Method for assigning production process data to length position of strip steel

A technology of production process and length position, applied in the direction of program control, electrical program control, comprehensive factory control, etc., can solve the problems of seldom application and shelving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

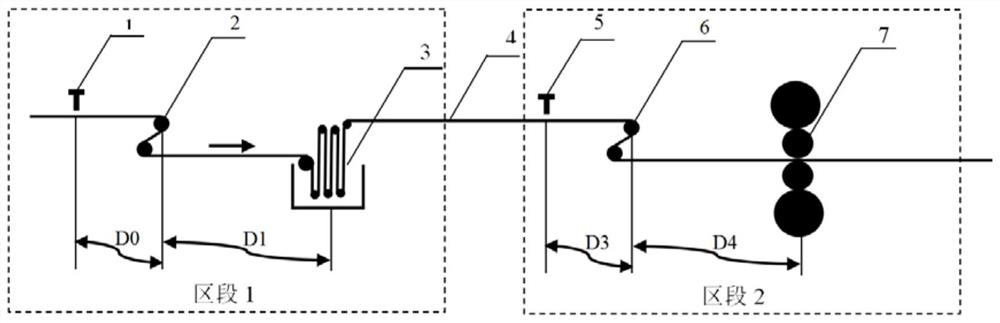

[0068] Take the skin-pass mill section of a cold-rolled hot-dip galvanizing unit as an example, such as figure 1 shown.

[0069] exist figure 1 In section 2 of , 5 represents the seam tracker, 6 represents the tension roller encoder, 7 represents the skin passer, 4 represents the strip, and the strip advancing direction is from left to right. The role of the skin passer is mainly to improve the shape and fine-tune the mechanical properties, and the longitudinal extension of the strip is very small and can be ignored.

[0070] Using the almost scheme of the present invention, assign the real-time process data of the skin passer to the physical position of the strip, and the specific method is as follows:

[0071] 1) Use the weld seam tracker 5 to detect the weld seam (ie, the head of the strip), and send the signal to the tension roller encoder 6 and the skin passer device 7 in real time.

[0072] 2) Calculate the strip stroke. The real-time real speed V of the unit output ...

Embodiment 2

[0082] Taking a hot-dip galvanizing unit as an example, such as figure 1 The process equipment in Section 1 is an annealing furnace, and the process equipment in Section 2 is a tempering machine.

[0083] Section 1 is the previous process of section 2, 1 indicates the weld seam tracker, 2 indicates the tension roller encoder, 3 indicates the annealing furnace, 4 indicates the strip steel, 5 indicates the weld seam tracker of section 2, and 6 indicates the area The encoder and 7 of section 2 represent the tempering machine of section 2, and the direction of strip steel advances from left to right. The main function of the annealing furnace is to adjust the mechanical properties of the strip steel, but due to the high heating temperature, the strip steel will extend longitudinally.

[0084] By adopting the technical scheme of the present invention, the real-time process data of the annealing furnace is assigned to the strip length position, and the specific method is as follows...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap