A method of manufacturing a battery

A manufacturing method and battery technology, which is applied in the field of battery manufacturing, can solve the problems of complicated process and inability to carry out industrial application, and achieve the effects of reducing liquid swelling, reducing the cycle performance of battery cells, and reducing excessive internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

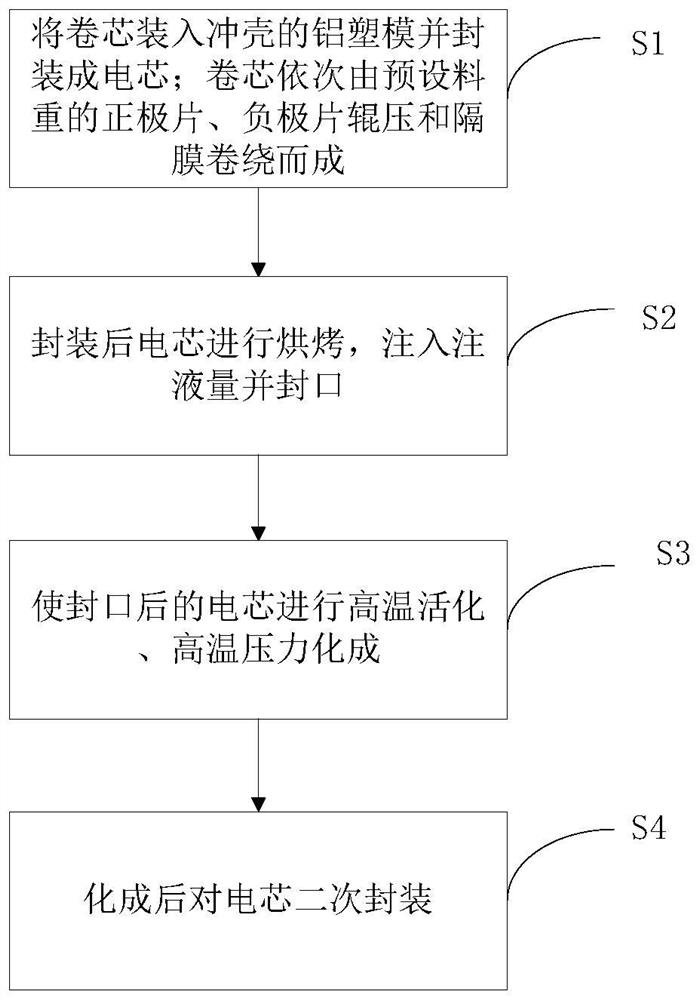

[0031] See figure 1 , the invention discloses a method for manufacturing a battery, comprising the steps of:

[0032] Preset the weight of positive and negative materials according to the battery model;

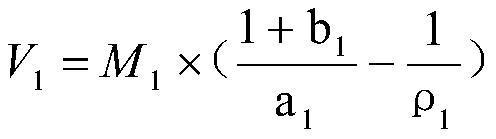

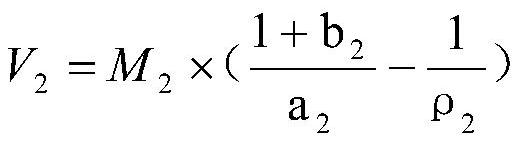

[0033] According to the formula Respectively get fully charged positive hole V 1 and the fully charged negative hole V 2 ;

[0034] m 1 Indicates the weight of positive electrode material, a 1 Indicates the design compaction of positive electrode, b 1 Indicates the full-charge rebound ratio of the positive electrode, ρ 1 It is positive and true;

[0035] m 2 Indicates the negative material weight, a 2 Design compaction for the negative electrode, b 2 Indicates the full-charge rebound ratio of the negative ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com