Nixie tube assembling machine

A digital tube and assembly machine technology, applied in the field of digital tube production, can solve the problems of pin confusion, low manual assembly efficiency, pin damage, etc., and achieve the effect of convenient transfer, easy assembly operation, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

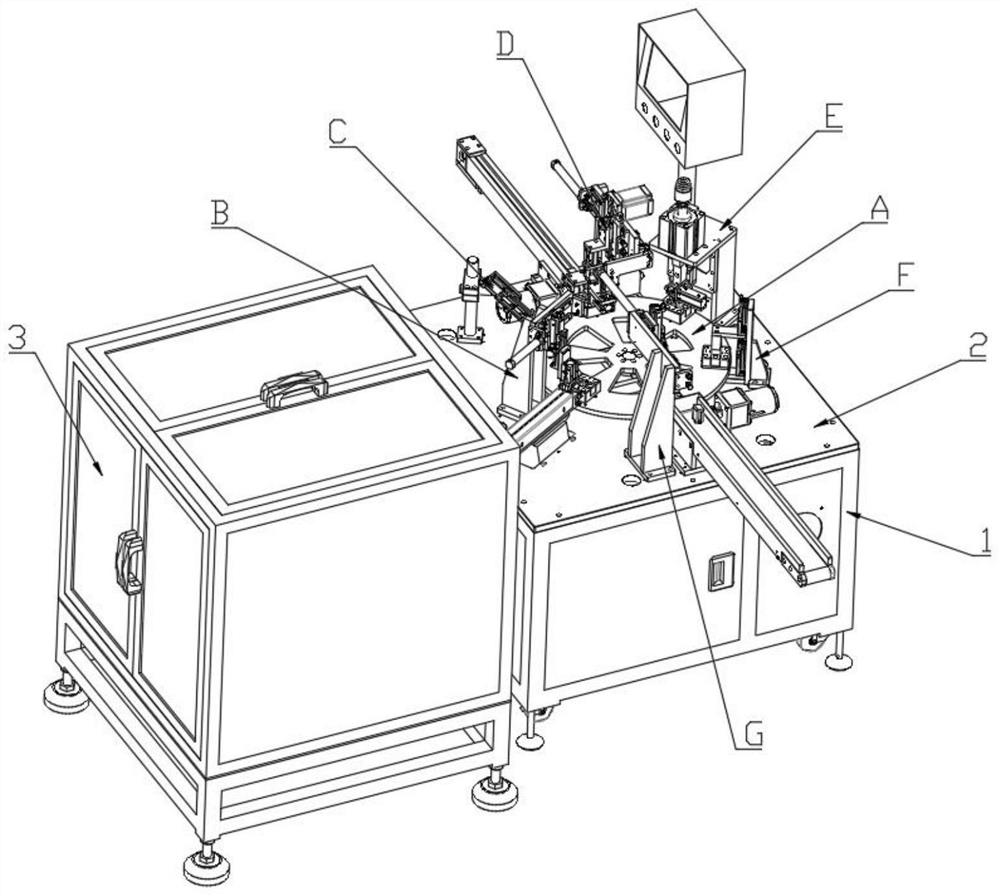

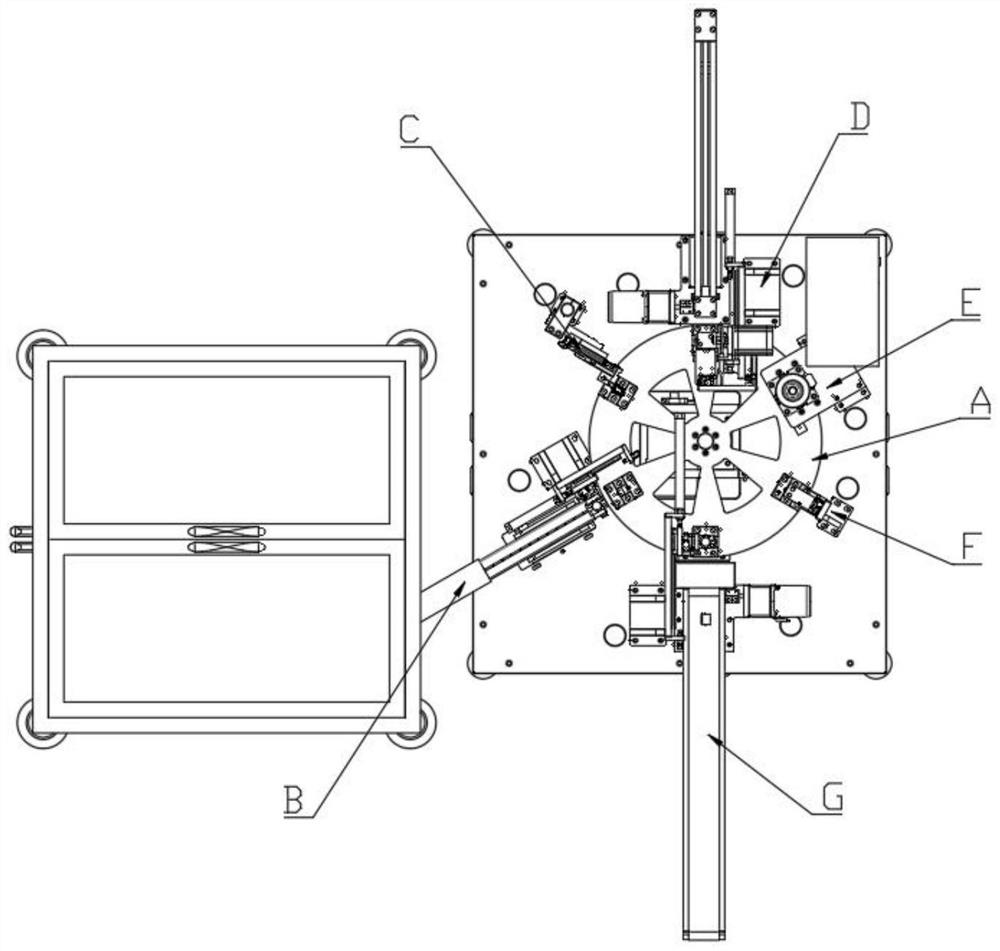

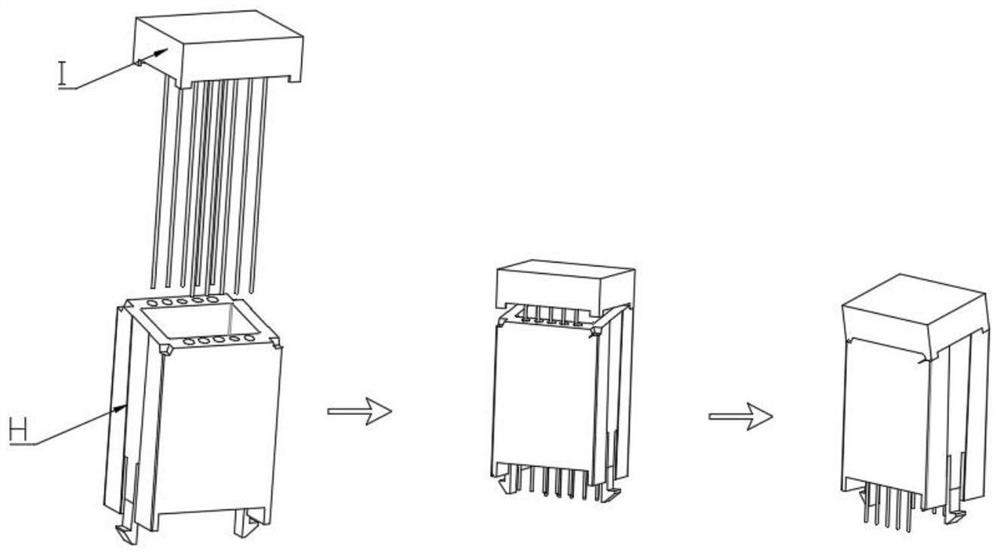

[0064] combined with Figure 1-2 , this embodiment discloses a digital tube assembling machine, including a main control box 1, an assembly workbench 2 arranged on the upper part of the main control box 1, and a feeding box 3 arranged on one side of the assembly workbench 2. On the assembly workbench 2 A rotating base mechanism A is provided, and a plurality of assembly bases 4 are arranged on the upper part of the rotating base mechanism A at equal distances in the circumferential direction, and a base feeding mechanism B and a base gluing mechanism corresponding to the positions of the assembly bases 4 are arranged outside the rotating base mechanism A. C. LED feeding mechanism D, pressing mechanism E, testing mechanism F and discharging mechanism G, the upper part of the rotating base mechanism A is arranged, the base feeding mechanism B, the base gluing mechanism C, the LED feeding mechanism D, the pressing mechanism The mechanism E, the testing mechanism F and the dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com