Device and method for the high-pressure treatment of bulk material by extraction and/or impregnation and use

A bulk material, high-pressure treatment technology, applied in chemical instruments and methods, biochemical equipment and methods, separation methods, etc., can solve problems such as adverse health effects, and achieve robustness and operational reliability, cost advantages, and compactness The effect of the movement mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

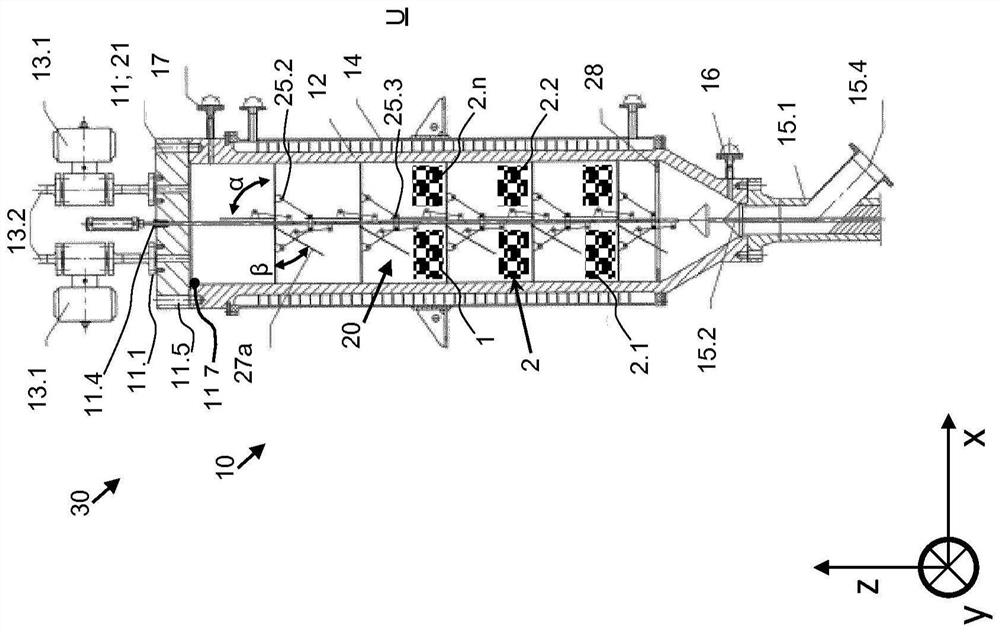

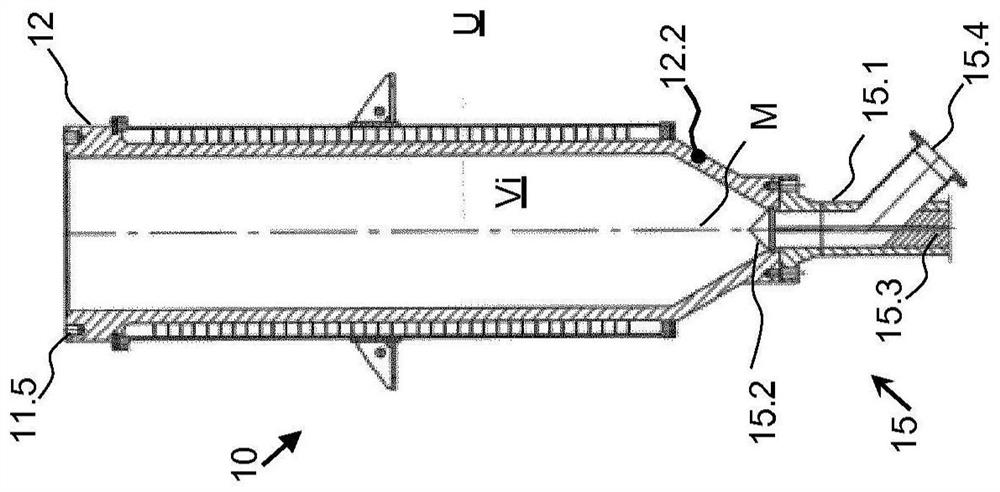

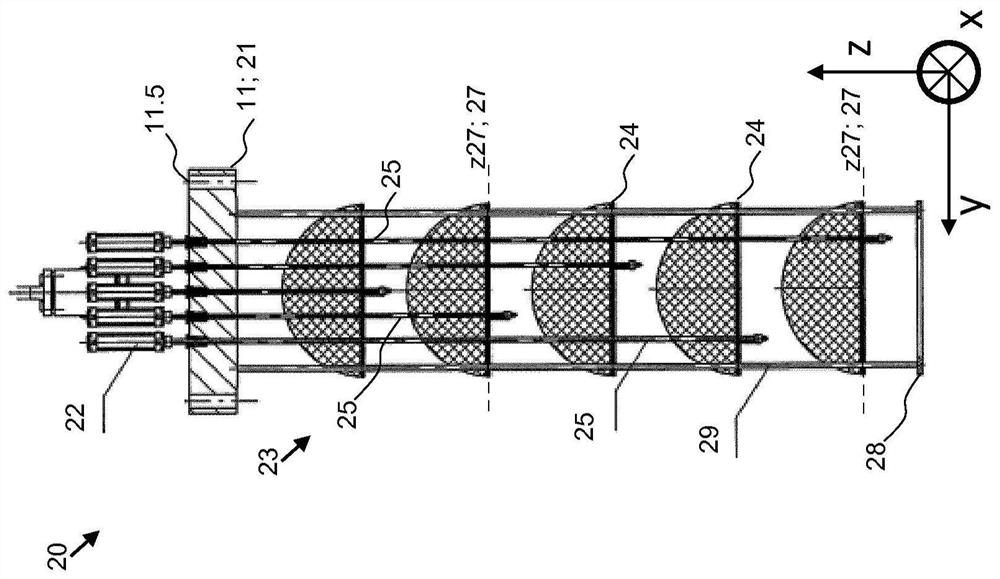

[0089] figure 1 Shown is a pressure vessel device 10 (shown in an installed state) in which a support tray module 20 is integrated and fitted for containing and arranging bulk material 1 or granules, wherein in a plurality of batches 2.1, 2.2, 2. Formed n-form beds or batches 2 are formed in the internal volume Vi (or in the corresponding cavity) delimited by the high pressure resistant walls 12 of the pressure vessel arrangement, these multiple batches being each arranged on a separate treatment stage 27 . For example, five processing stages are shown. The corresponding treatment stage 27 defines a height position z27 for arranging the bulk material 1 .

[0090] The cover 11 of the pressure vessel device 10 is provided by the cover 21 of the support tray module 20, or vice versa, the cover 11 can be fitted by an autoclavable sealing action. By mounting support tray modules, the container 10 can be closed in a pressure-tight manner (“one-piece construction”). A high-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com