Anti-cross infection probe film protecting bushing applied to ultrasonic inspection

A film sleeve and film technology, applied in ultrasonic/sonic/infrasonic diagnosis, application, sound wave diagnosis, etc., can solve problems such as cross-infection and no protective measures, and achieve the effect of reasonable shape layout and reasonable thickness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] TPU film cover, the thickness is 2 to 8 wires. TPU material is difficult to form when the thickness is less than 2 filaments, and the material is too thin and easy to break. When the thickness of the TPU material is less than 8 wires, its sound transmission rate is ≥ 95%, which does not affect the doctor's judgment on the condition at all.

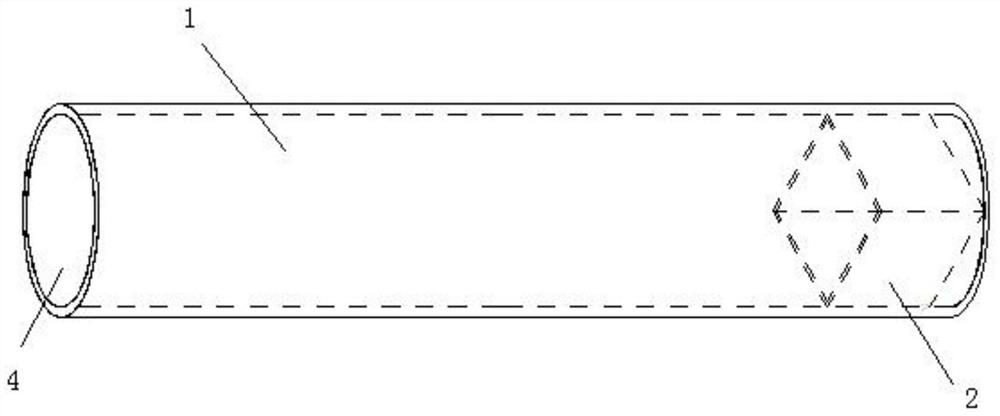

[0019] The TPU film sleeve includes a flexible sleeve body 1 that is columnar after being stretched out. The flexible sleeve body 1 includes an open end 4 and a closed end. The ultrasonic probe can be inserted into the flexible sleeve body from the open end. The closed end is the end surface of a TPU film, which is in direct contact with the generating end of the ultrasonic probe.

Embodiment 2

[0021] On the basis of embodiment 1, a thin wallpaper tube 2 is lined at the closed end of the TPU film sleeve. The thin wallpaper tube 2 is stretched or folded through creases, and the TPU film sleeve can be stretched by squeezing the thin wallpaper tube 2, which is convenient for suiting. At the same time, the thin wallpaper tube 2 can increase the tension on the surface of the front end of the TPU film sleeve to avoid wrinkling and stacking, which will affect the detection results. Moreover, the thin wallpaper tube 2 can increase the hardness of the front end of the TPU film cover, improve the stability of the TPU film cover on the probe, and avoid the occurrence of the rolling case.

Embodiment 3

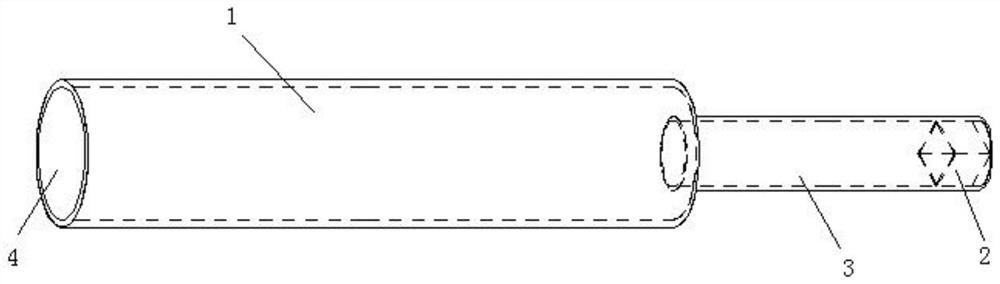

[0023] For some special ultrasound examinations, such as gynecological examinations, due to the limitation of the operation site, the shape of the corresponding ultrasound probe is also different. According to such situation, a protruding front end 3 is formed in the axial direction on the TPU film sleeve, which is also a columnar film body, preferably extending in the axial direction of the flexible sleeve.

[0024] Correspondingly, the thin wallpaper tube 2 is placed in the front end portion 3, therefore, the closed end surface of the front end portion 3 needs to be flat and uniform in texture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com