Construction method for underground diaphragm wall under condition of irremovable underground obstacle

A technology for underground diaphragm walls and underground obstacles, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of high pipeline safety risks, difficult soil excavation, and large economic losses, so as to ensure the overall rigidity and The effects of stress safety on the foundation pit and prevention of the risk of falling apart

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

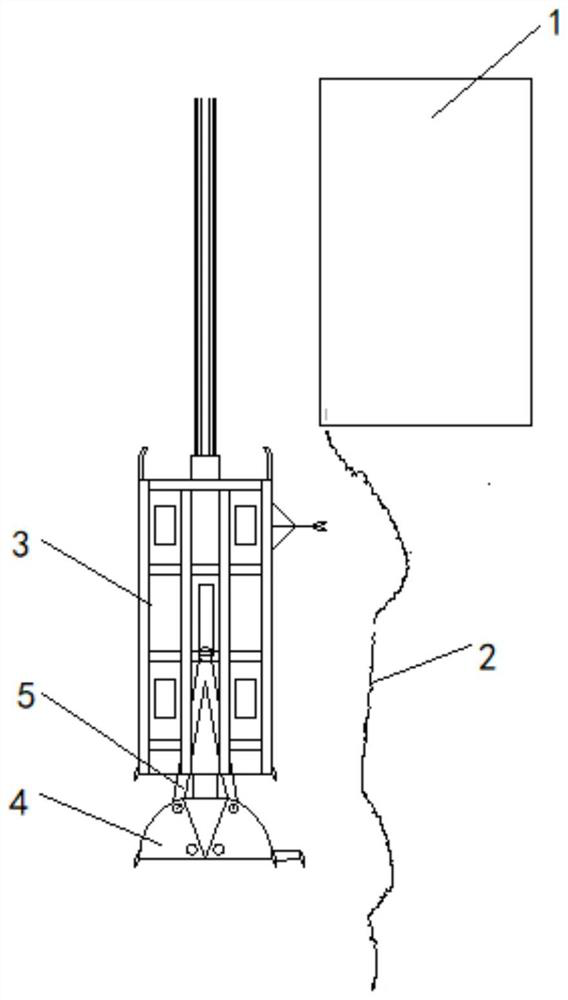

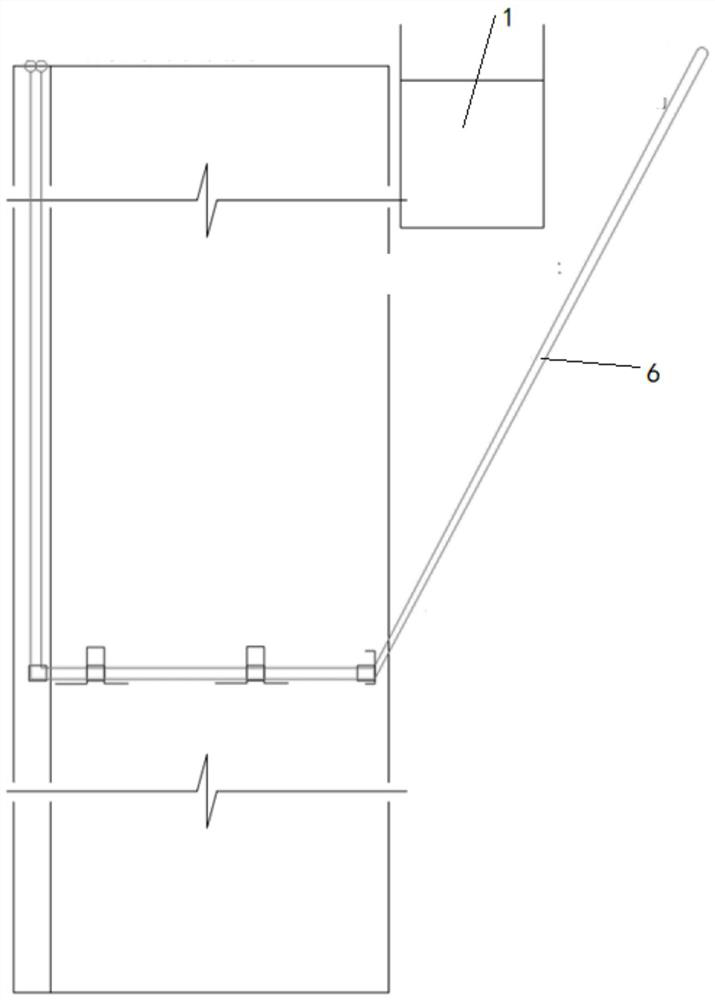

[0022] The present invention will be described in more detail below in conjunction with the accompanying drawings. It should be noted that the following description of the present invention with reference to the accompanying drawings is only illustrative rather than limiting. Different embodiments can be combined with each other to form other embodiments not shown in the following description.

[0023] The invention provides a construction method of an underground diaphragm wall under the condition of an unremovable underground obstacle, which is characterized in that it comprises the following steps:

[0024] Step 1. Make a deep guide wall to the bottom of the pipe gallery 1, and protect the pipe gallery with protective steel plates, specifically: use the method of hanging the well wall upside down to build a deep guide wall to the bottom of the pipe gallery, and use I-shaped steel skeleton and protection The steel plate connects the pipe gallery and the deep guide wall to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com