Illuminating device for sorting machine or inspecting machine

A lighting device and inspection machine technology, which is applied in the field of color sorting machines, can solve the problems of unclear detection images and failure to illuminate a part of grains, etc., and achieve the effects of miniaturization, quantity reduction, and envelope size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

[0042] The illumination light source applied to the illumination device of this embodiment is configured by arranging one row or a plurality of LED chips on a substrate according to the width of the slide rail. LEDs can also exist in multiple colors mixed. In addition, in other embodiments, light emitters other than LED chips may also be used.

[0043] In addition, the plurality of reflectors used in this embodiment are concave mirrors, and an elliptical concave mirror having an elliptical curvature is used. In addition, the concave curved surface does not necessarily have to have an elliptical curvature, and may be a concave surface having a parabolic or hyperbolic curvature when it is desired to weaken the light-gathering characteristic of the object to be detected. Furthermore, it may be a free-form surface capable of freely setting the incident angle, light-condensing position, and light-condensing degree of light toward the object to be detected.

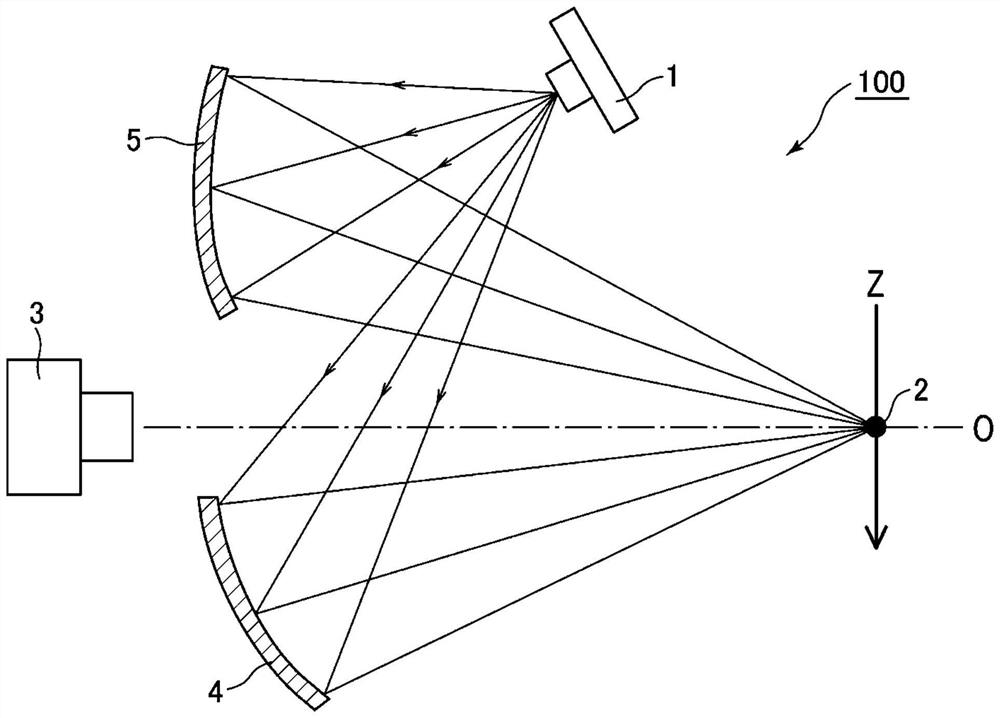

[0044] figure 1 It ...

no. 2 approach >

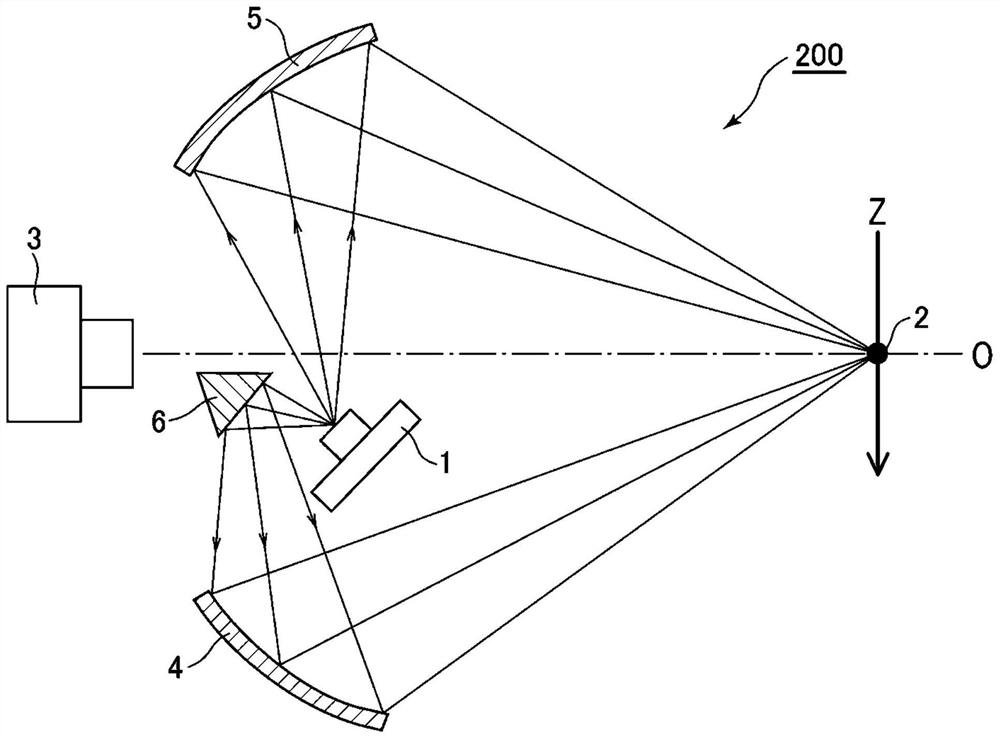

[0051] Such as figure 2 As shown, the lighting device 200 of the second embodiment further includes a refracting mirror 6 . The functions of other constituent elements are the same as those of the first embodiment, and therefore description thereof will be omitted.

[0052] The refracting mirror 6 of the present embodiment is a plane mirror, and is used to bend the optical path of the light emitted from the illumination light source 1 to make the light reach the first reflector 4 . Therefore, unlike the configuration in the first embodiment, as figure 2 As shown, the illumination light source 1 is arranged between the first reflector 4 and the second reflector 5, and the first reflector 4 (for example, an elliptical concave mirror) and the second reflector 5 are arranged to face each other. As shown in the figure, the light group from the illumination source 1 is not directly incident on the first reflector 4, but it is assumed that a part of the light group from the illum...

no. 3 approach >

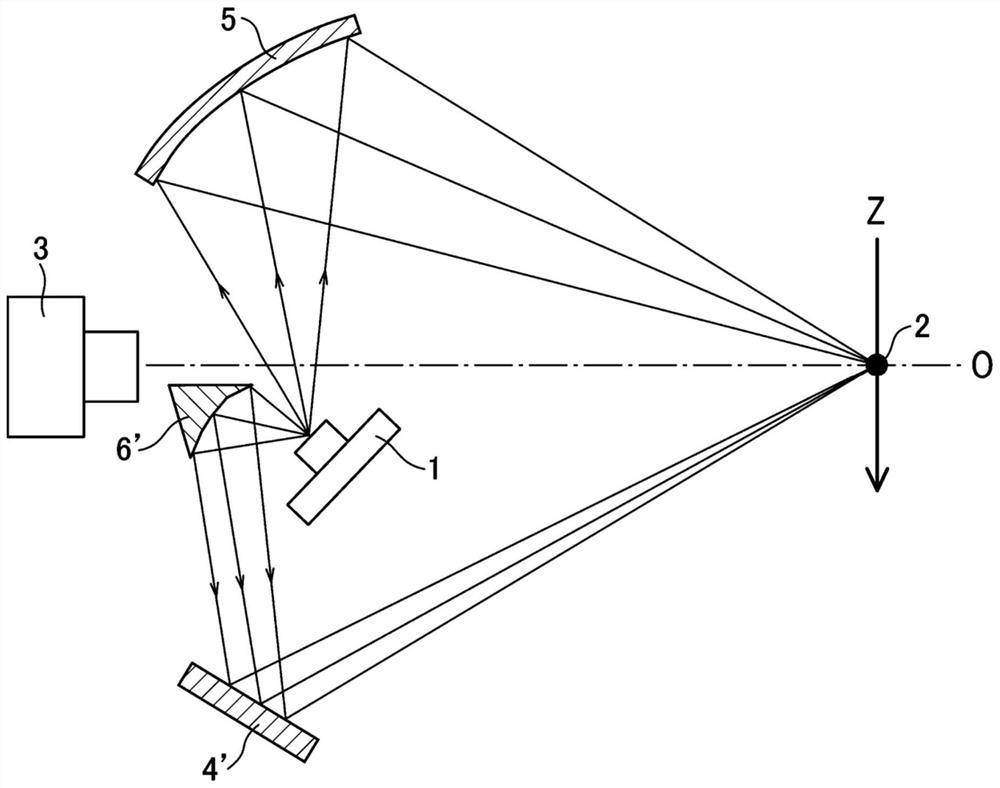

[0060] Such as Figure 4 As shown, the lighting device 300 of the third embodiment is characterized in that the refracting mirror 6 has a plurality of reflecting surfaces 6a, 6b. As shown in the figure, after being reflected by the first reflector 4 as a concave curved surface mirror (for example, an elliptical concave curved surface mirror), a part of light from the illumination source 1 whose light path is bent by the first reflecting surface 6a is reflected, and the reflected light becomes Illumination light from below rice grain 2. Similarly, after the part of the light from the illumination source 1 that has bent the optical path through the first reflective surface 6b is reflected by the second reflector 5 as a concave mirror (for example, an elliptical concave mirror), the reflected light becomes light from rice grains. 2 above the illumination light.

[0061] In other words, it is the following structure: figure 2 The refractor 6 of the second embodiment shown bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com