Preparation method of modified silane papermaking wastewater defoaming agent

A technology for papermaking wastewater and defoaming agent, applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc., can solve problems such as difficult to maintain effect, high temperature, high alkali content, etc., to improve washing effect, surface Low tension, the effect of promoting emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

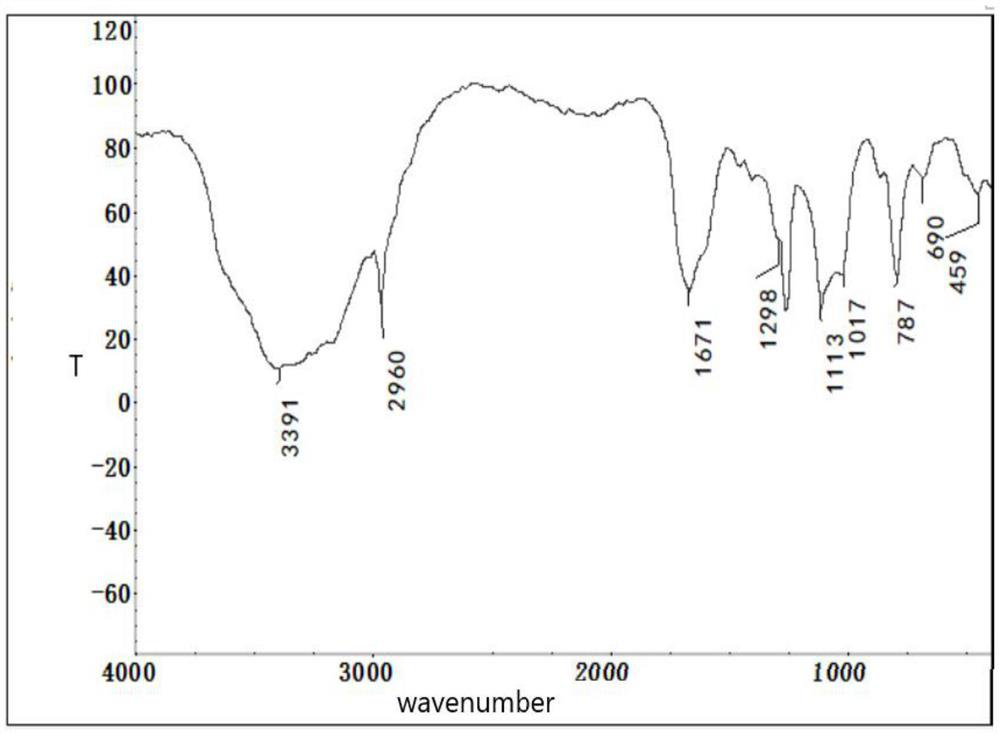

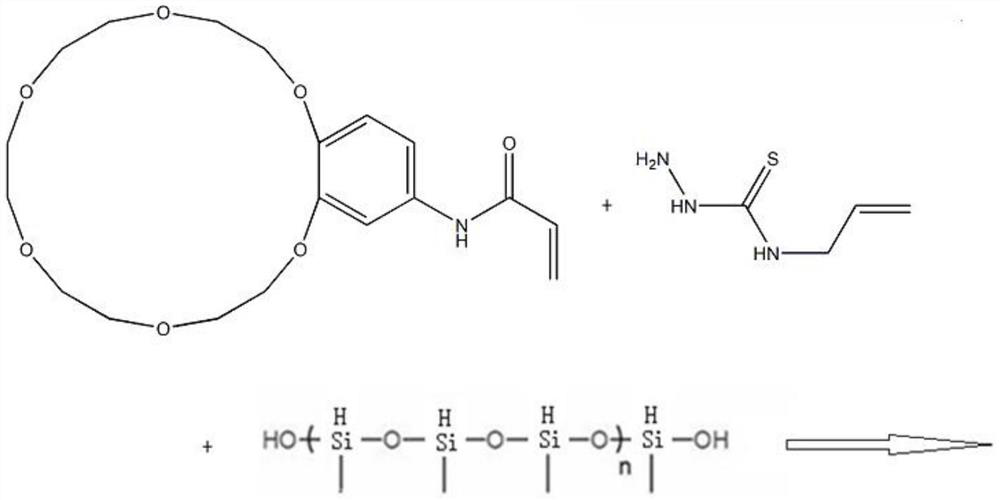

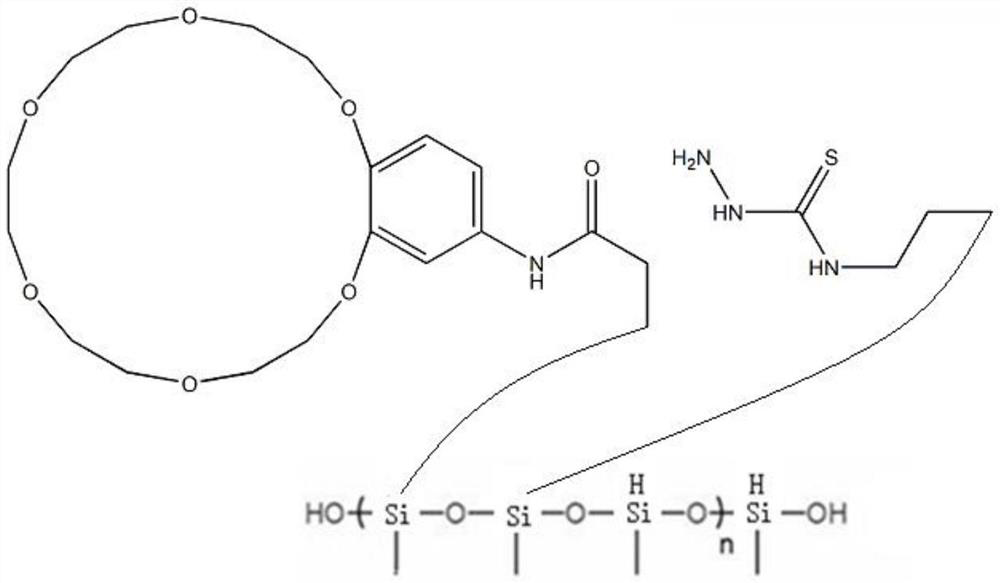

[0027] A kind of preparation method of modified silane papermaking waste water defoamer, its specific scheme is as follows:

[0028] Add 2.9g of octamethylcyclotetrasiloxane, 2.3g of octamethyltrisiloxane and 0.05g of catalyst into the reaction kettle, control the temperature at 100°C, and stir for 60 minutes. After completion, add 3.1g of 2,4,6, 8-Tetramethyl-2,4,6,8-tetrakis(3,3,3-trifluoropropyl)cyclotetrasiloxane was slowly added into the reaction kettle, and the addition was completed within 10 minutes, and then the stirring reaction was continued for 60 minutes. After completion, raise the temperature to 140°C, stir and react for 20 minutes; then add 24g semicarbazide modified silicone, 4g white carbon black and 0.01g catalyst into the reaction kettle, control the temperature at 80°C, stir and react for 30min, then add 0.1g emulsifier Stir and mix with 40g of pure water evenly, add it into the reaction kettle, and stir vigorously for 1 hour to obtain the modified silane ...

Embodiment 2

[0036] A kind of preparation method of modified silane papermaking waste water defoamer, its specific scheme is as follows:

[0037] Add 3.4g of octamethylcyclotetrasiloxane, 2.7g of octamethyltrisiloxane and 0.1g of catalyst into the reactor, control the temperature at 110°C, stir for 90 minutes, and add 3.8g of 2,4,6, 8-Tetramethyl-2,4,6,8-tetrakis(3,3,3-trifluoropropyl)cyclotetrasiloxane was slowly added into the reaction kettle, controlled for 20 minutes to complete the addition, and then continued to stir for 90 minutes. After completion, the temperature was raised to 155°C, and stirred for 25 minutes; then 32g of semicarbazide-modified silicone, 6g of white carbon black and 0.04g of catalyst were added to the reaction kettle, the temperature was controlled at 90°C, stirred for 40 minutes, and then 0.3g of emulsifier was added Stir and mix with 50 g of pure water evenly, add it into the reaction kettle, and stir vigorously for 2 hours to obtain the modified silane paperma...

Embodiment 3

[0044] A kind of preparation method of modified silane papermaking waste water defoamer, its specific scheme is as follows:

[0045] Add 3.8g of octamethylcyclotetrasiloxane, 3.2g of octamethyltrisiloxane and 0.15g of catalyst into the reactor, control the temperature at 120°C, stir for 120min, and add 4.8g of 2,4,6, 8-Tetramethyl-2,4,6,8-tetrakis(3,3,3-trifluoropropyl)cyclotetrasiloxane was slowly added to the reaction kettle, and the addition was completed within 30 minutes, and then continued to stir for 120 minutes. After completion, the temperature was raised to 165°C and stirred for 30 minutes; then 38g of semicarbazide-modified silicone, 10g of white carbon black and 0.08g of catalyst were added to the reaction kettle, the temperature was controlled at 110°C, stirred for 60 minutes, and then 0.6g of emulsifier was added Stir and mix with 60g of pure water evenly, add it into the reaction kettle, and stir vigorously for 3 hours to obtain the modified silane papermaking w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com