Automatic pull-out device for inner plastic part of cosmetics packaging material bottle lid

A technology for plastic parts and cosmetics, which is applied in the field of automatic pull-out devices for plastic parts in cosmetic packaging material bottle caps. The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

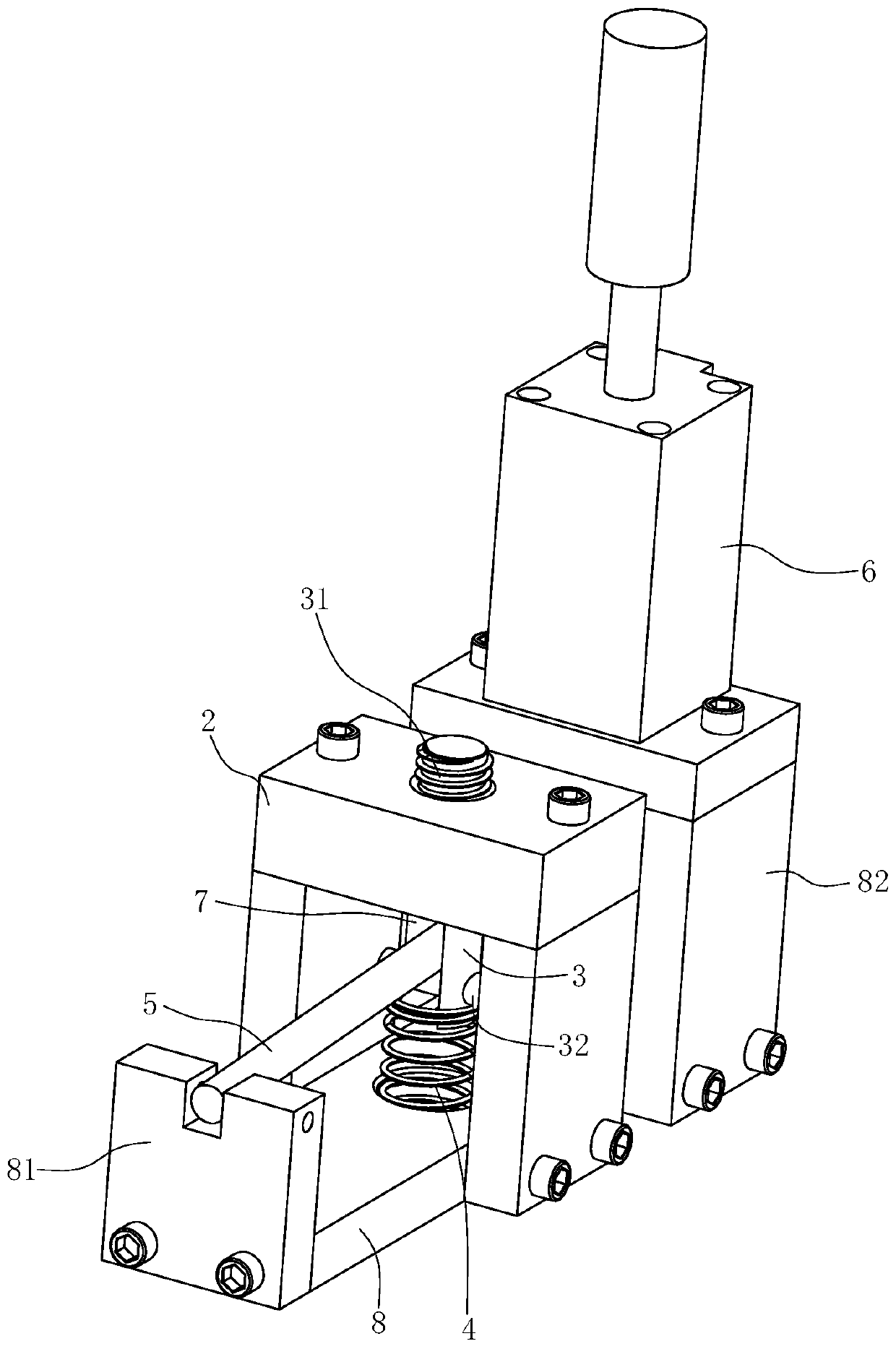

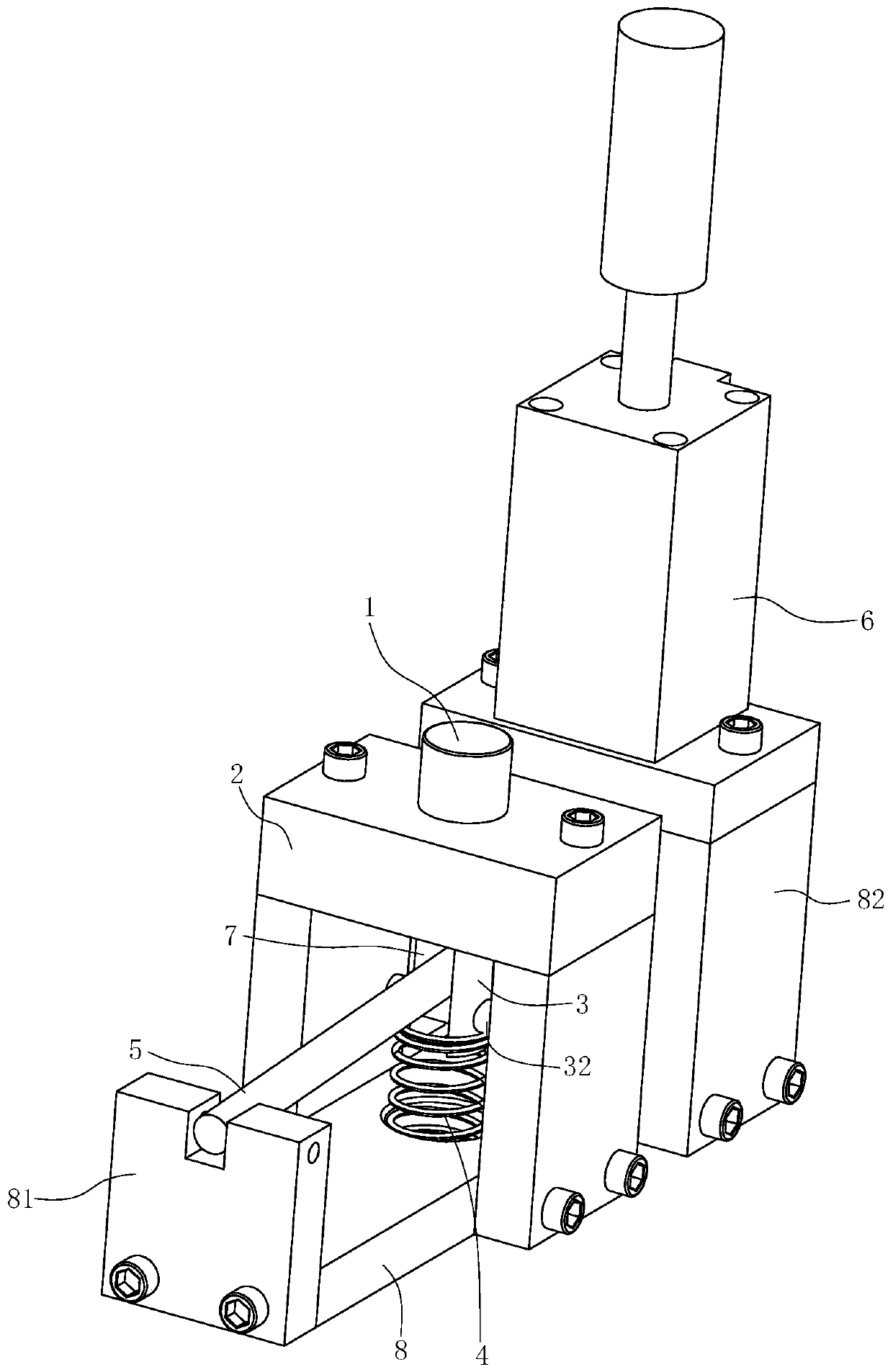

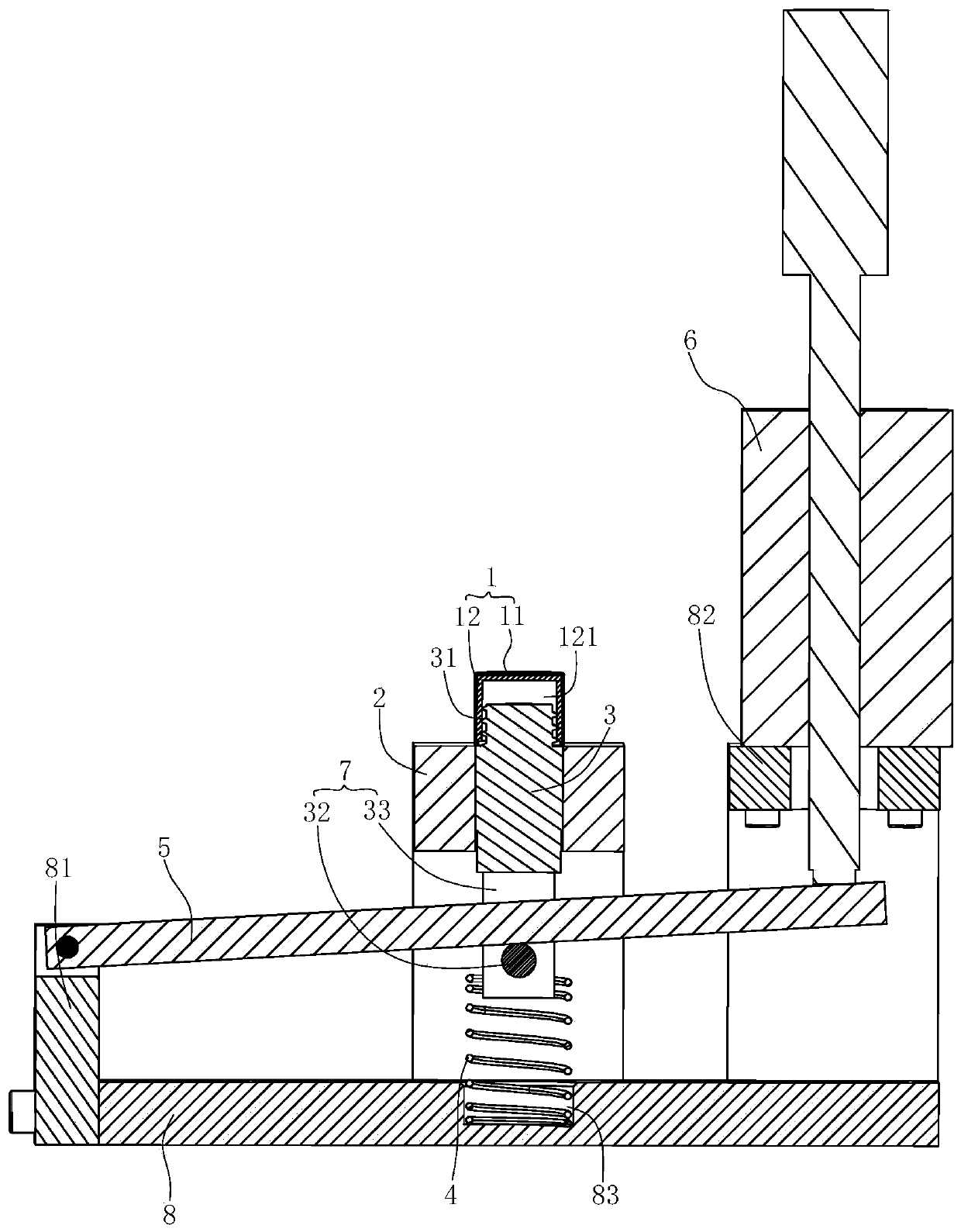

[0018] Such as Figure 1~4 Shown are the preferred embodiments of the present invention.

[0019] An automatic pull-out device for plastic parts in a cosmetic packaging material bottle cap. The cosmetic packaging material bottle cap 1 has an outer cover 11 and an inner plastic part 12 embedded therein, and the inner plastic part 12 has a threaded hole 121.

[0020] The device includes a support 2 and a discharge column 3. The upper end of the discharge column 3 has a threaded column portion 31 for threaded connection with the inner plastic part 12. The diameter of the threaded column portion 31 is smaller than the diameter of the discharge column 3. The diameter of the material column 3 is equal to or greater than the diameter of the inner plastic part 12. The bracket 2 is provided with a perforation 21 for the discharge column 3 to move through. The bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com