Scraper, scraping mechanism and photo-curing ceramic 3D printer

A scraper and scraper technology, applied in ceramic molding machines, manufacturing tools, additive processing, etc., can solve the problems of waste of slurry, inconvenient adjustment of scraper thickness, etc., and achieve the effect of ensuring certainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

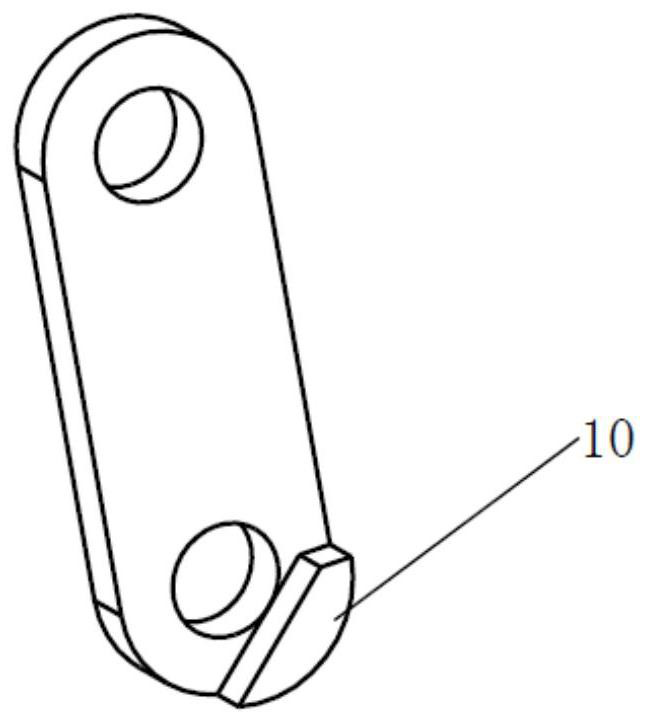

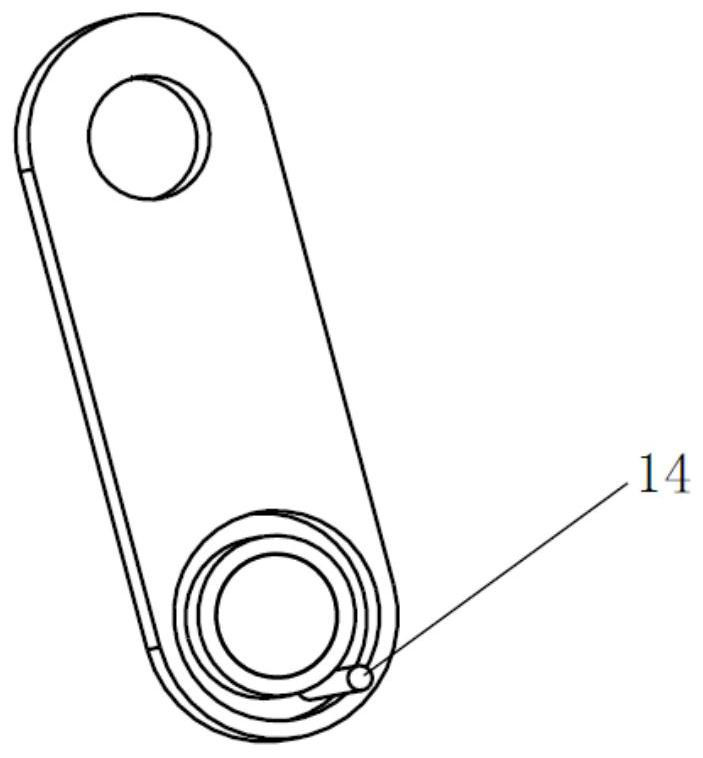

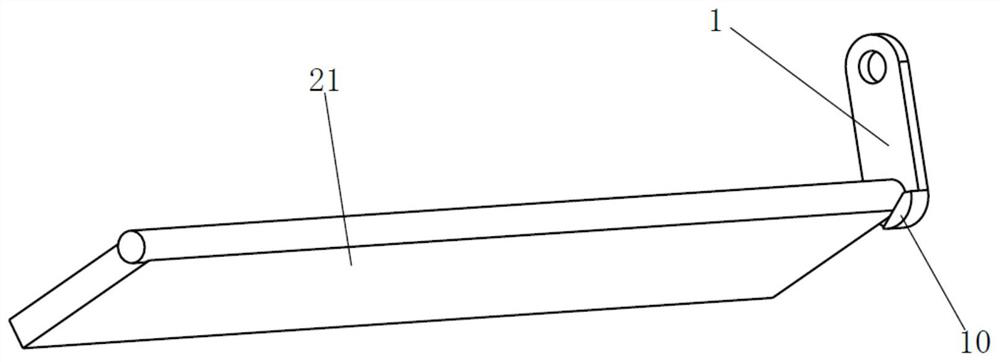

[0039] like Figure 3-4 As shown, this embodiment provides a scraper, including: a limit guide rod 1, one end of the limit guide rod 1 is a fixed end, and the other end is a free end, and the fixed end of the limit guide rod 1 is connected to There is a material spreading plate, the fixed end of the limit guide rod 1 is connected to the material spreading plate by screws, the moving direction of the material spreading plate when scraping is the first direction, and the fixed end of the limit guide rod is provided with a limit position device, the free end of the limit guide rod rotates around the fixed end, the material spreading plate approaches or moves away from the limit device with the rotation of the limit guide rod, when the material spread plate contacts the limit device is the scraping position of the spreading board, the rotation of the free end of the limit guide rod 1 can drive the laying board to turn over, and realize the turning of the scraper. The existence of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap