A fixture for surface finishing treatment of cast valve body

A technology of surface finishing and tooling fixtures, which is applied in the field of surface treatment of cast valve bodies, and can solve problems such as inconvenient fixture size adjustment, shaking, and reduced scope of fixture application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

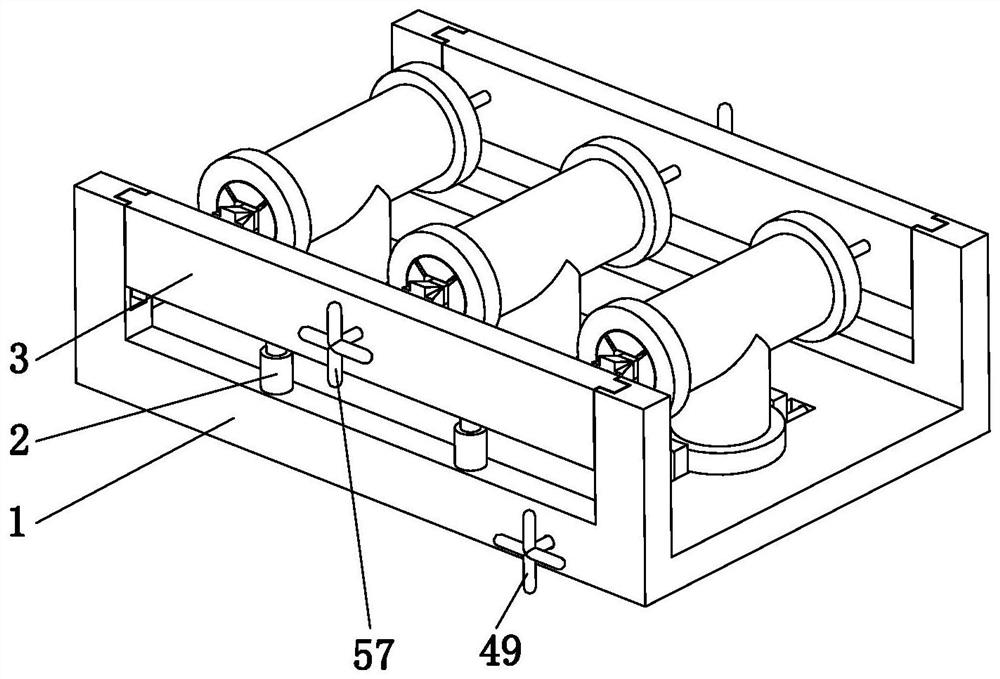

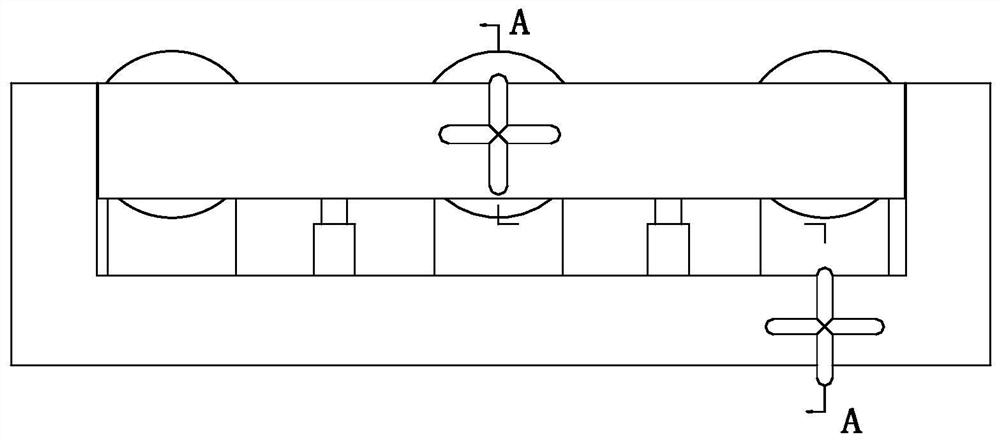

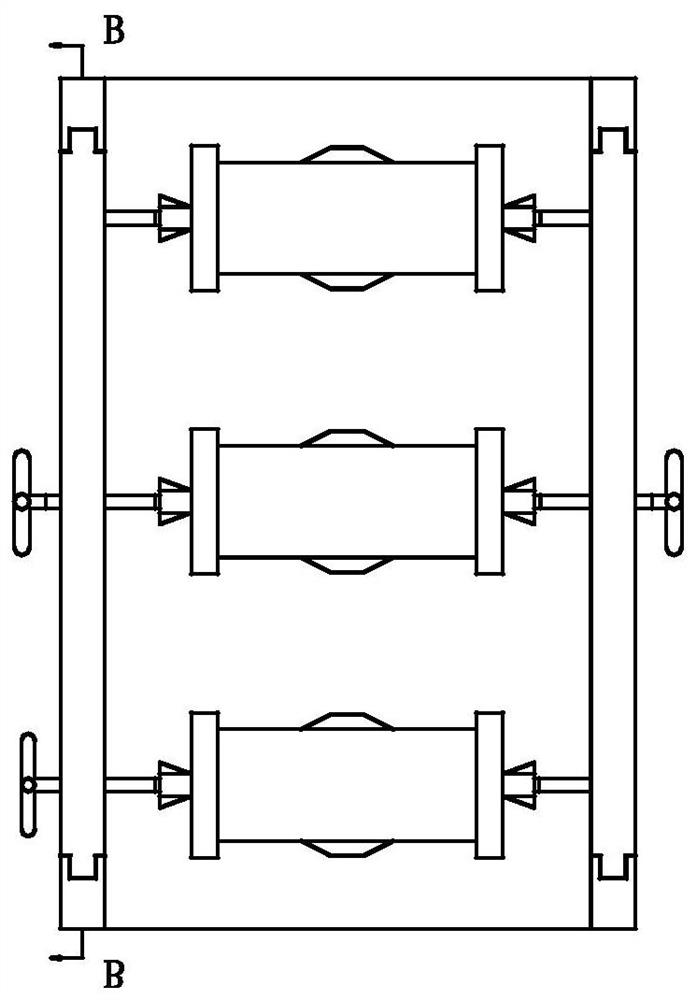

[0030] Such as Figure 1 to Figure 6 As shown, a casting fixture for surface finishing of a cast valve body adopts the following fixture structure, which includes a base 1, a cylinder 2, a moving plate 3, a positioning mechanism 4, and a clamping mechanism 5. The above-mentioned base 1 as a whole is a 匚-shaped structure with an opening facing upwards. The middle part of the base 1 is provided with rectangular grooves sequentially from front to back, and a cylinder 2 is installed in the middle of the left and right side walls of the base 1 along a linear direction. The moving plate 3 is fixedly installed on the left and right side walls of the base 1 through the cylinder 2, a positioning mechanism 4 is installed at the groove in the middle of the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com