Surfactant composition

A surfactant and composition technology, applied in the field of surfactant composition, can solve the problems of poor insecticidal effect, slow spreading and wetting speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments for carrying out the present invention will be described below. However, the scope of the present invention is not limited to the above-described embodiments, and various changes can be made to the present invention as long as the gist is not impaired.

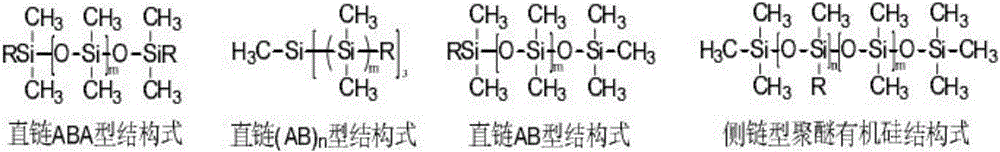

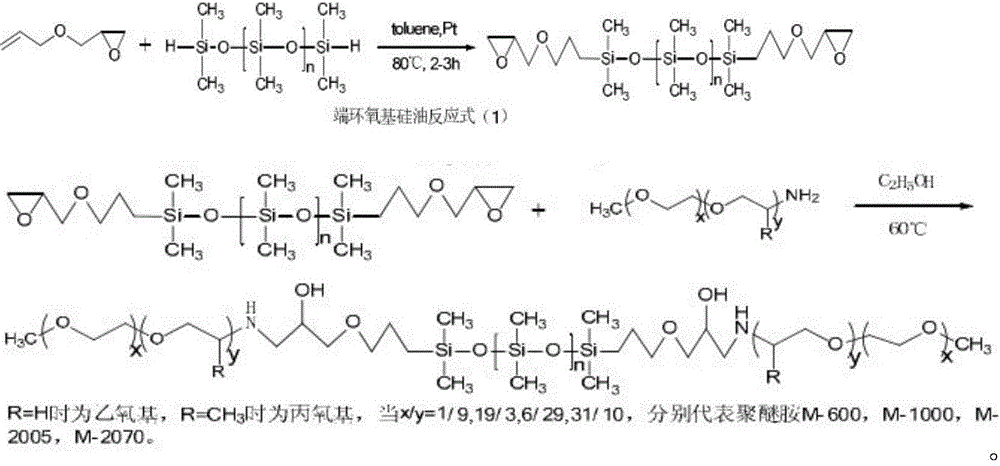

[0029] Preparation of Amino Polyether Silicone

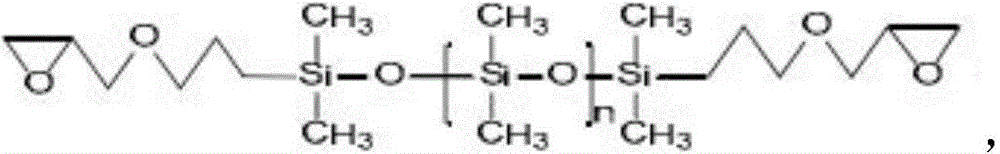

[0030] In a 250mL three-necked flask equipped with a nitrogen device and a reflux condenser, add epoxy silicone oil and polyetheramine M-600 with a molar ratio of amino groups and epoxy groups of 1:1, ethanol as a solvent, and W (ethanol) It is 25%-30%, heated to 60°C, 2h-3h, then discharged, and the solvent was distilled off under reduced pressure to obtain a light yellow transparent viscous liquid, which was dried overnight at 60°C in a vacuum oven, and the reaction was calculated by measuring the epoxy value Conversion rate. The product obtained by nucleophilic ring-opening addition of polyetheramine and epoxy-terminated silicone oil is designated as E-M-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com