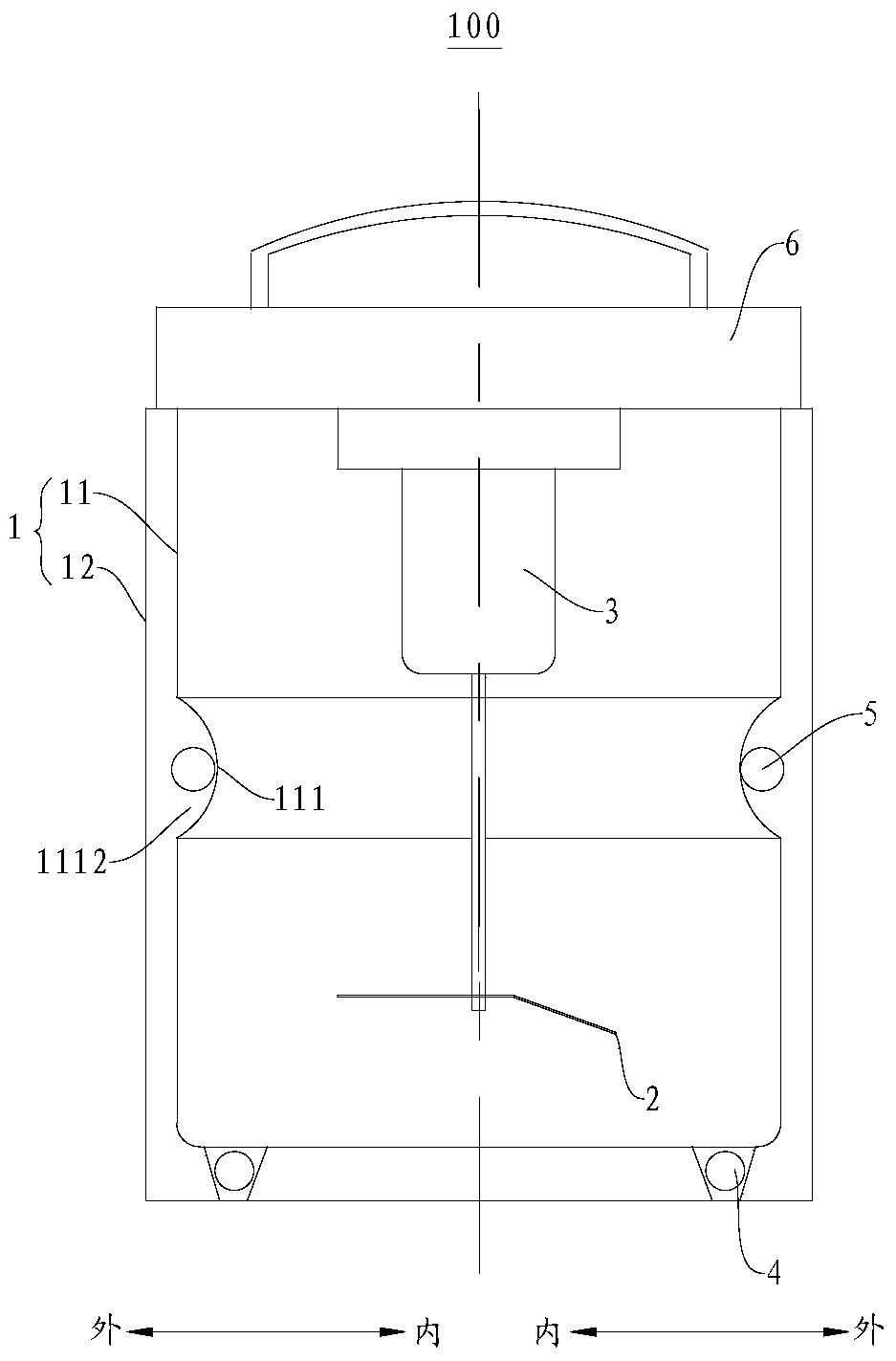

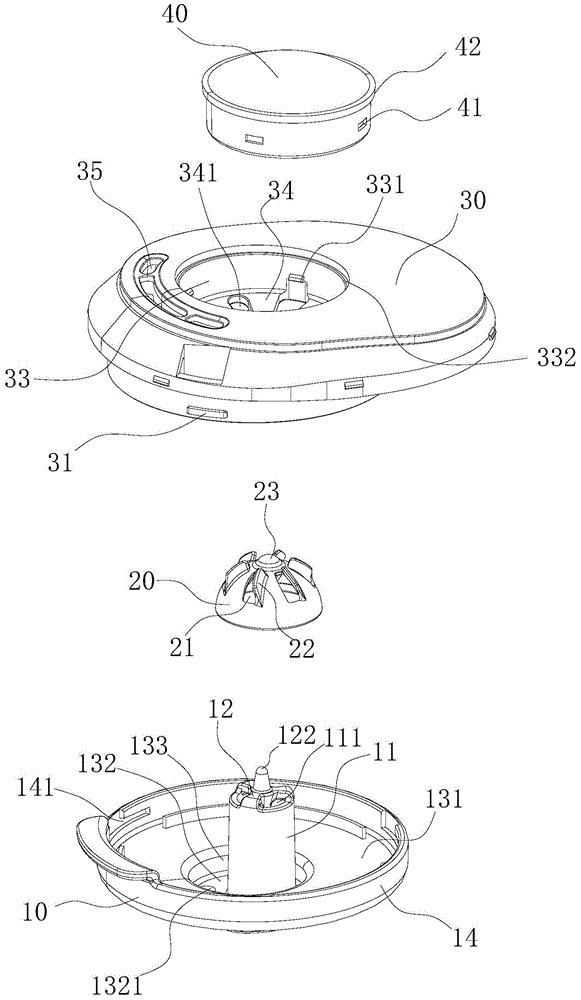

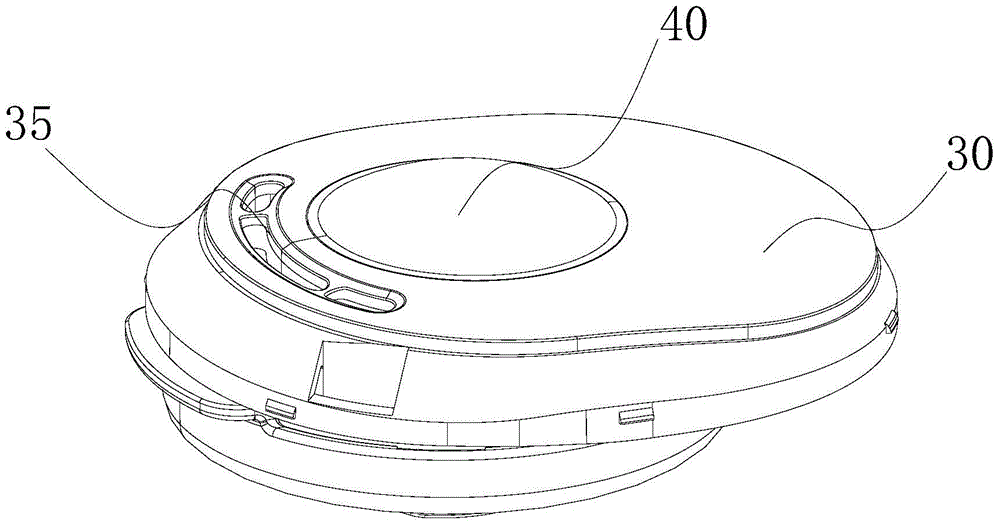

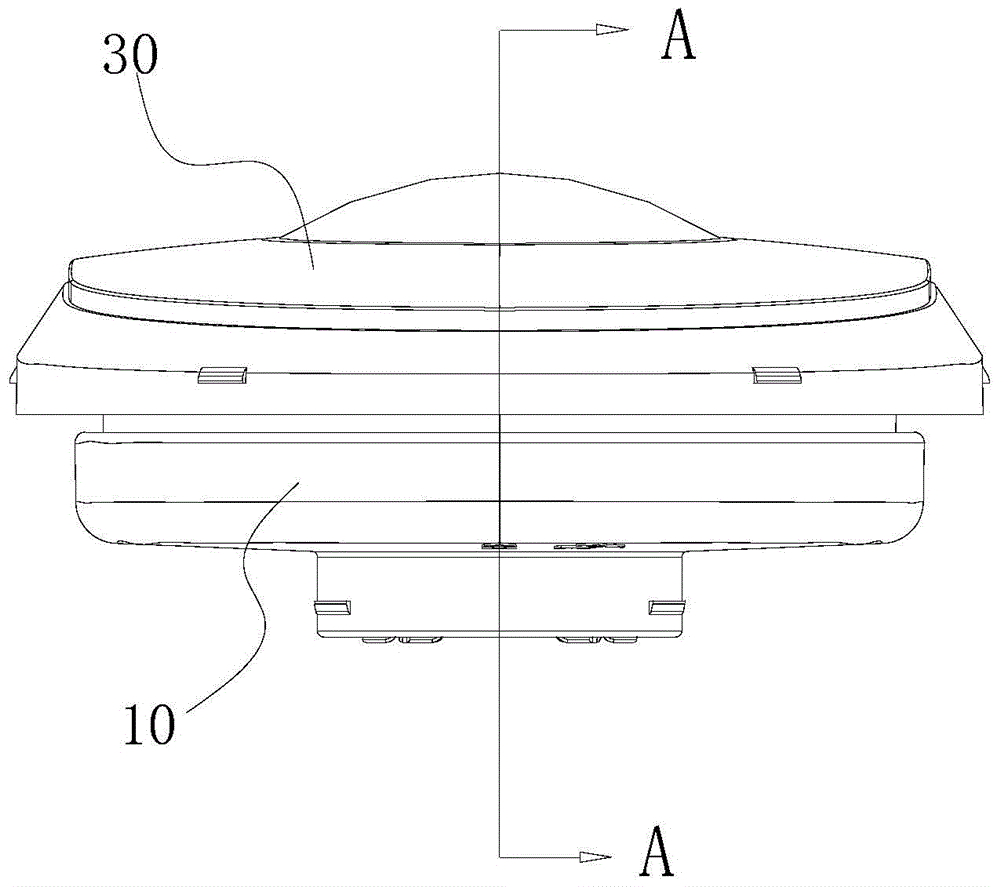

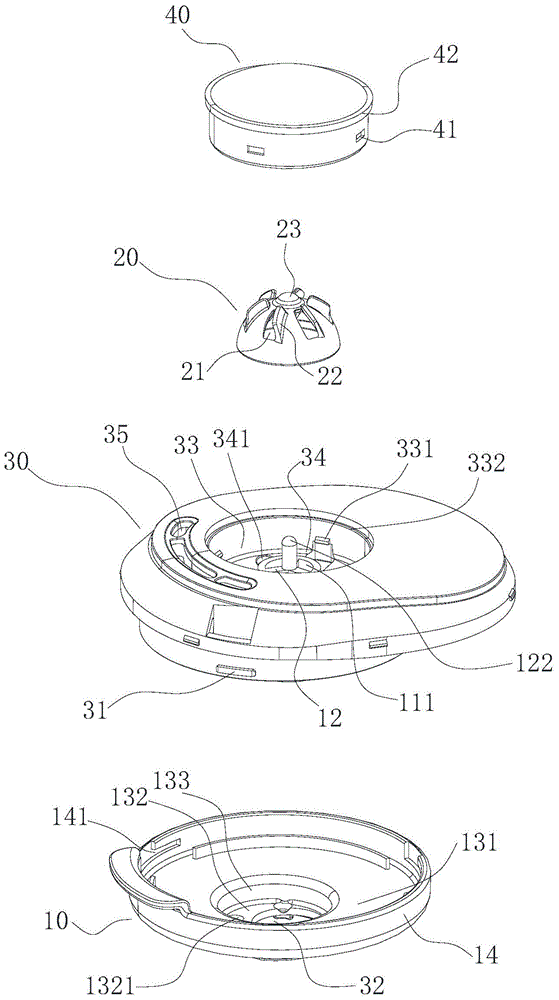

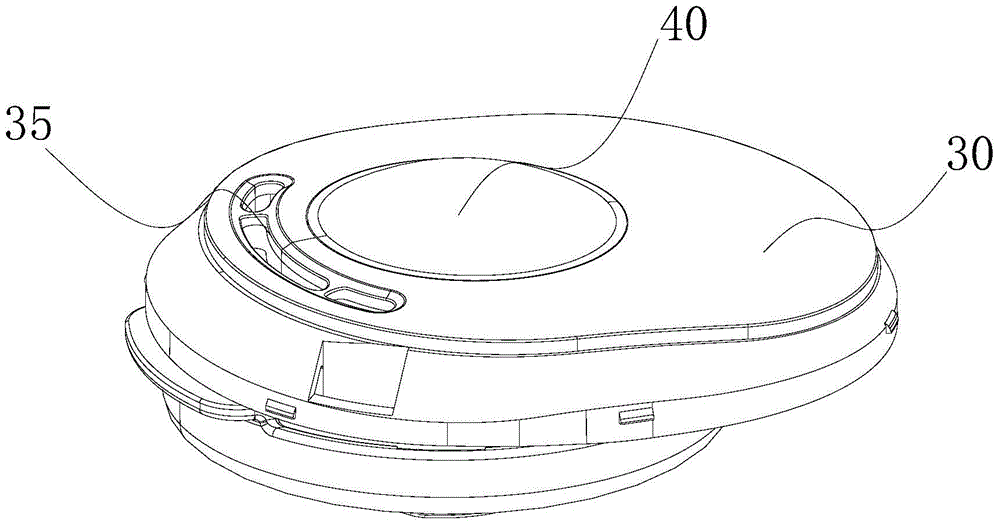

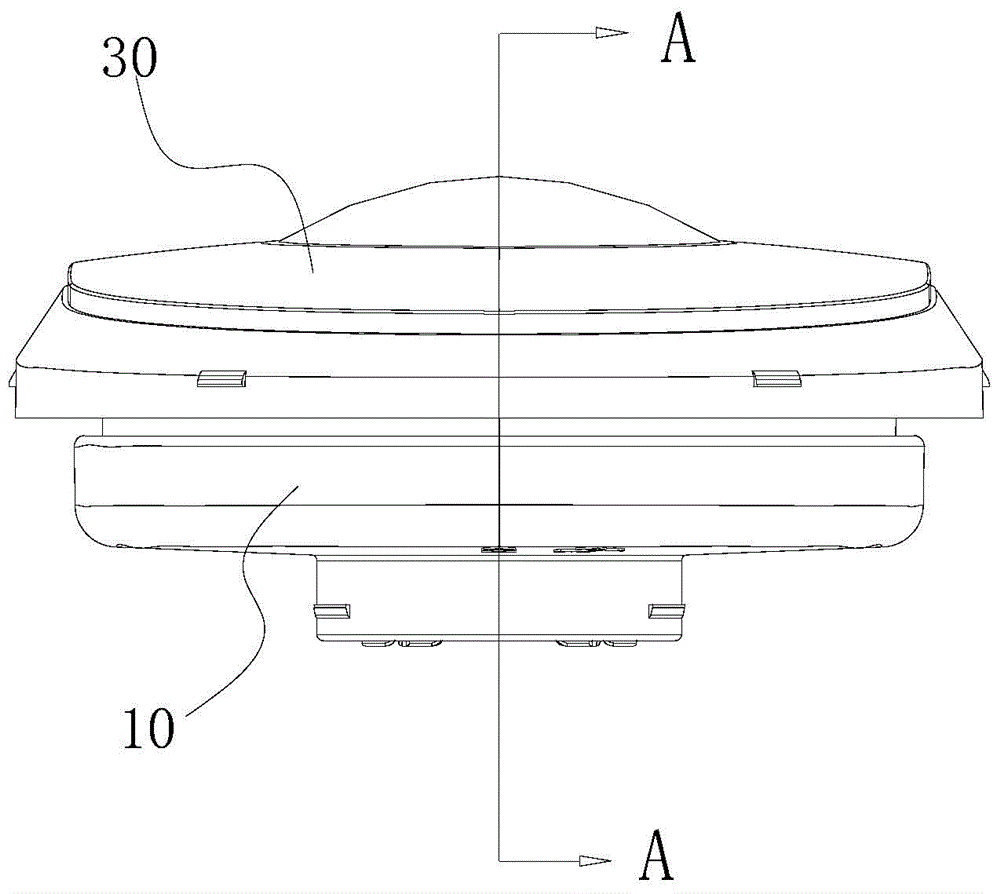

Steam valve and electric cooker comprising the steam valve

ActiveCN102599823AIncrease cooking tasteGuaranteed reflow effectCooking vesselsMultiple way valvesCookerEngineering

The invention provides a steam valve and an electric cooker comprising the steam valve. According to the invention, the steam valve comprises a valve body (10), a valve cap (30) and a valve seat (20), wherein the valve body (10) is provided with an air outlet (101) opening upwards; the valve cap (30) is arranged at the upper end of the valve body (10) and provided with an opening corresponding to the air outlet (101); the valve seat (20) is arranged at the lower end of the valve body (10); the bottom of the valve seat (20) is provided with an air inlet (201); and the air inlet (201) is provided with a returnable air retainer. According to the invention, the steam valve can effectively break foams, has good anti-spilling effect and can allow pressure difference to be generated inside the electric cooker so as to increase the cooking mouthfeel of rice. According to the invention, the electric cooker comprises the steam valve.

Owner:GREE ELECTRIC APPLIANCES INC

Surfactant composition

InactiveCN106492707AGood emulsificationOvercome the defect of difficult emulsificationTransportation and packagingMixingDefoaming AgentsEmulsion

The invention provides a surfactant composition comprising amino polyether organosilicone, silicon paste, an emulsifier, a thickener and water, wherein relative to each 25 g of the surfactant composition, the amount of the amino polyether organosilicone is 2-4 g, the amount of the silicon paste is 2-3 g, the amount of the emulsifier is 0.1-2 g, the amount of the thickener is 0.05-0.5 g, and the amount of water is 16-20 g; the silicon paste is prepared from gas-phase silica and dimethyl silicone oil, the amount of the fumed silica is 1-9 g / 100 g silicon paste, and the amount of the dimethyl silicone oil is 91-99 g / 100 g. The surfactant composition can be used as a defoaming agent; through thermal stability testing, the surfactant composition has no emulsion breaking and oil floating, and has the property of acid and alkali resistance.

Owner:余姚市楷瑞电子有限公司

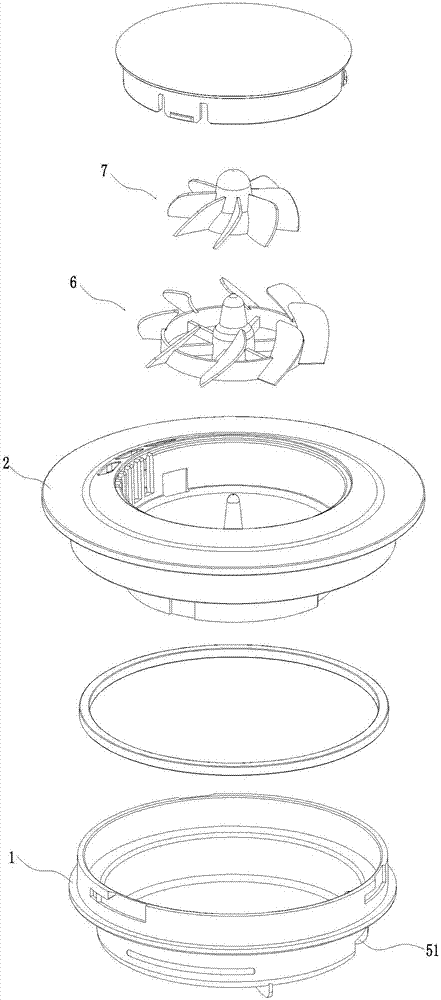

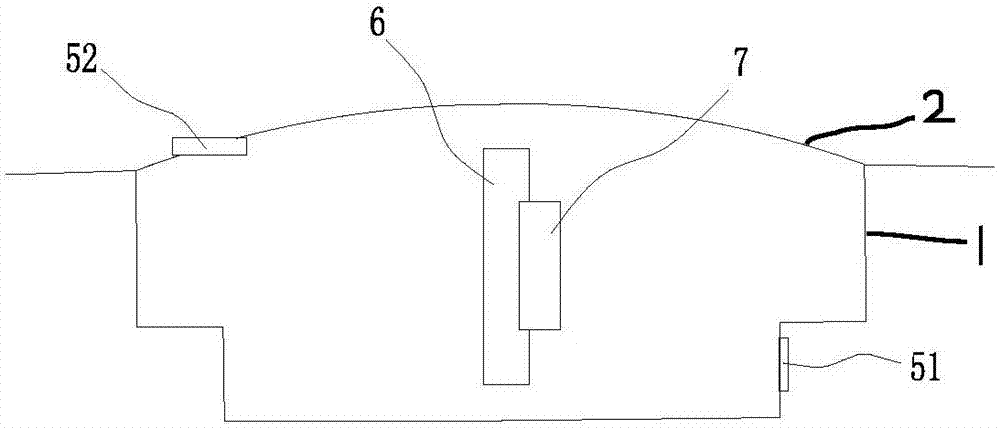

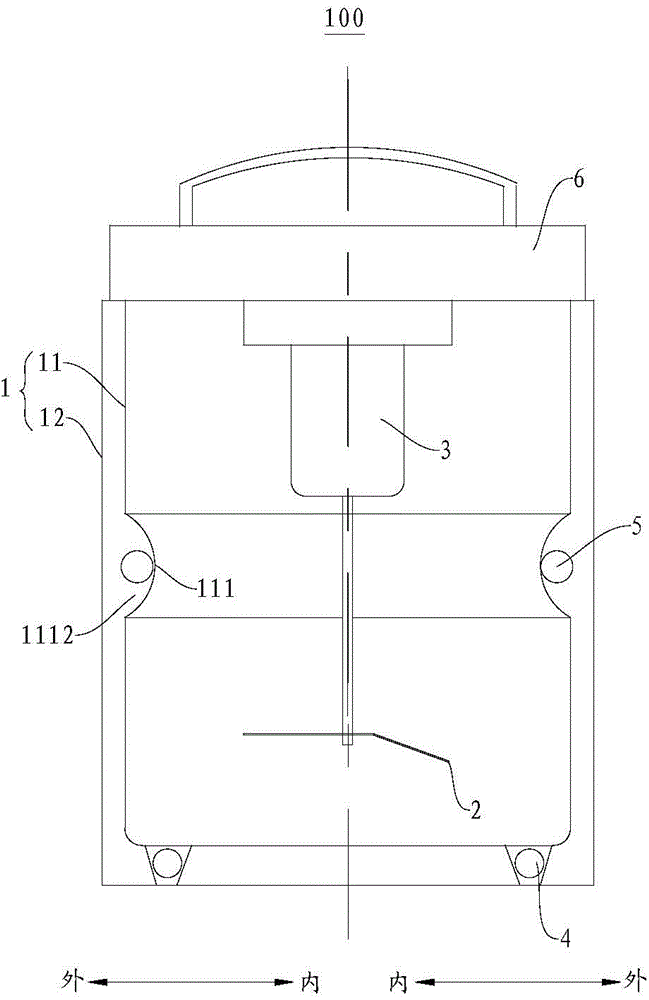

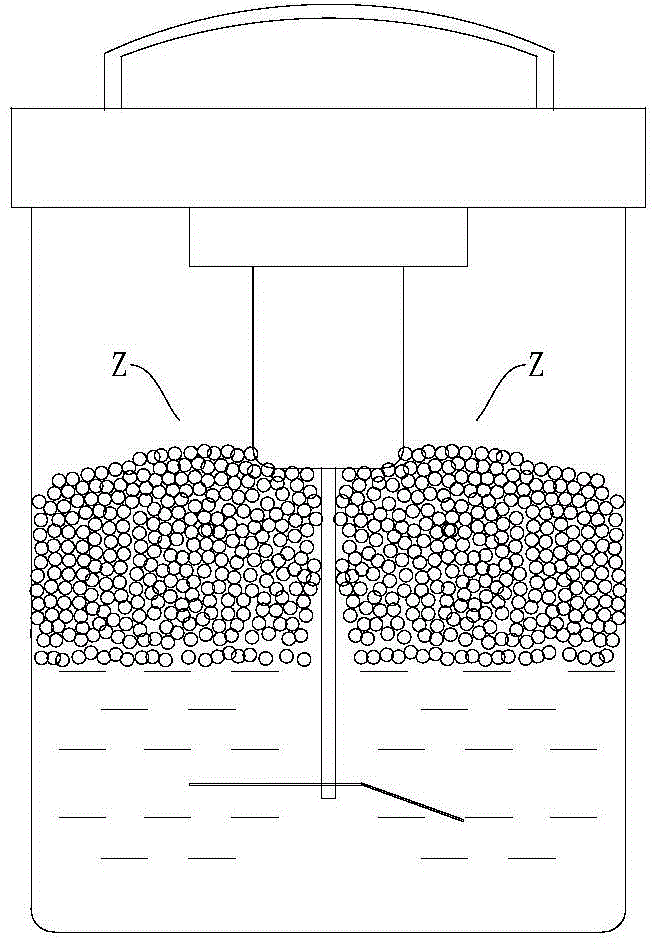

Steam valve with rotary bubble breaker

ActiveCN107041681ADisperse impactGood foam breaking effectBoiling over preventionSystem failureValve seat

The invention discloses a steam valve with rotary bubble breakers, and aims to solve the problems that an existing steam valve rotary bubble breaker is low in bubble breaking rate, poor in bubble breaking effect, and imbalance in motions; the steam valve comprises a valve seat and a valve cover; the valve seat is provided with a steam inlet; the valve cover and the valve seat can form a steam chamber connected with the steam inlet; the steam valve comprises a first rotary bubble breaker and a second rotary bubble breaker respectively arranged in the steam chamber in a rotary manner, and the rotary bubble breakers can be driven by the steam ejected from the steam inlet to rotate, thus breaking bubbles; the advantages are that the two rotary bubble breakers can be simultaneously driven to rotate, thus providing high bubble breaking rate, dispersing the steam impact force, and ensuring the rotary bubble breakers to stably and normally work; when one rotary bubble breaker fails, the bubble breaking work can be ensured to be normally done, thus preventing the steam valve bubble breaking system failure, and allowing the steam valve to have more stable bubble breaking effect.

Owner:HONGYANG HOME APPLIANCES

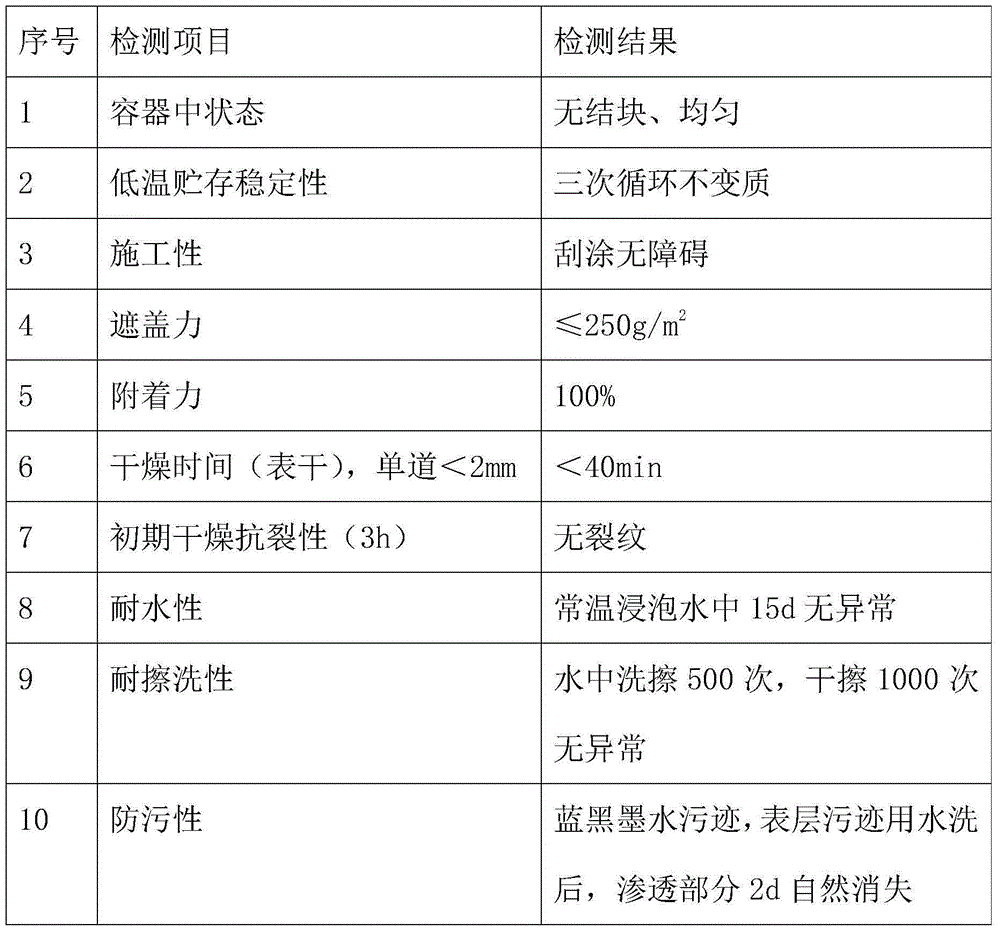

Scrubbing-resistant anti-microbial inner wall emulsion paint

InactiveCN105131672AHigh strengthImprove wear resistanceAntifouling/underwater paintsPaints with biocidesEmulsionPolyphosphate

The invention discloses a scrubbing-resistant anti-microbial inner wall emulsion paint. The emulsion paint comprises raw materials: modified PVA, methyl methacrylate, polymethyl methacrylate, light calcium carbonate, talcum powder, lithopone, calcined kaolin, hydroxyethyl cellulose, a dispersant SN-5040, a dispersant SN-5027, a multifunctional auxiliary agent AMP-95, 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate, an antifoaming agent NXZ, negative ion-anti-microbial additives, sodium polyphosphate, a flatting agent, a nano stain-resistant agent NZM-1, propylene glycol, 5-chloro-2-methyl-4- isothiazolin-3-ketone and deionized water. The inner wall emulsion paint is not easy to generate powder, has good scrubbing resistance and stain resistance, is safe and environmentally friendly, and has a long anti-microbial validity period.

Owner:TIANCHANG YINHU PAINT

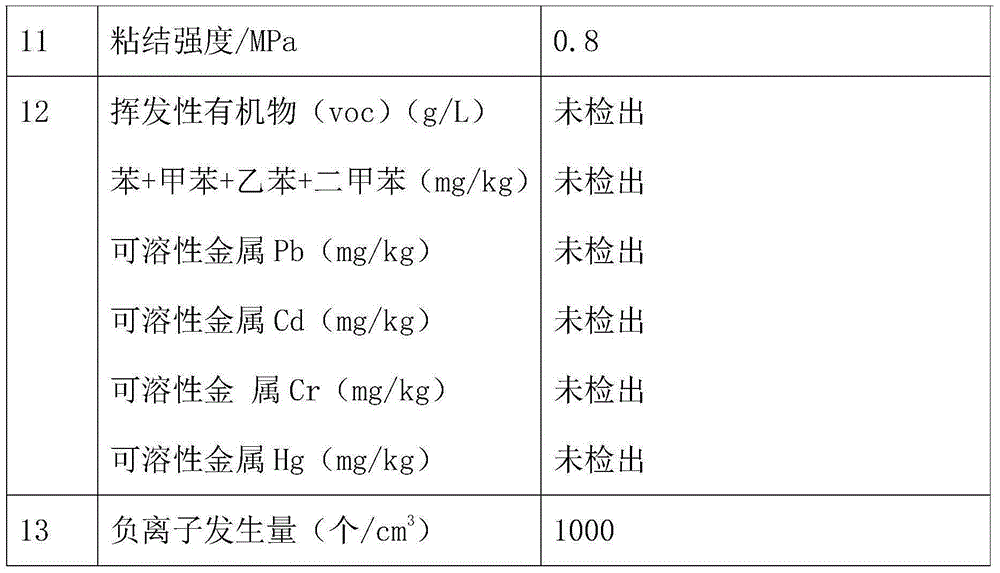

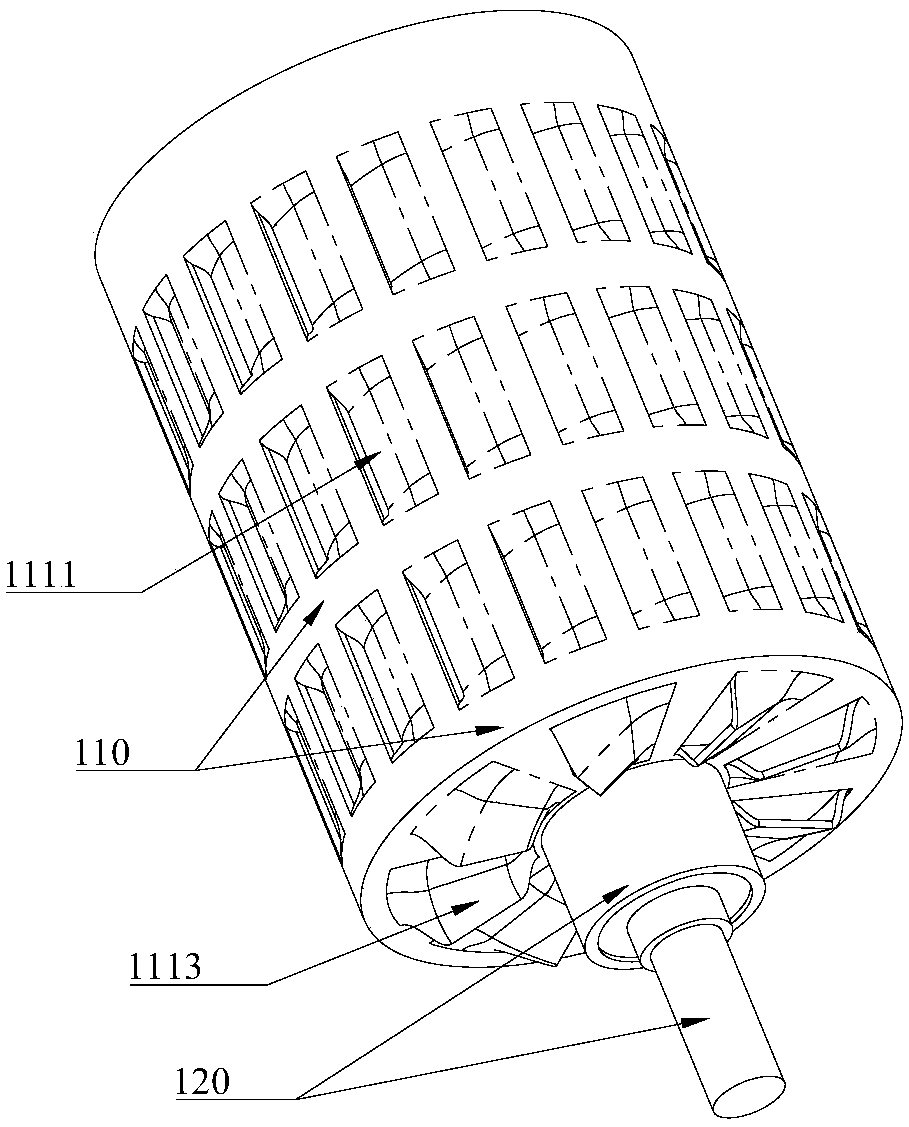

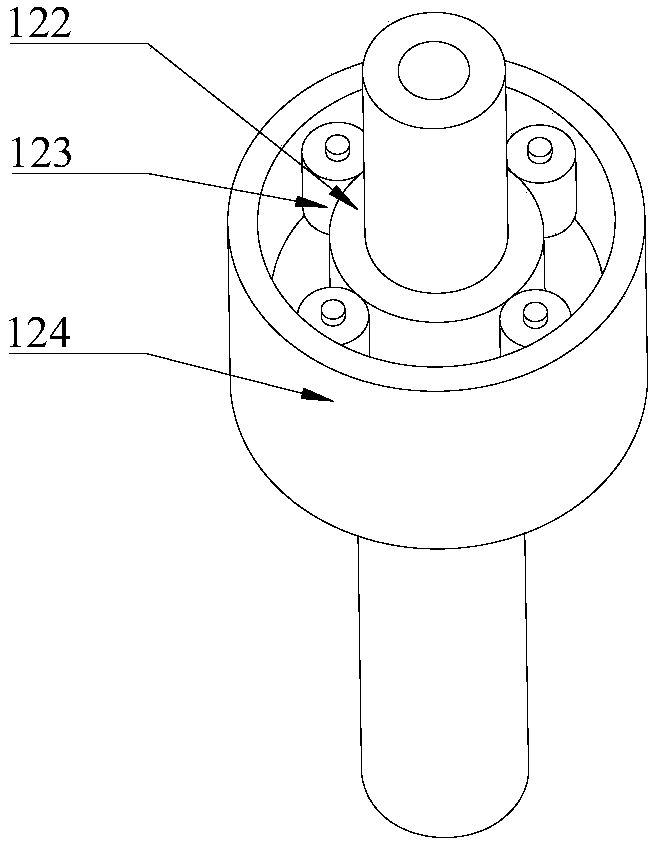

Bidirectional processing cutter set and wall breaking device

The invention provides a bidirectional processing cutter set and a wall breaking device and belongs to the field of food processing. The bidirectional processing cutter set comprises a cutter head, acutter cylinder, a transmission device and a driving device, wherein the output end of the driving device is connected with the input end of the transmission device, the transmission device comprisesa first output end and a second output end, the first output end and the second output end are coaxially arranged, the rotation direction of the first output end is opposite to the rotation directionof the second output end, the cutter head is arranged at the first output end, the cutter cylinder is arranged at the second output end, and the cutter head is arranged in the cutter cylinder. The directional processing cutter set disclosed by the invention can increase speed difference and contact chance between food materials and the cutter, so that a processing efficiency is effectively improved; the bidirectional processing cutter set has good stirring and foam breaking effects, makes the food materials evener and avoids bottom sticking; the bidirectional processing cutter set further canmaintain stable motor load and has a motor protection effect.

Owner:SICHUAN UNIV

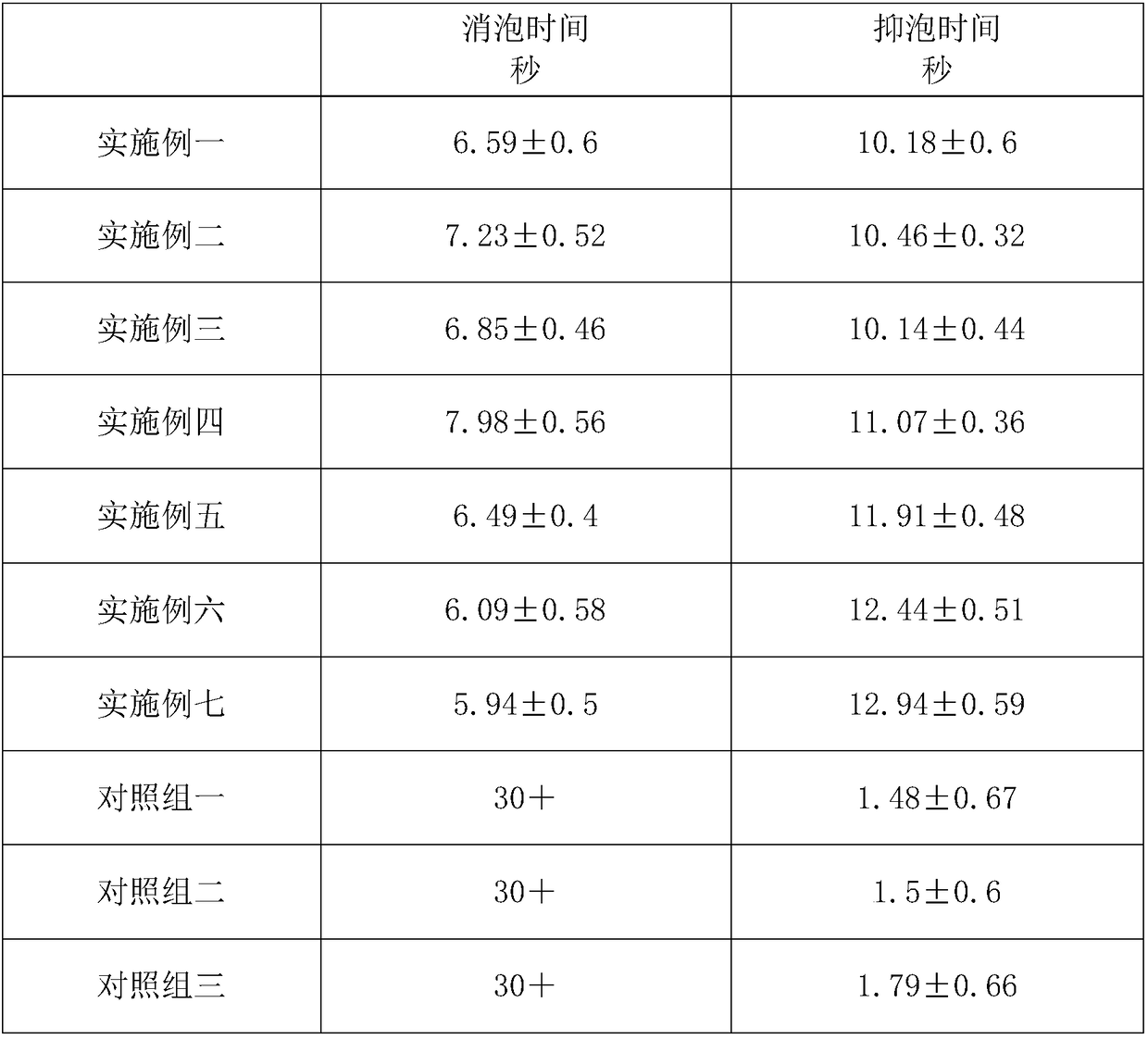

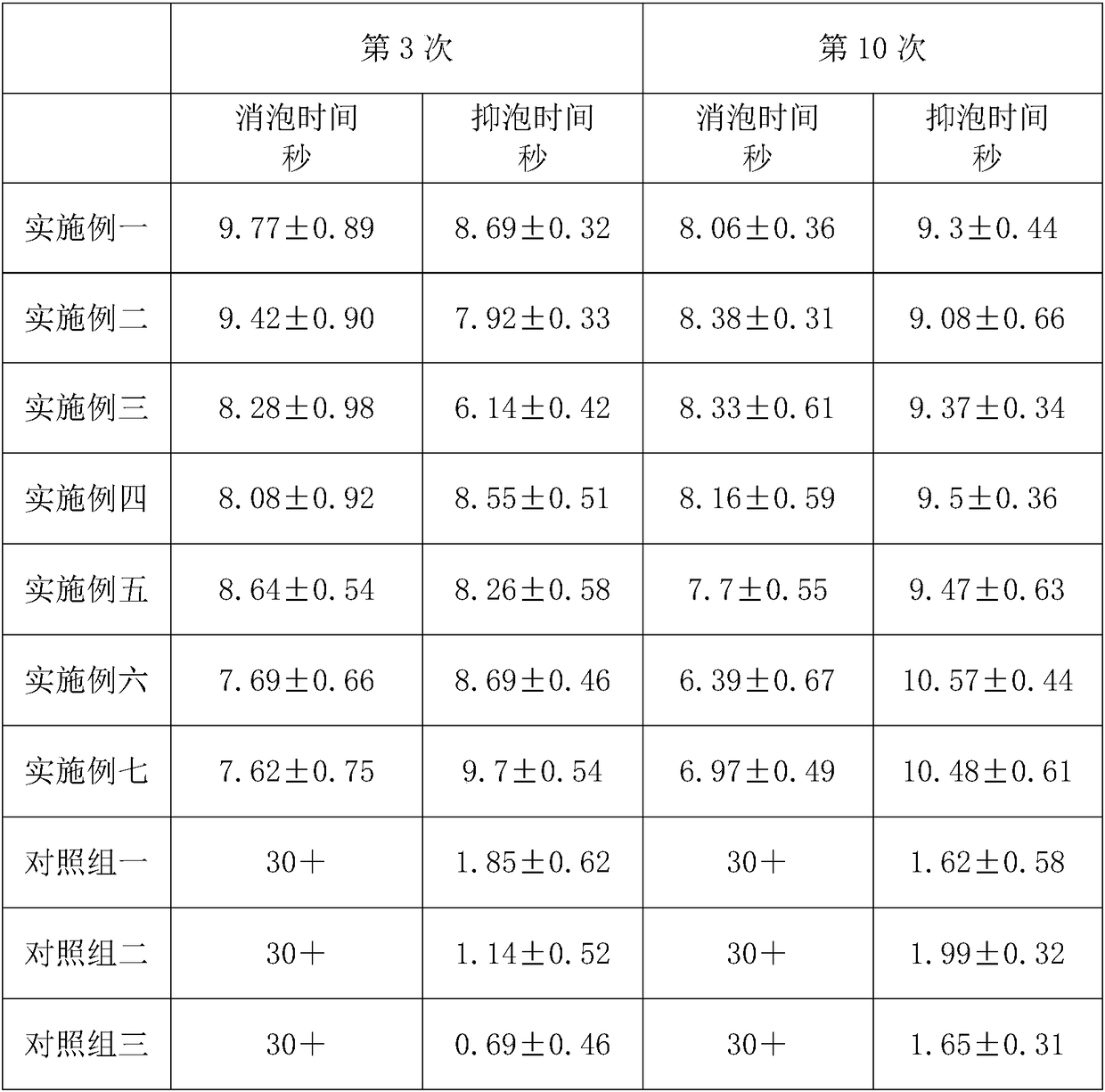

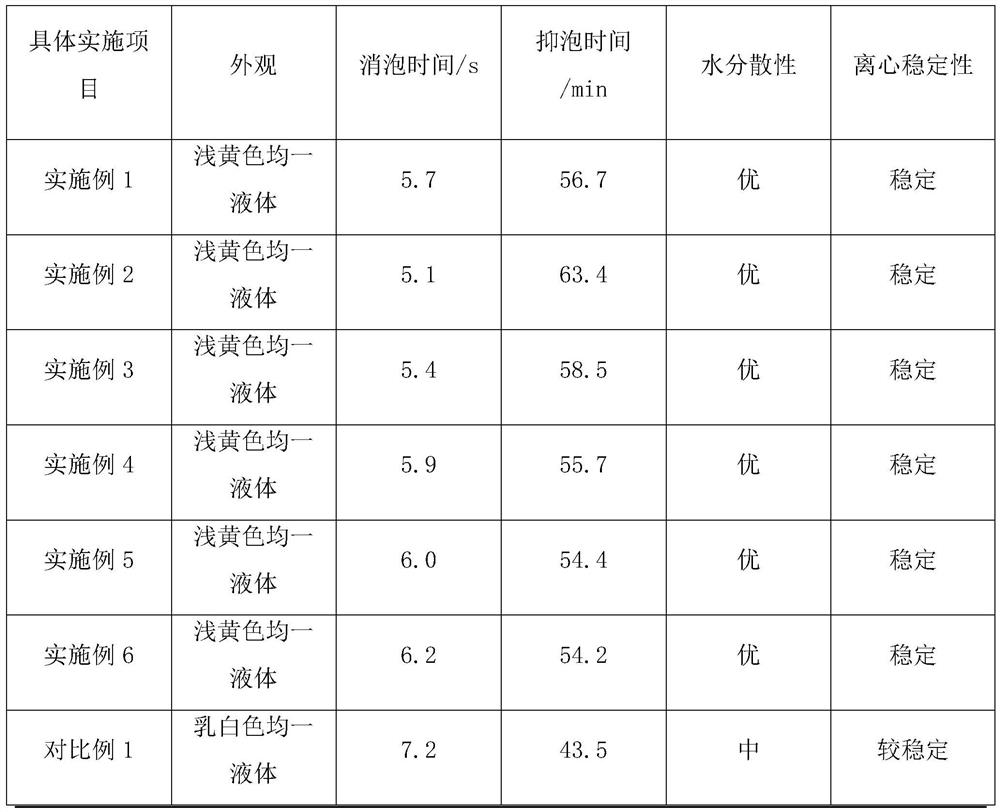

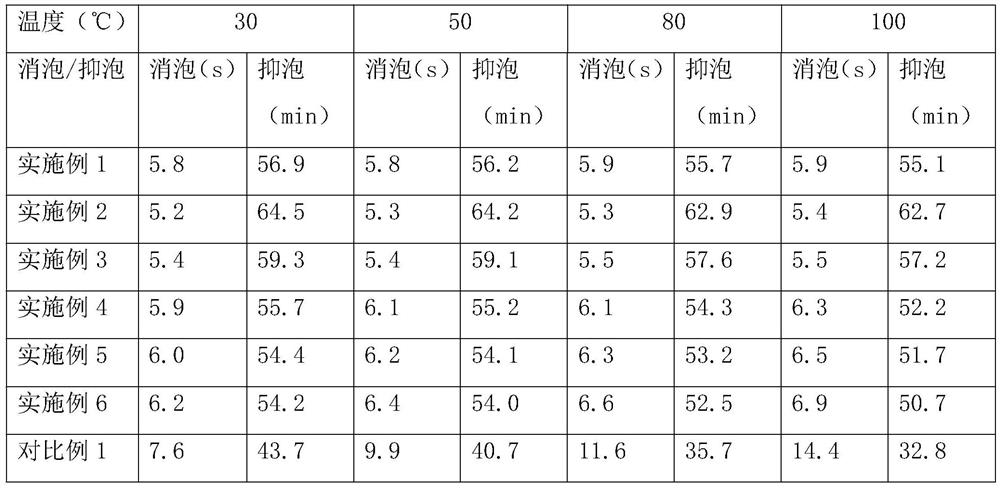

Production method of special defoaming agent for water-based concentrated pigment color paste

PendingCN112999703AImprove adsorption capacityImprove defoaming abilityFoam dispersion/preventionProcess engineeringColloid mill

The invention relates to a production method of a special defoaming agent for water-based concentrated pigment color paste. The defoaming agent comprises a defoaming active substance A, a defoaming active substance B, a defoaming synergistic substance, an emulsifier, an emulsion stabilizer and water. The production method of the defoaming agent comprises the following steps: adding the defoaming active substance A, the defoaming active substance B, the defoaming synergistic substance and the emulsifier into an emulsifying kettle, and stirring at 20-80 DEG C for 2-4 hours; gradually adding water into the mixture obtained in the previous step, and completing transfer emulsification; then adding the emulsion stabilizer; and finally, feeding the emulsion obtained in the previous step into a colloid mill, grinding for two to three times, cooling and discharging. According to the preparation method, an original staged temperature changing and water adding emulsification process is adopted, and a cloud point transfer process is ingeniously applied; the particle size curve of the prepared emulsion is in 'bimodal' distribution, the unique particle size distribution mode ensures the rapid diffusion performance, excellent defoaming property and durability of the defoaming agent, and the shrinkage resistance is also improved to a certain extent.

Owner:江西三越新材料有限公司

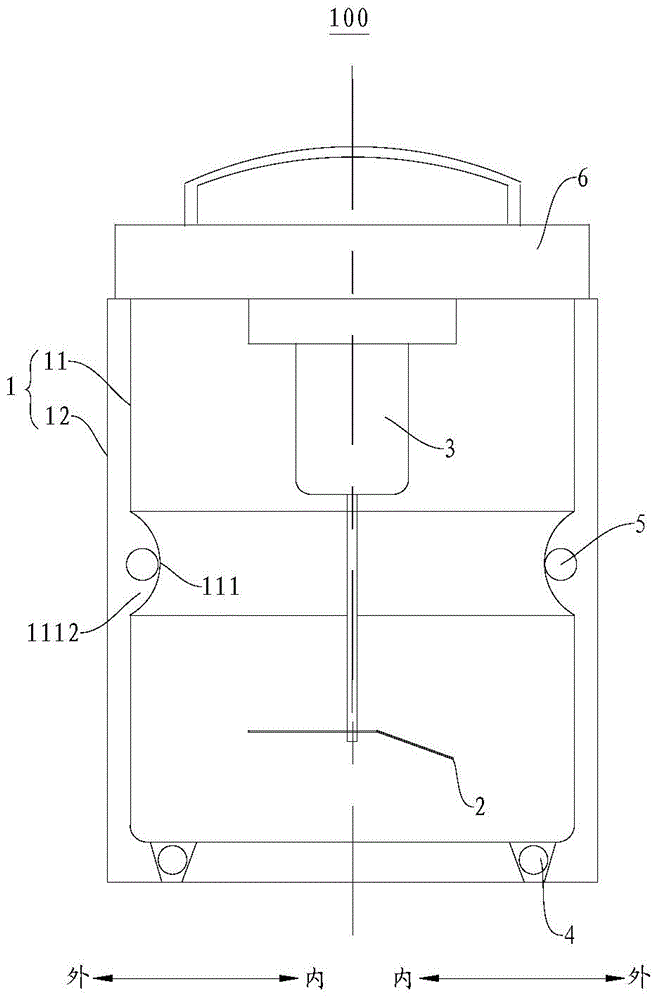

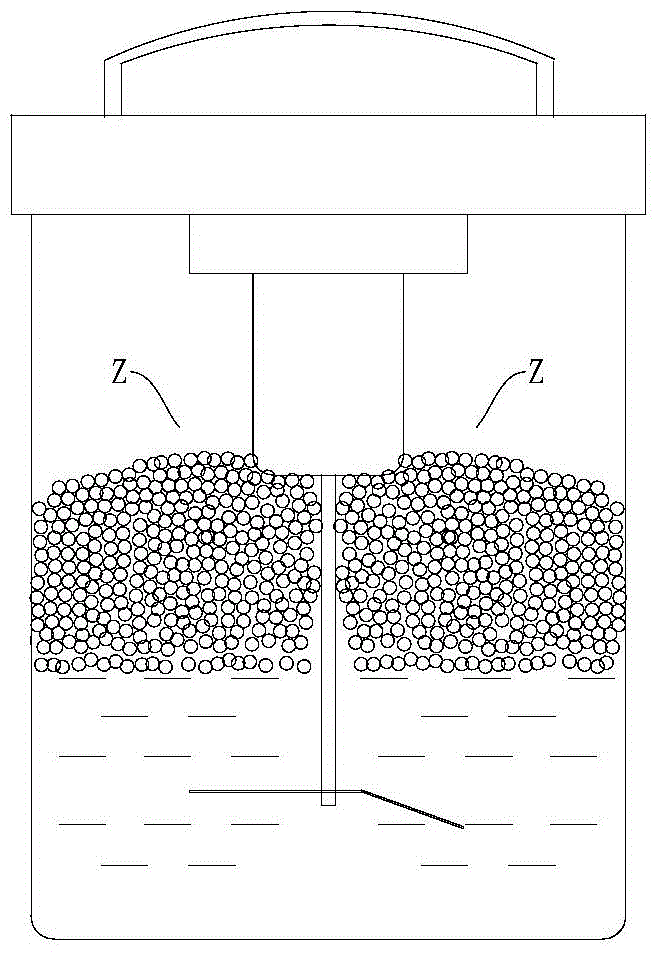

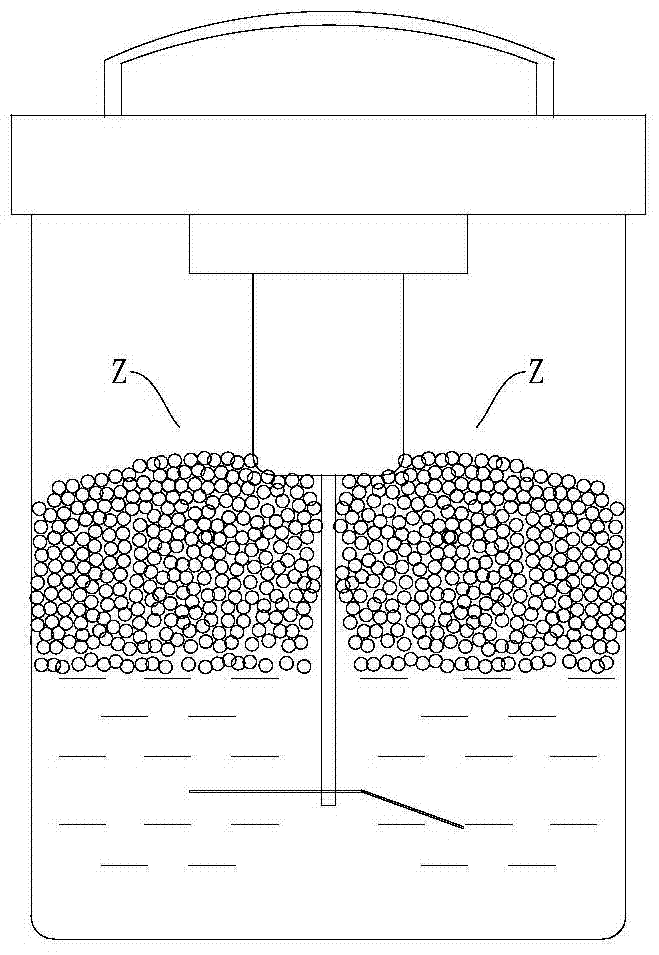

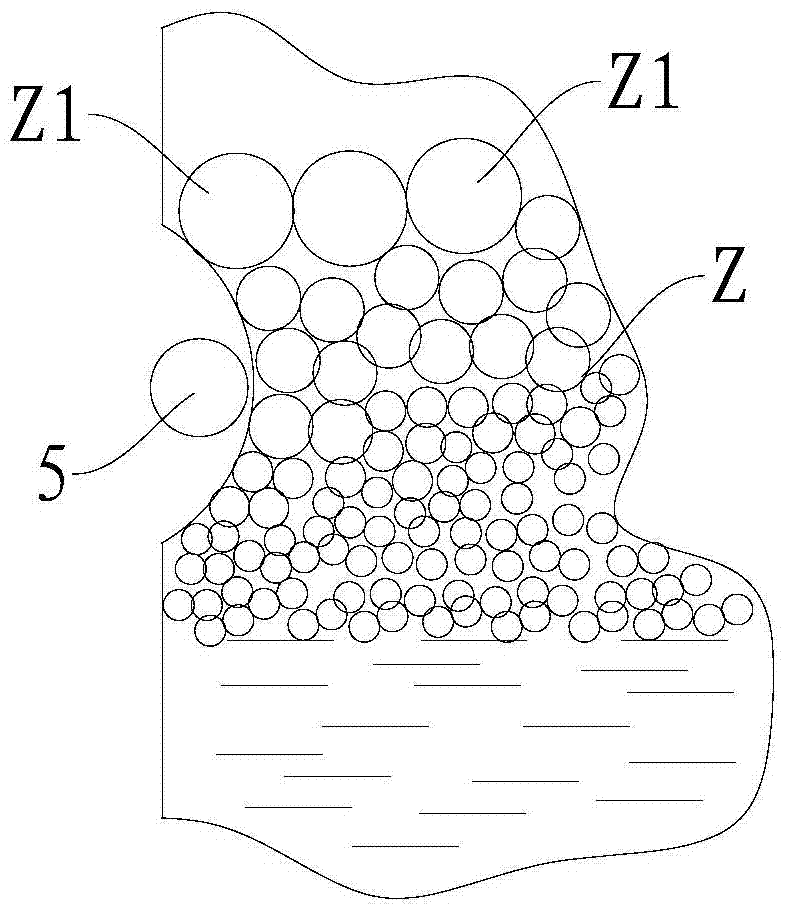

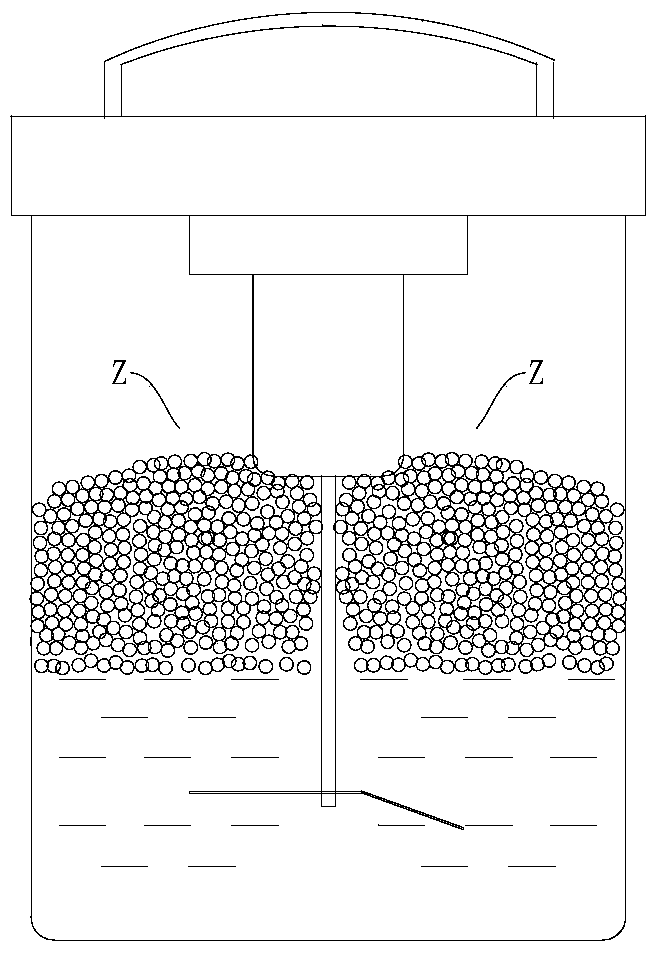

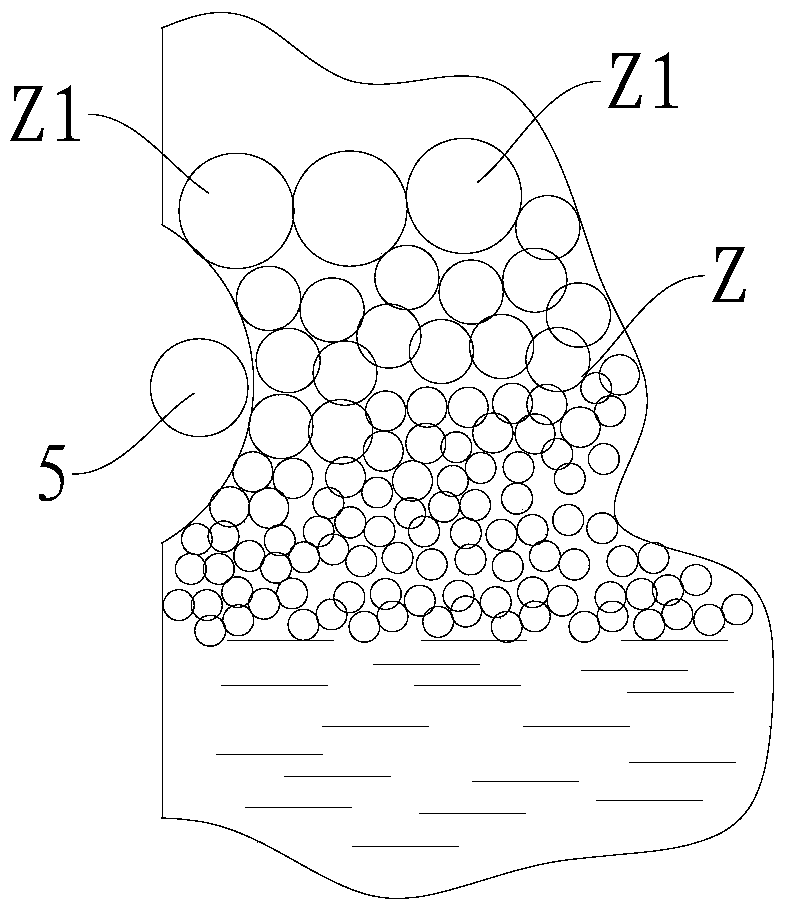

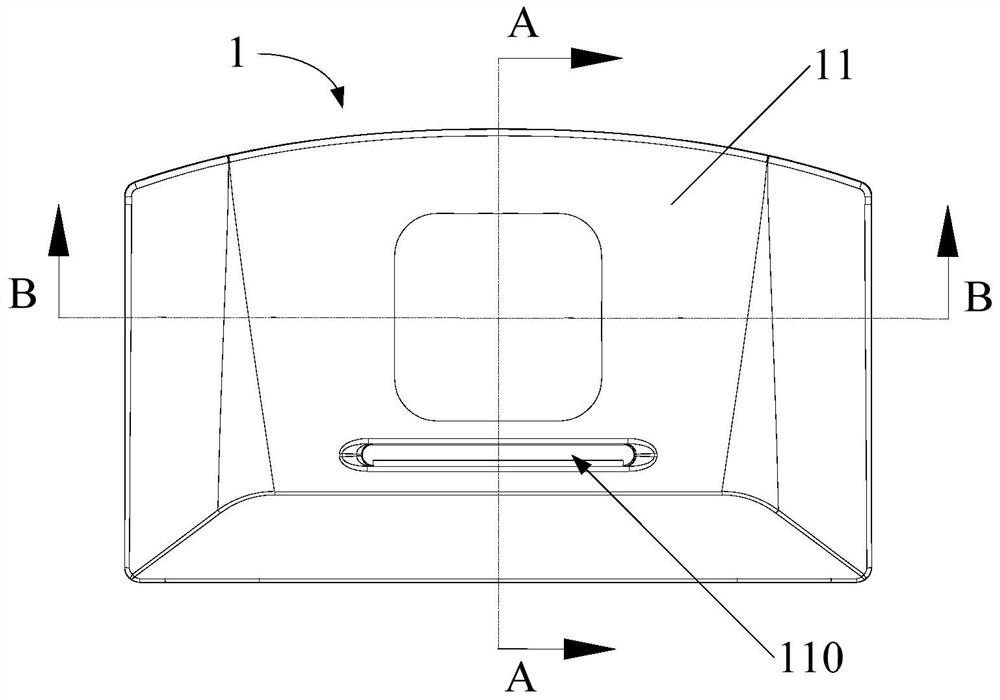

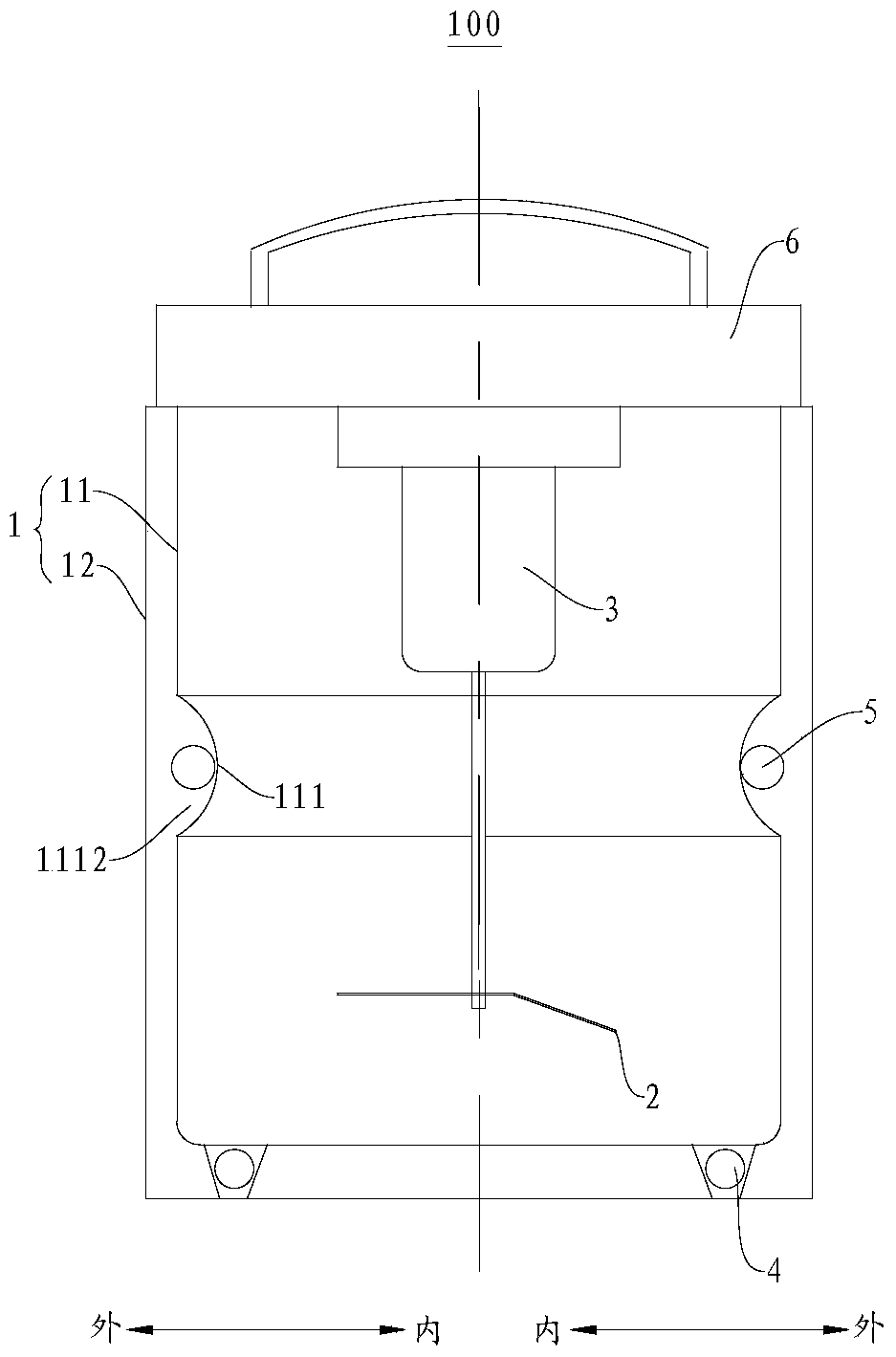

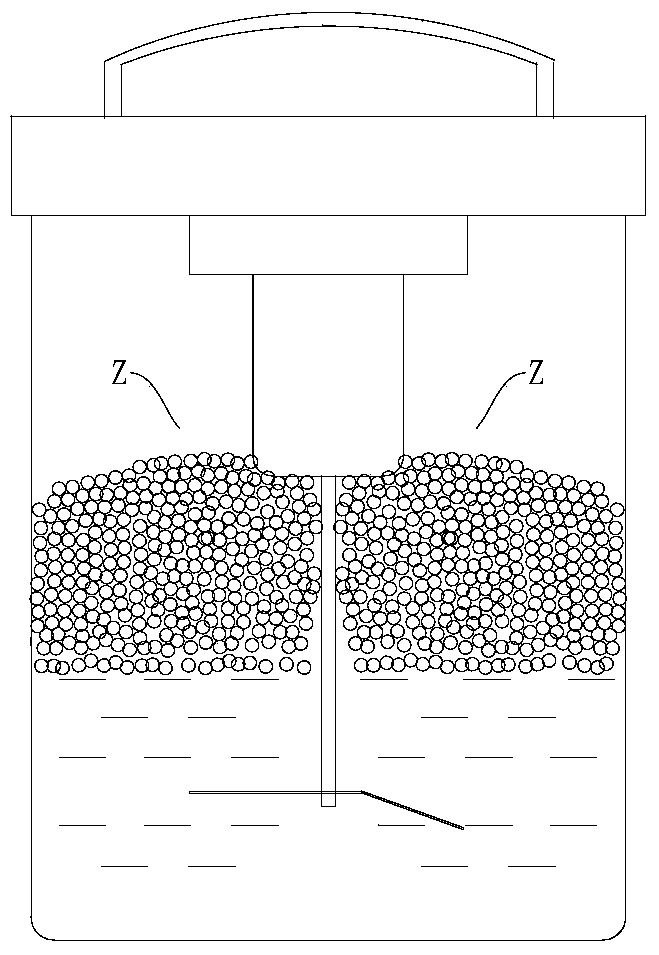

Soybean milk making machine

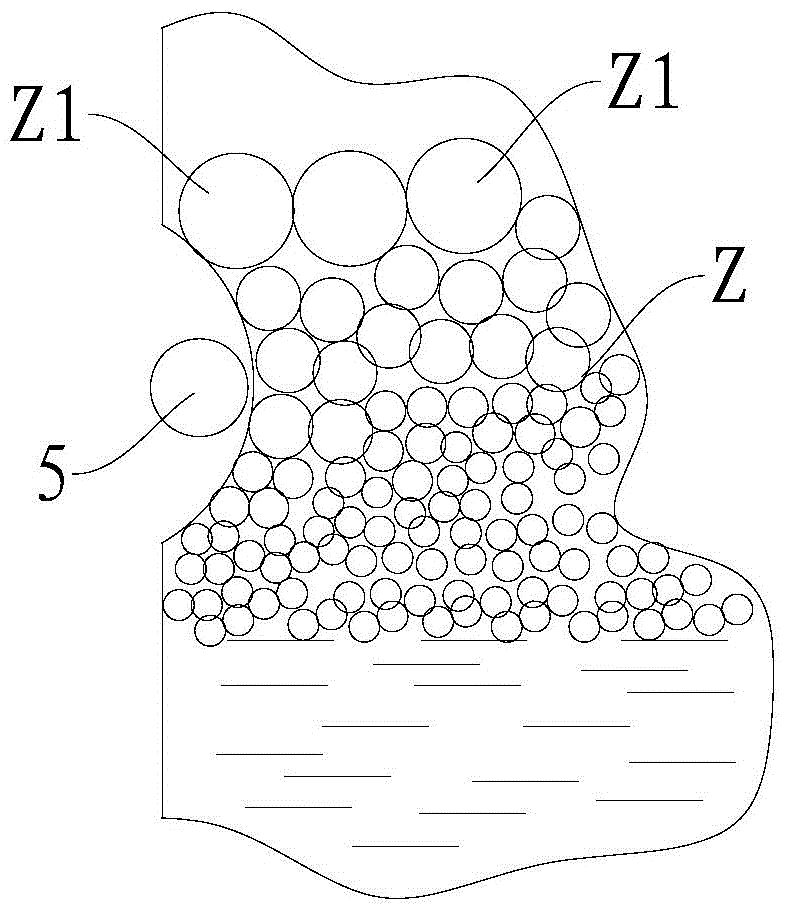

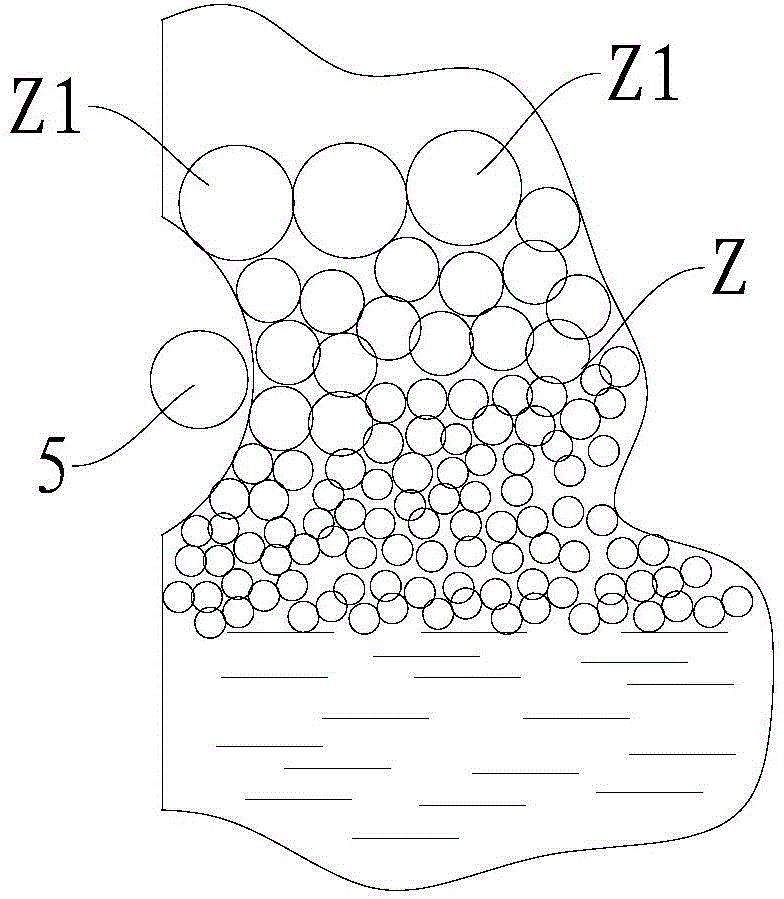

ActiveCN105193256AImprove foam breaking efficiencyImprove foam breaking abilityBeverage vesselsBoiling processEngineering

The invention discloses a soybean milk making machine which comprises a barrel, a crushing device, a crushing motor, a boiling heating component and a foam breaking heating component. Annular foam breaking ribs protruding out of the inner wall face of the side wall of the barrel are constructed on the side wall of the barrel. The crushing device is arranged inside the barrel. The crushing motor is connected with the crushing device. The boiling heating component is at least used for heating and boiling raw soybean milk. The foam breaking heating component is not lower than the highest liquid level inside the barrel in the heating and boiling process so as to heat and break foams generated in the heating and boiling process. The foam breaking ribs are not lower than the highest liquid level. Due to the fact that the independent foam breaking heating component is arranged on the soybean milk making machine, and foams are broken in a heating mode through the foam breaking heating component, the foam breaking efficiency is improved, and the foam breaking effect is better due to the facts that the foam breaking ribs are arranged and can effectively stop and extrude the foams and the foam breaking heating component is arranged in a matched mode.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

Soybean milk making machine

The invention discloses a soybean milk making machine which comprises a barrel, a crushing device, a crushing motor, a boiling heating component, a foam breaking heating component and an anti-overflowing structure. Annular foam breaking ribs protruding out of the inner wall face of the side wall of the barrel are constructed on the side wall of the barrel. The crushing device is arranged inside the barrel. The crushing motor is connected with the crushing device. The boiling heating component is at least used for heating and boiling raw soybean milk. The foam breaking heating component is not lower than the highest liquid level inside the barrel in the heating and boiling process. The foam breaking ribs are not lower than the highest liquid level. The anti-overflowing structure is arranged inside the barrel and is not lower than the highest liquid level. Due to the fact that the independent foam breaking heating component is arranged on the soybean milk making machine, and foams are broken in a heating mode through the foam breaking heating component, the foam breaking efficiency is improved, and the foam breaking effect is better due to the facts that the foam breaking ribs and the anti-overflowing structure are arranged and the foam breaking heating component is arranged in a matched mode.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

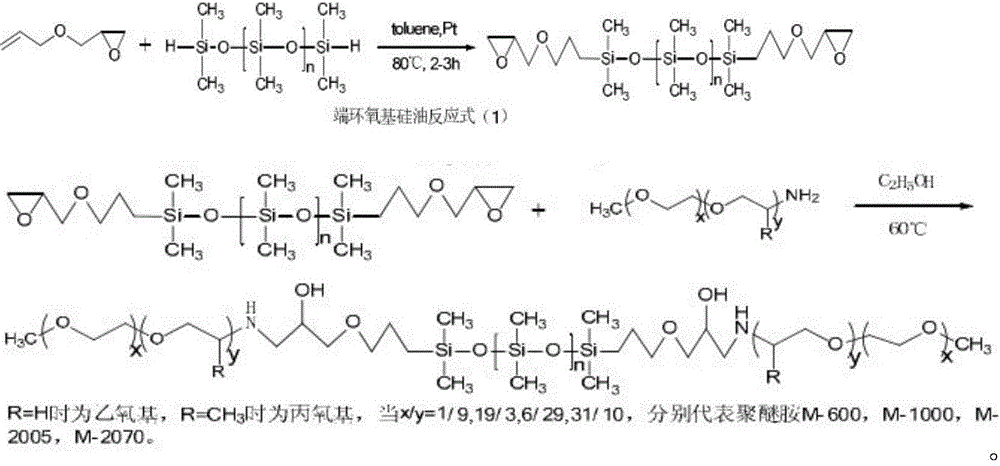

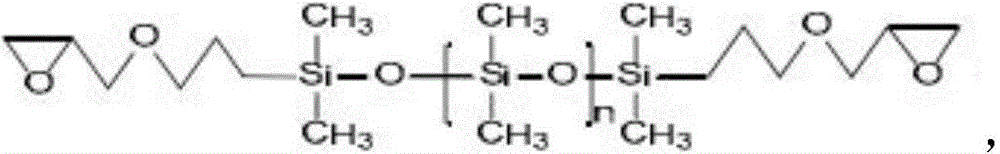

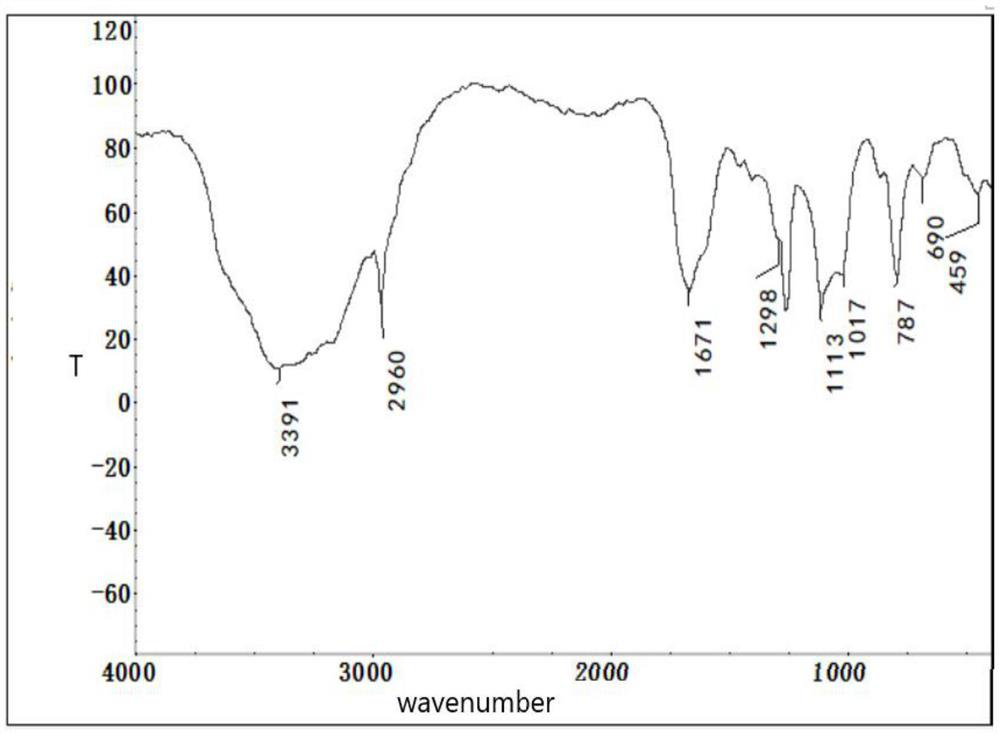

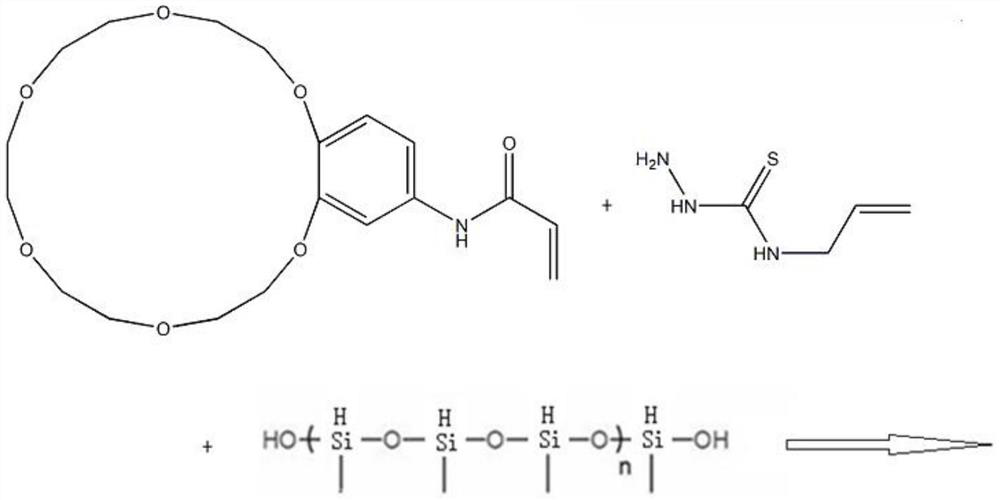

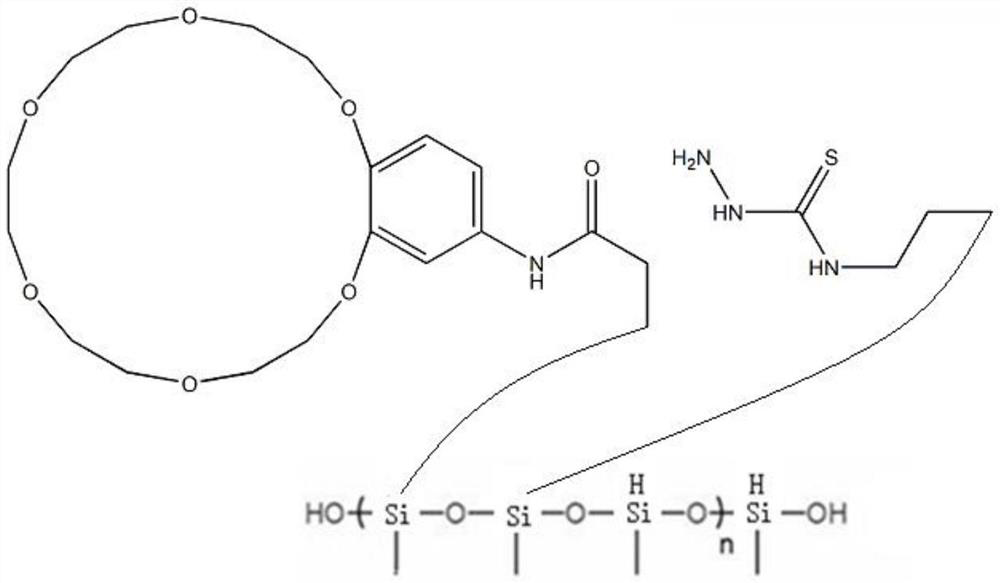

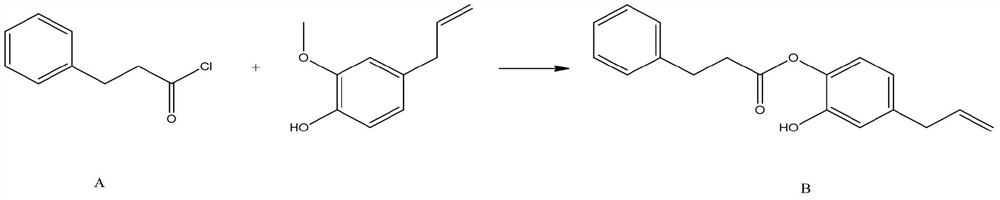

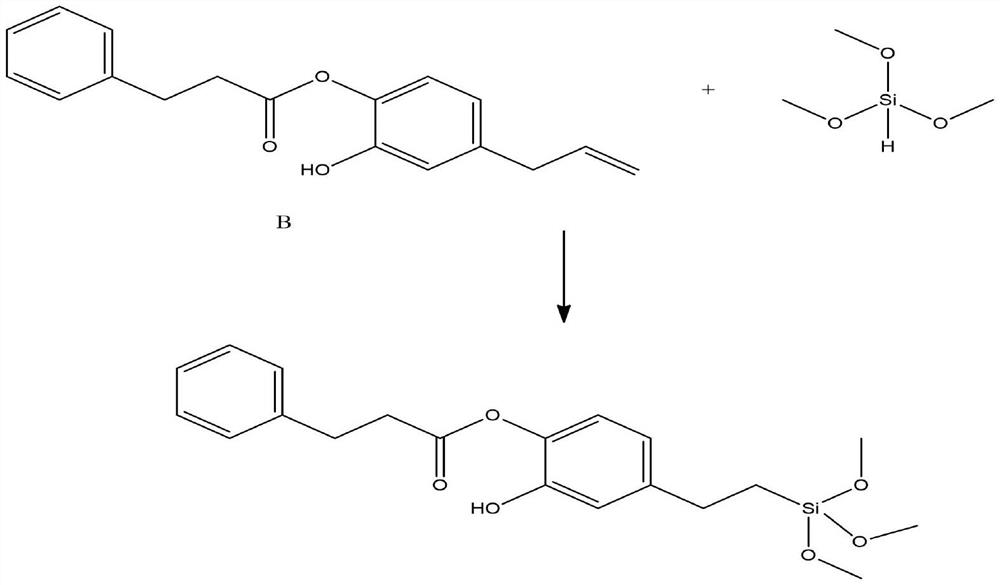

Preparation method of modified silane papermaking wastewater defoaming agent

InactiveCN112263852AReduce consumptionImprove hydrophilicityFoam dispersion/preventionPtru catalystBlack liquor

The invention relates to the field of chemical engineering, in particular to a preparation method of a modified silane papermaking wastewater defoaming agent. The preparation method comprises the following steps of firstly, synthesizing trifluoropropyl-containing fluoroalkyl modified siloxane, and then reacting with semicarbazide modified organic silicon and white carbon black under the action ofa catalyst to carry out hydrophobic modification on the surface of the white carbon black. The obtained defoaming agent has good defoaming and foam inhibition effects on black liquor generated in thepapermaking and pulping process with high temperature and high alkali content at the same time; by using the defoaming agent, the pulp washing effect can be improved, the water consumption is reduced,the energy is saved, the environment is protected, and the defoaming agent can be applied to each link of pulp production.

Owner:瑞普环保新材料(广州)有限公司

Soymilk machine

ActiveCN105193256BImprove foam breaking efficiencyImprove foam breaking abilityBeverage vesselsMaximum levelEngineering

The invention discloses a soymilk machine, which comprises: a barrel body, the side wall of the barrel body is constructed with foam-breaking ribs protruding from the inner wall surface of the side wall of the barrel body, the foam-breaking ribs are ring-shaped; a pulverizer, the pulverizer is equipped with In the barrel; the pulverizing motor, the pulverizing motor is connected with the pulverizer; at least the cooking heating part used for heating and boiling the raw pulp; the foam breaking heating part, the setting height of the foam breaking heating part is not lower than that during the heating and boiling process The highest liquid level in the barrel is used to heat and break the foam generated during the heating and boiling process, and the height of the broken ribs is not lower than the highest liquid level. The soya-bean milk machine of the present invention is owing to the cause of being provided with independent foam breaking heating part, realizes foam breaking by means of heating through the foam breaking heating part, thereby has improved foam breaking efficiency, simultaneously by setting foam breaking rib, the foam breaking rib can carry out foam Effective stop and extrusion function, combined with the foam breaking heating component, makes the foam breaking effect better.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

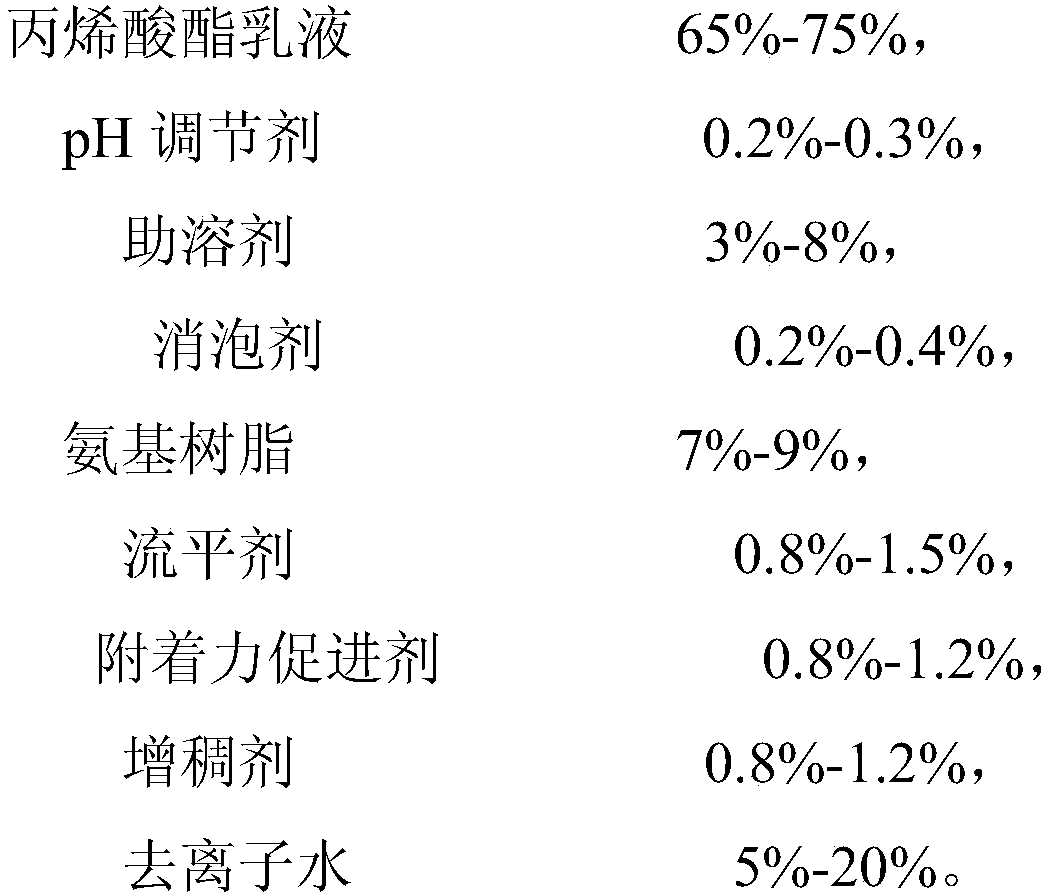

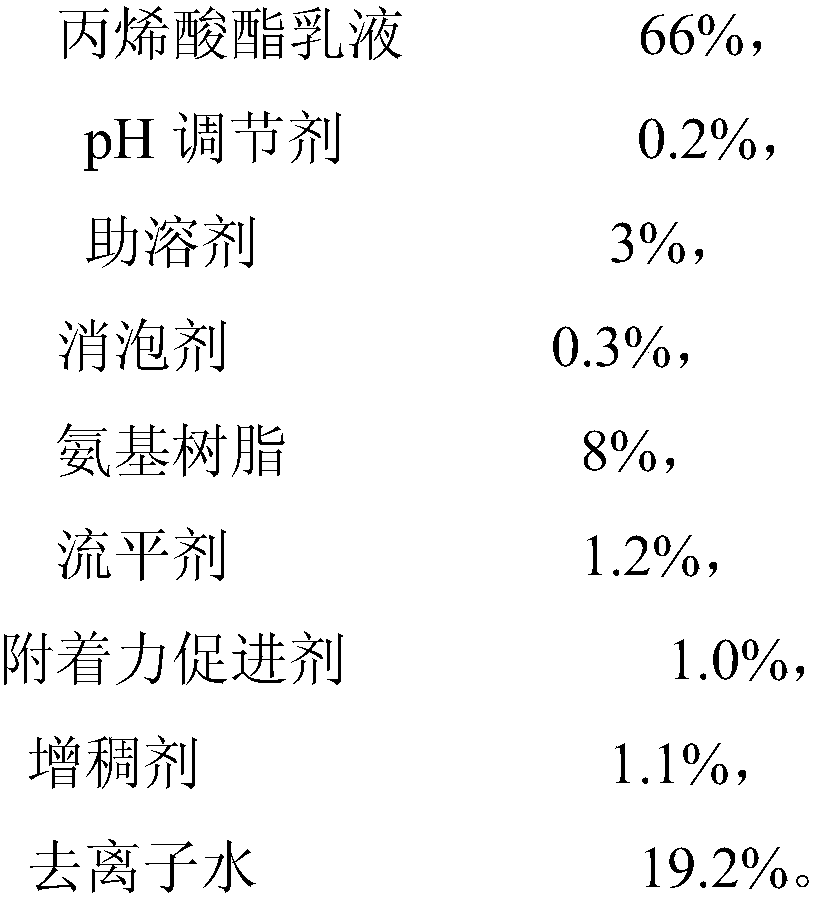

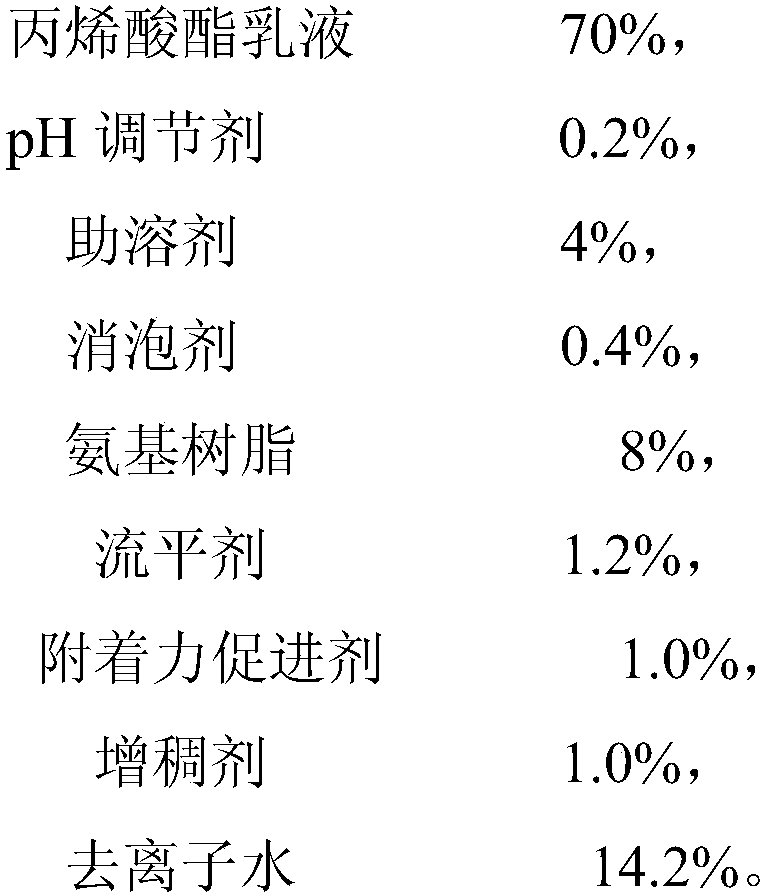

Waterborne emulsion type glazing golden varnish special for bicycles and preparation method thereof

The invention discloses a waterborne emulsion type glazing golden varnish special for bicycles and a preparation method thereof. The invention relates to the waterborne emulsion type glazing golden varnish special for the bicycles. The waterborne emulsion type glazing golden varnish special for the bicycles comprises the following components by the mass percentage: 65%-75% of an acrylate emulsion,0.2%-0.3% of a pH regulator, 3%-8% of a cosolvent, 0.2%-0.4% of a defoamer, 7%-9% of amino resin, 0.8%-1.5% of a leveling agent, 0.8%-1.2% of an adhesive force promoter, 0.8%-1.2% of a thickener, and5%-20% of deionized water. The waterborne emulsion type glazing golden varnish special for the bicycles has the advantages of low VOC, high weather resistance, abrasion resistance, high gloss, good decorative effect, and easy construction, and can be applied to bicycles, electric bicycles and the like.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

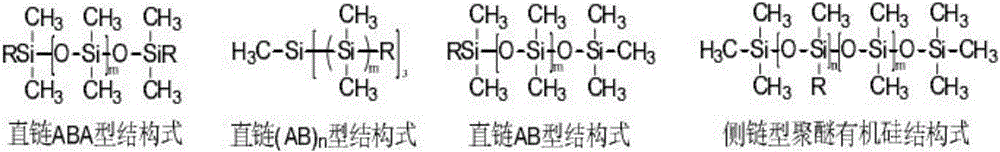

Method for preparing emulsion type defoaming agent by utilizing polyether modified silicone oil

InactiveCN111437632ALess impuritiesGood flexibilityFoam dispersion/preventionSodium acid carbonateEmulsion

The invention discloses a method for preparing an emulsion type defoaming agent from polyether modified silicone oil. The method is as follows: adding the polyether modified silicone oil, silicon dioxide, sodium carbonate, white carbon black and malonic acid into a reaction kettle, uniformly stirring the components, heating to 110-140 DEG C, stirring at a speed of 20-120 rpm for reacting for 3-5 hours, cooling to room temperature, adding a fatty acid amide anionic surfactant, uniformly stirring, and standing for at least 1 hour to obtain a mixture; heating the mixture to 60-80 DEG C, adding anOP-10 emulsifier and an SP-80 emulsifier, uniformly stirring, reacting for 20-30 minutes, adding deionized water, continuously stirring for 10-15 minutes, stopping stirring, cooling to room temperature, and standing for 1 hour to obtain the product.

Owner:五色石新材料(杭州)有限公司

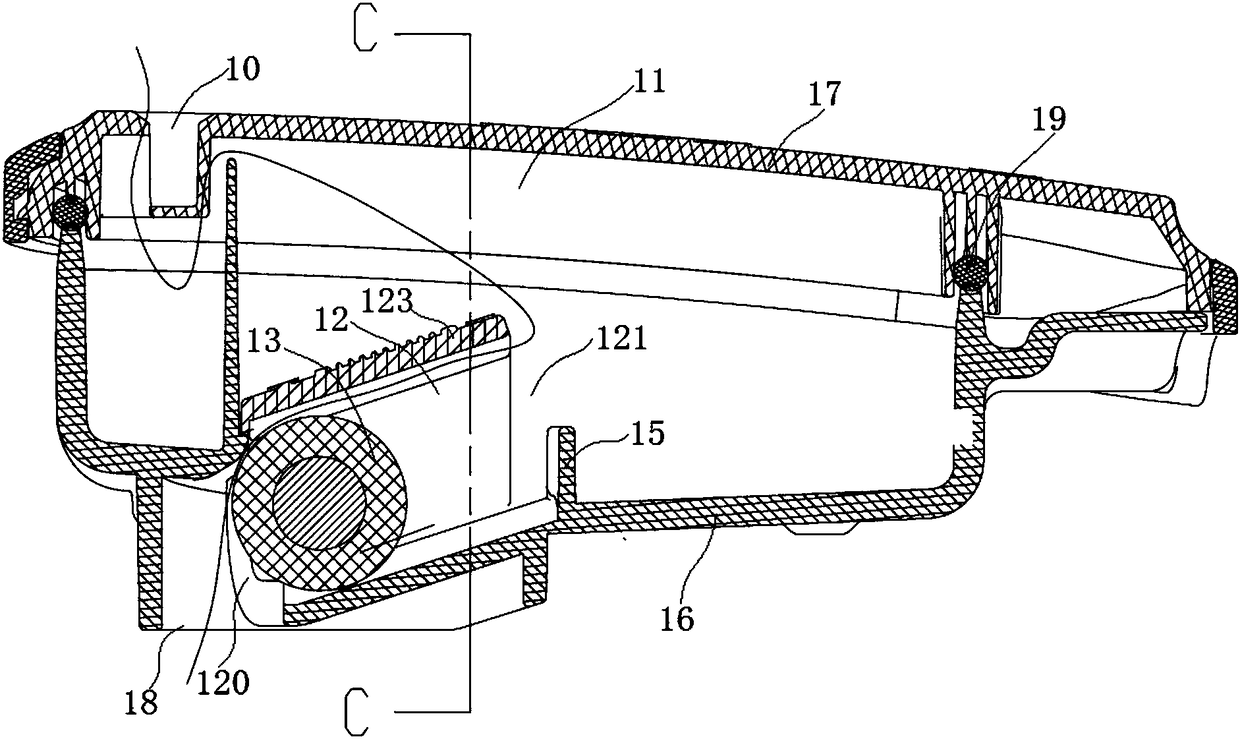

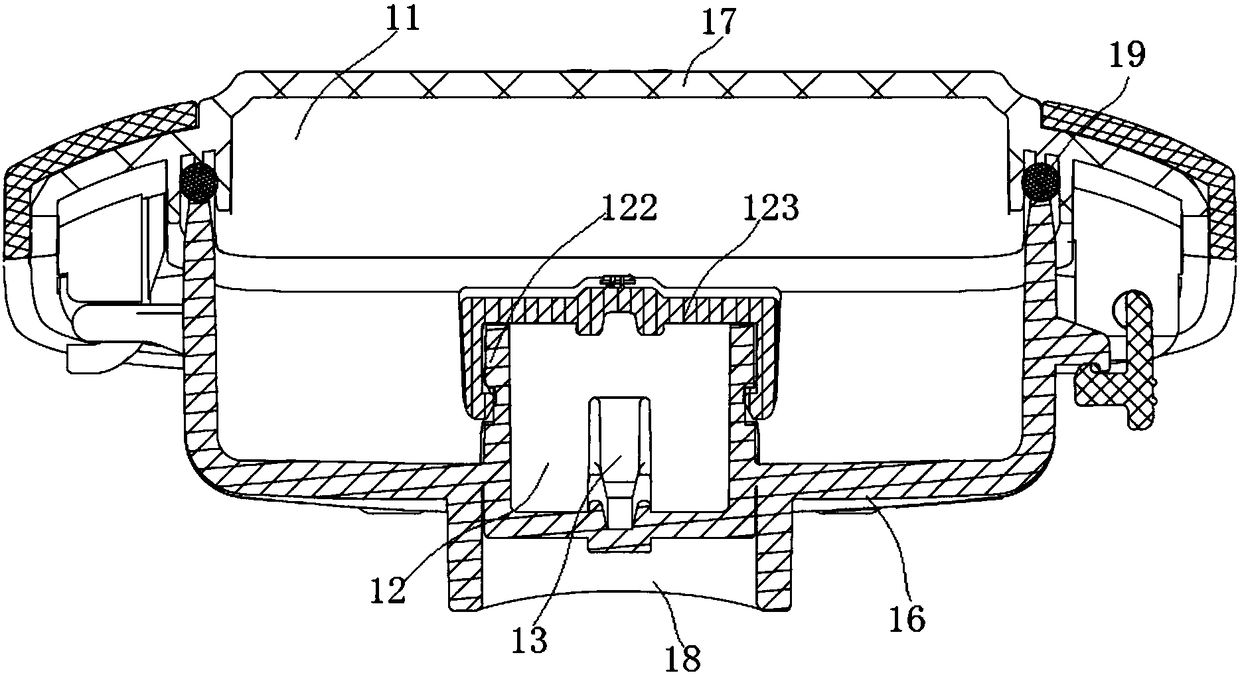

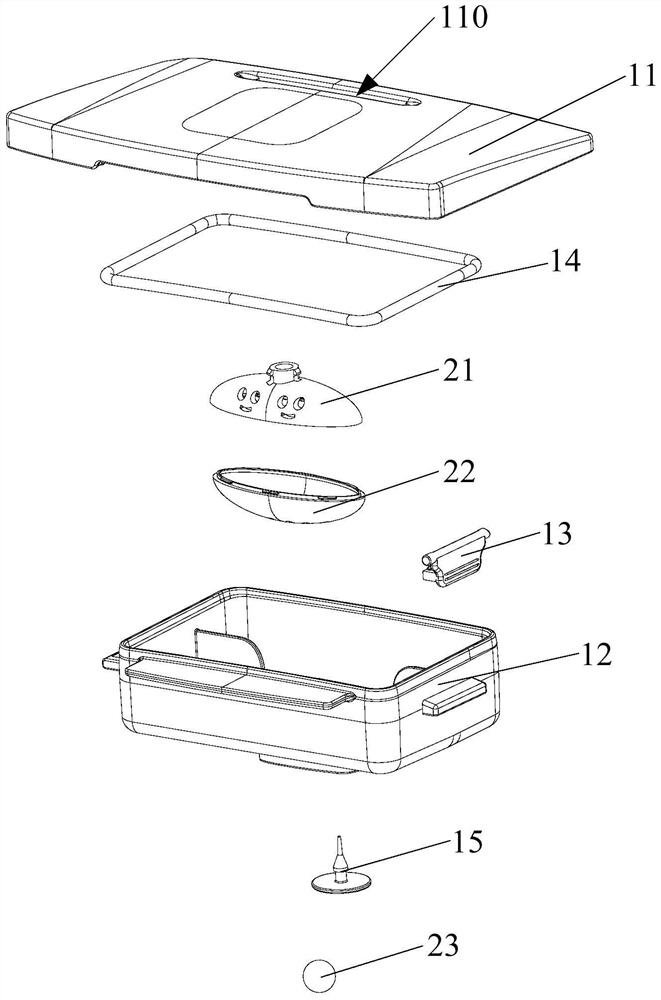

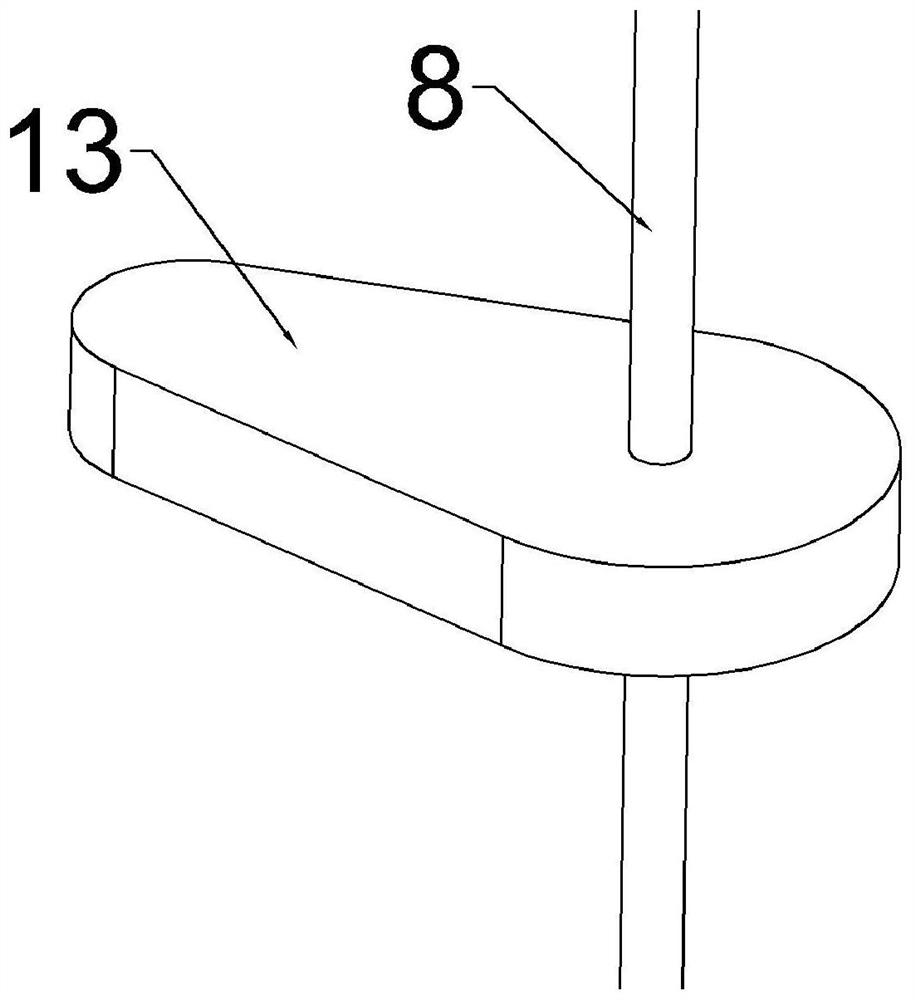

Steam valve and electric cooker

PendingCN108236384AIncrease the frequency of movementRelieve pressureBoiling over preventionReciprocating motionEngineering

The invention relates to the field of household appliances and discloses a steam valve and an electric cooker. The steam valve comprises a foam breaking structure, the foam breaking structure comprises a foam breaking chamber (12) and a foam breaking member (13), the foam breaking chamber (12) has a steam inlet (120) and a steam outlet (121), and the foam breaking member is arranged in the foam breaking chamber and can reciprocate between the steam inlet and the steam outlet, so that the foam breaking chamber is in an expanding shape from the steam inlet to the steam outlet. The expanding foambreaking chamber enlarges the steam discharge area, so that liquid such as rice soup can flow back easily. By applying the steam valve to the electric cooker, the cleanness and the safety performanceof the electric cooker are improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Steam valve and electric cooker comprising the steam valve

ActiveCN102599823BGood foam breaking effectIncrease cooking tasteCooking vesselsMultiple way valvesEngineeringPressure difference

The invention provides a steam valve and an electric cooker comprising the steam valve. According to the invention, the steam valve comprises a valve body (10), a valve cap (30) and a valve seat (20), wherein the valve body (10) is provided with an air outlet (101) opening upwards; the valve cap (30) is arranged at the upper end of the valve body (10) and provided with an opening corresponding to the air outlet (101); the valve seat (20) is arranged at the lower end of the valve body (10); the bottom of the valve seat (20) is provided with an air inlet (201); and the air inlet (201) is provided with a returnable air retainer. According to the invention, the steam valve can effectively break foams, has good anti-spilling effect and can allow pressure difference to be generated inside the electric cooker so as to increase the cooking mouthfeel of rice. According to the invention, the electric cooker comprises the steam valve.

Owner:GREE ELECTRIC APPLIANCES INC

Defoaming agent for papermaking

PendingCN113577839AReduce surface tensionIncreased diffusion rateFoam dispersion/preventionPtru catalystPapermaking

The invention discloses a defoaming agent for papermaking, which comprises an active component, an emulsifier, an auxiliary agent, a solvent and water in a mass ratio of (25-35):(5-15):(15-25):(3-13):(27-37), and the active component is one or a combination of more of ethylene glycol monostearate, modified organic silicon and ethylene bisstearamide; and the modified organic silicon is prepared from an amino-terminated organic silicon intermediate, an organic silicon monomer and a silane coupling agent under the catalytic action of a basic catalyst. According to the defoaming agent, modified organic silicon serving as an active component of the defoaming agent is low in surface tension and excellent in wetting and spreading performance, meanwhile, due to introduction of amino groups, the molecular hydrophilicity is improved, the dispersity in water can be improved, the defoaming agent is used for defoaming a water-based system, the emulsification of the defoaming agent is promoted, in addition, the amino groups can be ionized to carry positive charges, and a good bubble breaking effect is achieved on a bubble film with negative electricity.

Owner:海宁美浪有机硅科技有限公司

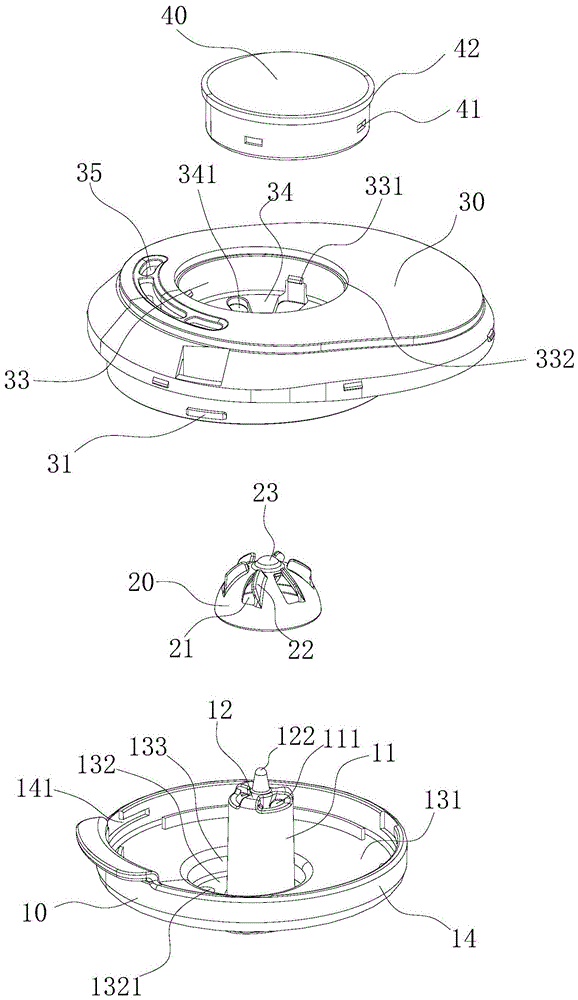

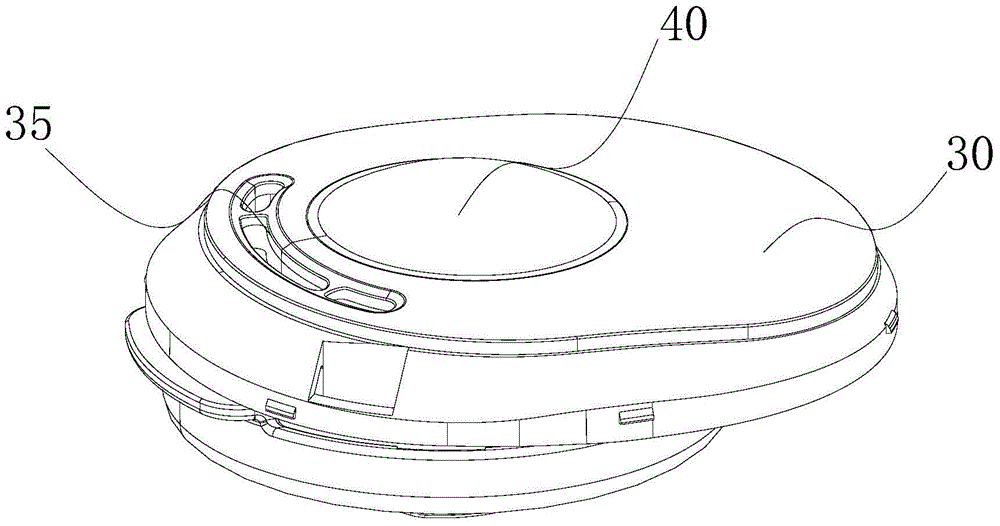

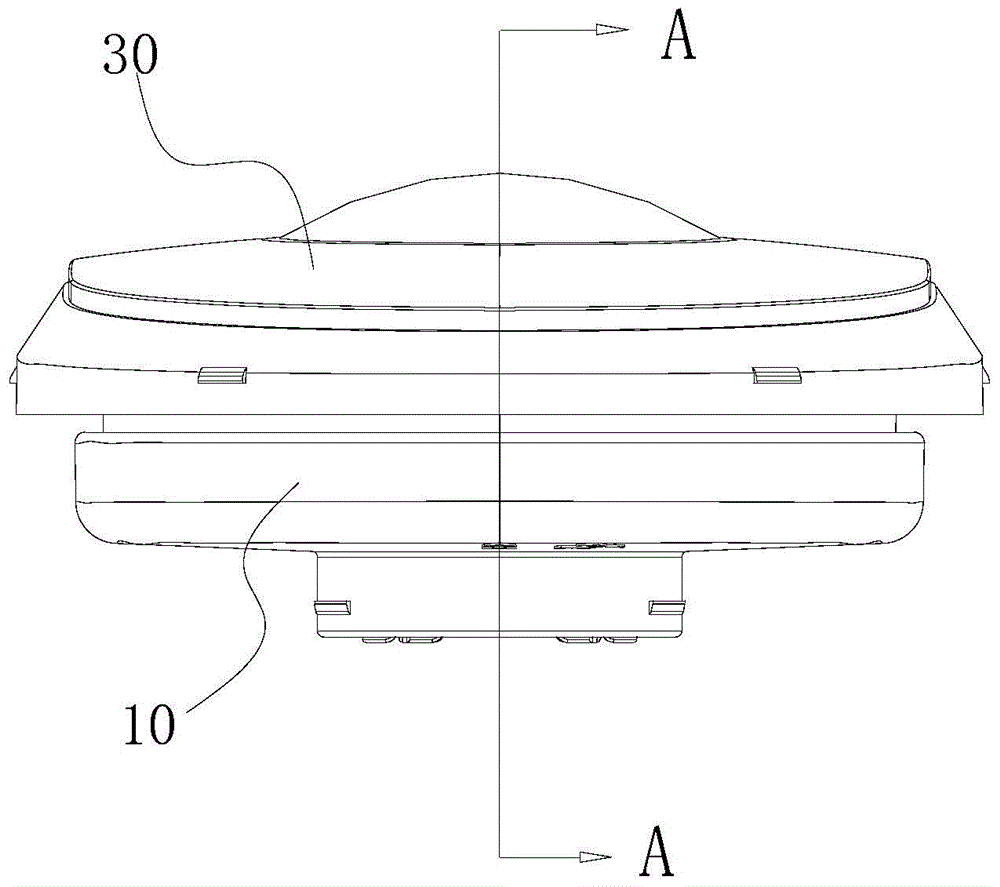

rice cooker

ActiveCN104510341BSimple structureGood foam breaking effectValve arrangementsBoiling over preventionEngineeringSteam drum

The invention discloses an electric cooker. The electric cooker comprises an electric cooker body and an electric cooker cover; a steam valve assembly is arranged on the electric cooker cover; the steam valve assembly comprises a steam valve seat, a rotating foam breaking cover and a steam valve cover; a steam drum communicated with the lower surface of the steam valve seat is arranged on the steam valve seat and a steam hole is formed in the upper part of the steam drum; the rotating foam breaking cover is rotatably mounted on the upper part of the steam drum; at least one airflow hole is formed in the rotating foam breaking cover; airflow ejected out of the steam hole goes through the airflow hole and drives the rotating foam breaking cover to rotate. The steam valve assembly of the electric cooker comprises few parts, and is simple in structure, convenient to assemble, high in rate of finished products and good in foam breaking effect.

Owner:MIDEA GRP CO LTD +1

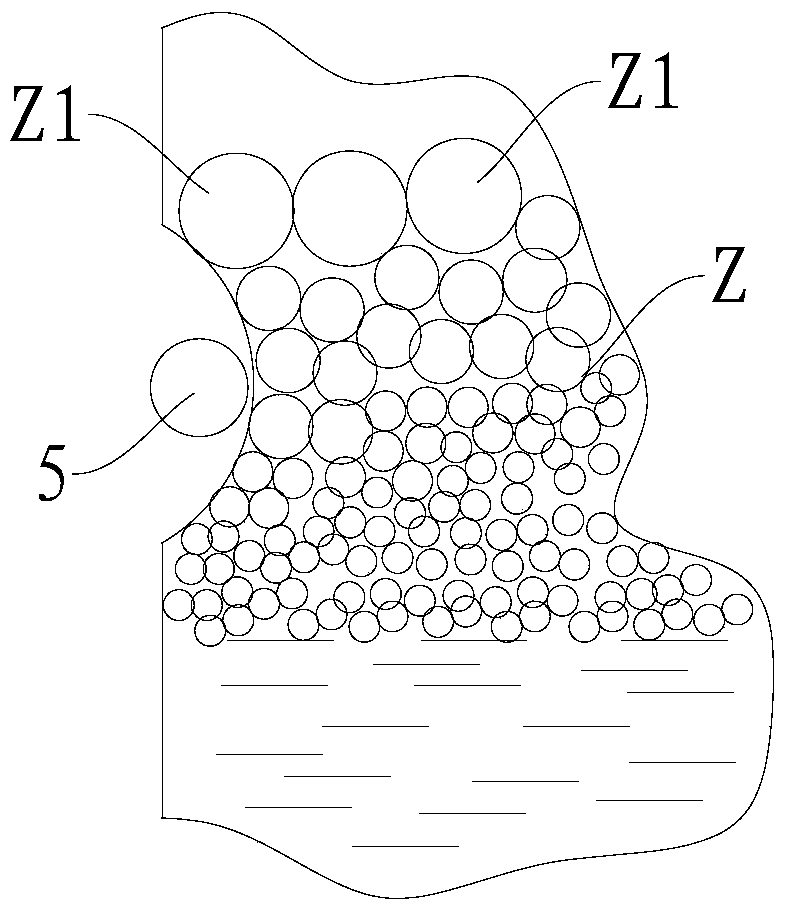

Soymilk machine

ActiveCN105310507BImprove foam breaking efficiencyImprove foam breaking abilityBeverage vesselsMilk substitutesMaximum levelSlurry

The invention discloses a soybean milk machine, which comprises: a barrel body, the side wall of the barrel body is configured with annular bubble-breaking tendons protruding from the inner wall surface of the side wall of the barrel body, and the inner wall surface of the side wall of the barrel body is also provided with a spoiler flow ribs; pulverizer, the pulverizer is set in the barrel; pulverizer, the pulverizer motor is connected to the pulverizer; at least the cooking heating part used to heat and boil the raw pulp; the foam breaking heating part, the setting of the foam breaking heating part The height is not lower than the highest liquid level in the barrel during the heating and boiling process to heat and break the foam generated during the heating and boiling process, and the height of the foam breaking ribs is not lower than the highest liquid level. The soya-bean milk machine of the present invention is owing to the cause of being provided with independent foam breaking heating part, realizes foam breaking by means of heating through the foam breaking heating part, thereby has improved foam breaking efficiency, simultaneously by setting foam breaking rib, the foam breaking rib can carry out foam Effective stop and extrusion function, combined with the foam breaking heating component, makes the foam breaking effect better.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

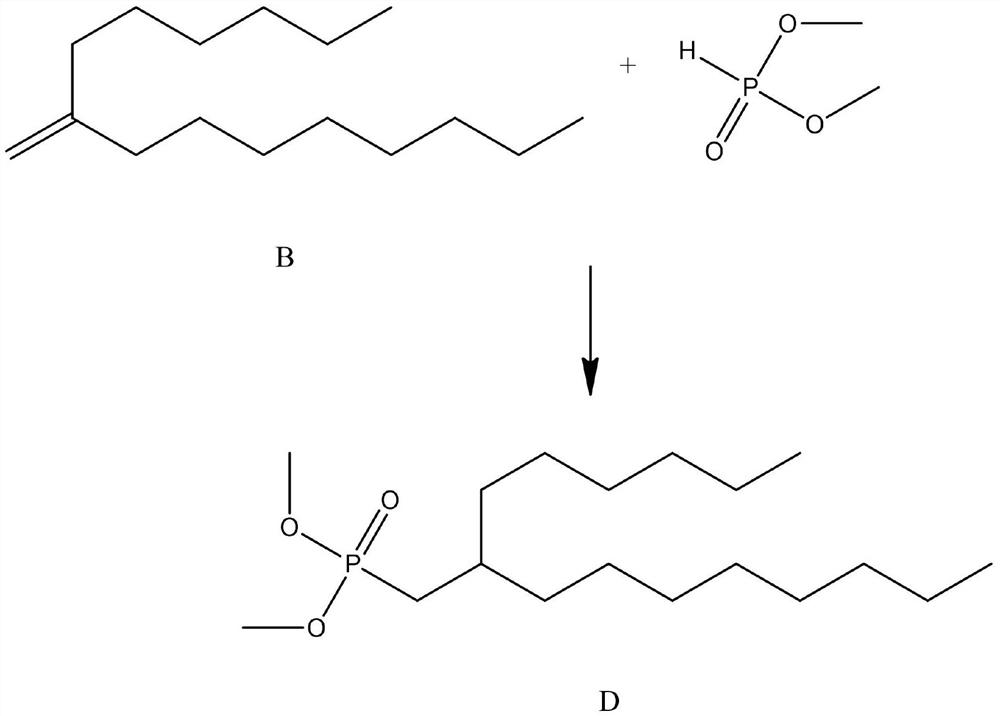

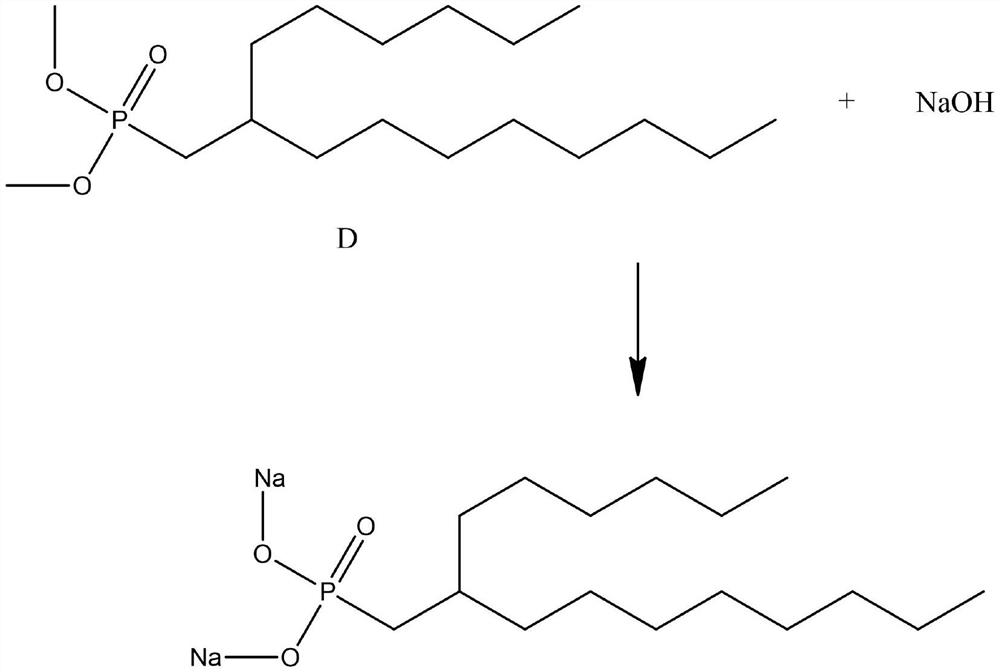

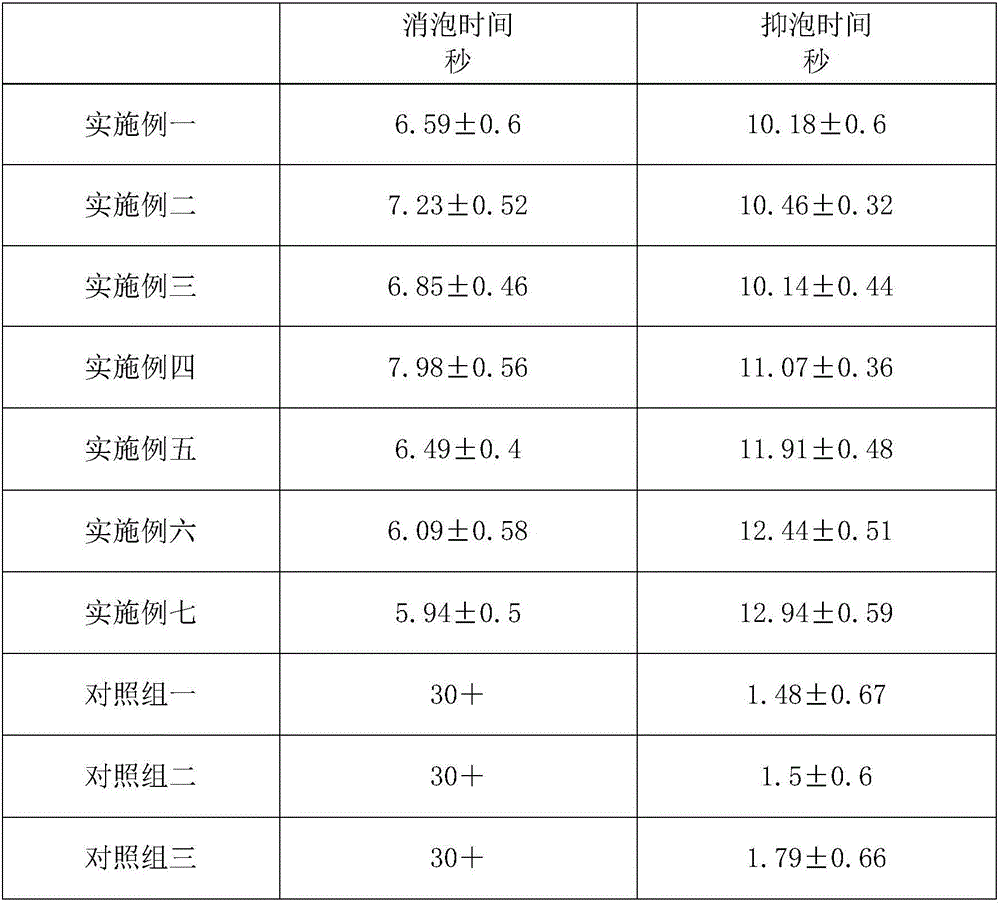

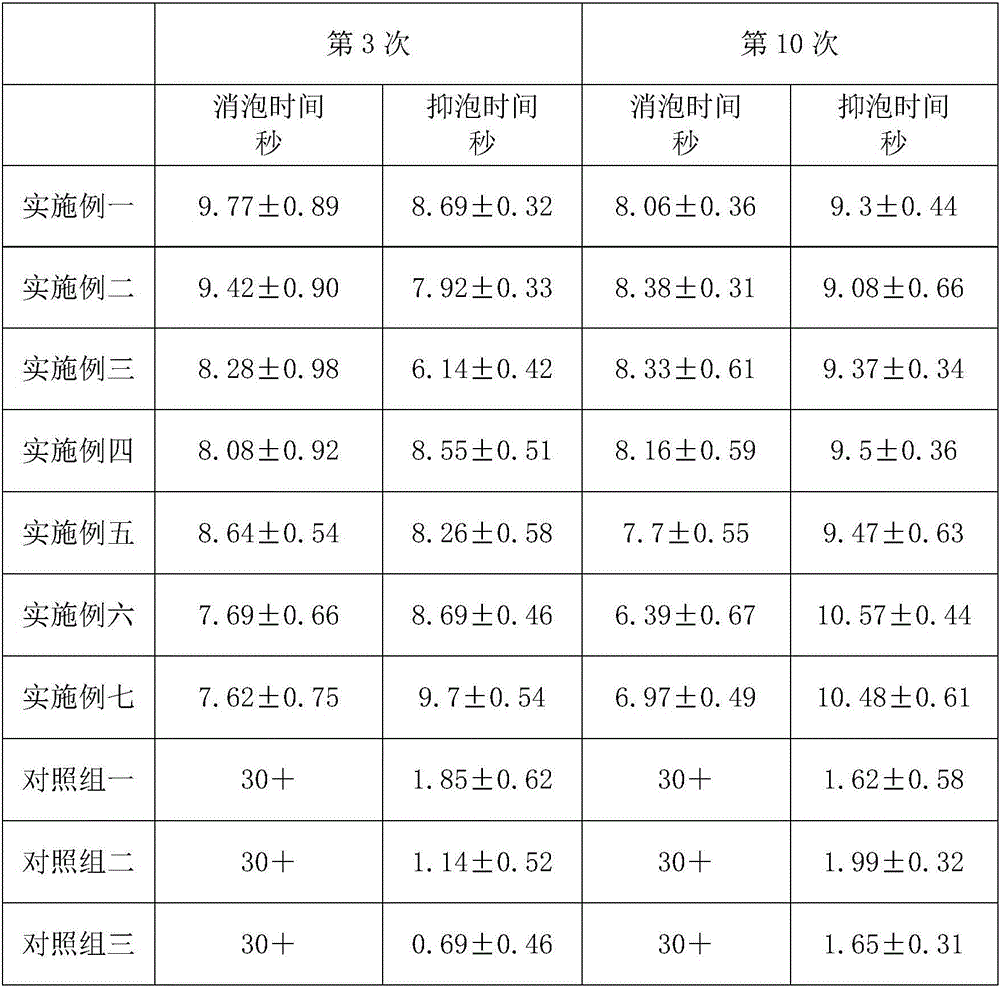

A kind of propofol phosphate gas defoamer and its preparation method and use method

ActiveCN106731031BGood defoamingGood dispersionFoam dispersion/preventionPhosphoric Acid EstersPhosphate

The invention belongs to the technical field of textile auxiliaries and discloses a propofol phosphate gas defoamer. The propofol phosphate gas defoamer is prepared from the following components in parts by weight: 0.1 to 0.8 part of propofol phosphate, 0.5 to 1.7 parts of ipratropium bromide, 100 to 150 parts of nitrogen, 15 to 20 parts of helium, 1 to 4 parts of oxygen, 0.1 to 1.5 parts of carbonic oxide, 12 to 14 parts of argon and 10 to 15 parts of ethanol. The preparation method of the propofol phosphate gas defoamer comprises the following steps: dissolving propofol phosphate into an ethanol solution, heating and stirring at the temperature of 30 to 40 DEG, collecting evaporation gas and mixing the evaporation gas with nitrogen; then mixing the mixed gas with isopropyl ammonium bromide aerosol, subsequently carrying out ultraviolet irradiation treatment for 1 to 2 hours, and mixing a treated mixture with other gases, thus obtaining a finished product. The gas defoamer is introduced into the bottom of a working bath for use, wherein the use amount of working solution per liter is 1 to 2L per minute; by means of adding gas, the dispersion uniformity of the working bath is improved; at the same time, a good foam eliminating and inhibiting effect is achieved; the propofol phosphate gas defoamer can be recycled and is high in economic benefit.

Owner:浙江伟丰新材料有限公司

rice cooker

ActiveCN104510361BEasy to assembleTo achieve the effect of breaking bubblesCooking vesselsEngineeringValve seat

The invention discloses an electric cooker. The electric cooker comprises an electric cooker body and a cover body; a steam valve assembly is arranged on the cover body, comprising a steam valve seat, a rotary foam breaking hood and a steam valve cover; a steam barrel which communicates with the lower surface of the steam valve seat is arranged on the steam valve seat; a returning through hole is formed in the steam valve seat; an end cover is arranged at the upper end of the steam barrel; one or a plurality of steam holes which are circumferentially formed at intervals are formed in the end cover; each steam hole is structured as that steam in the steam hole is obliquely upwards sprayed out; the rotary foam breaking hook is equipped with at least one airflow opening; airflow sprayed out from the steam holes passes through the airflow opening to drive the rotary foam breaking hook to rotate. According to the electric cooker, the steam valve assembly is equipped with few parts, simple in structure, convenient to assemble, high in yield and good in foam breaking effect.

Owner:MIDEA GRP CO LTD +1

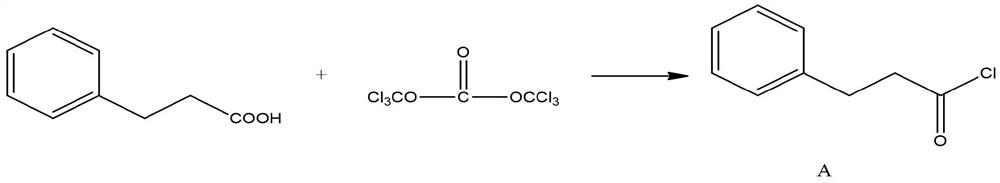

Weeding composition containing propanil and tembotrions

PendingCN113951260ASpread evenlyReduce churnBiocideGroup 4/14 element organic compoundsPlant StomataPropanoic acid

The invention discloses a weeding composition containing propanil and tembotrions, and relates to the field of pesticides. Phenylpropionic acid is added into a three-necked flask, a catalyst and toluene are added as a solvent, trichloromethyl carbonate is ground and added into the three-necked flask, and reduced pressure distillation is performed to obtain an intermediate A. The problem that when A pesticide liquid is attached to target plant leaves, due to the influence of physicochemical properties of the liquid medicine, the pesticide rolls off on the surfaces of the plant leaves, or is separated out through evaporation and crystallization on the target surfaces and cannot permeate into cell walls of resistant barnyard grass and resistant moleplant leaves, and therefore the pesticide effect is limited is solved. The pesticide liquid can reach the maximum coverage on target plant leaves within an extremely short time, so that the pesticide liquid can enter a plant body through morphological structures such as plant pores and skin pores, and the maximum holding capacity and the expansion diameter of the weeding composition on the leaf surfaces are increased, so that the pesticide effect is improved, and the fresh weight control effect on barnyard grass and goosegrass is achieved.

Owner:安徽喜田生物科技有限公司

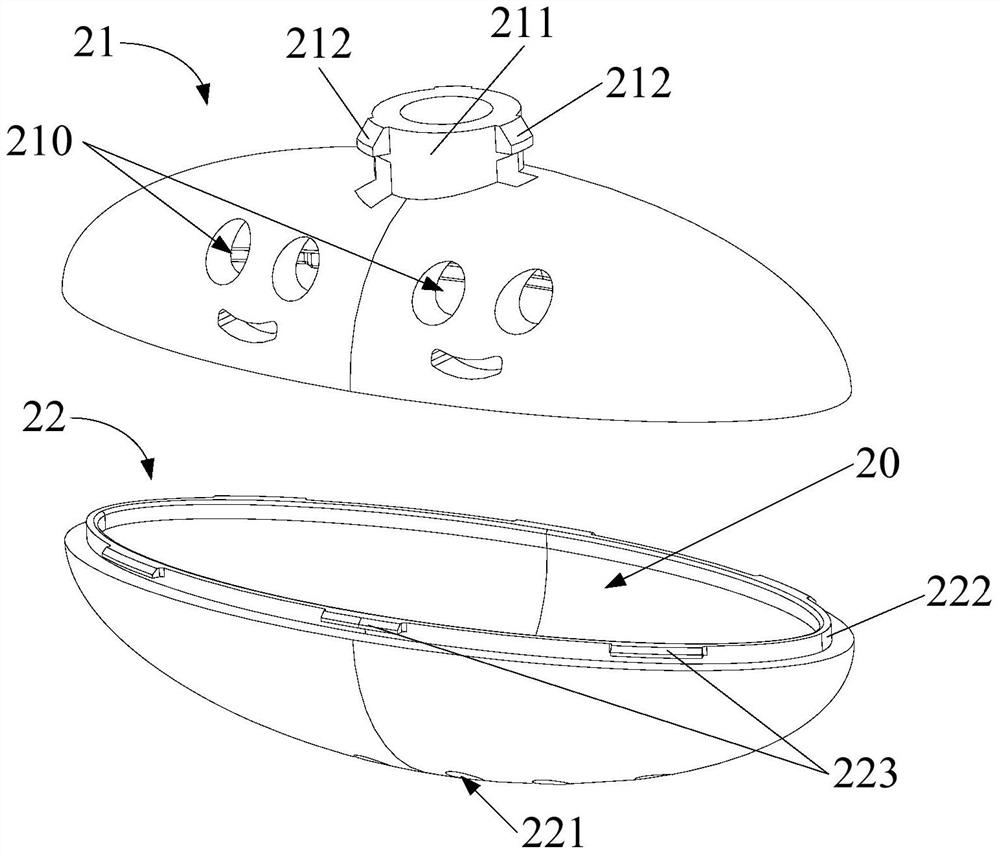

Steam Valves and Cooking Appliances

ActiveCN107440538BAvoid spills to the outside of the rice cookerImprove convenienceCooking vesselsThermodynamicsEngineering

The invention provides a steam valve and a cooking appliance, wherein the steam valve comprises a valve body and a bubble breaking piece; a steam cavity is formed in the valve body; a steam inlet and a steam outlet are formed in the steam cavity; the bubble breaking piece is arranged in the steam cavity; a bubble breaking cavity is formed in the bubble breaking piece; a steam inlet hole, which communicates with the steam inlet, and a steam outlet hole, which communicates with the steam outlet, are formed in the bubble breaking cavity; and the longitudinal sectional area of the bubble breaking cavity is gradually diminished from middle to two ends. According to the steam valve provided by the invention, the inner cavity (the bubble breaking cavity) of the bubble breaking piece is represented in the form of a submarine; when rice grains, porridge, soup and the like enter the steam valve along with steam as steam pressure in the cooking appliance is relatively high, the submarine-like inner cavity can take a squeezing effect on the steam, so that the rice grains, the porridge, the soup and the like, which are entrained in the steam, can be gradually separated from the steam in the bubble breaking cavity and then can drop back into the bubble breaking cavity; therefore, a good bubble breaking effect is achieved, the circumstance that the rice grains, the porridge, the soup and the like spill over of the cooking appliance is effectively prevented and the convenience of a user in cleaning is enhanced.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Soymilk machine

ActiveCN105193257BImprove foam breaking efficiencyImprove foam breaking abilityBeverage vesselsMaximum levelLiquid height

The invention discloses a soybean milk machine, which comprises: a barrel body, the side wall of the barrel body is constructed with annular bubble-breaking ribs protruding from the inner wall surface of the side wall of the barrel body; a pulverizer, which is arranged in the barrel body; a pulverizer motor, The pulverizing motor is connected to the pulverizer; at least the cooking heating part used for heating and boiling the raw pulp; the foam breaking heating part, the setting height of the foam breaking heating part is not lower than the highest liquid level in the barrel during the heating and boiling process, The setting height of the bubble-breaking ribs is not lower than the highest liquid level; the anti-overflow structure is set in the barrel and the setting height is not lower than the highest liquid level. Because the soymilk machine of the present invention is provided with a separate foam-breaking heating part, the foam-breaking can be realized by means of heating through the foam-breaking heating part, thereby improving the foam-breaking efficiency. Heated parts for better foam breaking.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

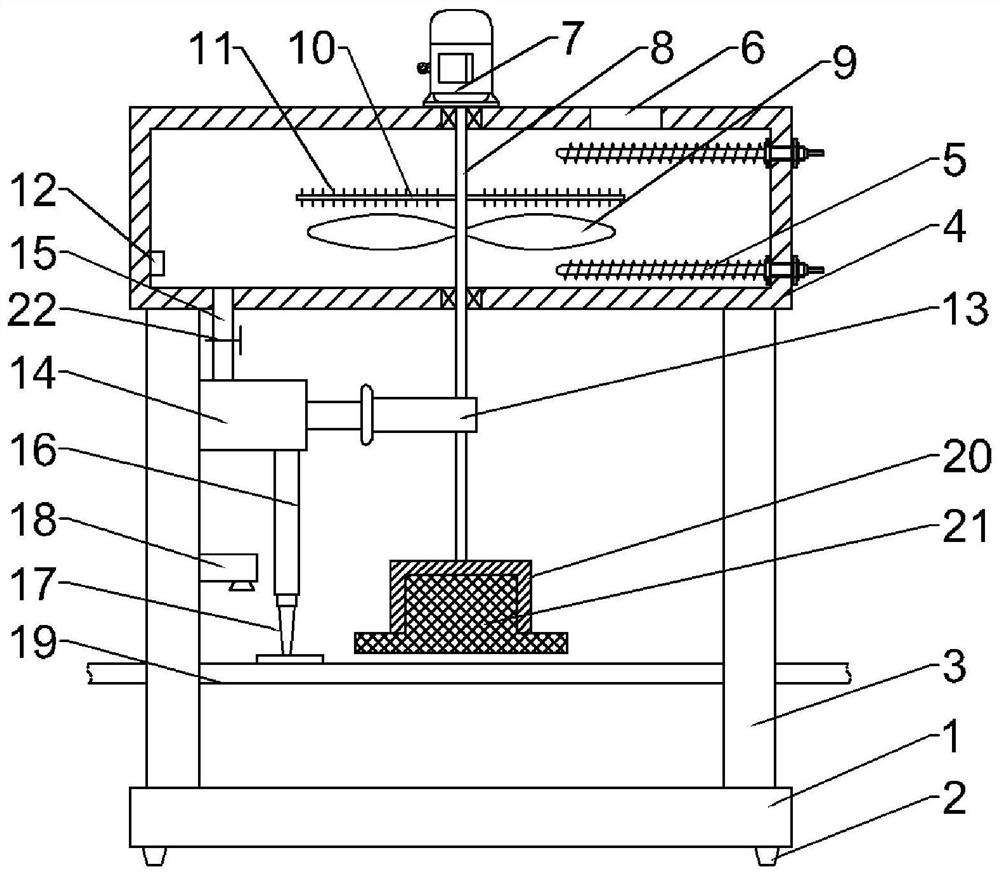

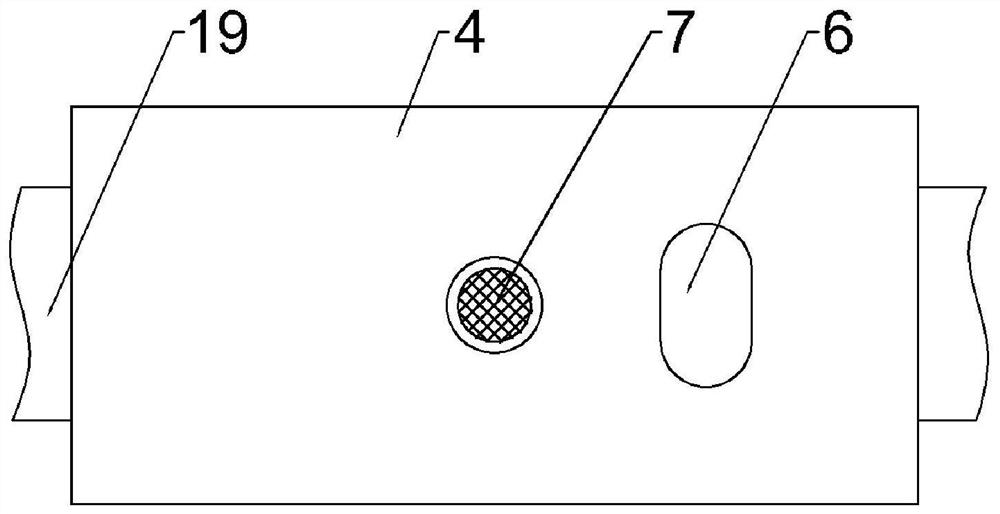

Selective vacuum resin hole plugging machine

InactiveCN111712042AAchieve clearingSimple structurePrinted circuit aspectsPrinted element electric connection formationElectric machineBilateral symmetry

Owner:陈超鹏

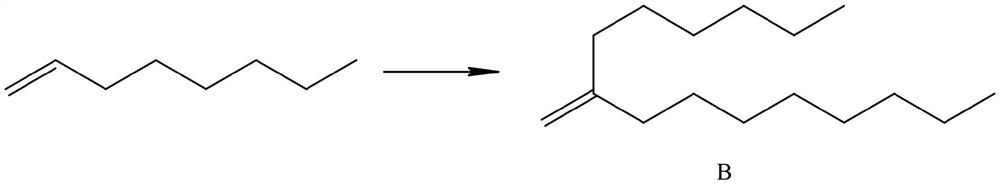

Insecticidal composition containing fluensulfone and allyl isothiocyanate

InactiveCN113729025ANot corrosiveNo structural adjustabilityBiocideAnimal repellantsPtru catalystAllyl thiocyanate

The invention discloses an insecticidal composition containing fluensulfone and allyl isothiocyanate, and relates to the field of pesticides. Chloroplatinic acid is added into isopropanol to obtain a catalyst, allyl glycidyl ether and the catalyst are added into a three-necked flask, a toluene solution containing hydrogen silicone oil is dropwise added to obtain an intermediate A, the intermediate A and polyether amine are added into the three-necked flask, ethanol is added as a solvent, a stabilizing aid is obtained; the stabilizing aid is added into the composition, the problems that foams are easily generated in the dilution process of the existing pesticide, the dispersion uniformity of the pesticide is reduced, the pesticide effect is influenced and the spraying operation is interfered are solved; the amino group is introduced, so that the hydrophilicity is increased, and the amino group can be ionized, is positively charged, has a good bubble breaking effect on a negatively charged bubble film, remarkably reduces the surface tension, enables a pesticide to be quickly spread, wet and permeate on the surface of a plant, and enables the pesticide to exert higher efficiency, thereby achieving the purpose of reducing the generation of bubbles.

Owner:合肥巨卓农业科技合伙企业(有限合伙)

Preparation method and use method of propofol phosphate gas defoamer

ActiveCN106731031AImprove dispersionStrong spreading and spreading abilityFoam dispersion/preventionChemistryOxide

The invention belongs to the technical field of textile auxiliaries and discloses a propofol phosphate gas defoamer. The propofol phosphate gas defoamer is prepared from the following components in parts by weight: 0.1 to 0.8 part of propofol phosphate, 0.5 to 1.7 parts of ipratropium bromide, 100 to 150 parts of nitrogen, 15 to 20 parts of helium, 1 to 4 parts of oxygen, 0.1 to 1.5 parts of carbonic oxide, 12 to 14 parts of argon and 10 to 15 parts of ethanol. The preparation method of the propofol phosphate gas defoamer comprises the following steps: dissolving propofol phosphate into an ethanol solution, heating and stirring at the temperature of 30 to 40 DEG, collecting evaporation gas and mixing the evaporation gas with nitrogen; then mixing the mixed gas with isopropyl ammonium bromide aerosol, subsequently carrying out ultraviolet irradiation treatment for 1 to 2 hours, and mixing a treated mixture with other gases, thus obtaining a finished product. The gas defoamer is introduced into the bottom of a working bath for use, wherein the use amount of working solution per liter is 1 to 2L per minute; by means of adding gas, the dispersion uniformity of the working bath is improved; at the same time, a good foam eliminating and inhibiting effect is achieved; the propofol phosphate gas defoamer can be recycled and is high in economic benefit.

Owner:浙江伟丰新材料有限公司

A kind of modified tung linoleic acid polyether ester coating defoamer and preparation method thereof

ActiveCN112742073BGood compatibilityFast defoamingFoam dispersion/preventionPolymer sciencePolymer chemistry

The invention belongs to the technical field of defoaming agents, and in particular relates to a modified tungsten linoleic acid polyetherester coating defoaming agent, which is characterized in that it comprises the following components in mass percentage: fluoroalkyl hydrogen-containing silicone oil modified tungsten oil Linoleic acid polyether ester 6-10%, mineral oil 5-9%, propylene glycol block polyether 4-6%, emulsifier 2-4%, thickener 1-2%, modified silica 1- 3%, diglyceride oleate 3-5%, and the rest is water. The invention also provides a preparation method of the modified tung linoleic acid polyether ester coating defoamer. The modified tung linoleic acid polyether ester coating defoamer disclosed in the invention has rapid defoaming, strong foam suppressing ability, excellent foam breaking ability, good compatibility with coatings, and rarely causes coating silicon spots and shrinkage cavities. , and only add a small amount of mineral oil.

Owner:山东峰泉新材料有限公司

Defoamer composition

InactiveCN107754385ASmall sizeLarge specific surface areaFoam dispersion/preventionFuel oilSilicon dioxide

The invention discloses a defoamer composition, which comprises, in parts by weight: 20-30 parts of hyperbranched polyether; 15-25 parts of modified nano silicon dioxide; 20-30 parts of polyorganosiloxane; stabilizer 10-20 parts; 20-30 parts of fuel oil; the defoamer composition has high defoaming efficiency, stable performance, long service life, and has characteristics such as very fast defoaming speed and good foam suppression performance in various systems The defoamer synthesized by modified nano / micro silica can be widely used to eliminate harmful foam in industrial production.

Owner:SICHUAN KELIXIN NEW MATERIALS CO LTD

rice cooker

ActiveCN104510362BEasy to assembleTo achieve the effect of breaking bubblesCooking vesselsEngineeringSteam drum

The invention discloses an electric cooker. The electric cooker comprises an electric cooker body and an electric cooker cover; a steam valve assembly is arranged on the electric cooker cover; the steam valve assembly comprises a steam valve seat, a steam valve cover and a rotating foam breaking cover; a liquid return through hole and a vent hole both penetrating through the upper surface and the lower surface of the steam valve seat are formed in the steam valve seat; the steam valve cover is mounted on the steam valve seat; a steam drum is arranged on the steam valve seat, an end cover is arranged on the upper end of the steam drum and one or more steam holes arranged in the circumferential direction are formed in the end cover; at least one airflow hole is formed in the rotating foam breaking cover; airflow ejected out of the steam hole goes through the airflow hole and drives the rotating foam breaking cover to rotate. The steam valve assembly of the electric cooker comprises few parts, and is simple in structure, convenient to assemble, high in rate of finished products and good in foam breaking effect.

Owner:MIDEA GRP CO LTD +1

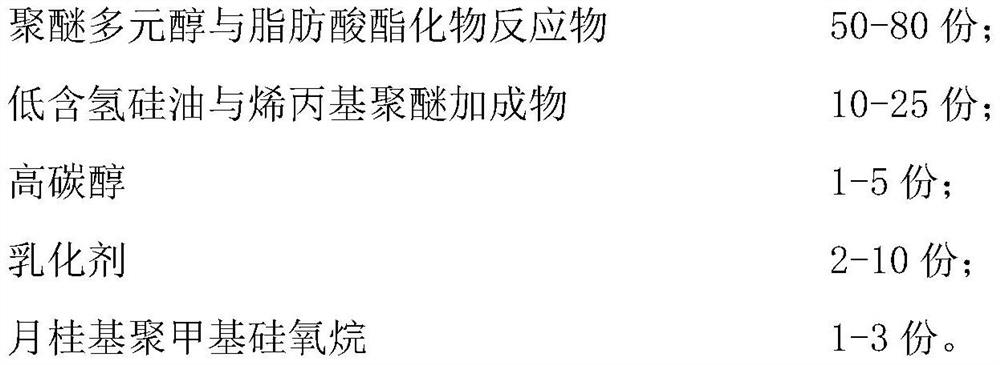

A kind of desulfurization and defoaming agent of high temperature resistant body type power plant and preparation method thereof

The invention provides a high-temperature-resistant body-type desulfurization defoamer for power plants, which is an emulsion prepared by mixing after stepwise reaction, and contains the following components corresponding to the following parts by weight: polyether polyol reacted with fatty acid ester compound 50-80 parts of compound; 10-25 parts of low-hydrogen silicone oil and allyl polyether adduct; 1-5 parts of high-carbon alcohol; 2-10 parts of emulsifier; 1-3 parts of lauryl polymethicone share. Also provided is a method for preparing a desulfurization and defoaming agent for a high-temperature-resistant body-type power plant, including the following steps: S1: reacting to prepare polyether polyols and fatty acid esterified reactants; S2: reacting to prepare low-hydrogen-containing silicone oil and allyl polyether plus S3: Preparation of high temperature-resistant body-type desulfurization defoamer for power plants by mixing. The object of the present invention is to provide a high-temperature-resistant body-type power plant desulfurization defoamer with faster defoaming speed, longer foam suppression time and better effect and its preparation method.

Owner:湖北隆胜四海新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com