Low temperature damage resisting device of propylene refrigeration compressor

A technology for propylene refrigeration and compressors, applied in the field of compressors, can solve the problems of turntable occlusion, high compressor pressure, blockage, etc., and achieves the effect of slowing down the operation efficiency, improving the heat transfer speed, and maintaining a stable thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

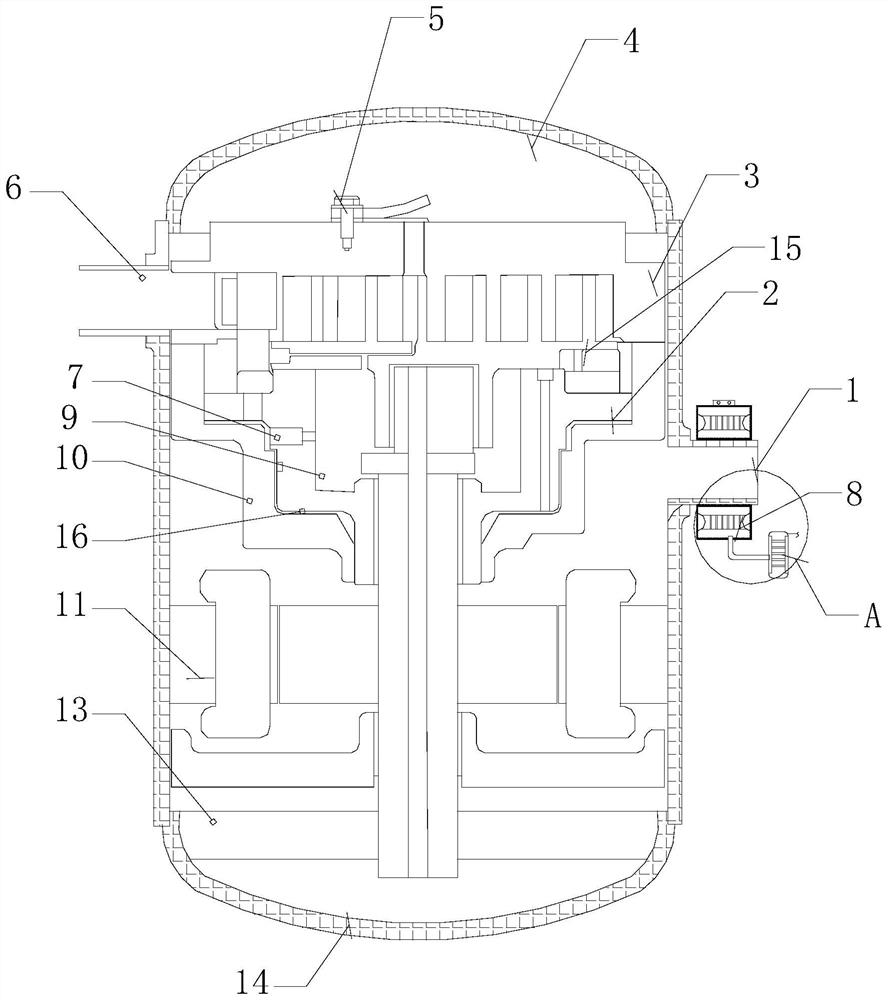

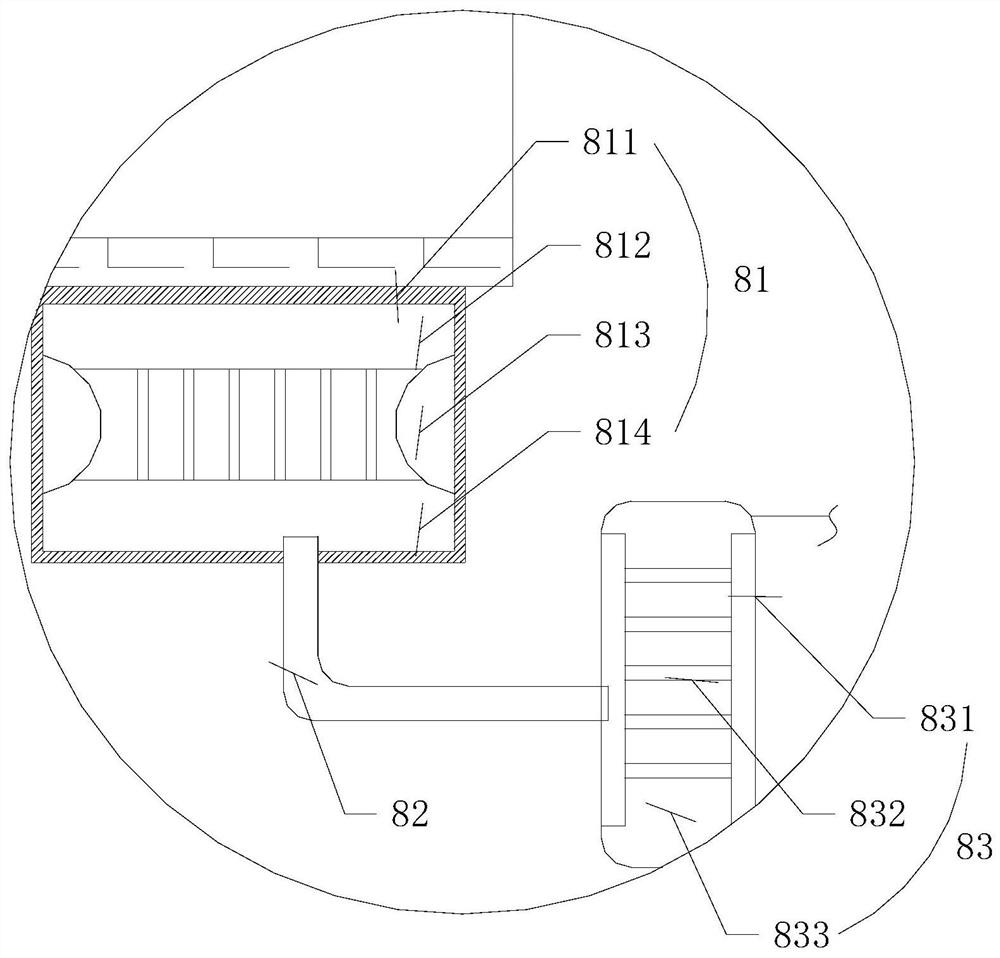

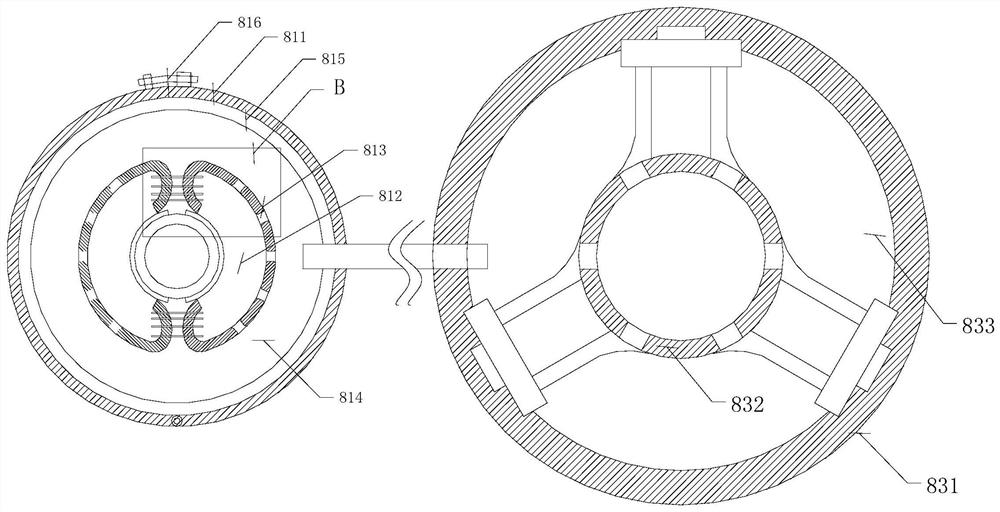

[0024] see Figure 1-Figure 4 , a low-temperature damage prevention device for propylene refrigeration compressors. The present invention provides a low-temperature damage prevention equipment for propylene refrigeration compressors. 5. Exhaust port 6, control valve 7, constant temperature gasification structure 8, back pressure chamber 9, bearing seat 10, motor 11, lubricating oil pool 13, housing 14, movable scroll 15, oil return pipeline 16, the The inner bottom of the housing 14 is a lubricating oil pool 13, and a motor 11 is installed directly above the lubricating oil pool 13. A bearing housing 10 is installed on the top of the motor 11, and a movable scroll 15 is installed directly above the bearing housing 10. The scroll 15 and the fixed scroll 3 rotate and movably cooperate, and the space between the movable scroll 15 and the bearing seat 10 is a back pressure chamber 9, and the back pressure chamber 9 is connected with the exhaust pipe 2 on one side of the back press...

Embodiment 2

[0033] see Figure 1-Figure 4 , a low-temperature damage prevention device for propylene refrigeration compressors. The present invention provides a low-temperature damage prevention equipment for propylene refrigeration compressors. 5. Exhaust port 6, control valve 7, constant temperature gasification structure 8, back pressure chamber 9, bearing seat 10, motor 11, lubricating oil pool 13, housing 14, movable scroll 15, oil return pipeline 16, the The inner bottom of the housing 14 is a lubricating oil pool 13, and a motor 11 is installed directly above the lubricating oil pool 13. A bearing housing 10 is installed on the top of the motor 11, and a movable scroll 15 is installed directly above the bearing housing 10. The scroll 15 and the fixed scroll 3 rotate and movably cooperate, and the space between the movable scroll 15 and the bearing seat 10 is a back pressure chamber 9, and the back pressure chamber 9 is connected with the exhaust pipe 2 on one side of the back press...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap