High-precision cement paste density and flow monitoring equipment

A flow monitoring and cement slurry technology, applied in mass flow measurement devices, measuring devices, specific gravity measurement, etc., can solve the problems of increasing the influence of human factors, unable to fully guarantee the density of cement slurry, etc., to achieve a wide range of adaptation, avoid The effect of human participation in cost and convenient equipment positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

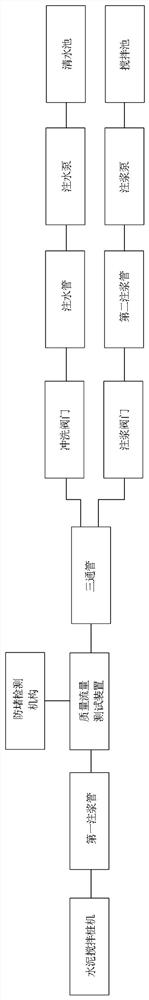

[0034] The invention includes a cement mixing pile driver, a grouting pump and a mixing tank, and is characterized in that it also includes a mass flow meter 1, a water injection pump, an anti-blocking detection mechanism and a clear water tank,

[0035] The stirring tank is communicated with the first input end of the tee pipe through the grouting pump and the second grouting pipe, and a grouting valve is arranged between the second grouting pipe and the tee pipe.

[0036] The clear water pool is connected to the second input end of the three-way pipe through the water injection pump and the water injection pipe, and a flushing valve is arranged between the water injection pipe and the three-way pipe.

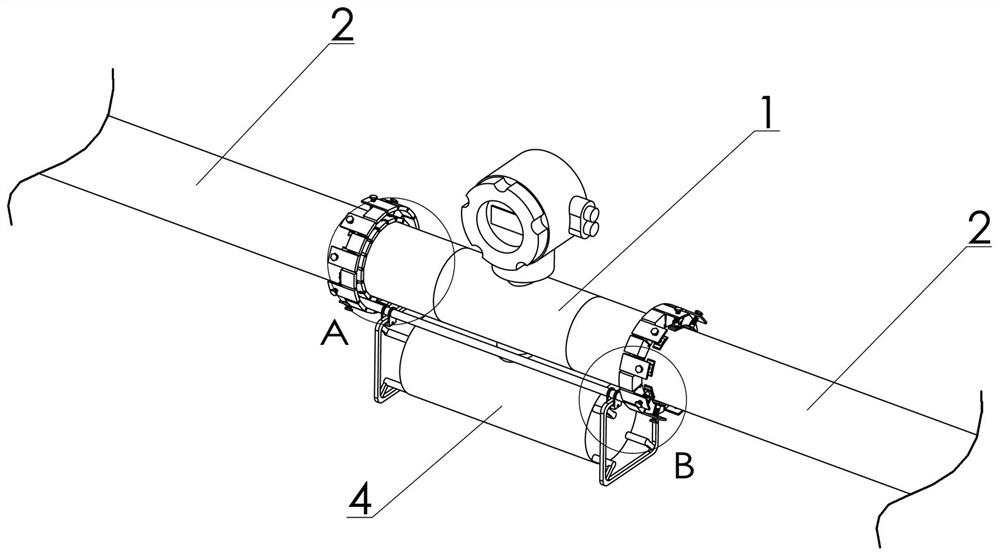

[0037] The output end of the three-way pipe is connected with the input end of the cement mixing pile machine after passing through the mass flow meter 1 and the first grouting pipe 2. The mass flow meter 1 is provided with an anti-blocking detection mechanism,

[0038] The an...

Embodiment 2

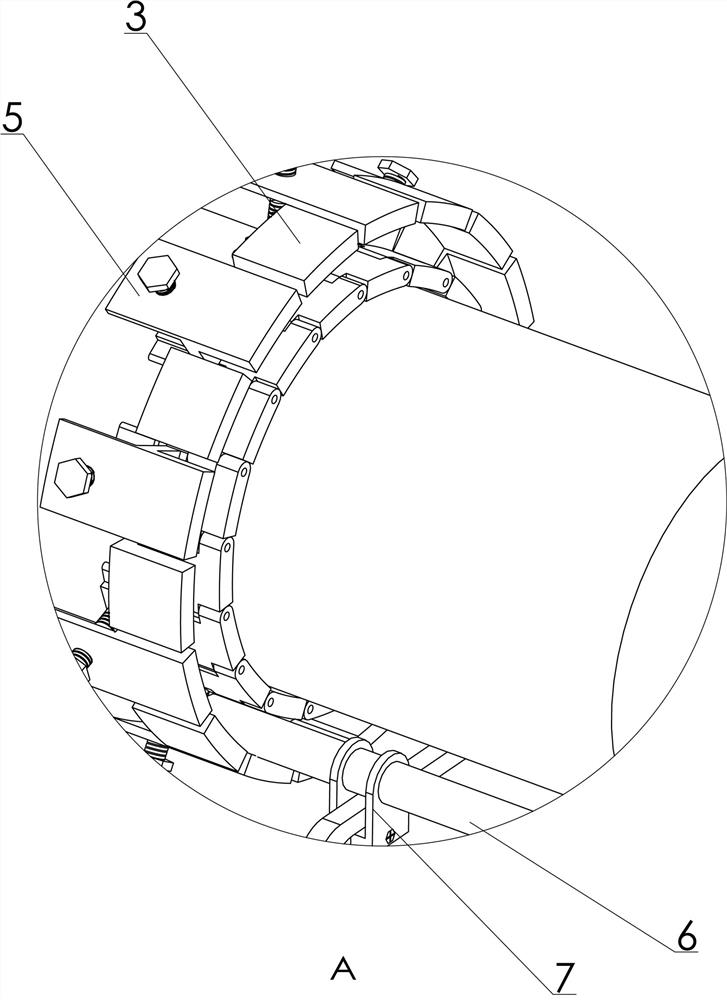

[0044] Based on Embodiment 1, there are 18 arc-shaped limiting blocks 3 .

Embodiment 3

[0046] Based on Embodiment 2, there are two horizontal suspension rods 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com