An emergency braking device for a hoist

A technology of emergency braking and braking device, which is applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of inability to lock the gearbox, falling objects, hidden dangers, etc., and achieves a simple structure, avoids motor overload, and avoids accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

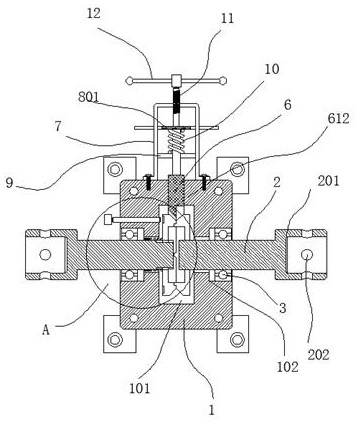

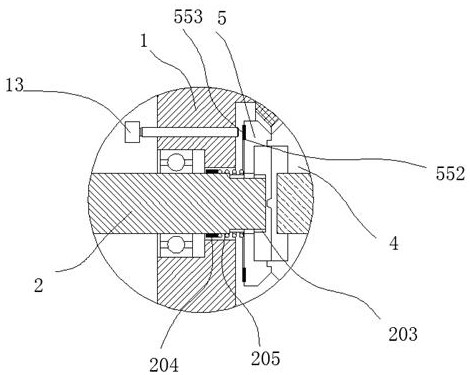

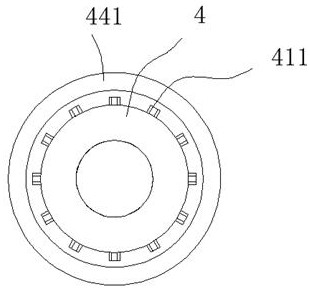

[0034]An emergency braking device for a hoist, comprising a box body 1, an inner cavity 101 is arranged inside the box body 1, and stepped holes 102 communicating with the inner cavity 101 are arranged on both sides of the box body 1, through which the The stepped hole 102 is equipped with a rotating shaft 2, and a bearing 3 is fitted between the rotating shaft 2 and the stepped hole 102. One end of the rotating shaft 2 is inserted into the inner cavity 101, and the other end is located outside the box body 1. The end of the rotating shaft 2 located outside the box body 1 is provided with a connecting sleeve 201, and the outside of the connecting sleeve 201 is processed with a threaded hole 202. The rotating shaft 2 on the right is processed with a fixed engagement disc 4, and the rotating shaft 2 on the left is processed with a fixed engagement disc 4. The rotating shaft 2 is equipped with a movable meshing disc 5; the inner side of the movable engaging disc 5 is annularly pro...

Embodiment 2

[0036] A frame 7 is arranged on the outside of the box body 1, a rod 8 is arranged on the outside of the insert plate 6, a force plate 801 is arranged on the end of the rod 8, and a force plate 801 is arranged on the inside of the frame 7. There is a cross plate 9, the rod 8 passes through the cross plate 9, a first spring 10 is sleeved on the rod 8, and the first spring 10 acts on the cross plate 9 and the cross plate 9. Between the force plates 801, the force plate 801 is pushed back at this time, the insert plate 6 is separated from the fixed engagement plate 4 and the movable engagement plate 5, and a threaded push plate is installed at the frame 7. rod 11 , the threaded push rod 11 is against the force plate 801 , and a plurality of handles 12 are arranged at the end of the threaded push rod 11 . In the above-mentioned structure, the main purpose is to push the inserting plate in safely, and the threaded push rod 11 is used, which makes the operation more convenient. Whe...

Embodiment 3

[0038] The width of the stress plate 801 is greater than the width of the frame 7, and the two sides of the stress plate 801 are provided with a first retreat groove 881 that retreats from the frame 7, and the two ends of the force plate 801 Extend to the outside of the frame 7; in the above structure, the width of the force plate 801 is relatively large, so when we encounter an emergency, we can first manually press the force plate 801, first cut off the power input of the motor, Then screw in threaded push rod 11 by a workman and lock.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com