A prefabricated equipment for prefabricated building parts based on bim

A pre-fabricated, prefabricated technology, applied in the direction of stone processing equipment, work accessories, stone processing tools, etc., can solve problems such as impact, waste of resources, environment, drilling deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

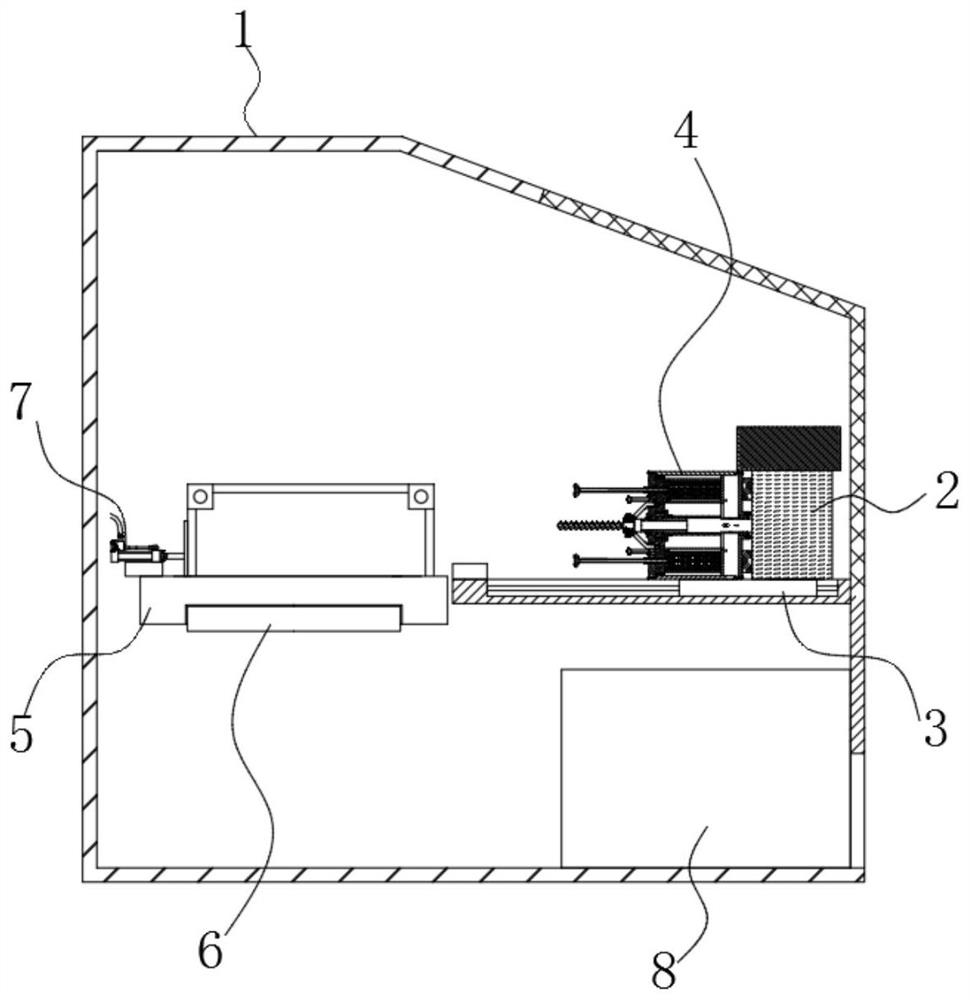

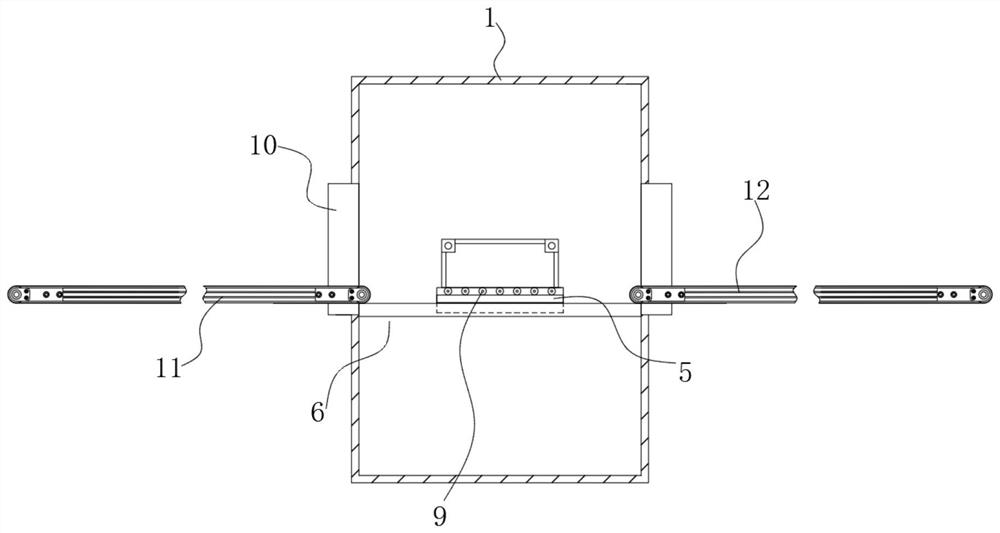

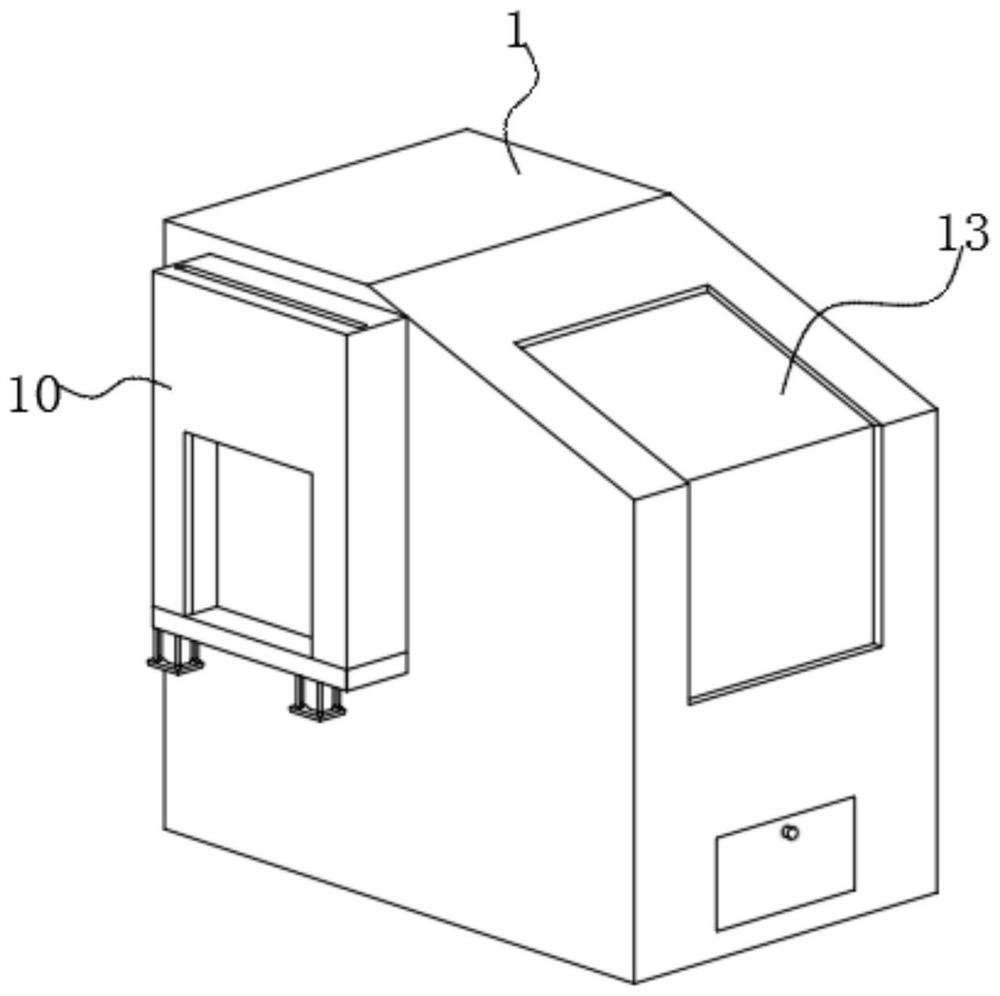

[0032] see Figures 1 to 7 , In the embodiment of the present invention, a BIM-based prefabricated equipment for prefabricated building parts includes a chassis 1, a drilling motor 2, a placement seat 5, a track plate 6, a feeding conveyor belt 11 and a discharging conveyor belt 12, wherein all the The front and rear sides of the chassis 1 are respectively provided with inlet and outlet ports, so that the infeed conveyor belt 11 and the outfeed conveyor belt 12 are correspondingly embedded therein. 6. The sliding seat 5 is used to transfer the aerated concrete placed on the seat 5. The driving method for driving the seat 5 to slide along the track plate includes a screw nut structure, a cylinder, an electric telescopic rod, etc. The air cylinder is used as the driving source, the telescopic end of the air cylinder is connected with the placing seat 5, the other end of the air cylinder is fixed on the side wall of the chassis, and the placing seat 5 is driven to slide along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com