Defoaming agent for papermaking

A technology of defoaming agent and auxiliary agent, applied in the field of defoaming agent for papermaking, can solve problems such as affecting production efficiency, low foam breaking rate, easy generation of bubbles, etc., achieving excellent wetting and spreading performance, improving molecular hydrophilicity, Good foam breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

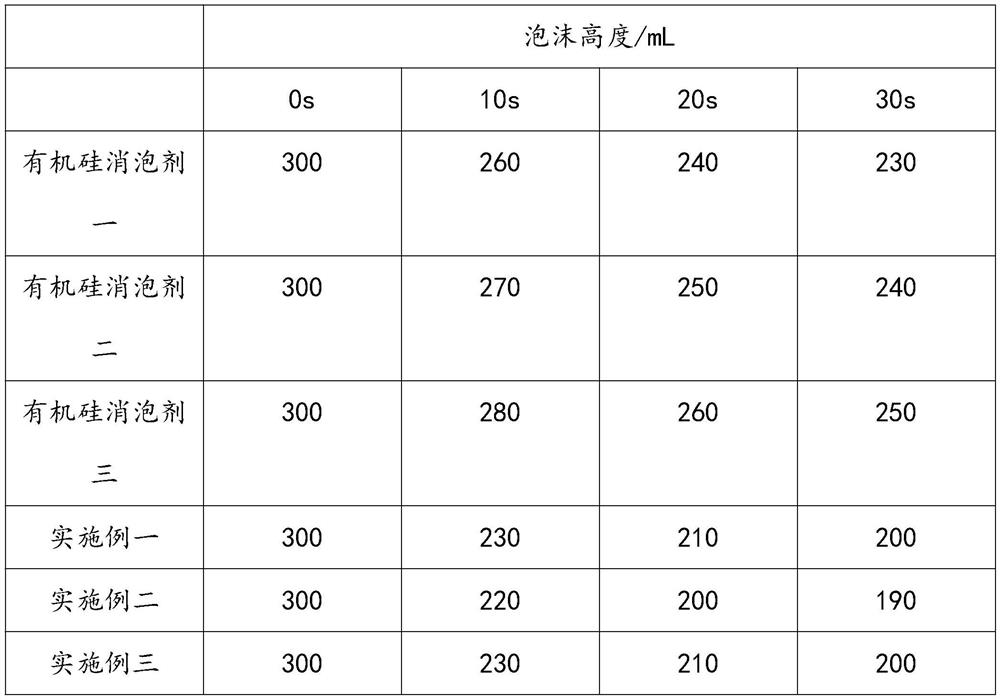

[0035] Please refer to Table 1, the present invention provides a technical solution: a defoamer for papermaking, composed according to the mass ratio, including 30 components of active components, 10 components of emulsifiers, 20 components of auxiliary agents, 8 components Components of solvent and 32 components of water, the active component is a mixture of ethylene glycol monostearate, modified silicone and ethylene bisstearic acid amide in a mass ratio of 1:3:1, with defoaming effect;

[0036] Among them, the modified silicone is prepared from amino-terminated silicone intermediates, silicone monomers, and silane coupling agents under the catalysis of a basic catalyst;

[0037] Concretely, the preparation method of modified organosilicon comprises the following steps:

[0038] (1) Add amino-terminated organosilicon intermediates, a mixture of octamethylcyclotetrasiloxane and dimethylcyclosiloxane, and a silane coupling agent sequentially into the reactor at a mass ratio o...

Embodiment 2

[0051] Please refer to Table 1, the present invention provides a technical solution: a defoamer for papermaking, composed according to the mass ratio, including 28 components of active components, 15 components of emulsifiers, 18 components of auxiliary agents, 6 components Component solvent and 33 component water, the active component is a mixture of ethylene glycol monostearate and modified silicone in a mass ratio of 1:1, which has defoaming effect;

[0052] Among them, the modified silicone is prepared from amino-terminated silicone intermediates, silicone monomers, and silane coupling agents under the catalysis of a basic catalyst;

[0053] Concretely, the preparation method of modified organosilicon comprises the following steps:

[0054](1) According to the mass ratio of 1:50:1, add amino-terminated organosilicon intermediate, dimethylcyclosiloxane and 1,3,5,7-tetramethylcyclotetrasiloxane to the reactor in sequence The mixture and the silane coupling agent are stirred...

Embodiment 3

[0067] Please refer to Table 1, the present invention provides a technical solution: a defoamer for papermaking, composed according to the mass ratio, including 32 components of active components, 18 components of emulsifiers, 17 components of auxiliary agents, 9 components Component solvent and 34 component water, the active component is a mixture of modified silicone and ethylene bis stearic acid amide in a mass ratio of 2:1, which has defoaming effect;

[0068] Among them, the modified silicone is prepared from amino-terminated silicone intermediates, silicone monomers, and silane coupling agents under the catalysis of a basic catalyst;

[0069] Concretely, the preparation method of modified organosilicon comprises the following steps:

[0070] (1) According to the mass ratio of 1:50:1, add amino-terminated organosilicon intermediate, octamethylcyclotetrasiloxane and 1,3,5,7-tetramethylcyclotetrasiloxane to the reactor in sequence a mixture of alkane and a silane coupling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com