Foaming plate edge grinding machine

A technology of foamed sheet and edger, which is applied in the direction of grinding frame, machine tools suitable for grinding the edge of workpieces, and parts of grinding machine tools, etc. It can solve the problems of poor effect and uneven edge of the sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

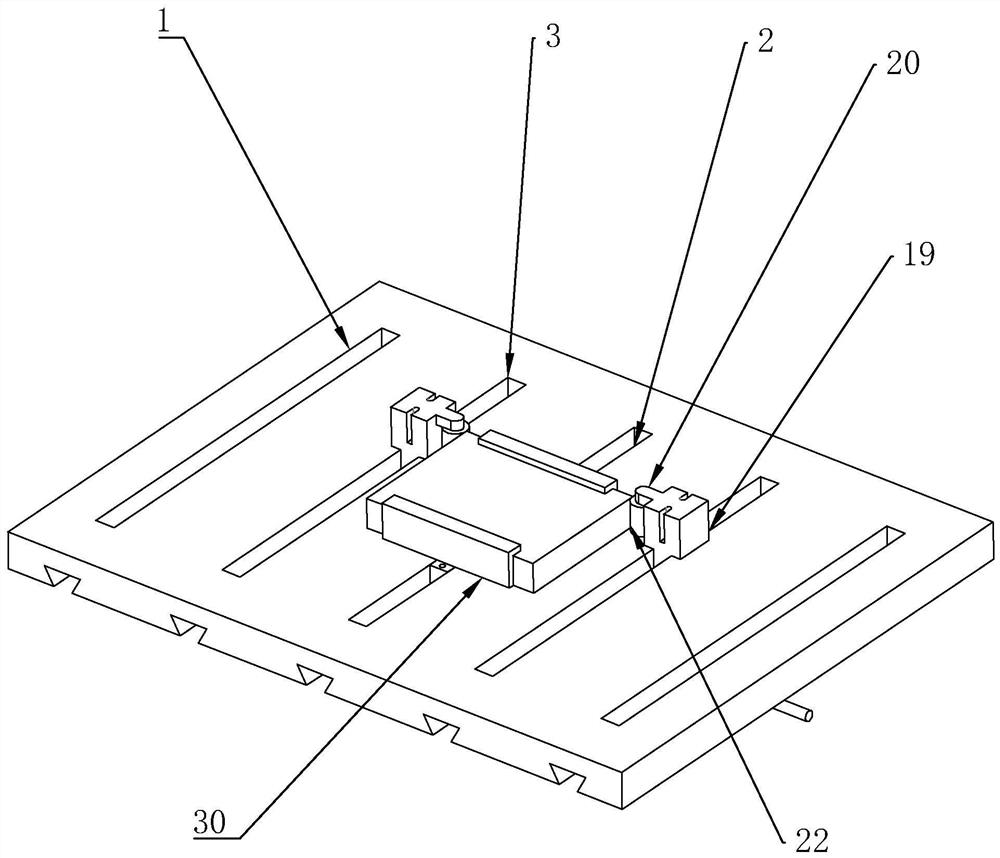

Examples

specific Embodiment approach

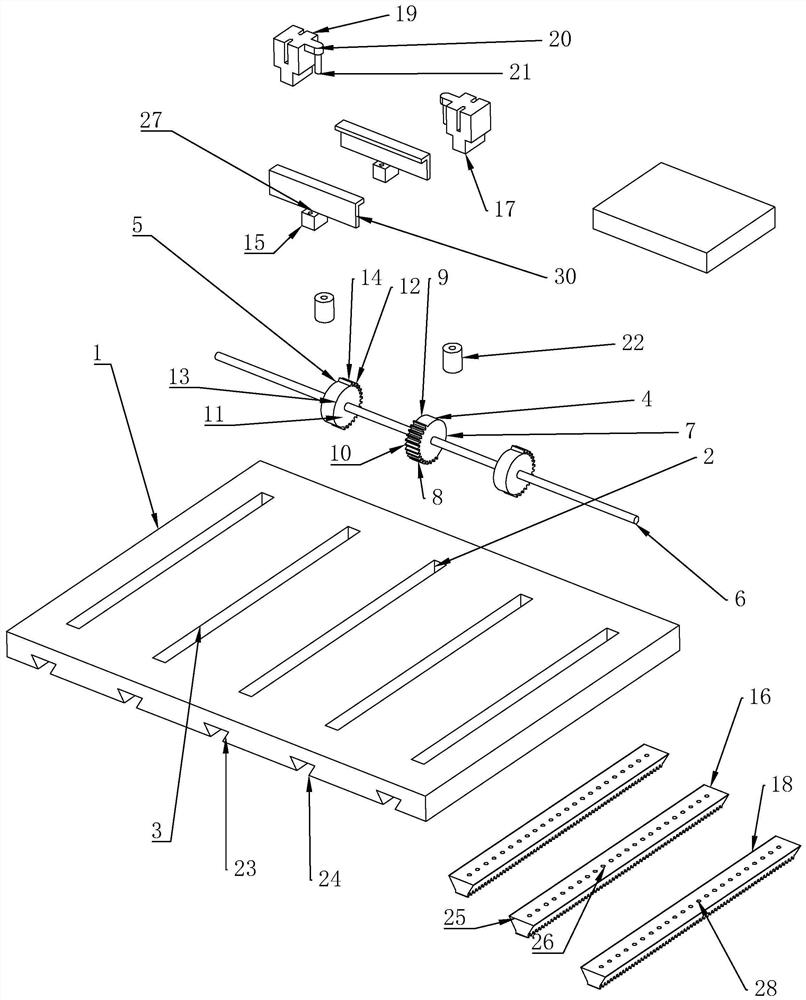

[0045] The first meshing teeth 10 account for one-half of the outer diameter of the first rotating disk 7;

[0046] The second meshing teeth 14 account for one-half of the outer diameter of the second rotating disk 11;

[0047] The projections of the first meshing teeth 10 and the second meshing teeth 14 do not overlap at all.

[0048] Through the above technical solution, both the first meshing teeth 10 and the second meshing teeth 14 occupy half of the first rotating disk 7 and the second rotating disk 11 , so that the smoothing process can be better connected without idling.

[0049] As an improved specific implementation,

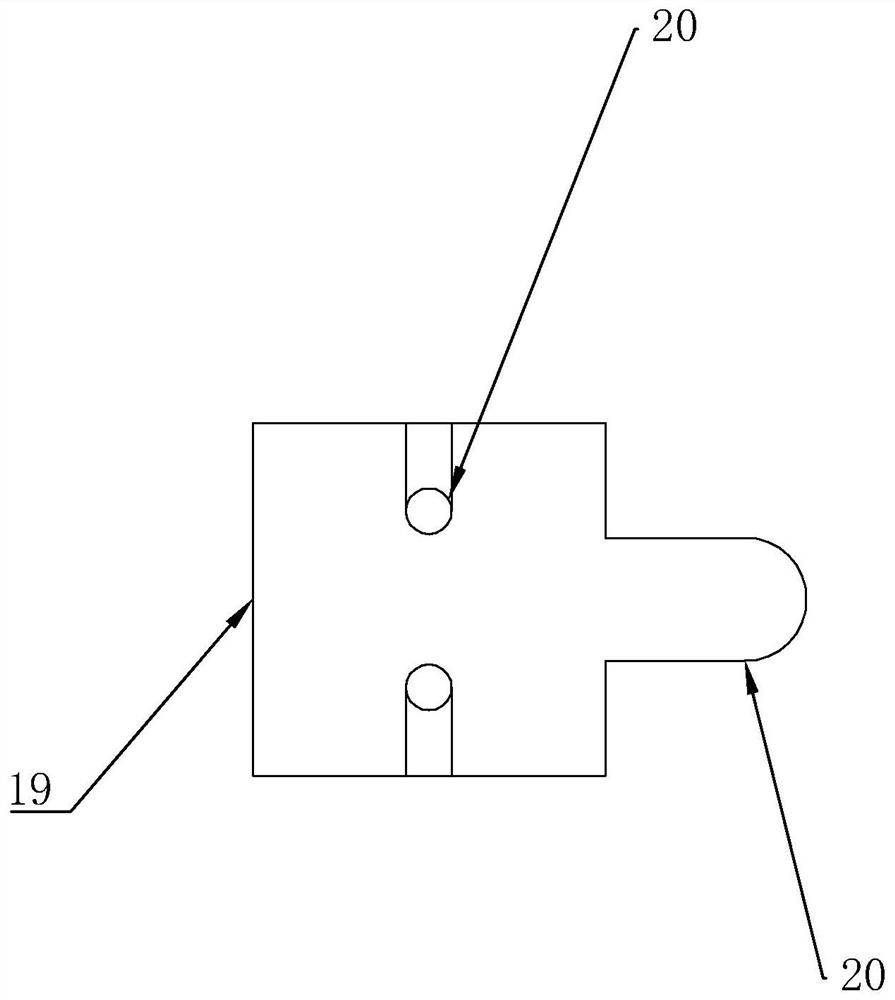

[0050] The edging mechanism includes a mounting table 19, and the mounting table 19 is provided with an extension plate 20 facing the direction of the fixing mechanism. The extension plate 20 is provided with a rotating shaft 21, and a grinding wheel 22 is provided on the rotating shaft 21.

[0051] Through the above technical solution, through the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com