Locking structure of flat plate mop

A technology of locking structure and flat mop, which is applied in the direction of cleaning floors, carpets, cleaning equipment, etc., can solve the problems of large storage space, complex structure, water accumulation, etc., and achieves a small storage space, which is convenient for assembly and operation, and simplifies the structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

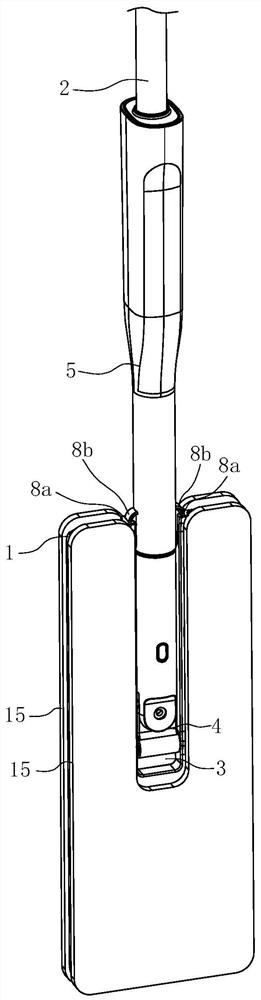

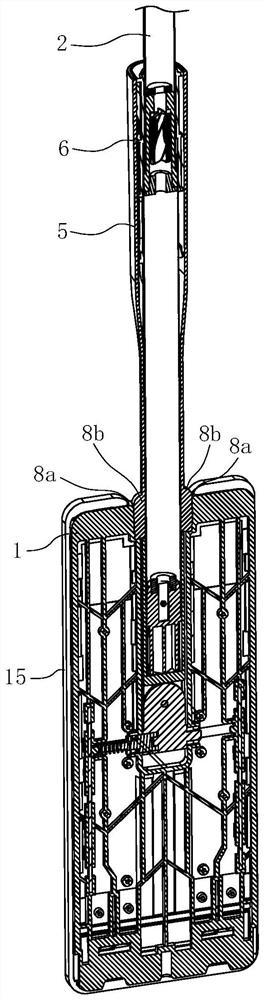

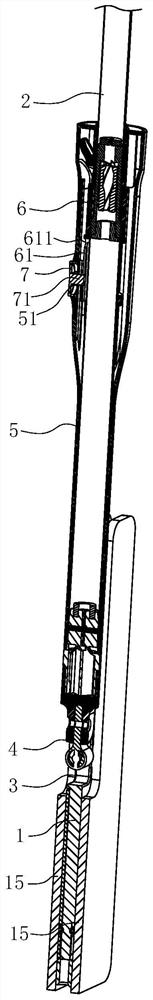

[0040] Such as Figure 1-9 Shown is the first embodiment of the present invention.

[0041] A locking structure of a flat mop, comprising a flat mop head 1 and a mop rod 2, the flat mop head 1 is provided with a through groove 3 which is open at one end and can accommodate part of the mop rod 2, and the lower end of the mop rod 2 passes through a joint 4 Rotationally connected to the bottom of the through groove 3, the front and rear end surfaces of the flat mop head 1 are provided with wipers 15; when the mop rod 2 is rotated to an angle with the flat mop head 1, it is in the state of mopping the floor, and the mop rod 2 is rotated to accommodate When it is in the through groove 3 of the flat mop head 1, it corresponds to the spin-dried or folded state.

[0042] The mop rod 2 is covered with a locking part 5 that can slide axially along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com