Patents

Literature

37results about How to "Warranty limitations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

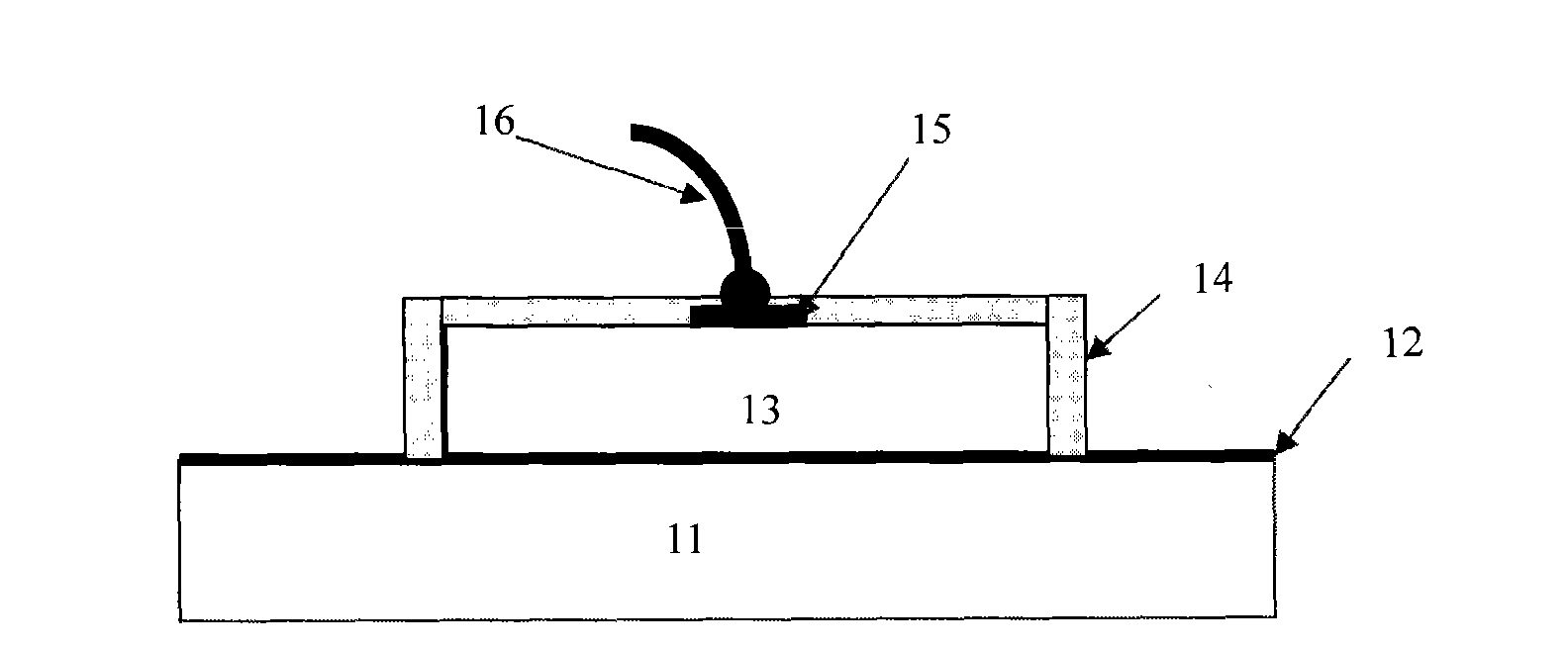

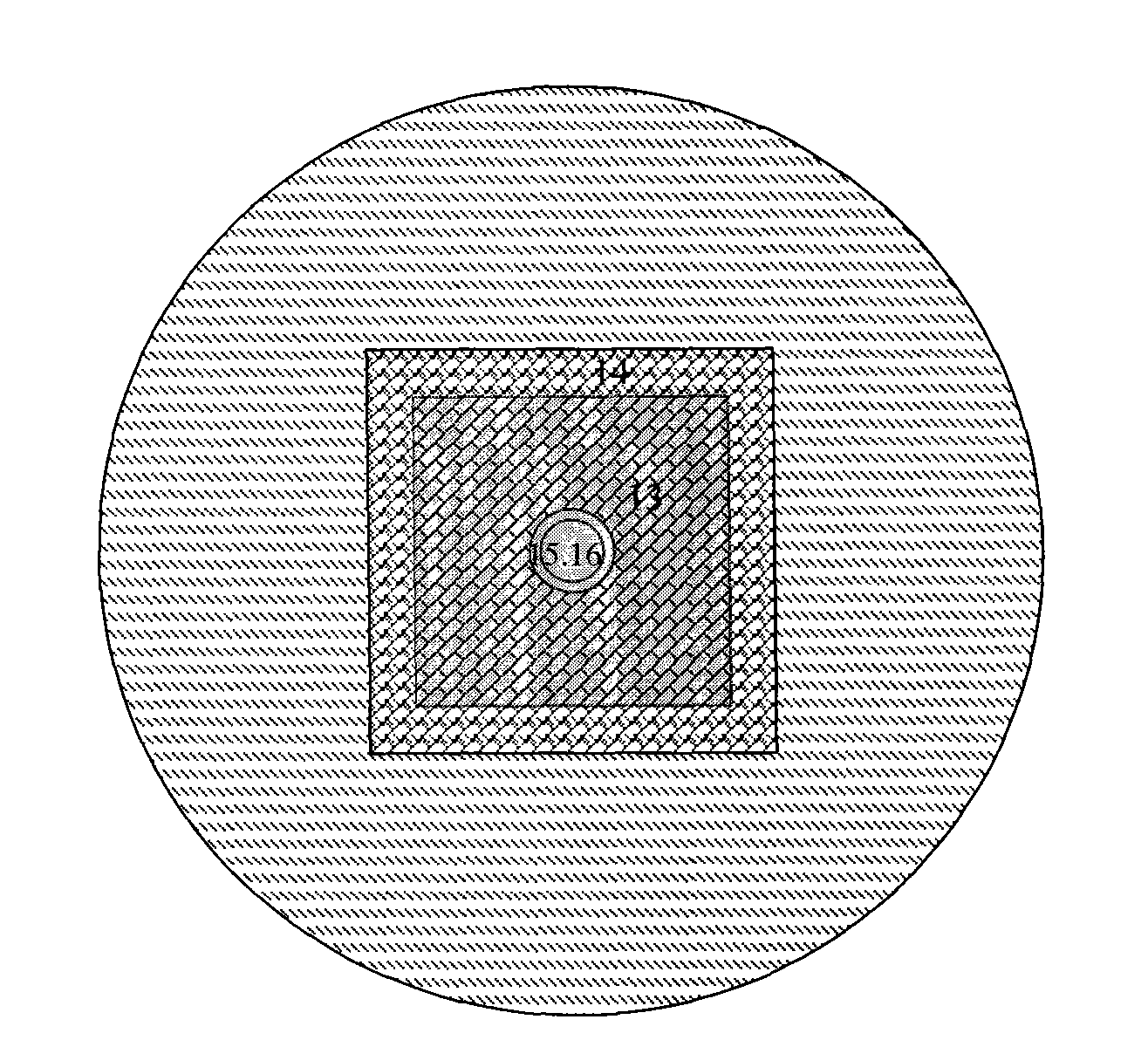

Method for packaging white LED locally sprayed with fluorescent powder and fluorescent powder local coating structure

InactiveCN101807659APrecise quantitative formationPromote wettingSolid-state devicesSemiconductor devicesFluorescenceEngineering

The invention discloses a method for packaging a white LED locally sprayed with fluorescent powder. The method comprises the following steps: after an LED chip is subjected to die bonding and wire bonding on a power bracket, putting the LED bracket into a die, and exposing the chip and an edge area; atomizing the sprayed fluorescent powder by using an atomizing nozzle of an automatic glue dispenser, and connecting fine fluorescent powder glue drops on the surface and side wall of the chip into a film; treating the surface of a heat sink of the bracket by using plasmas, and mainly converging the glue drops at the periphery of the chip; and forming a layer of uniform fluorescent powder glue film, and forming the local coating of the LED fluorescent powder after thermocuring or ultraviolet curing. The photochromic uniformity of the white LED is improved; and because the fluorescent powder forms the uniform coating layer on the surface and the side face of the chip through surface tension, the ratios of fluorescence excitation and chip emitting light in various directions are almost equal, and the photochromism is uniform.

Owner:江苏米优光电科技有限公司

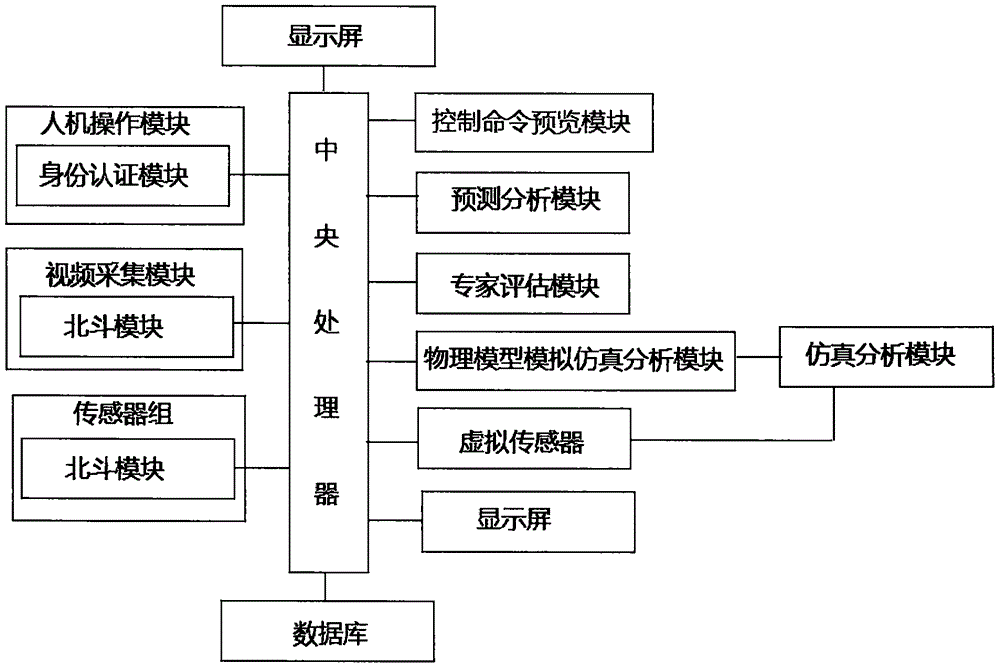

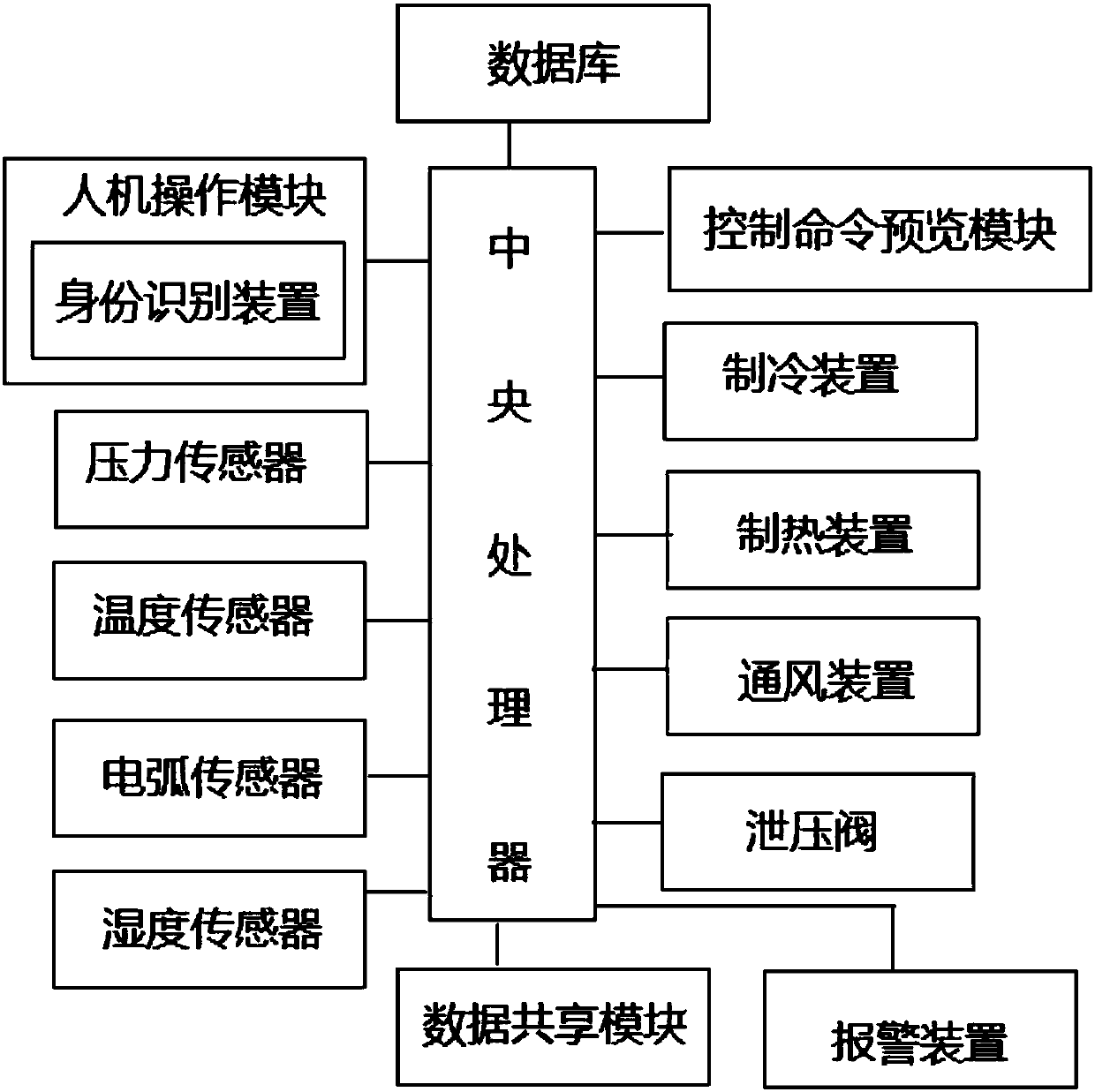

Electrical fire monitoring system

InactiveCN106355811AVisibleRealize real-time monitoringFire alarm electric actuationElectrical devicesPhysical model

The invention discloses an electrical fire monitoring system, comprising a human-machine operating module, a sensor set, a video collection module, a central processing unit, a control command preview module, a prediction analysis module, an expert estimation module, a physical model analog simulation analysis module, a simulation analysis module, and a virtual sensor. The use of multi-mode inputting manner provides great convenience for use; the input of each command is self-provided with authentication information, limiting system control rights is guaranteed, and the input of every control command is traceable; before confirmation of the output of each command, previewing the control command is required, and therefore, output errors of the control command are well avoided and every control command is visualized; real-time monitoring is provided for electrical equipment current and temperature, surroundings and the like, data estimation and analysis functions are self-provided to the system, and the technical problem that electrical fire detection is low in efficiency and poor in detection result is effectively solved; analog simulation analysis can be carried out for late development conditions of electrical equipment according to detected data.

Owner:HENAN UNIV OF URBAN CONSTR

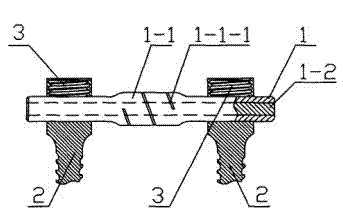

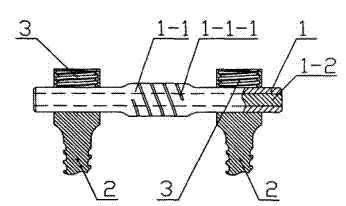

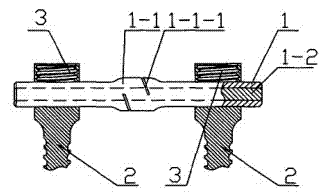

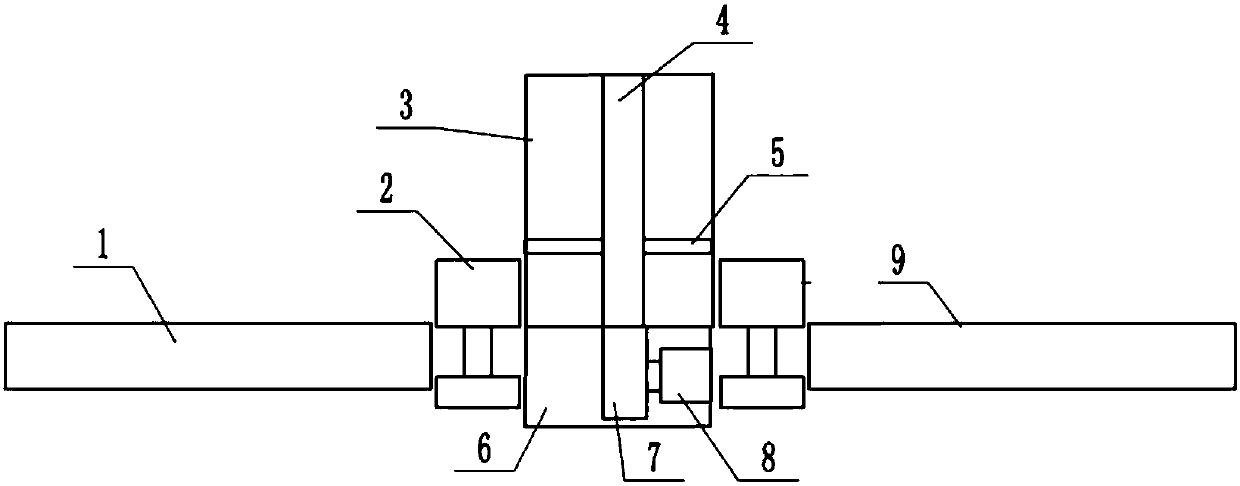

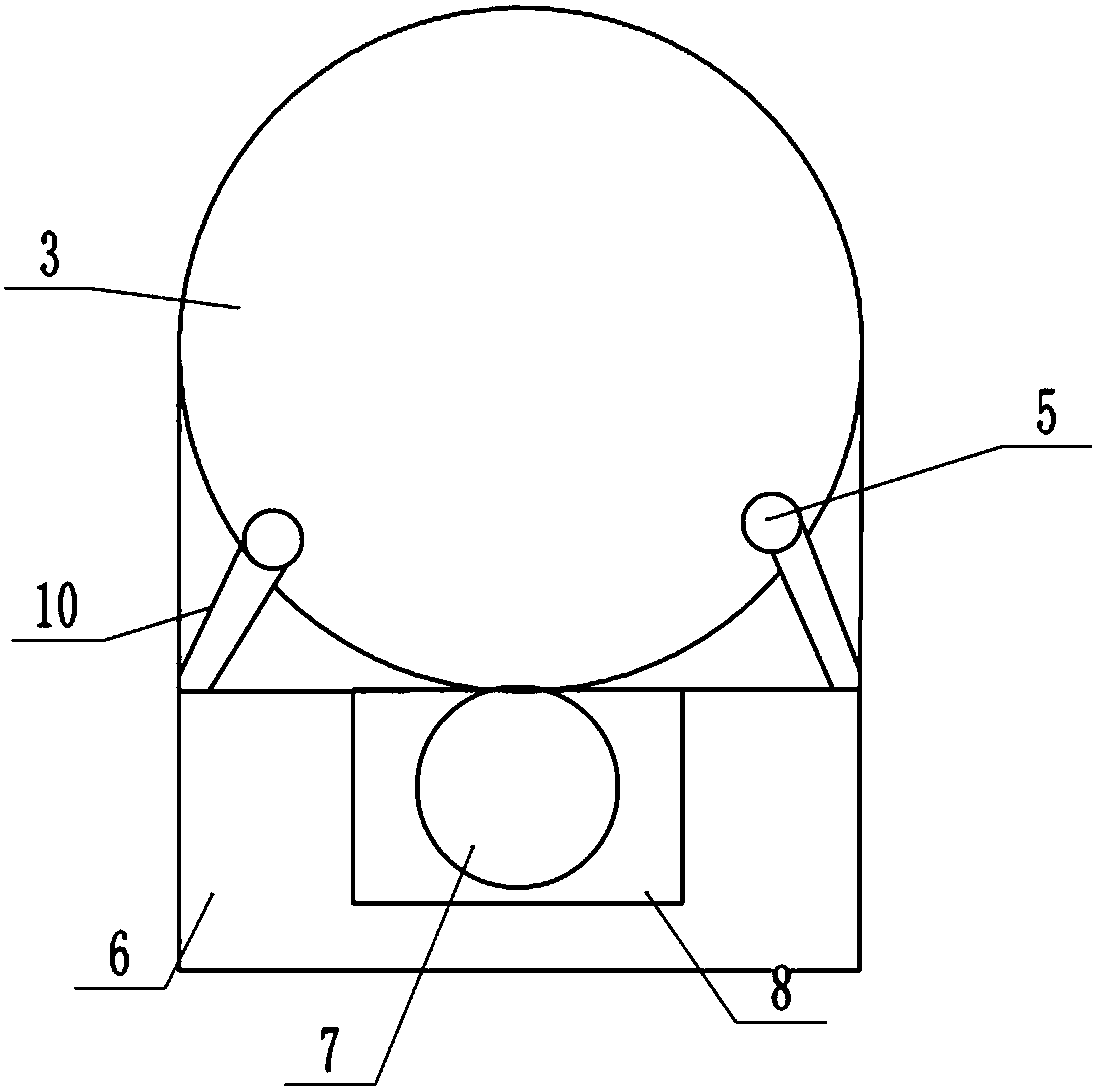

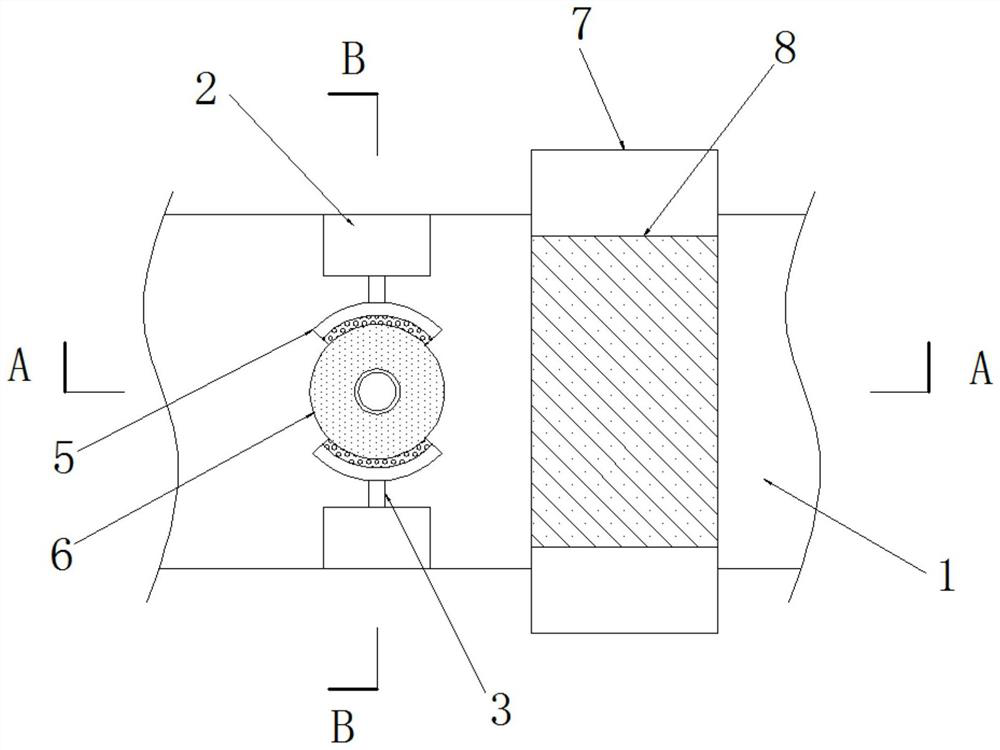

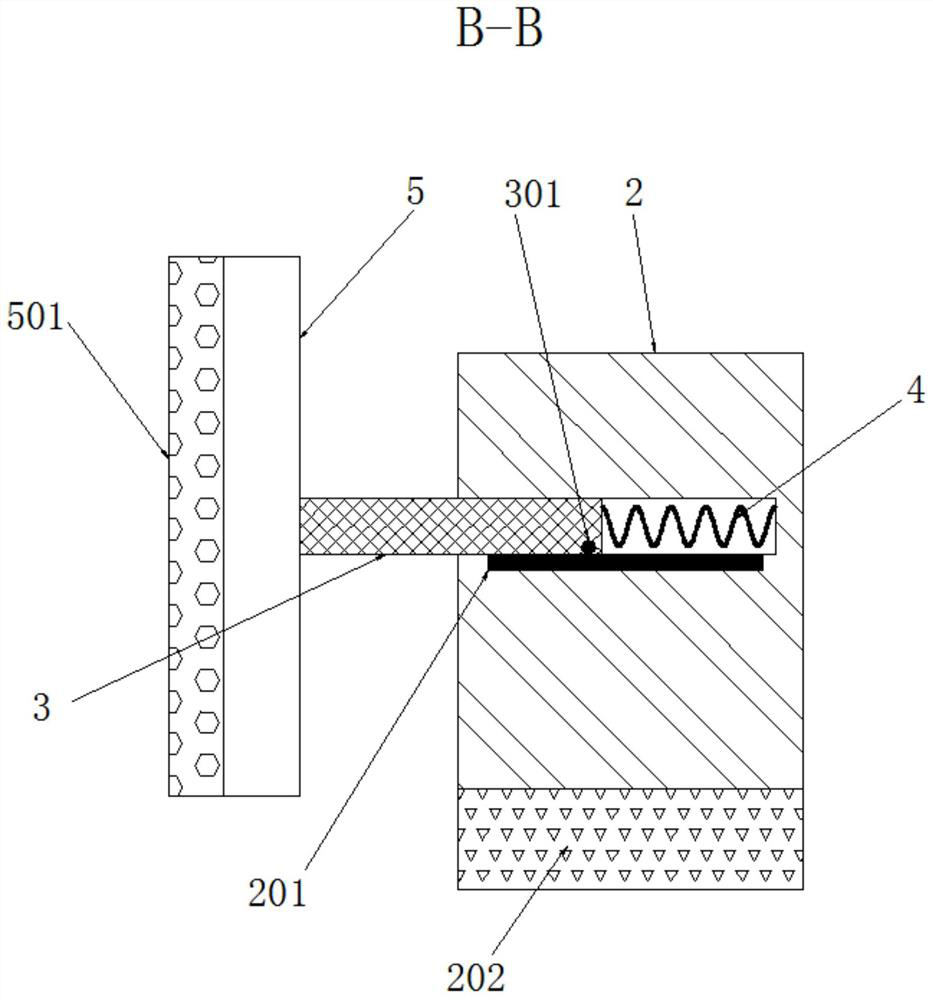

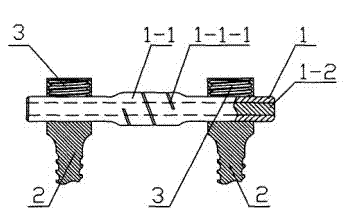

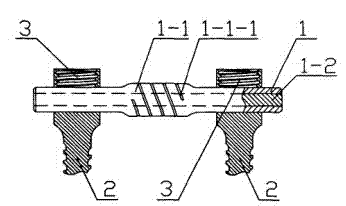

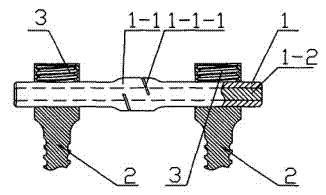

Dynamic lumbar vertebra fixing system

ActiveCN102362816AImprove rigidityIncrease elasticityInternal osteosythesisSpinal columnLumbar vertebrae

The invention discloses a dynamic lumbar vertebra fixing system. The dynamic lumbar vertebra fixing system comprises a dynamic rod (1), and at least two pedicle screws (2) connected to the dynamic rod (1), wherein the upper part of each pedicle screw (2) has a cavity; a screw bolt (3) is arranged in the cavity and is in threaded connection with the pedicle screw (2); the dynamic rod (1) passes through the cavity in the upper part of the pedicle screw (2); the screw bolt (3) in the cavity presses the dynamic rod (1); the dynamic rod (1) is a hollow rod; an elastic core shaft (1-2) is inserted into a hole of the dynamic rod (1); at least one section of lead screw part (1-1) of which the diameter is larger than those of two sides is arranged on an excircle of the dynamic rod (1); and more than one circles of lead threads (1-1-1) are arranged on the lead screw part (1-1). The dynamic lumbar vertebra fixing system can return a lumbar segment to a normal three-dimensional line and keep the normal height of a lumbar disc well, allows the limited movement of a spinal column and well accords with the physiological stability of the spinal column, so that the effects of relieving pains and preventing regression of neighboring segments are achieved.

Owner:瞿玉兴

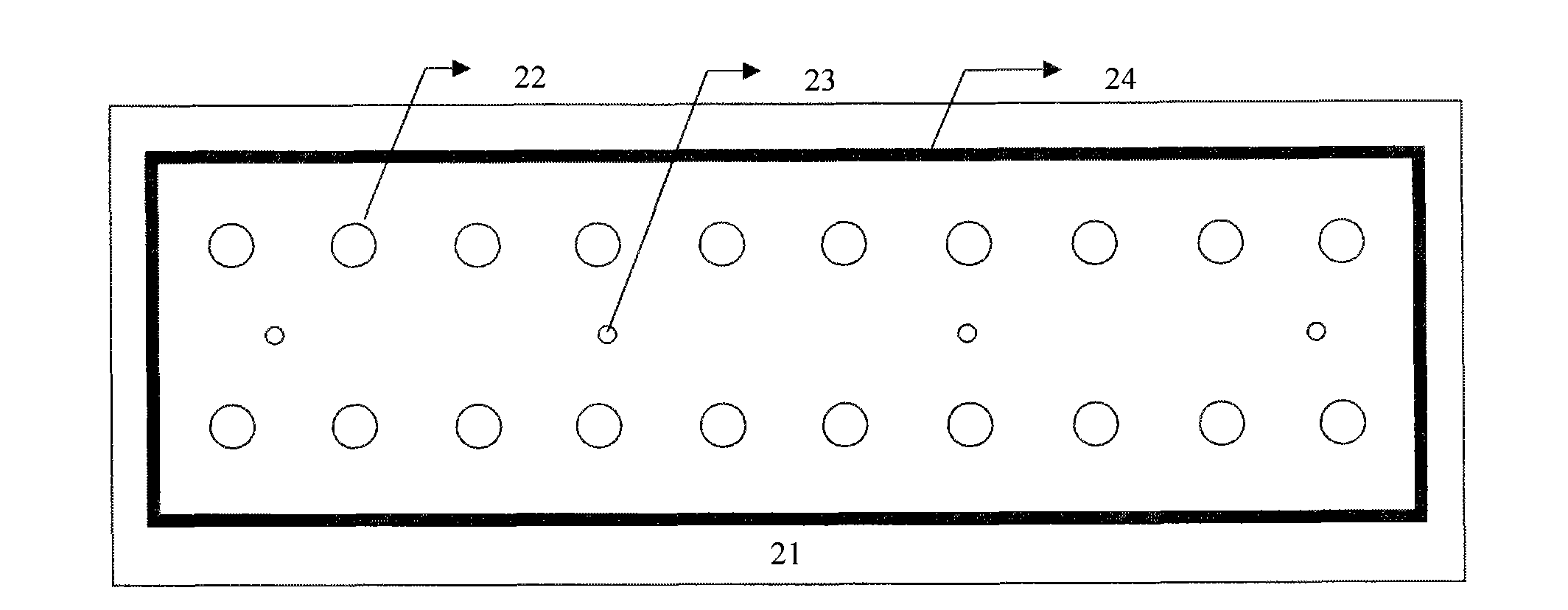

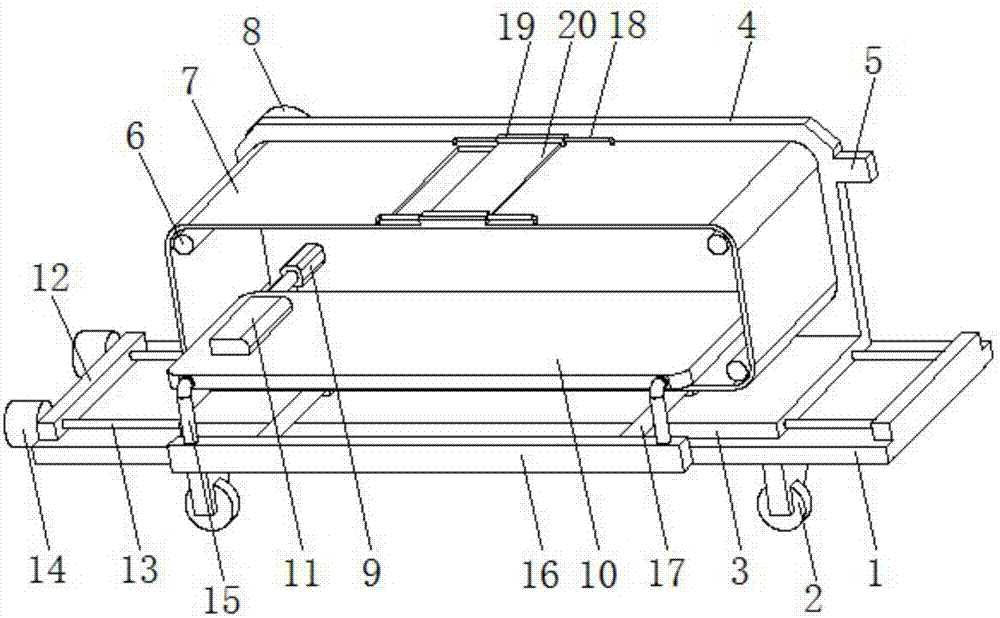

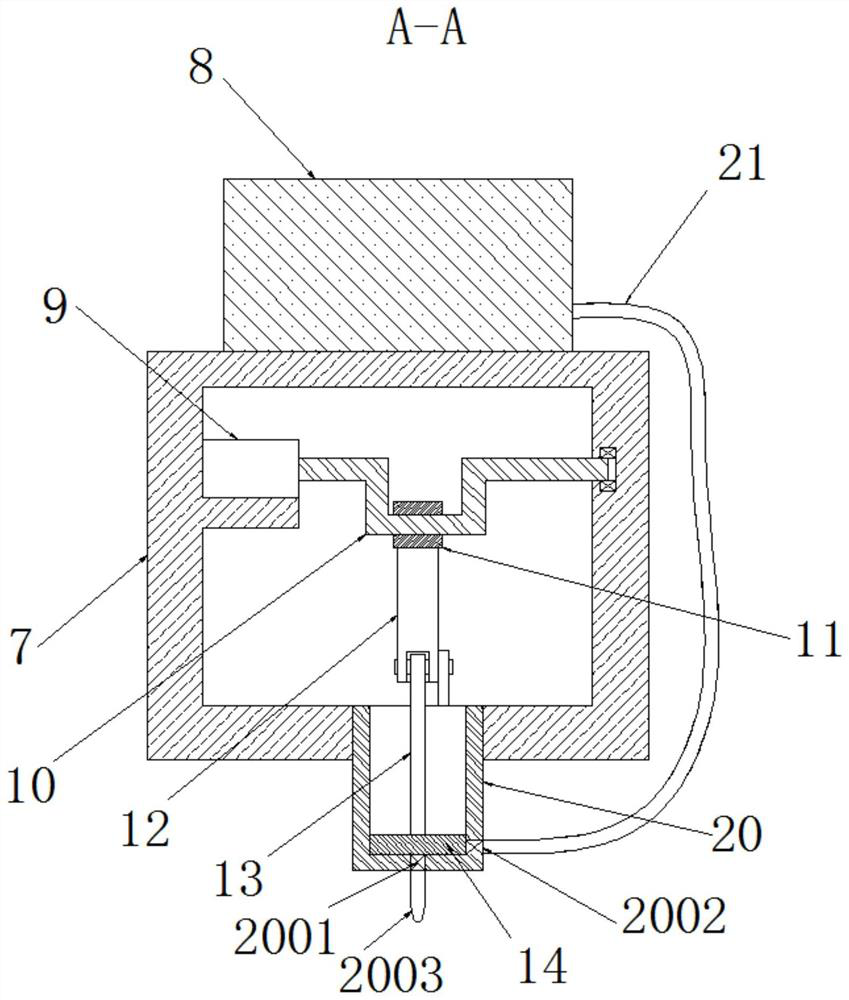

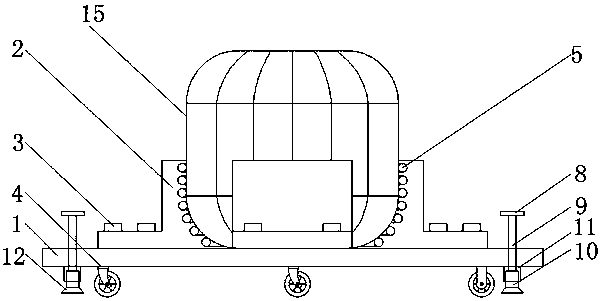

CT scanning radiation protecting bed

ActiveCN107468270ASimple structureEasy to installPatient positioning for diagnosticsComputerised tomographsCt scannersEngineering

The invention discloses a CT scanning radiation protecting bed. The CT scanning radiation protecting bed comprises a base plate. Idler wheels are installed at the four corners of the lower surface of the base plate through wheel frames respectively; a sliding base in sliding connection with the base plate is arranged on the upper surface of the base plate, a side plate perpendicular to the sliding base is fixed onto the lateral side of the sliding base, and a control switch is installed on the right lateral side of the side plate. The CT scanning radiation protecting bed is simple in structure, a rectangular detection hole is a hole corresponding to a CT scanner, the body portions, free of detection, of a patient are isolated through a protecting cover, the ray permeation limitation is guaranteed, the absorption dose of rays is reduced, and injury, of CT scanning, to the human body is reduced; a bed plate can be laterally pulled, convenience is brought to lying of the patient, comfortability is improved, and meanwhile space is saved; the effective area of the rectangular detection hole can be adjusted by changing the position of the protecting cover and conveniently adapts to CT scanning of different portions and different pieces of tissue, the CT scanning radiation protecting bed can be effectively matched with the CT scanner for installation, and usage is more convenient.

Owner:杨自力

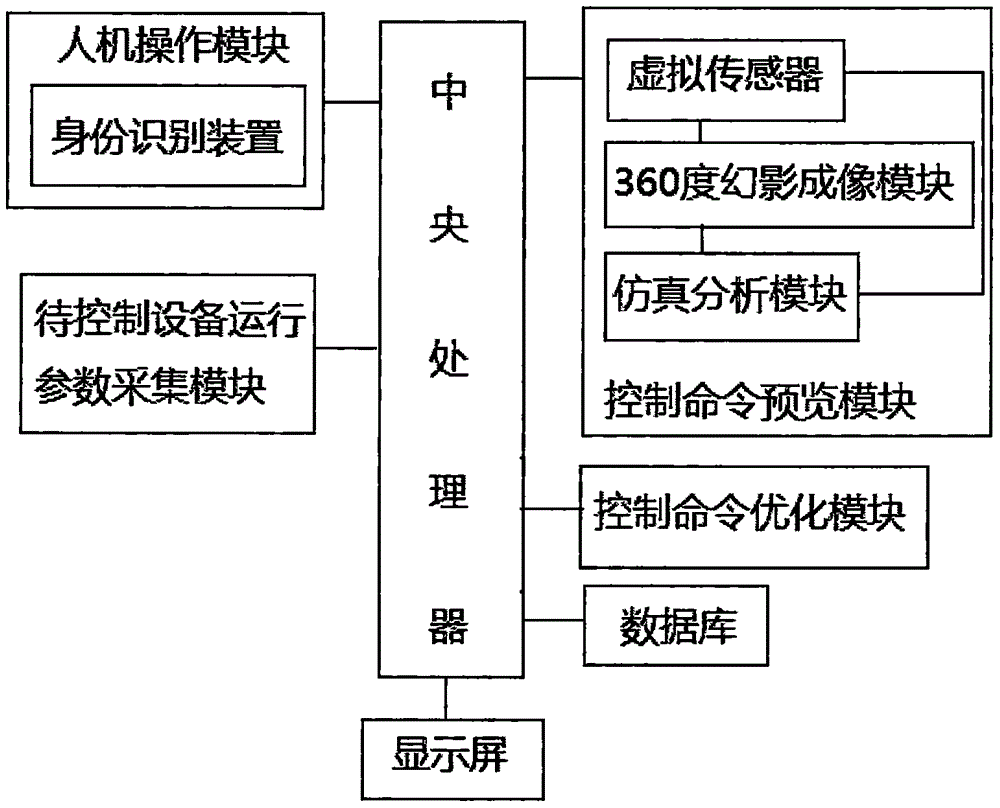

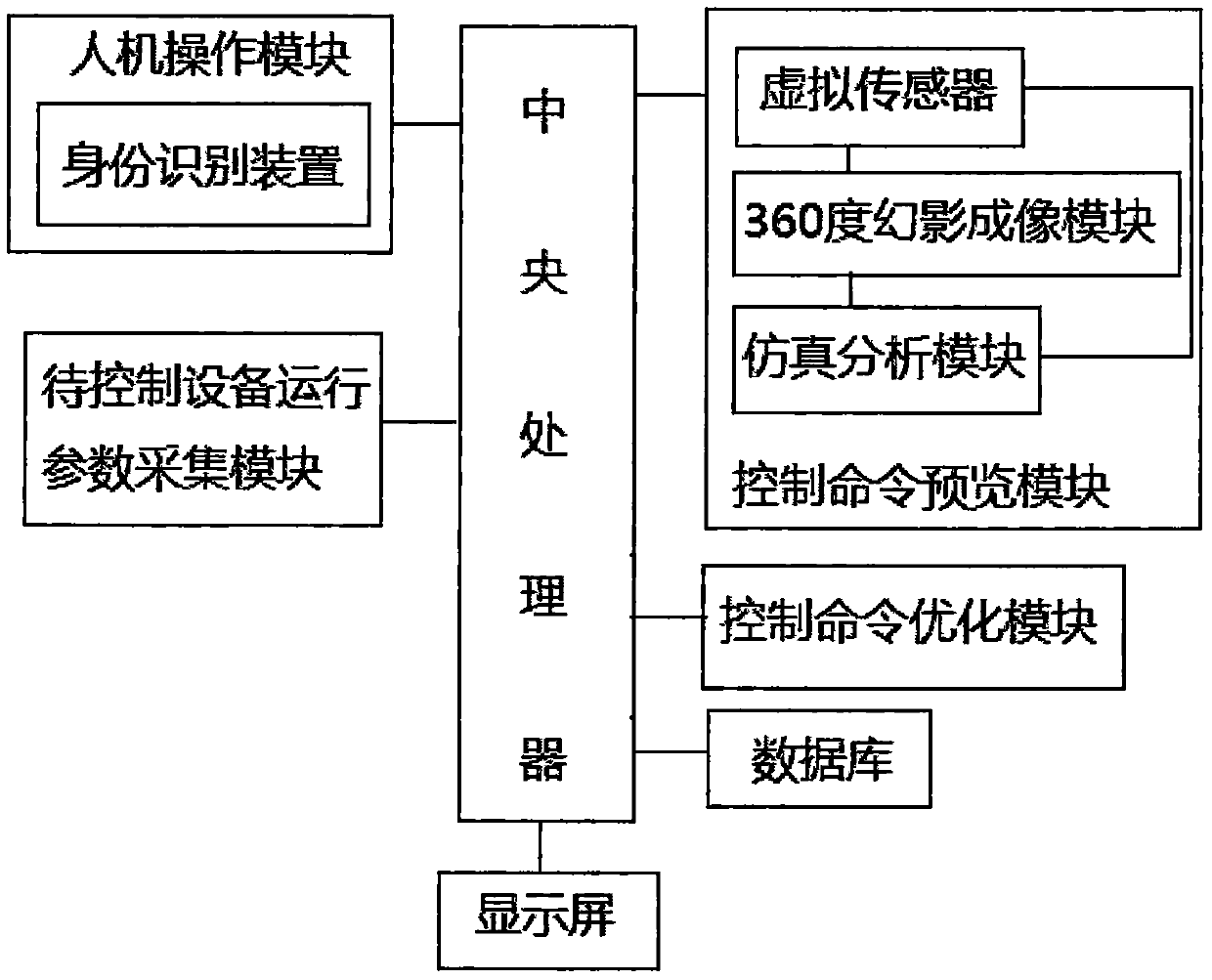

Electrical automation control system

ActiveCN105867279ARealize real-time monitoringEasy to useProgramme controlComputer controlControl systemMan machine

The invention discloses an electrical automation control system. The electrical automation control system comprises a man-machine operating module, a to-be-controlled equipment operating parameter acquisition module, a central controller, a control command previewing module and a control command optimizing module. Multiple input modes are adopted, great convenience is brought to use, and input of each command carries identity authentication information; on the one hand, limitation of system control authority is guaranteed, and on the other hand, input of each control command has traceability; each control command needs to be previewed before being confirmed to be output, so that output errors of the control commands are well avoided, and each control command has visuality; real-timing monitoring on the operating condition of to-be-controlled equipment is achieved, therefore, output of each control command can achieve optimal parameter adjustment, pertinence is high, and the generation efficiency is improved to a certain degree.

Owner:黑龙江省农业机械工程科学研究院佳木斯农业机械化研究所

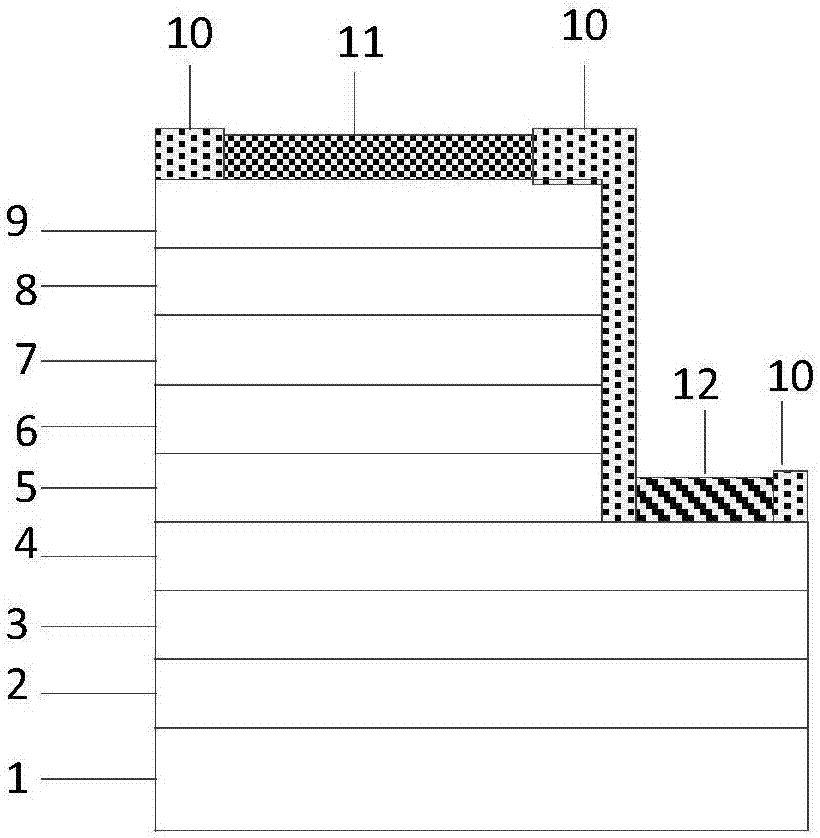

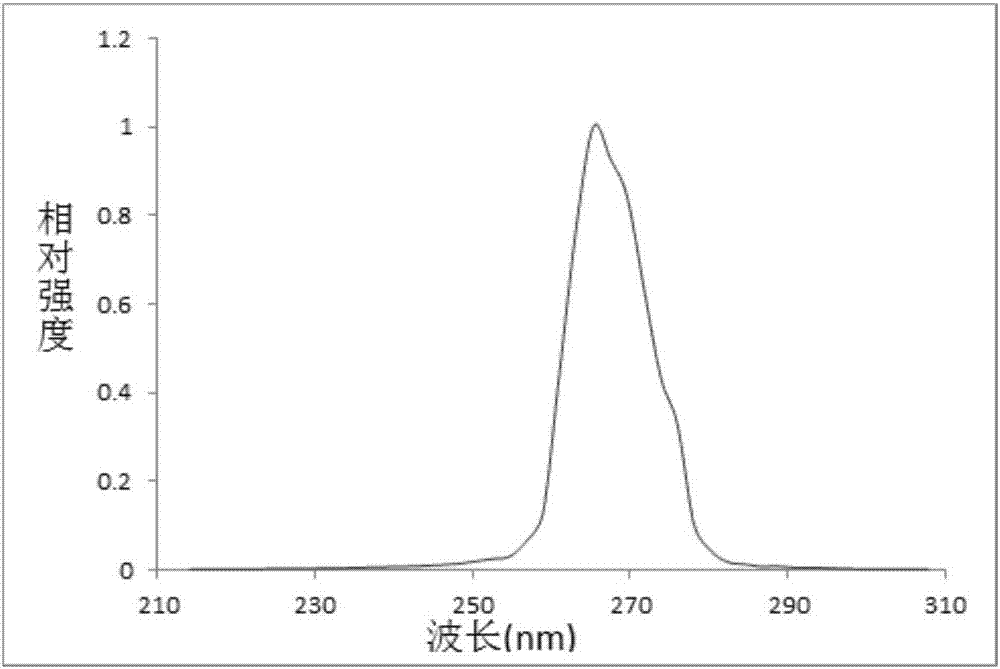

Deep ultraviolet LED epitaxial structure and fabrication method thereof

PendingCN106981548AGuaranteed crystal qualityImprove luminous efficiencySemiconductor devicesChemistryUltraviolet

The invention discloses a deep ultraviolet LED epitaxial structure and a fabrication method thereof. The deep ultraviolet LED epitaxial structure comprises a substrate, wherein a nucleating layer is grown on the substrate, a buffer layer is grown on the nucleating layer, an n-type AlGaN layer, a periodic structure AlGa<1-a>N / GaN current extension layer, a periodic structure AlGa<1-b>N / Al<c>Ga<1-c>N light-emitting layer, a periodic structure AlN / Al<d>Ga<1-d>N barrier layer, a periodic structure Al<e>Ga<1-e>N / GaN barrier layer and a p-type GaN layer are sequentially grown on the buffer layer, a Al<e>Ga<1-e>N layer in a Al<e>Ga<1-e>N / GaN barrier layer 8 is a unintentional doping layer, and a GaN layer is a Mg-doped layer. The periodic structure Al<e>Ga<1-e>N / GaN barrier layer is employed, Al<e>Ga<1-e>N is the unintentional doping layer, the GaN layer is the Mg-doped layer, holes are successfully introduced to the light-emitting layer by a memory effect of Mg and hole tunneling, electrons can be limited in the light-emitting layer by the barrier layer, the crystal quality of the barrier layer is also ensured, and the light-emitting efficiency is higher.

Owner:ZEARAY WUHAN OPTOELECTRONICS TECH CO LTD

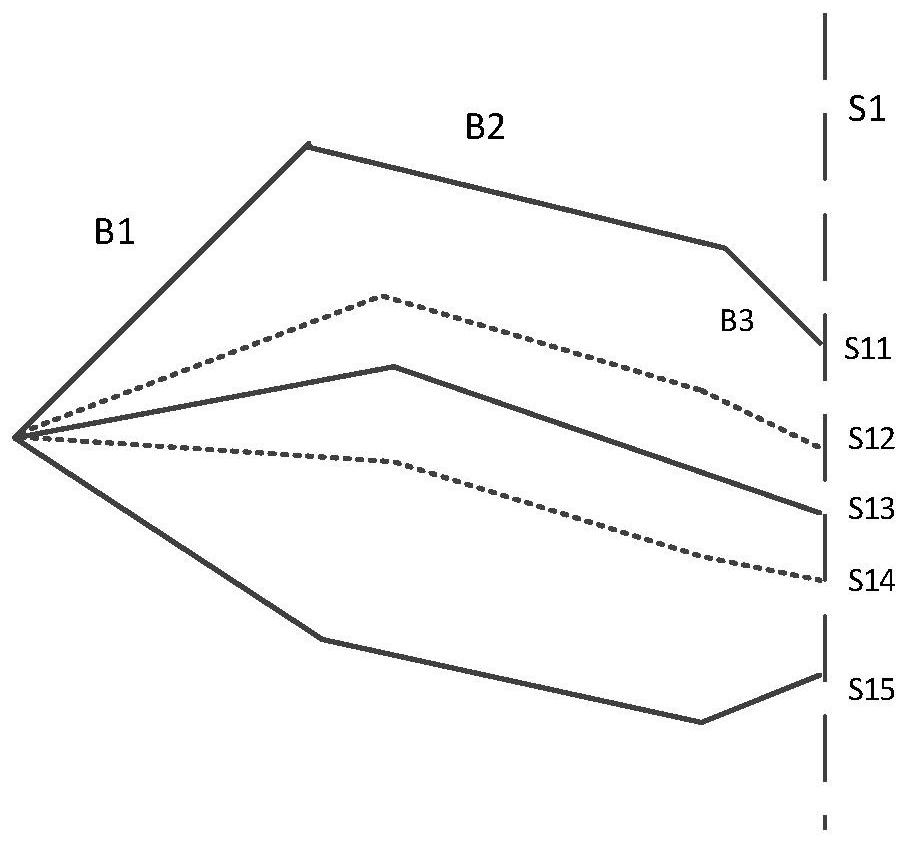

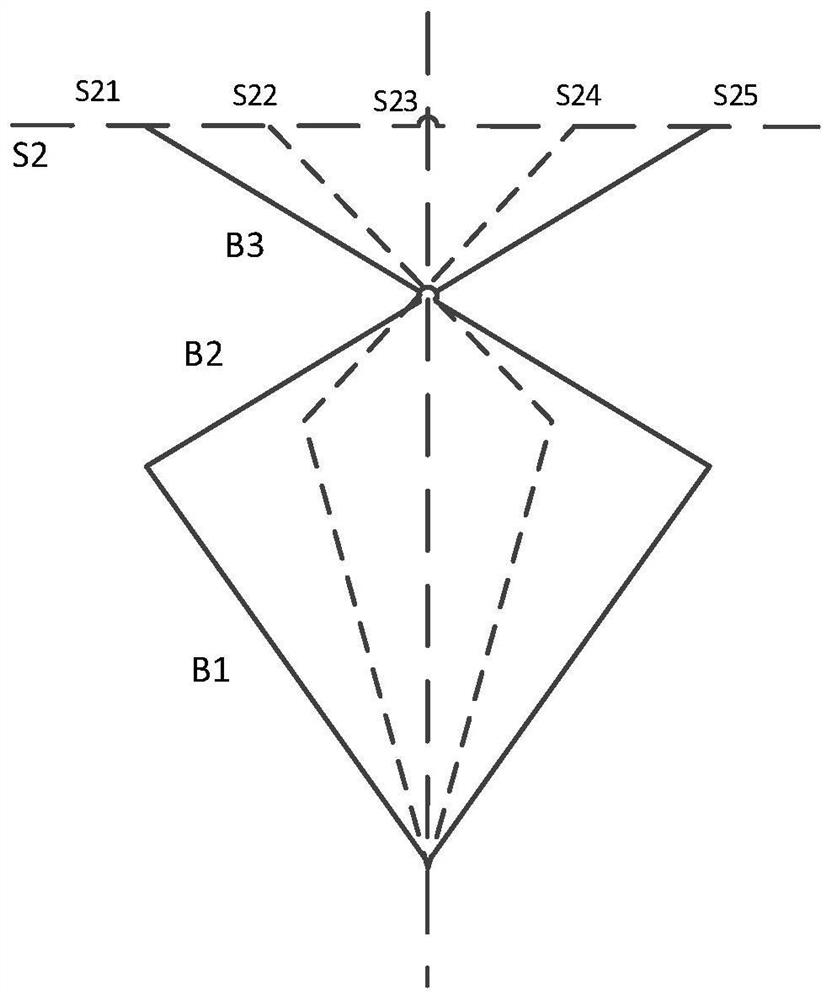

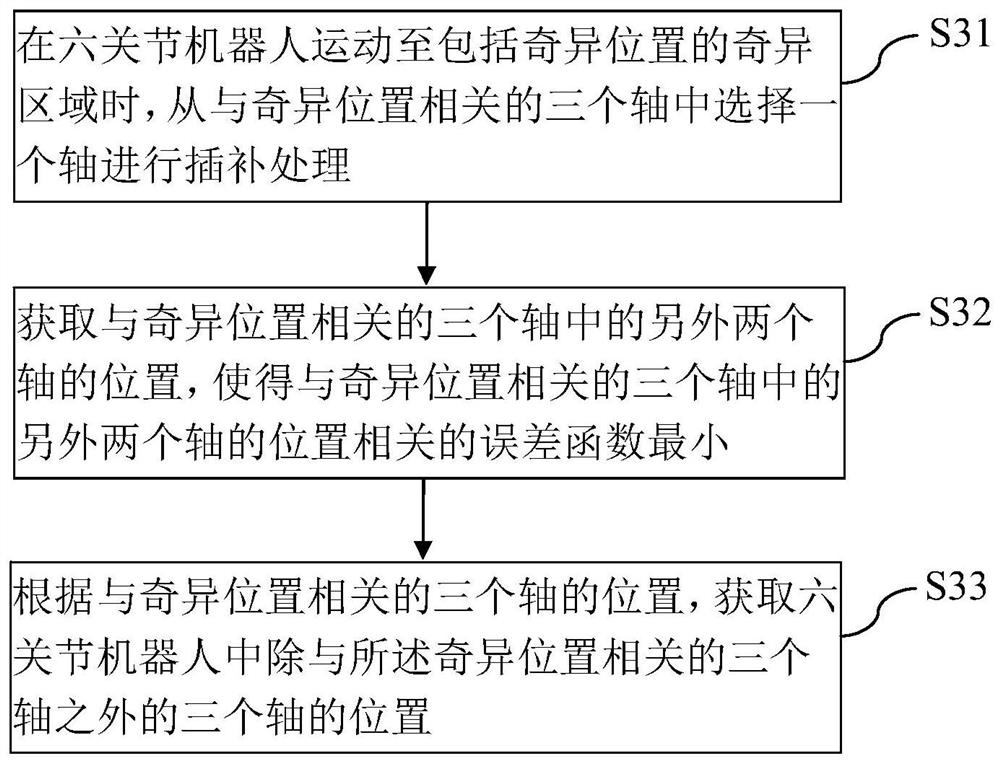

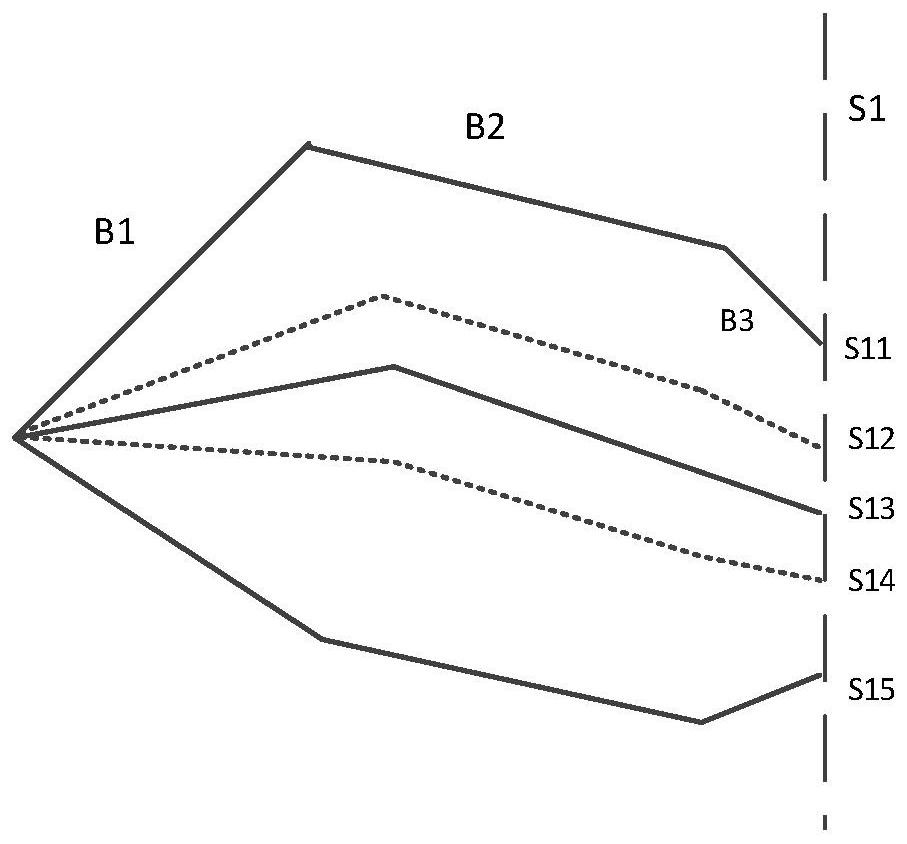

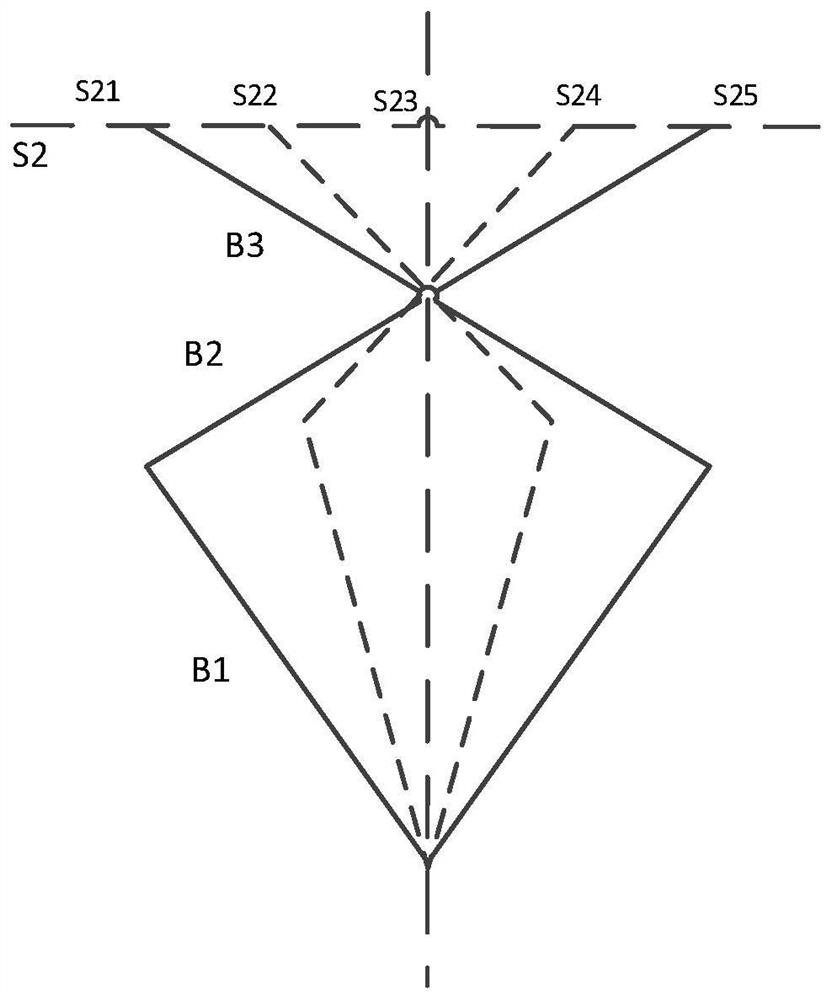

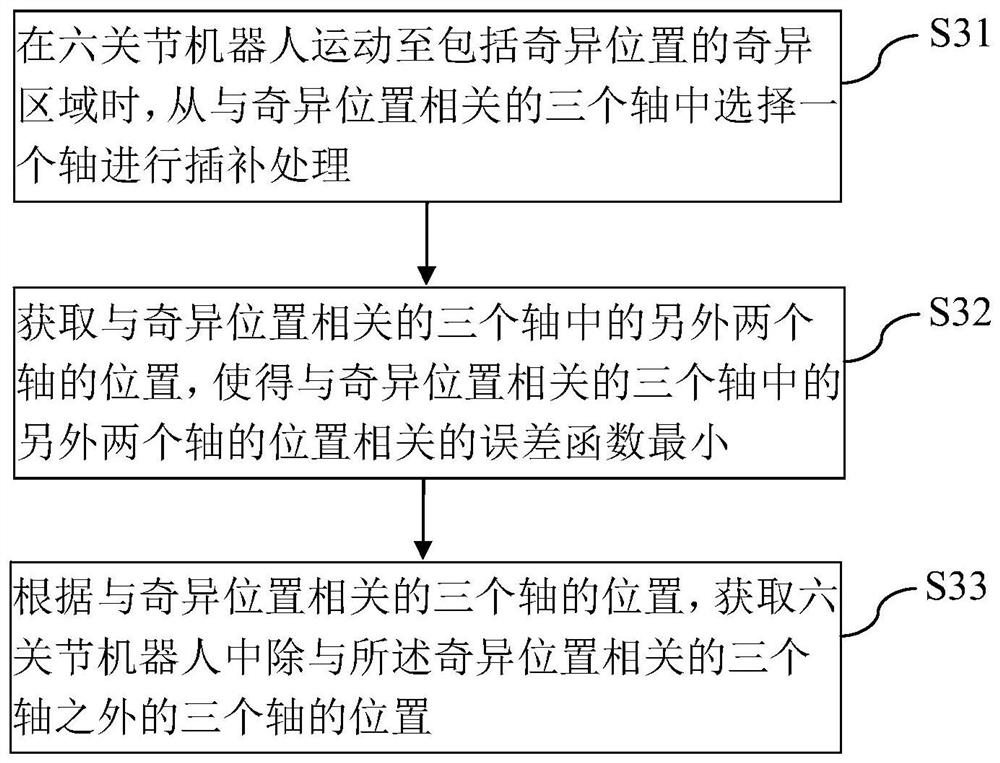

Singular position avoidance method, system and device, and computer readable storage medium

ActiveCN112405525AGuaranteed continuityWarranty limitationsProgramme-controlled manipulatorSimulationComputer vision

The invention provides a singular position avoidance method, system and device, and a computer readable storage medium which are used for controlling a six-joint robot to cross a singular position from a track starting point to move to a track end point. The method comprises the following steps: when the six-joint robot moves to a singular region comprising the singular position, one axis is selected from the three axes related to the singular position for interpolation processing; the positions of the other two axes in the three axes related to the singular position are obtained, and the error functions related to the positions of the other two axes in the three axes related to the singular position are enabled to be the minimum; and according to the positions of the three axes related tothe singular position, the positions of the three axes, except the three axes related to the singular position, in the six-joint robot are obtained. According to the embodiment of the invention, highreal-time performance and low calculation amount are achieved, and no reduction of the Cartesian speed at the tail end, and high track precision in the whole movement process can be ensured.

Owner:SHENZHEN INOVANCE TECH

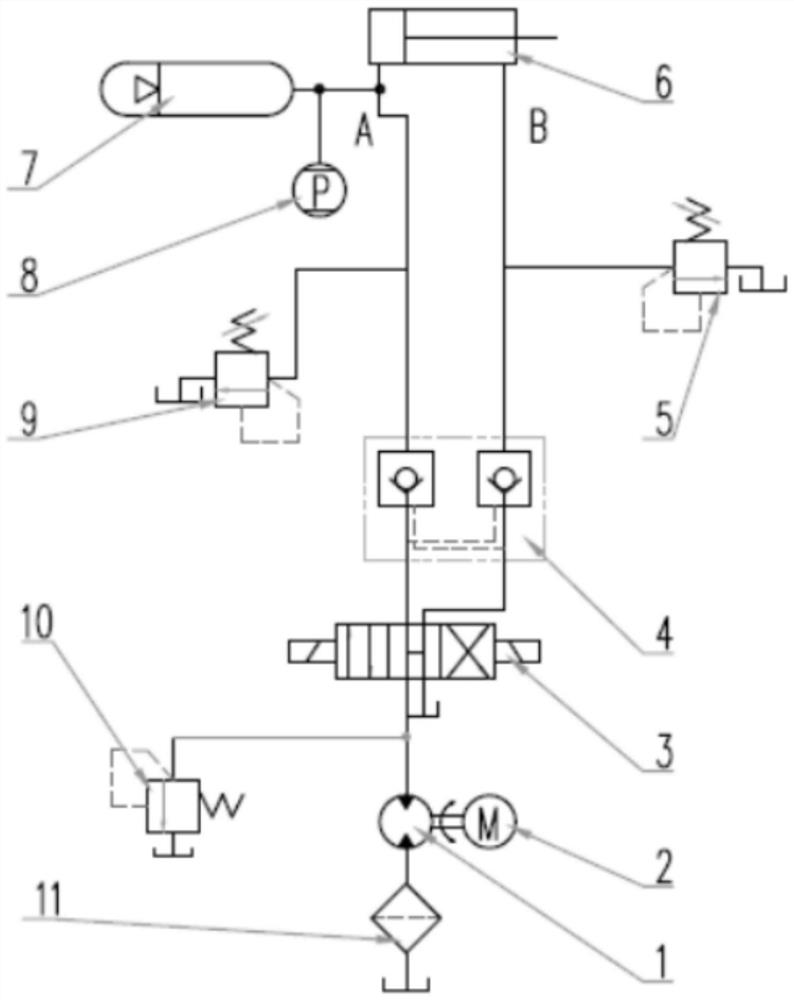

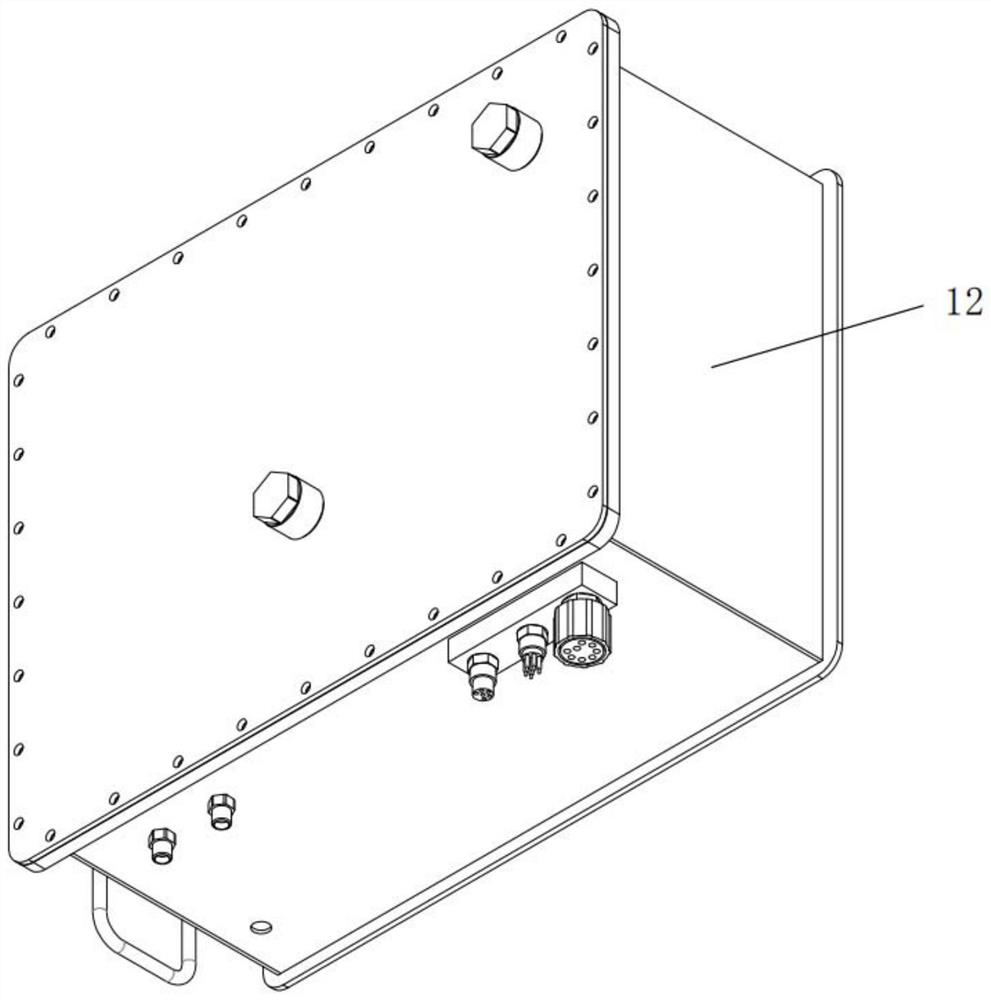

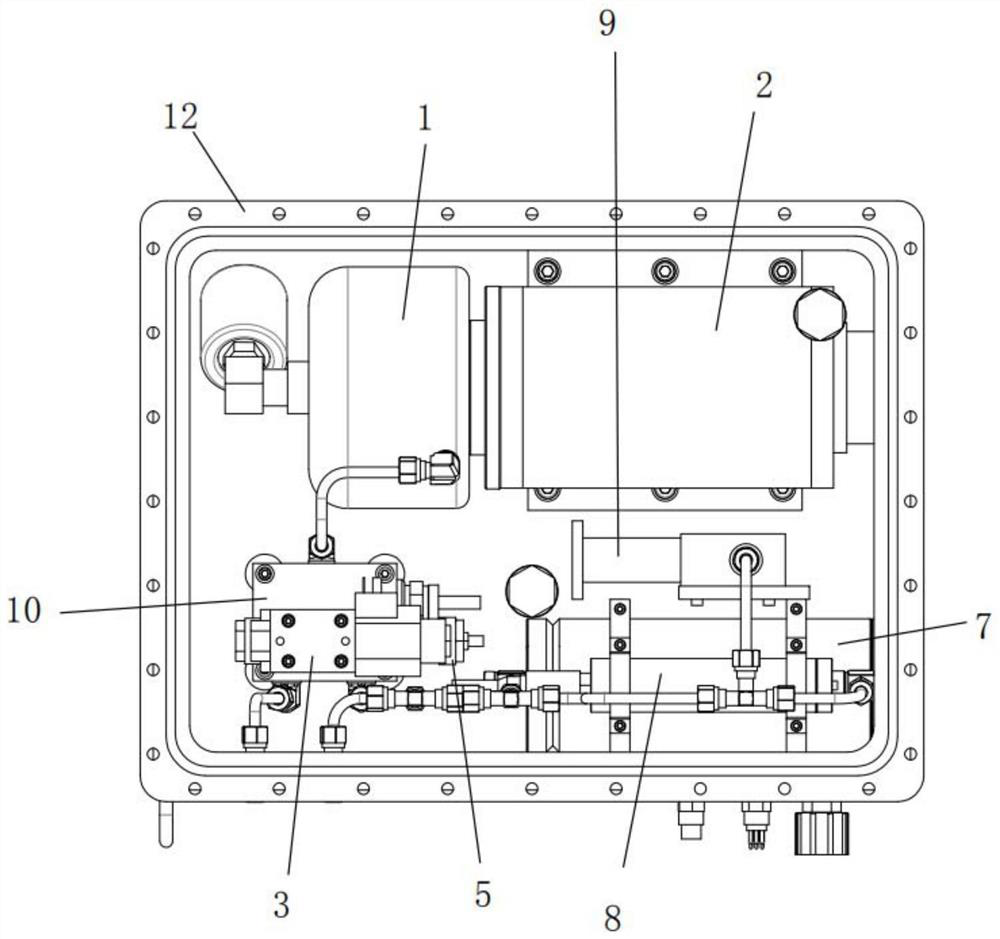

Deep sea hydraulic station

PendingCN112503041AAchieve pressure balancePressure oil in timeFluid-pressure actuator safetyFluid-pressure actuator testingBrushless motorsHydraulic cylinder

The invention provides a deep sea hydraulic station. The deep sea hydraulic station comprises a box body, a radial pump, a direct-current brushless motor, a stacked three-position four-way electromagnetic reversing valve, a stacked hydraulic control one-way valve, a stacked overflow valve, a hydraulic cylinder, an energy accumulator, a pressure sensor, a direct-acting overflow valve and an integrated block plug-in overflow valve. The radial pump, the direct-current brushless motor, the stacked three-position four-way electromagnetic reversing valve, the stacked hydraulic control one-way valve,the stacked overflow valve, the energy accumulator, the pressure sensor, the direct-acting overflow valve and the integrated block plug-in overflow valve are all located in the box body. The deep seahydraulic station has the advantages of being compact in structure, good in sealing performance, stable, safe and capable of adapting to the special deep sea environment.

Owner:杭州瀚陆海洋科技有限公司

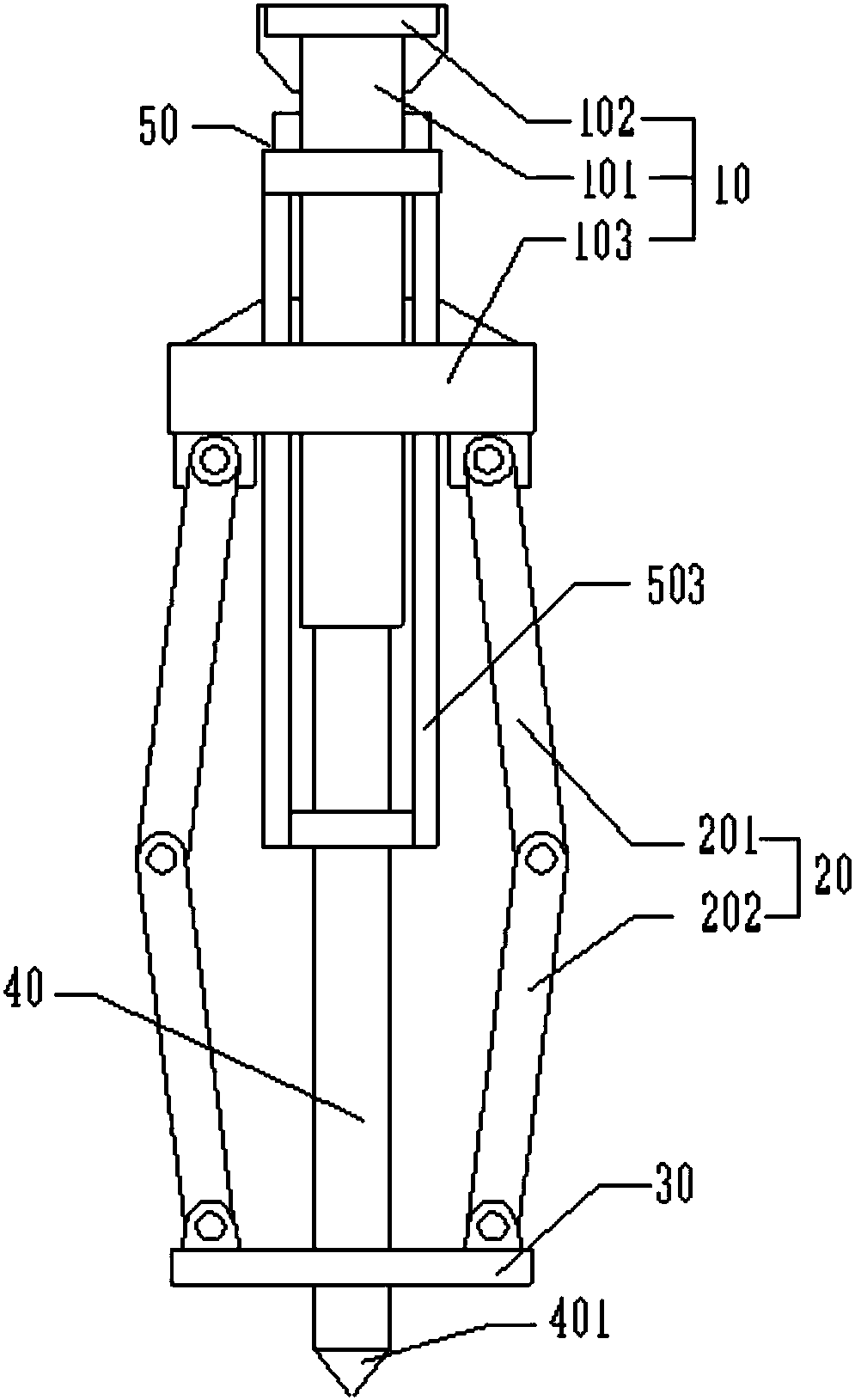

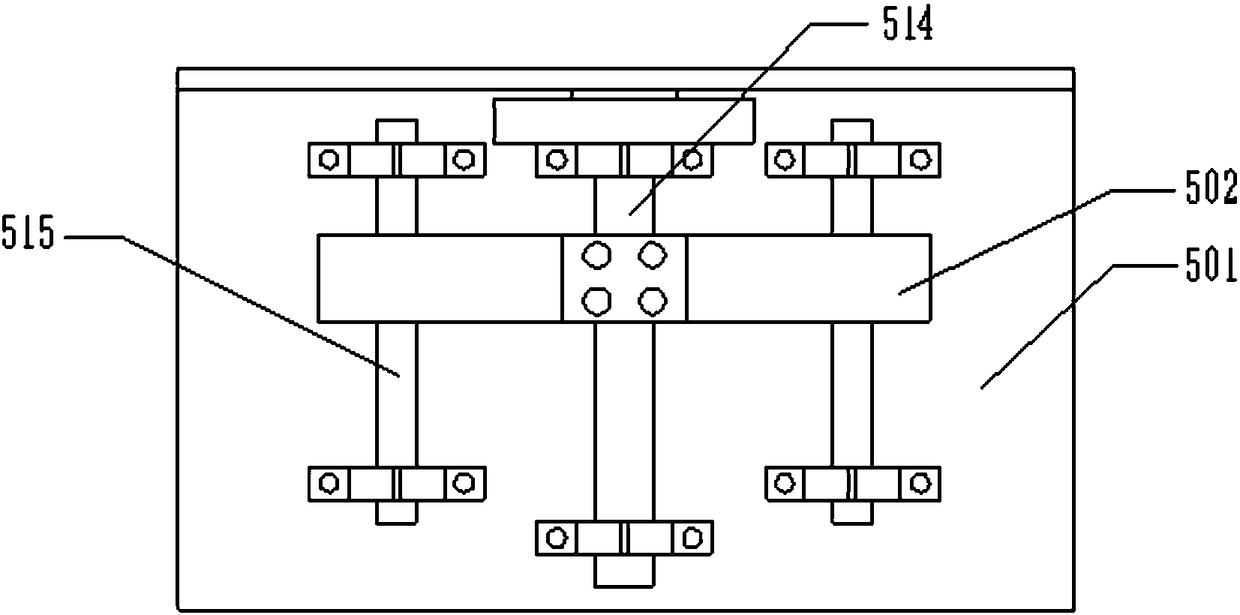

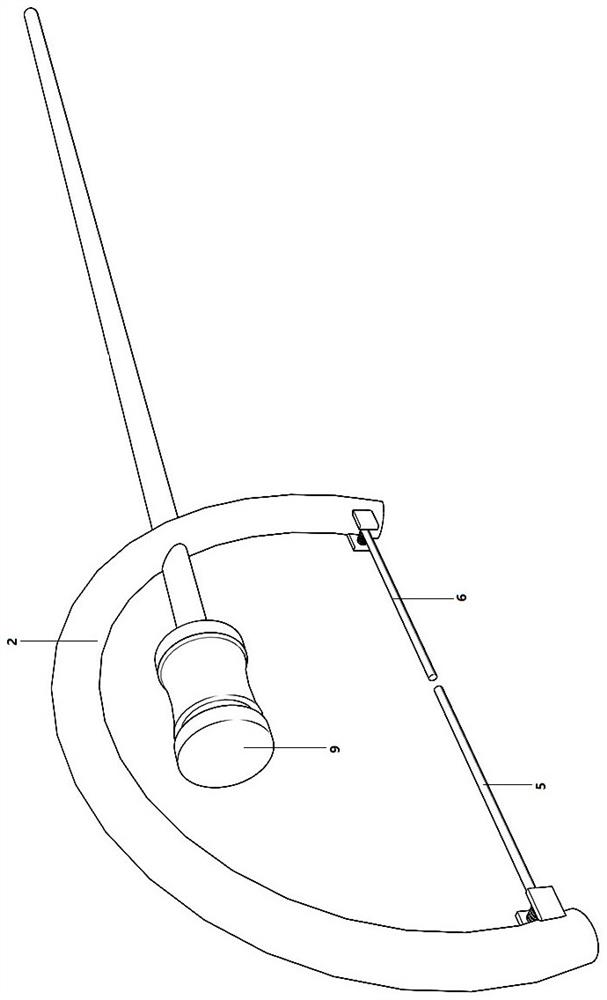

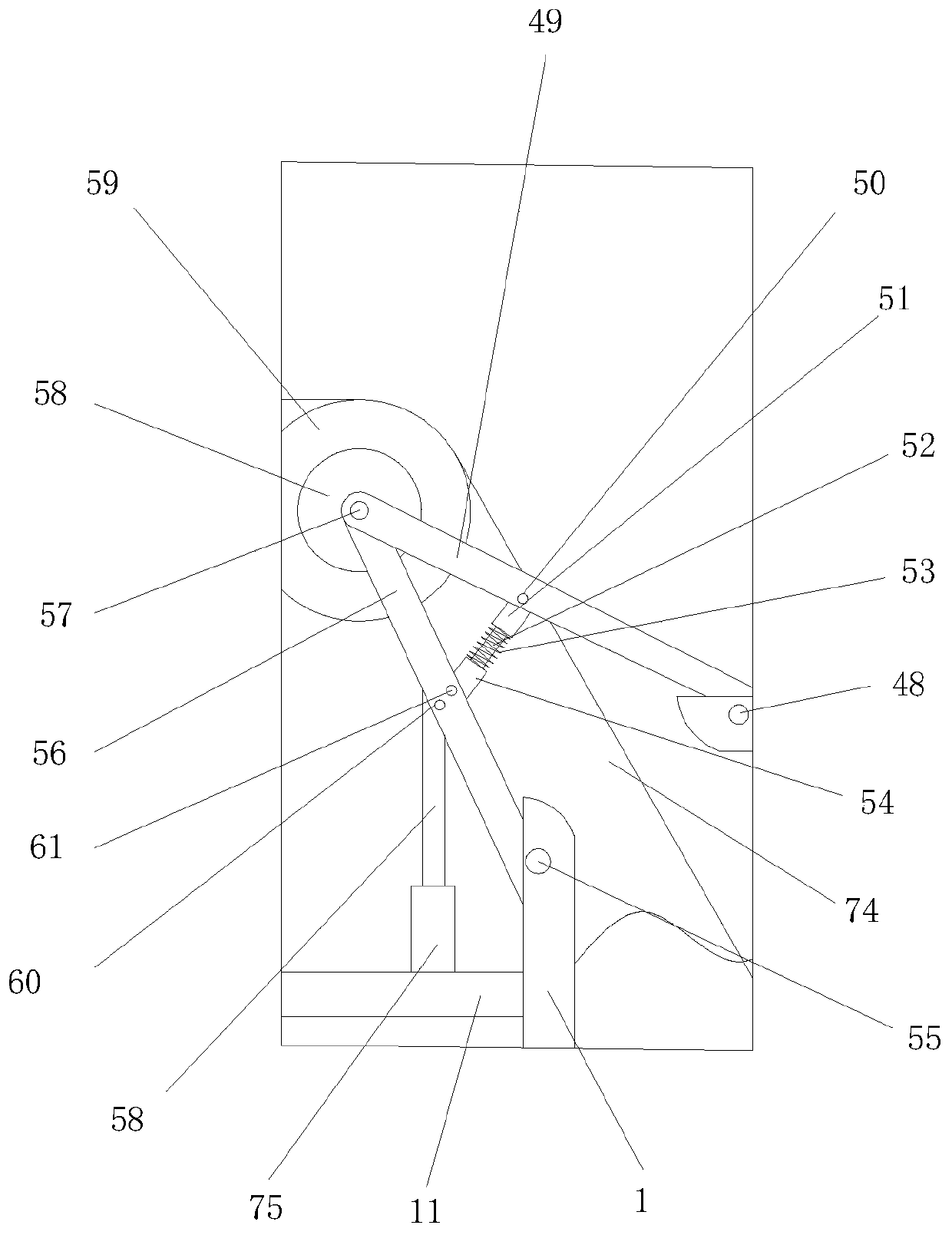

Novel adjustable type underreaming drill bit used for well

The invention provides a novel adjustable type underreaming drill bit used for a well. The drill bit includes a lifting main body, an underreaming wing main body, a bottom plate, a central positioningshaft and a limit main body; the central positioning shaft is coaxially sleeved by the lifting main body; one end of the underreaming wing main body is hinged to the lower side of the lifting main body, and the other end of the underreaming wing main body is hinged to the upper surface of the bottom plate; the lower end of the central positioning shaft vertically and coaxially penetrates throughthe bottom plate; the lower end of the central positioning shaft is coaxially provided with an inserting tip; and the limit main body vertically passes through the lifting main body. By adoption of the underreaming drill bit, the novel adjustable type underreaming drill bit can meet hole expanding requirements of drilling hole diameters of various specifications, enables a work progress of a continuous hole expanding operation to be shortened, enables the service life of the entire underreaming drill bit to be prolonged, and can ensure a good accurate opening angle of an underreaming wing to improve the hole expanding quality and effectively avoid cost loss.

Owner:TIANJIN TIANYI VALVE

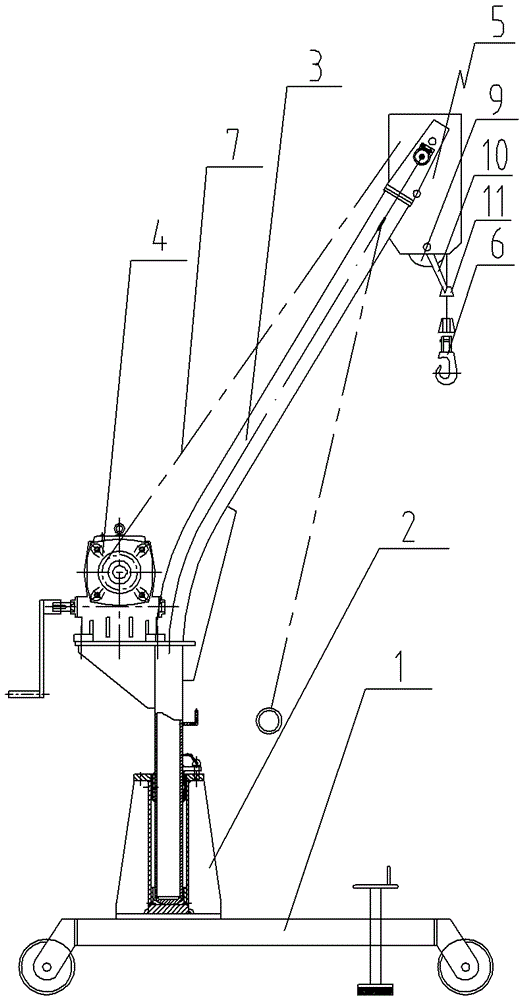

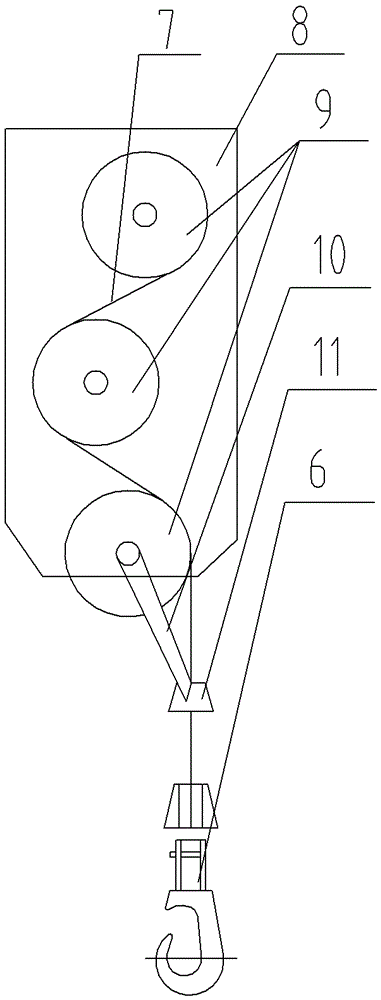

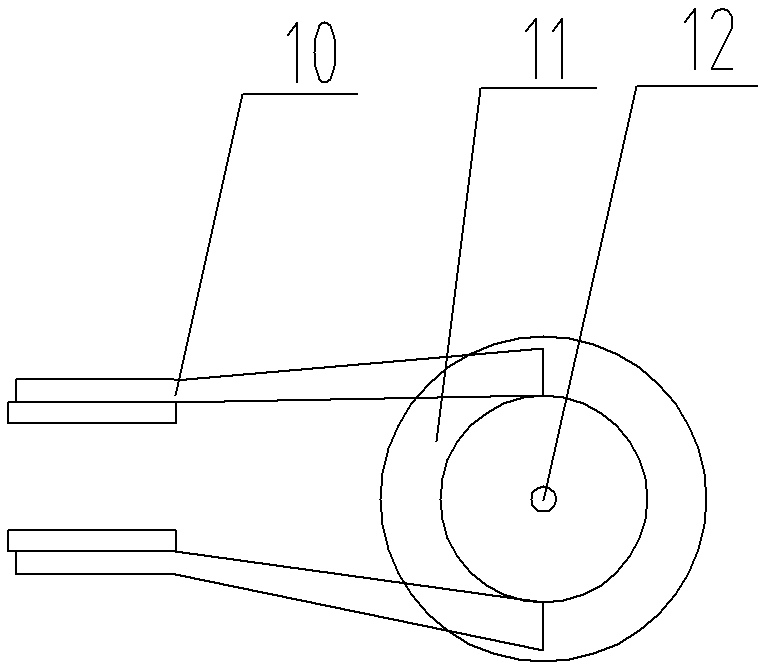

Limiting garbage hoist

The invention relates to the technical field of garbage hoisting, in particular to a limiting garbage hoist. A hoisting hook of the limiting garbage hoist cannot cause damage with a tackle during a hoisting process. The limiting garbage hoist comprises the pulley trolley; a hoisting rod base is mounted on the pulley trolley; a hoisting rod is mounted on the hoisting rod base; a winch device is mounted on the hoisting rod; the tackle is mounted at the top end of the hoisting rod; the hoisting hook is connected with the tackle and the winch device through hoisting ropes; the limiting garbage hoist is characterized in that the tackle comprises a pulley mounting frame; three pulleys are mounted on the pulley mounting frame from top to bottom; the three pulleys are in triangular arrangement; a connecting rod which is arranged in an inclined downward manner is mounted on a wheel axle of the pulley at the lowest end; a limiting cover is mounted at the bottom of the connecting rod; a groove which is matched with the top of the hoisting hook is formed in the lower end of the limiting cover; a hanging rope through hole is formed in the top of the groove.

Owner:WUXI SHENGOU MARINE EQUIP

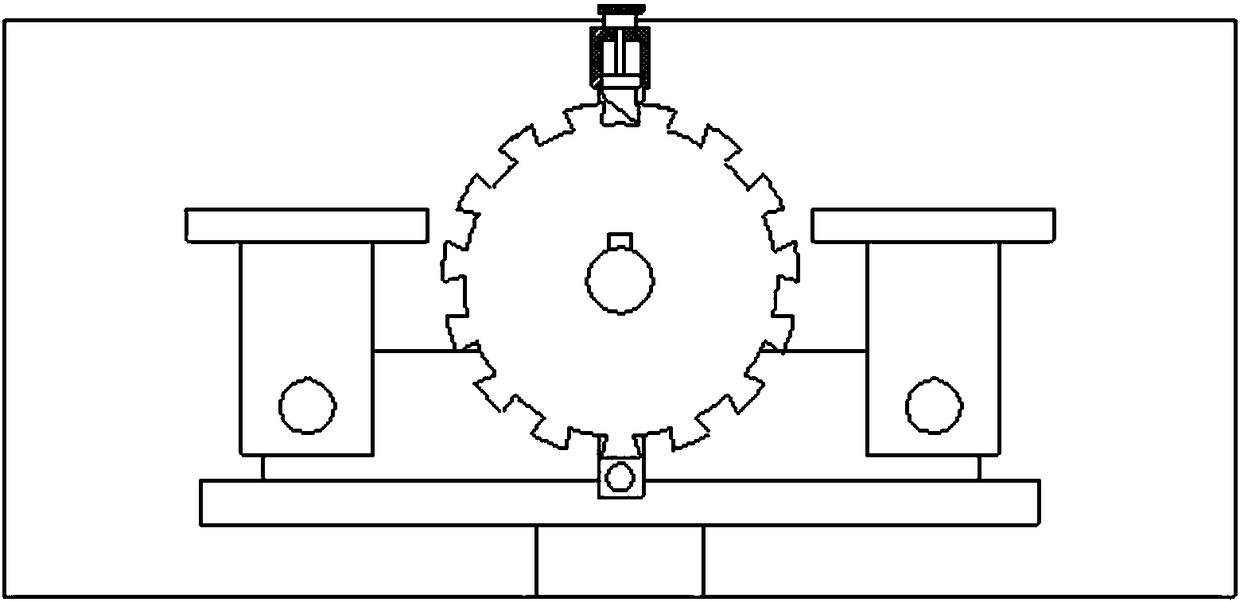

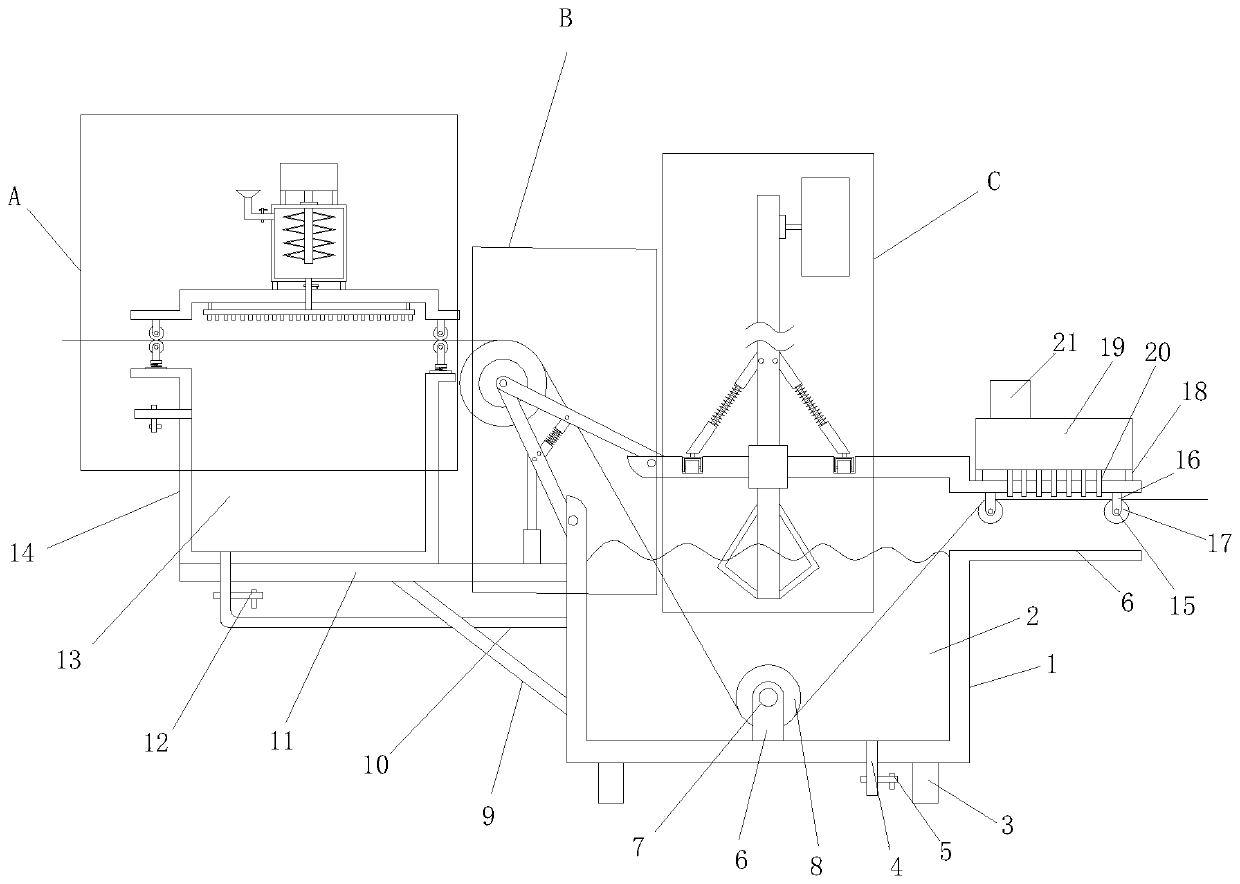

Casting grinding equipment

InactiveCN108032165AAvoid displacementImprove sanding effectEdge grinding machinesGrinding feedersEngineeringConveyor belt

The invention belongs to the field of grinding equipment, and specifically discloses casting grinding equipment. The casting grinding equipment includes a first conveyor belt and a second conveyor belt for transporting castings, and a grinding mechanism is arranged between the first conveyor belt and the second conveyor belt; the grinding mechanism includes a base, the upper surface of the base isa circular-arc-shaped concave cavity, an arc-shaped through slot is formed in the concave cavity, and a grinding ring with a frosted inner surface is rotatably disposed on the concave cavity; the outer surface of the grinding ring is provided with a circle of secondary gears which can extend into the through slot, a motor is mounted on the inner wall of the base, and the output end of the motor is provided with a main gear meshed with the secondary gears; symmetric supporting rods are fixedly arranged on the side wall of the base, and stop levers which can limit the castings are fixedly installed on the supporting rods; and lifting tables are further arranged between the first conveyor belt and the second conveyor belt and the base. According to the casting grinding equipment, the castings can be automatically ground without manual operation, the efficiency is high, and time is saved.

Owner:重庆市铭鼎机械制造有限公司

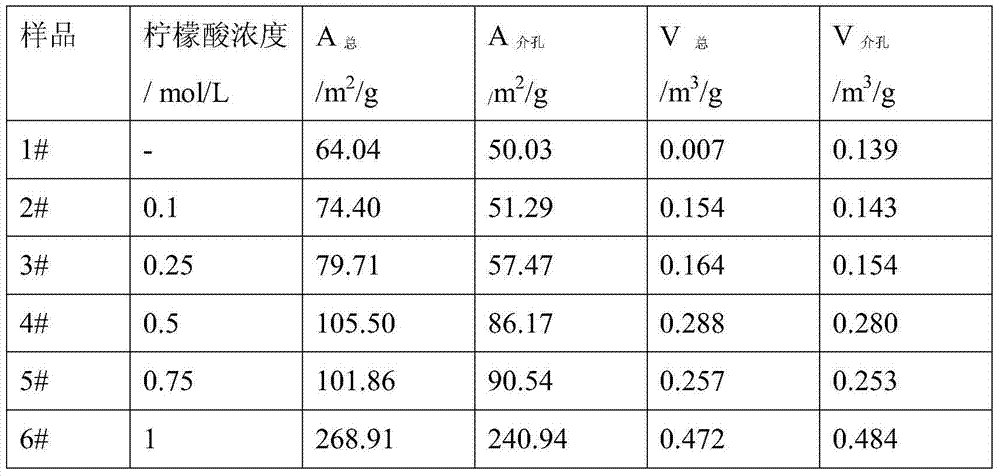

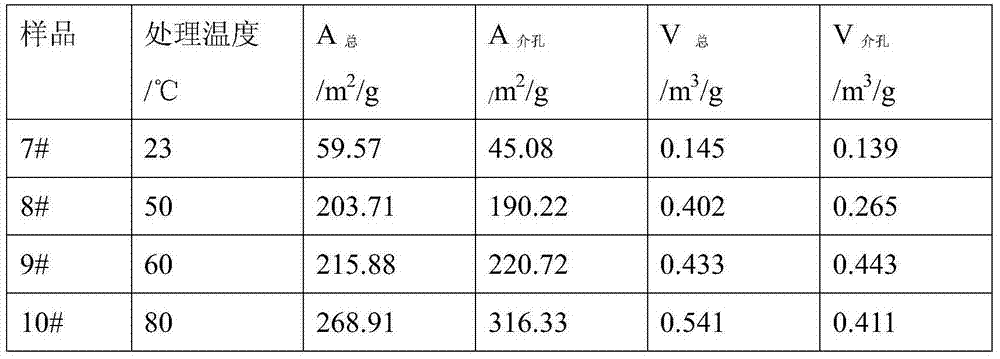

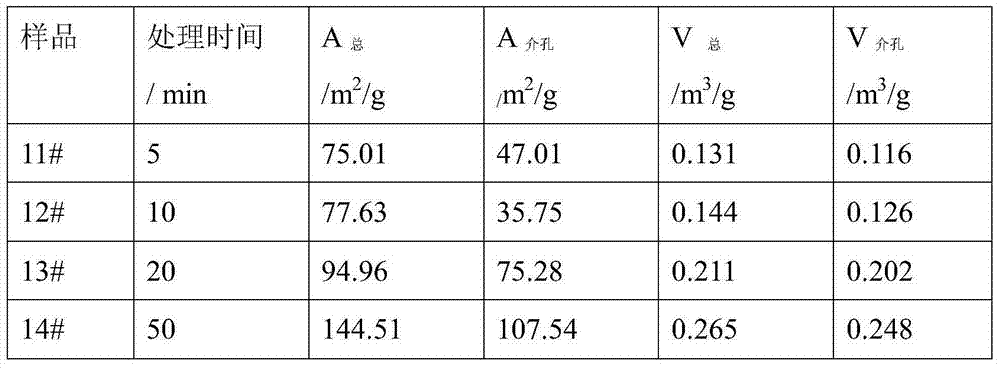

Catalytic cracking catalyst capable of increasing yield of gasoline rich in isoalkane

InactiveCN103878019AFacilitate isomerization reactionImprove compositionCatalytic crackingMolecular sieve catalystsChemistryMolecular sieve

The invention relates to a catalytic cracking catalyst, and particularly relates to a catalytic cracking catalyst capable of increasing the yield of gasoline rich in isoalkane for petroleum hydrocarbon catalytic cracking reaction. The catalytic cracking catalyst consists of the following raw materials in parts by weight: 30 parts of a USY molecular sieve, 5-15 parts of an auxiliary, 50 parts of a catalyst carrier and 10 parts of a bonding agent. The auxiliary is a silicoaluminophosphate molecular sieve or a citric acid modified silicoaluminophosphate molecular sieve. The catalyst prepared from the auxiliary can increase the yield of gasoline components rich in isoalkane by virtue of macromolecule hydrocarbon cracking reaction without changing existing equipment and fundamental process.

Owner:PETROCHINA CO LTD +1

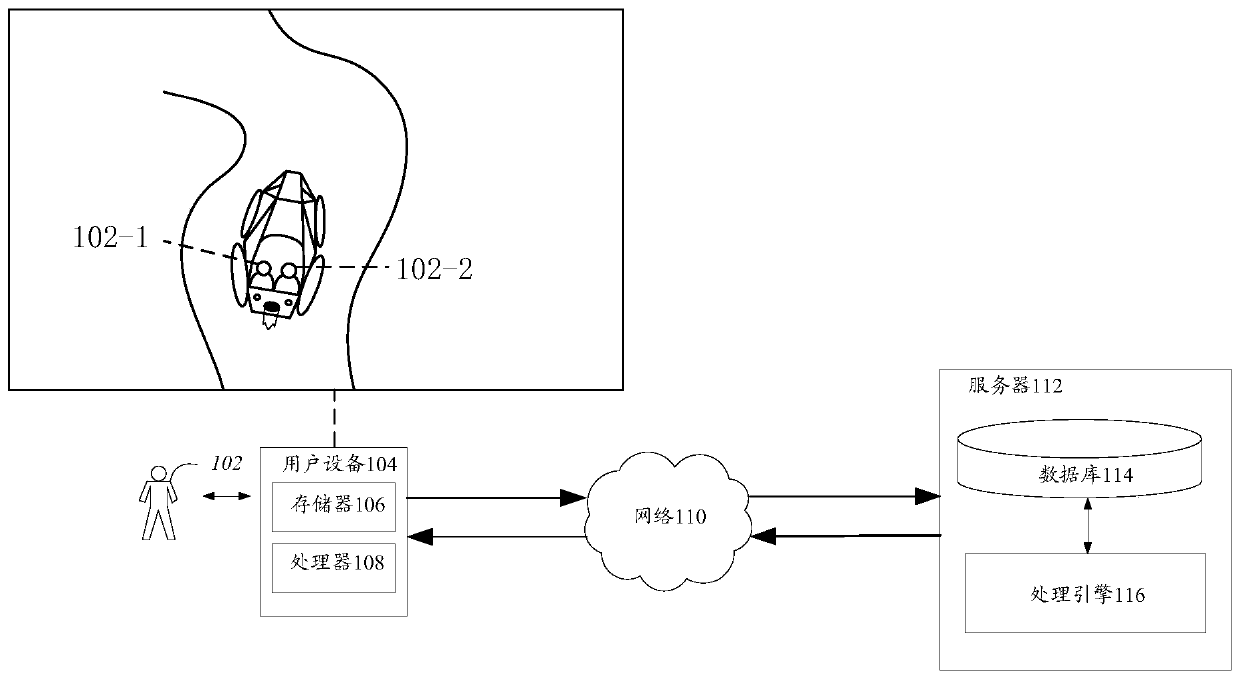

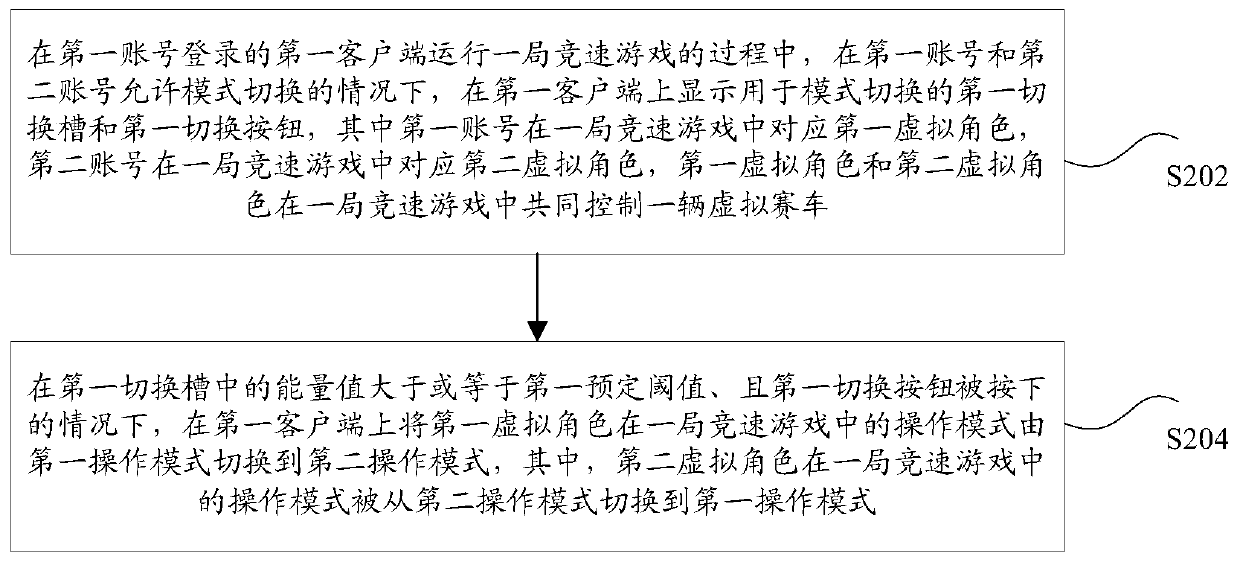

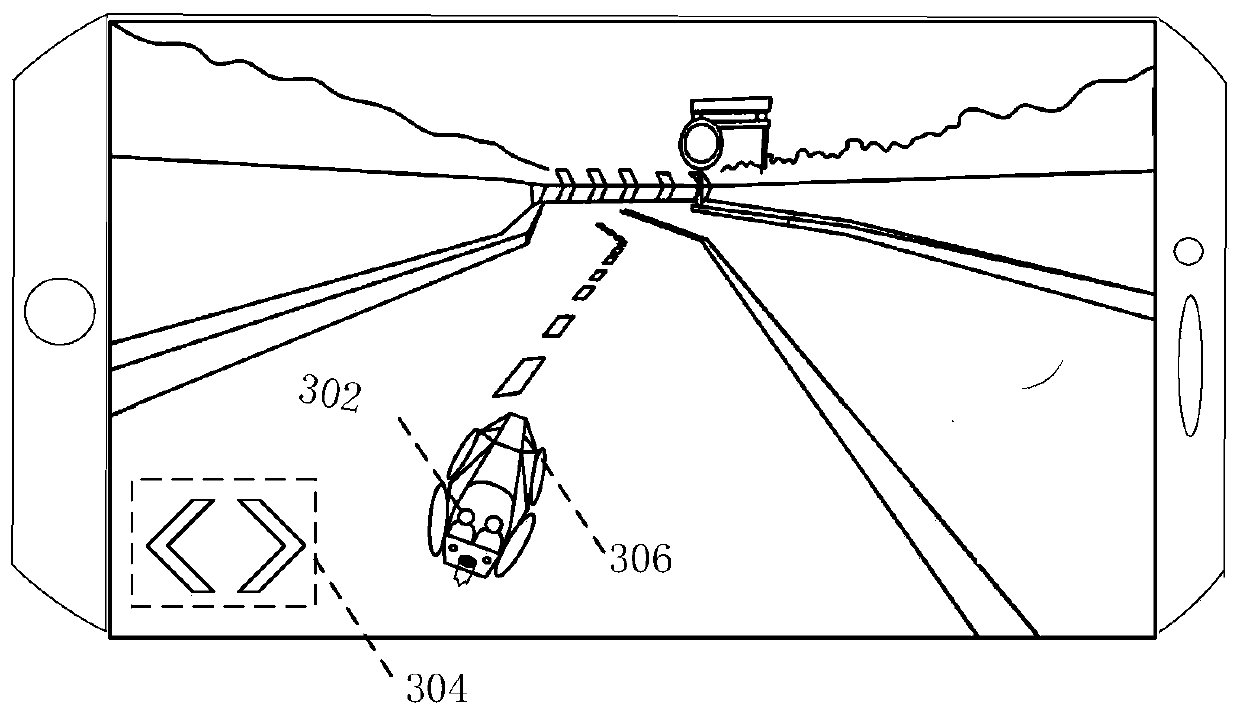

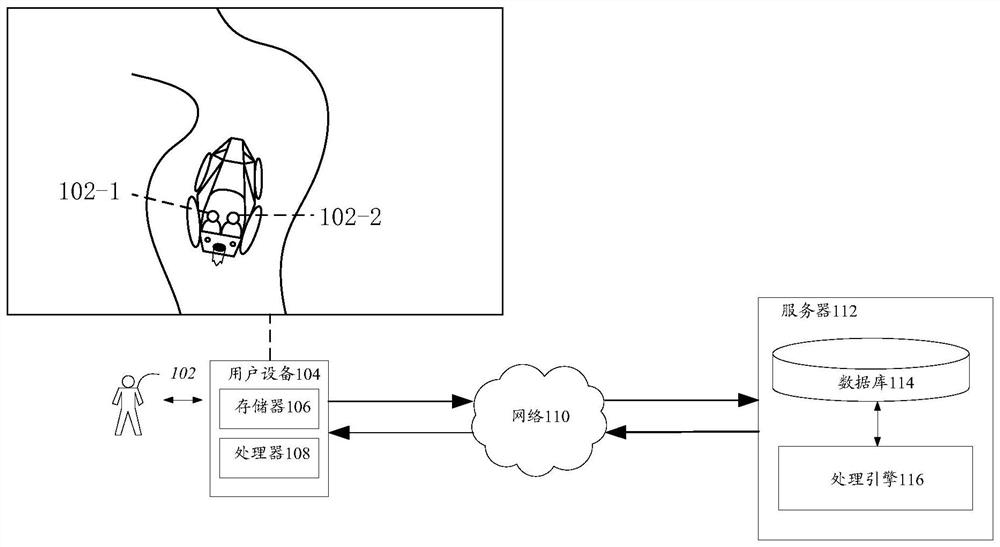

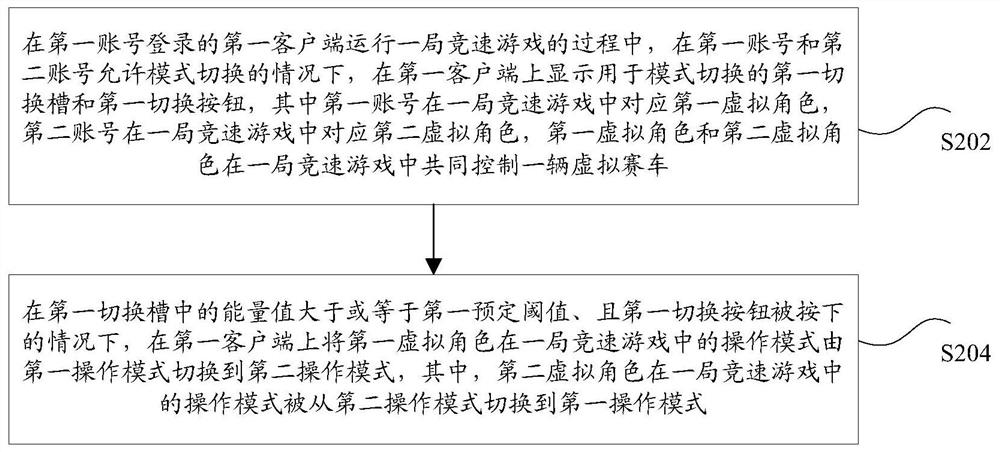

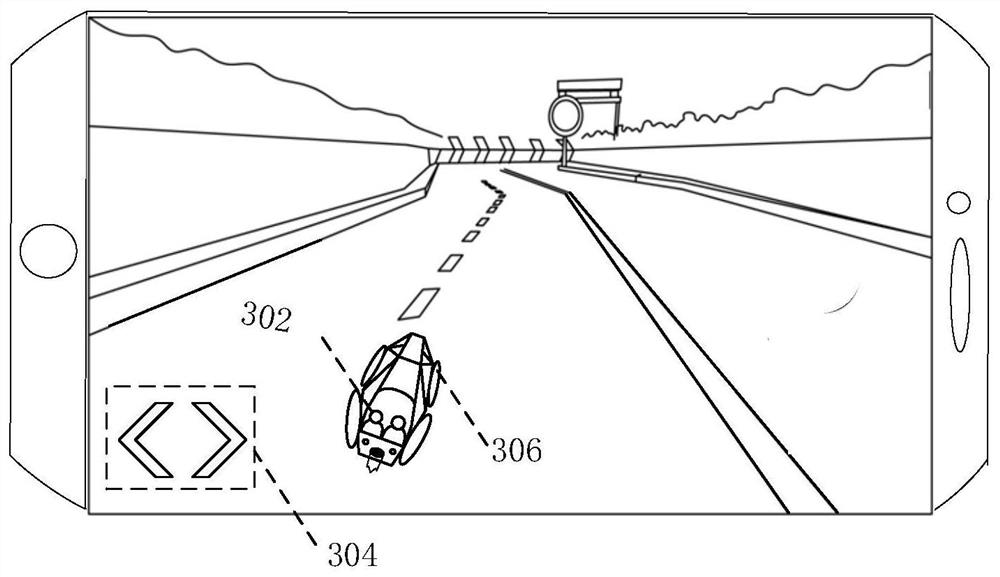

Virtual character control method and device, storage medium and electronic device

ActiveCN110134462AImprove control efficiencySolve technical problems of low control efficiencyExecution paradigmsClient-sideMode switching

The invention discloses a virtual character control method and device, a storage medium and an electronic device. The method comprises the steps that in the process that a first client side logged inby a first account runs a racing game, a first switching groove and a first switching button which are used for mode switching are displayed on the first client side under the condition that mode switching is allowed by the first account and a second account; when the energy value in the first switching groove is greater than or equal to a first preset threshold value and the first switching button is pressed down, the first switching button is turned off; an operation mode of the first virtual character in a round of racing game is switched from a first operation mode to a second operation mode on the first client, and the operation mode of the second virtual character in the round of racing game is switched from the second operation mode to the first operation mode. The technical problemof low control efficiency of the virtual racing car in the prior art is solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Intelligent control system of electromechanical equipment

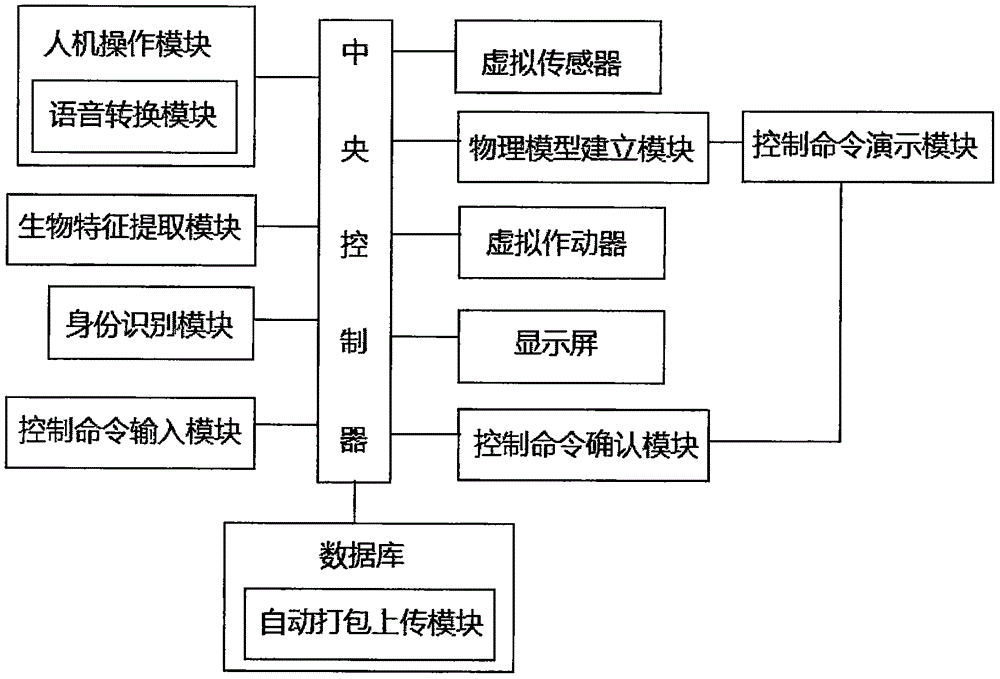

InactiveCN106055945AWarranty limitationsAvoid mistakesInput/output for user-computer interactionDigital data authenticationIdentity recognitionComputer module

The invention discloses an intelligent control system of electromechanical equipment. The system comprises a man-machine operation module, a biologic characteristic extraction module, an identity recognition module, a central controller, a physical model establishment module, a virtual actuator, a virtual sensor, a control command demonstration module and a control command confirmation module, wherein the virtual actuator feeds back results to the control command demonstration module through cyclic execution of analysis; the control command demonstration module automatically extracts data to the vertical sensor; and the virtual sensor automatically displays the data. The system disclosed by the invention is characterized in that multiple modes of input manners are adopted, and use becomes much more convenient; input of each command carries identity authentication information, so that limiting of a system control permission is guaranteed, and input of each control command is traceable; and control command demonstration shall be carried out before output confirmation of each commend, so that mistakes of control commend output can be effectively avoided, and each control commend becomes visualized.

Owner:ORDO POLYTECHNIC SCHOOL

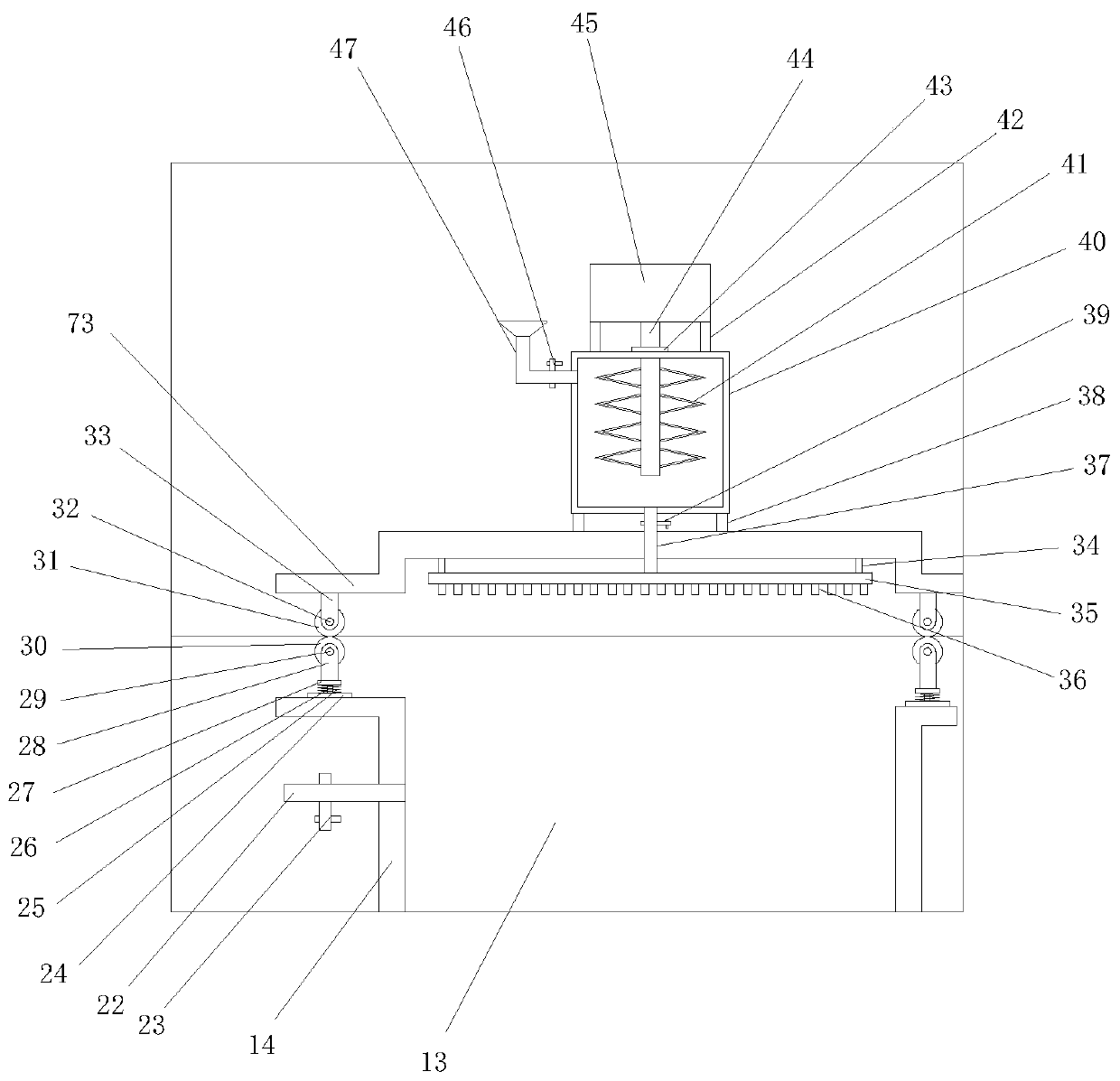

Quantitative adjustable filling equipment for cosmetics processing and production

InactiveCN111924778ASolve practicalitySolve the filling accuracy differenceLiquid bottlingElectric current flowMechanical engineering

The invention relates to the technical field of cosmetics, and discloses quantitative adjustable filling equipment for cosmetics processing and production. The quantitative adjustable filling equipment comprises a conveying belt, wherein a fixed block comprises a variable resistor and a rubber mat, a metal ball which corresponds to the variable resistor is arranged on one end, which is close to the fixed block, of a sliding rod, a second metal block which corresponds to a first lantern ring is arranged in the first lantern ring, a first magnetic block is arranged on the upper part of a slidingblock, an antiskid post is connected to the first magnetic block, a second magnetic block is connected to the upper end of a tapered column, and a coil is arranged on the inner side of the upper partof a fixed frame. The first magnetic block is pushed to drive the sliding block to extrude a third spring by virtue of a magnetic field on the generating side of the coil, the position of the slidingblock in the fixed frame is different according to different electric currents in the coil, so that the amplitude of up-and-down movement of a piston head on a quantifying cylinder, and the problemsof low practicability, poor filling accuracy, high working strength and inapplicability of filling cosmetics of different sizes of existing filling equipment are solved by adopting the structure.

Owner:黄中明

Intelligent controller for diesel vehicle preheating system

InactiveCN107765679AWarranty limitationsAvoid mistakesProgramme controlElectric testing/monitoringInput controlControl theory

The invention discloses an intelligent controller for a diesel vehicle preheating system, which includes a man-machine operation module, a temperature sensor, a humidity sensor, a pressure sensor, an arc sensor, a central controller, a control command preview module, a heating device, a refrigeration device, and a ventilation device. The alarm device, the temperature sensor is set separately from the cooling device and the heating device, the humidity sensor is set separately from the ventilation device, and the data is converted into a chart form by the data processing unit and stored in the data storage module. This specific implementation adopts multiple input modes, which greatly facilitates the use, and the input of each command has its own identity authentication information, which ensures the limitation of system control authority on the one hand, and makes the input of each control command It is traceable; each command needs to preview the control command before confirming the output, thus avoiding the error of the control command output and making each control command visible.

Owner:SHIYAN HERONG AUTOMOBILE ELECTRICAL APPLIANCES

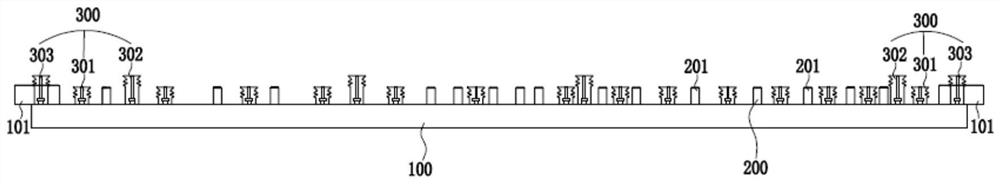

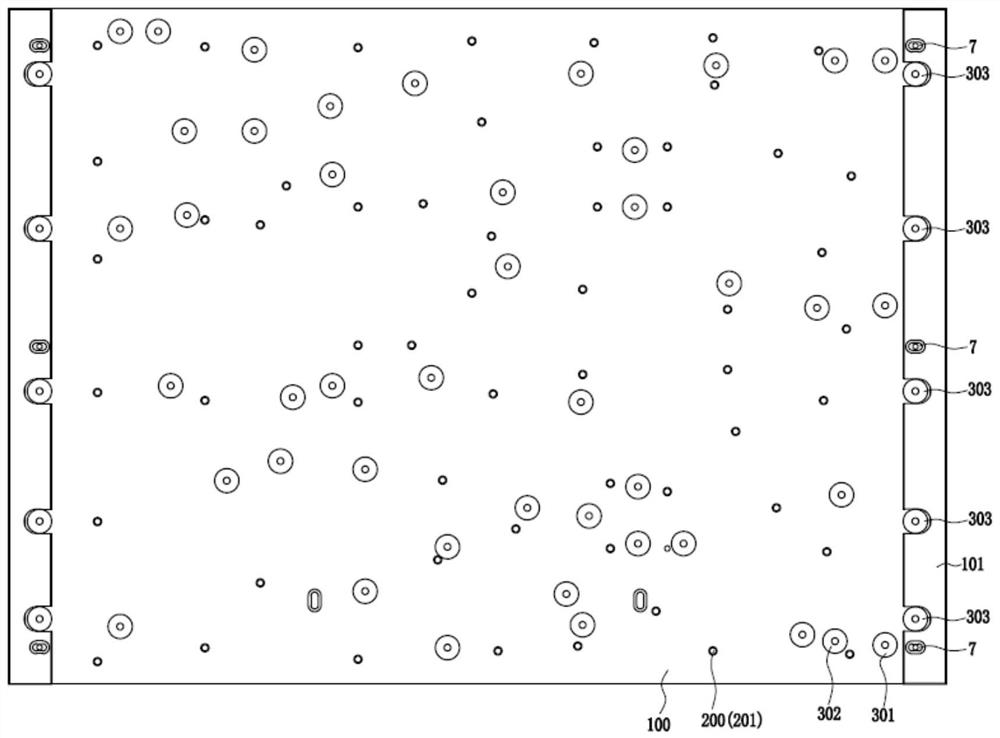

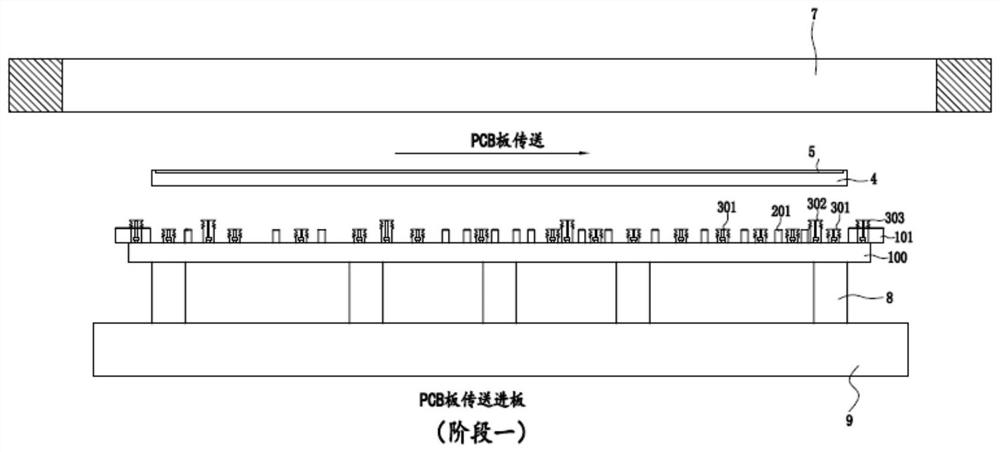

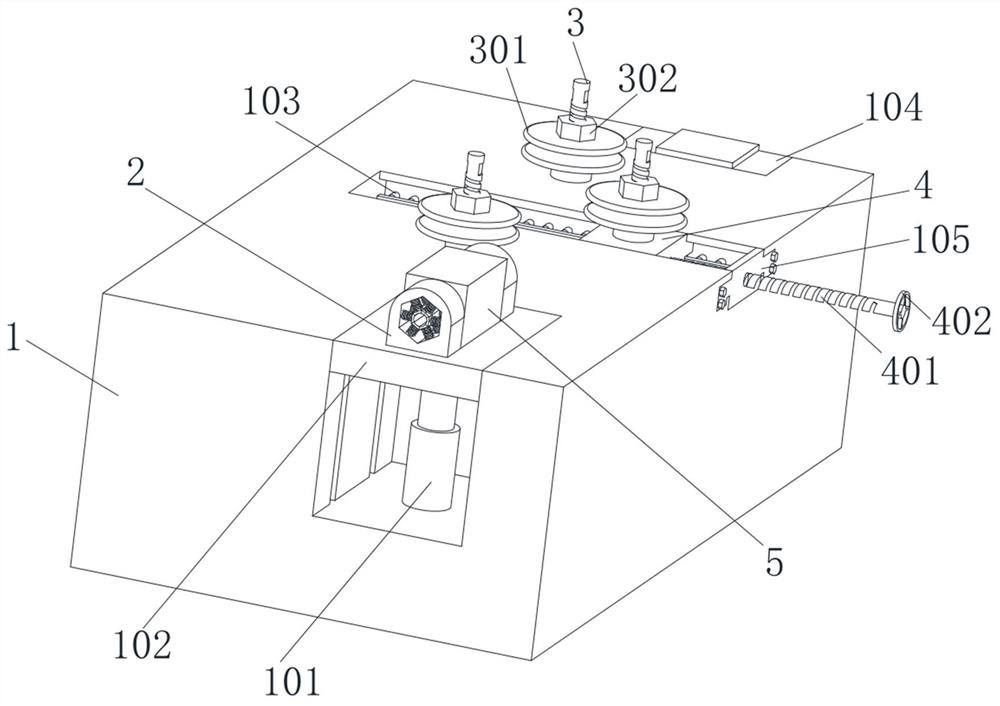

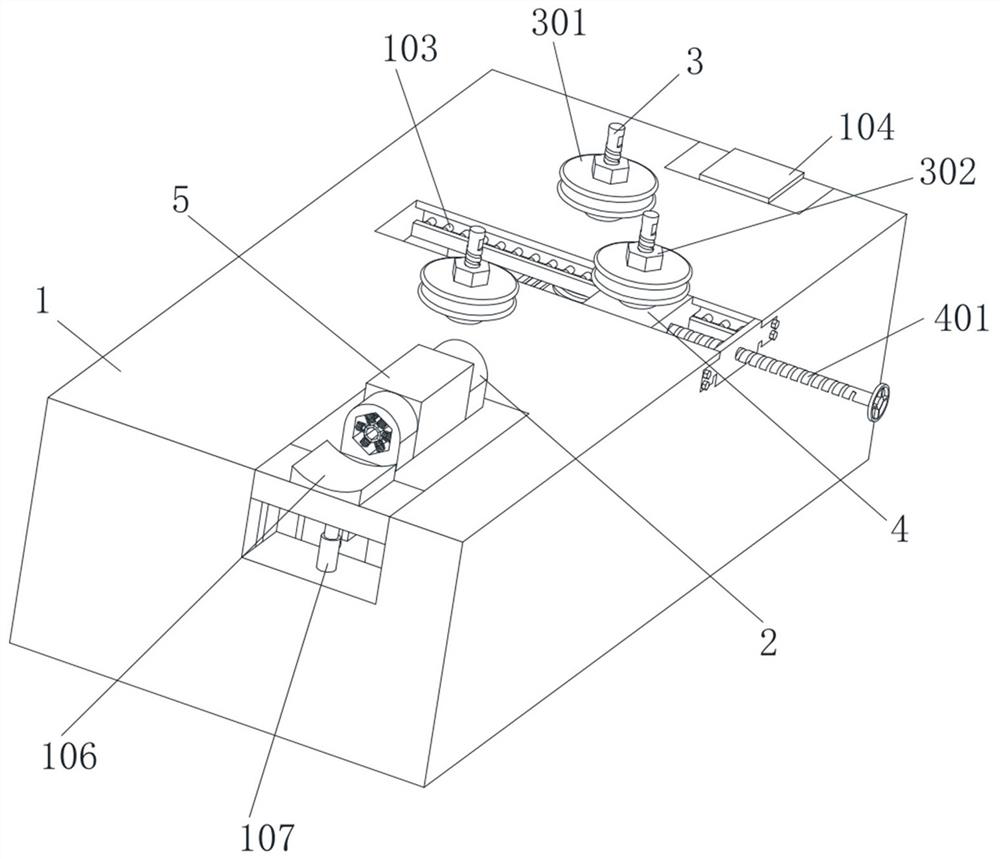

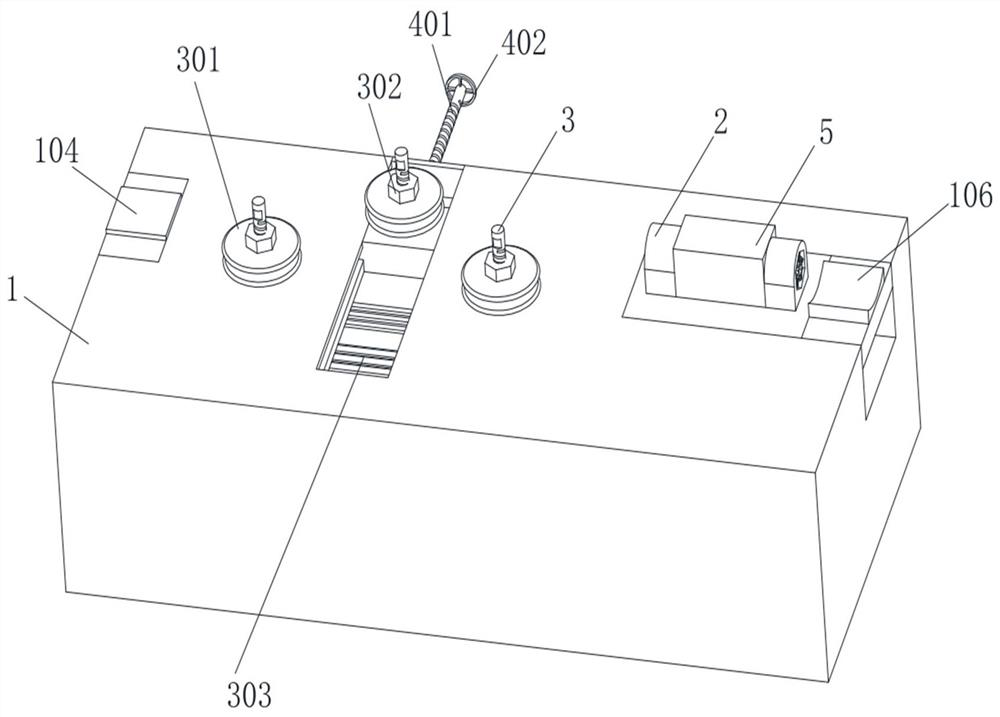

Vacuum platform for printing machine and using method of vacuum platform

PendingCN113733724AAvoid deformation effectsGuaranteed stabilityScreen printersConductive pattern formationEngineeringPrinting press

The invention discloses a vacuum platform for a printing machine and a using method of the vacuum platform, and relate to the technical field of printing machines. The vacuum platform for the printing machine comprises a main body platform, a supporting structure and a suction cup structure, the main body platform is fixed on a lifting workbench, the supporting structure comprises supporting ejector pins, and the suction cup structure comprises a PCB suction cup, a first steel mesh suction cup and a second steel mesh suction cup. When the vacuum platform is used, a PCB is jacked up through the supporting ejector pins, so that a gap is formed between the PCB and the inner bottom surface of a tool jig, and the PCB is prevented from being influenced by deformation of the bottom surface of the tool jig; then the PCB is adsorbed through the PCB suction cup, so that the PCB is tightly attached to the supporting ejector pins, and movement of the PCB is limited; a steel mesh is adsorbed through the first steel mesh suction cup and the second steel mesh suction cup, so that the steel mesh can be tightly and seamlessly attached to the PCB, then the phenomena of tin connection, tin shortage and the like of the PCB in the printing process are avoided, and the printing quality of the PCB can be effectively guaranteed.

Owner:HONGYI TECH AUTOMATION EQUIP HUIZHOU CO LTD

Curve bending equipment for secondary machining of pipes

PendingCN112338013AAvoid damageSolve the problem of bending blockingShaping toolsEquipment useStructural engineering

The invention belongs to the technical field of pipe machining equipment, and particularly relates to curve bending equipment for secondary machining of pipes. The curve bending equipment comprises adevice body, wherein a supporting platform, a first supporting block, a second supporting block and an adjusting platform are connected to the device body in a sliding mode; a transmission mechanism is arranged on the device body; the supporting platform is connected with the device body through a first electric push rod; the first supporting block and the second supporting block are both connected with the device body through a second electric push rod; the supporting platform is fixedly connected with supporting seats and a mounting seat; the inner walls of the supporting seats are fixedly connected with clamping blocks through telescopic rods; and the telescopic rods are sleeved with springs. According to the curve bending equipment, the supporting platform is arranged on the device body, and is connected with the device body through the first electric push rod, so that the supporting platform can be selectively retracted into the device body according to whether a pipeline needs tobe heated or not during use of the equipment, and the supporting seats and the mounting seat do not block the placement of the pipeline during bending of a pipeline which does not need to be heated.

Owner:东莞市中帆新材料科技有限公司

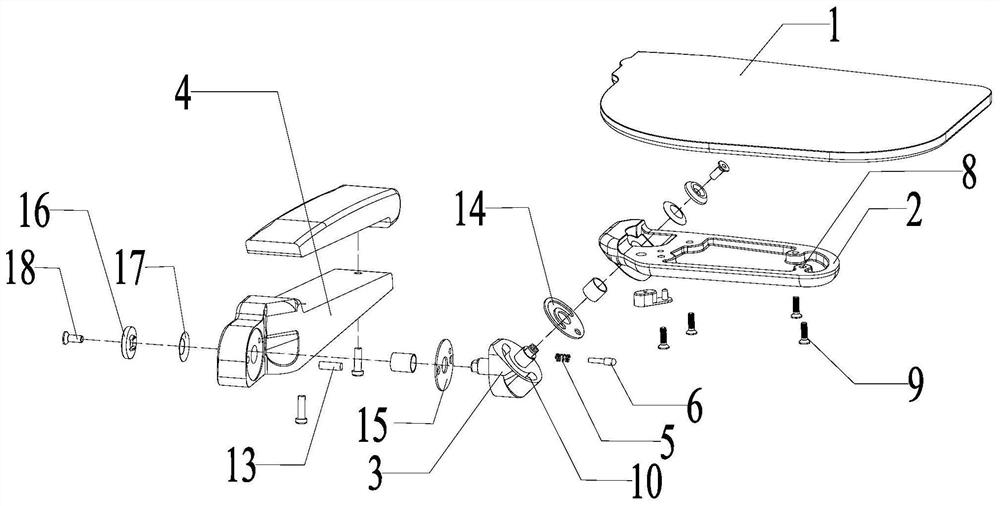

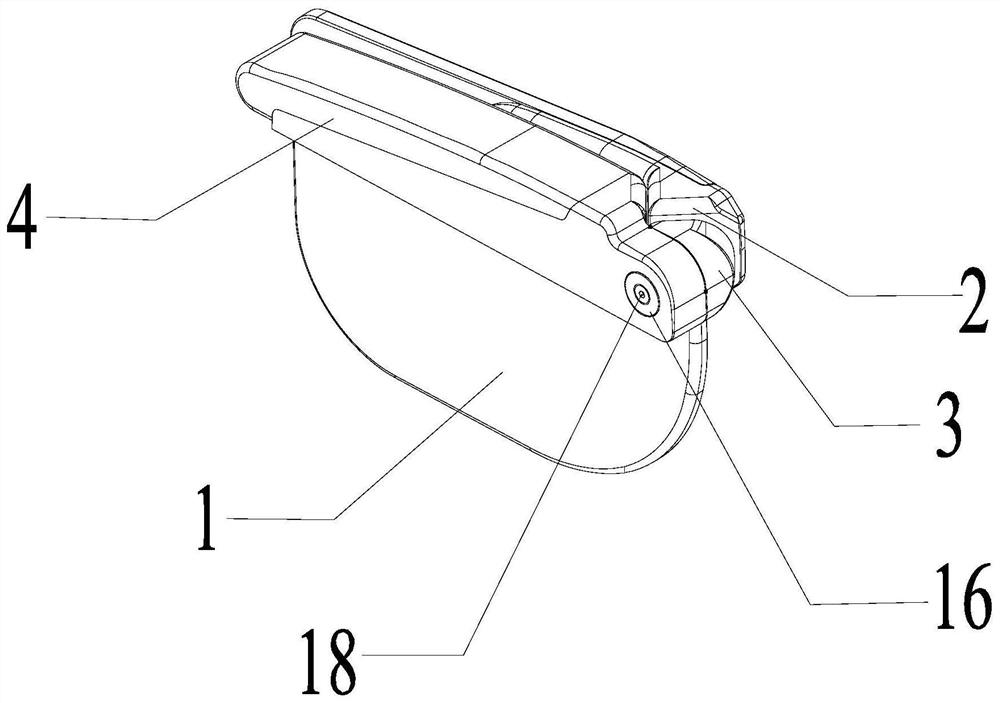

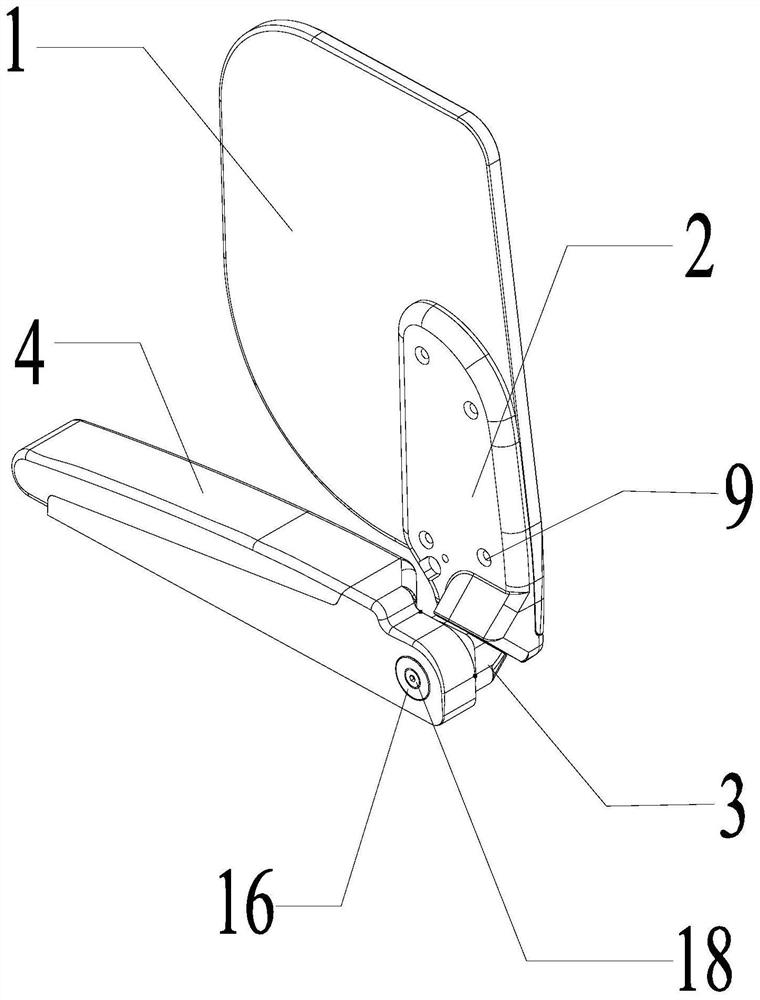

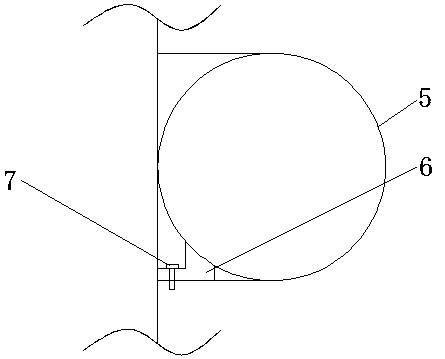

Foldable and openable writing board

The invention discloses a foldable and openable writing board which comprises a writing board main body, a tray, a rotating head, a plug pin and a handrail. The writing board main body is installed on the tray, the rotating head is connected with the tray and the handrail, a first arc-shaped groove and a second arc-shaped groove are formed in the two sides of the rotating head, a protrusion is arranged on the tray, a roller pin is arranged on the handrail, the protrusion and the roller pin are inserted into the first arc-shaped groove and the second arc-shaped groove respectively, the tray rotates relative to the rotating head through the protrusion and the first arc-shaped groove, the rotating head rotates relative to the handrail through the roller pin and the second arc-shaped groove, the plug pin is installed on the rotating head, and a limiting hole matched with the plug pin is formed in the tray. The limiting hole is provided with an inclined plane groove, and the plug pin enters the limiting hole from the inclined plane groove. The writing board has the advantages that the rotating angle and distance of the tray and the rotating head can be controlled, excessive rotation is avoided, friction between writing board mechanisms can be avoided, and use in production and life is facilitated.

Owner:广东筑丰巢家具科技有限公司

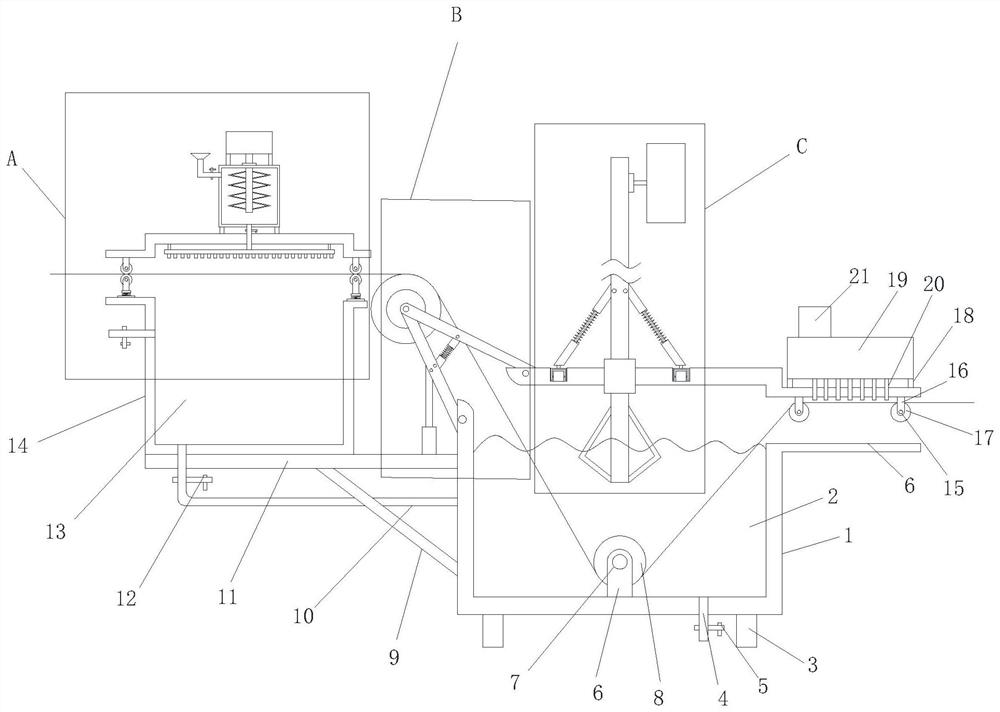

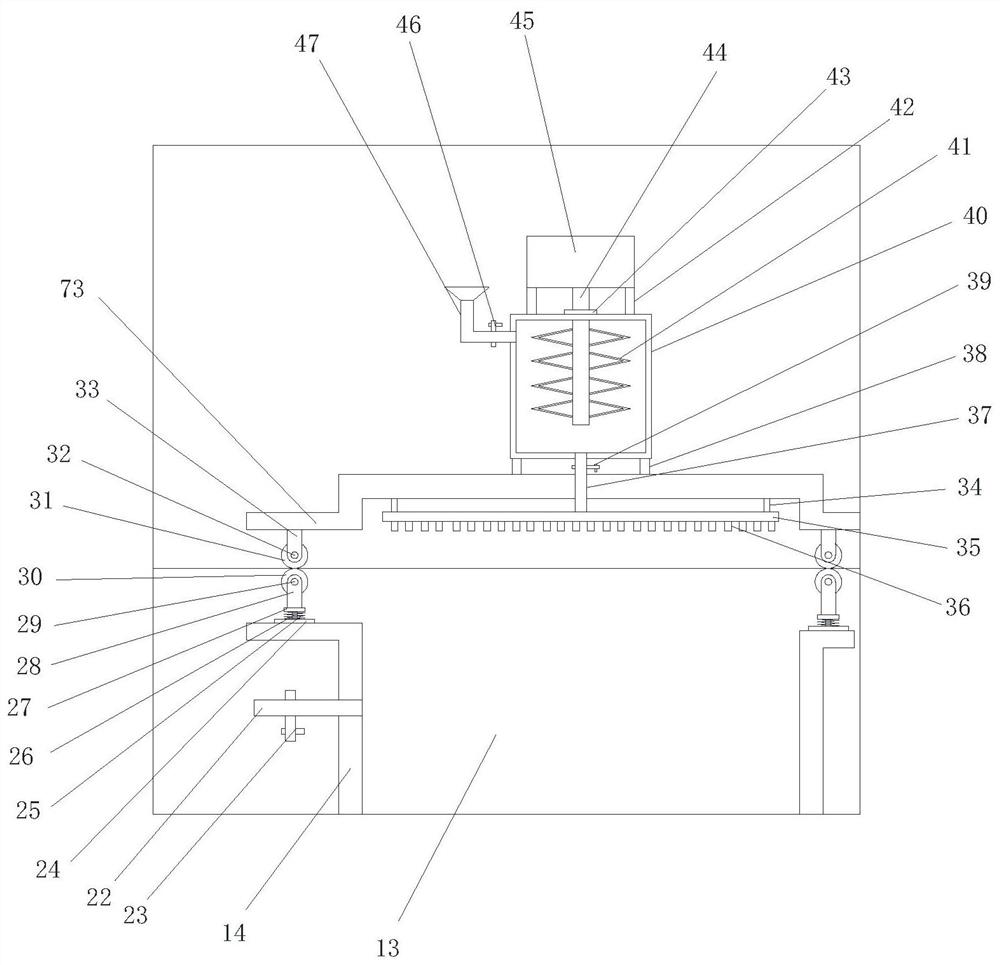

An energy-saving printing and dyeing device utilizing wind power

ActiveCN109944005BImprove printing and dyeing efficiencyImprove printing and dyeing qualitySucessive textile treatmentsLiquid/gas/vapor treatment machines driving mechanismsElectric machineryEngineering

The invention discloses an energy-saving printing and dyeing device utilizing wind power. A first cavity is provided in the first box, a second cavity is provided in the second box, and a connection is made between the first box and the second box. The first transmission pipe, a stirring box is installed on the upper end of the second box body, the second transmission pipe is connected between the stirring box and the second box body, the second feeding pipe is installed on one side of the stirring box, and the first feeding pipe is installed on the stirring box A motor, the first motor is equipped with a first stirring shaft in the stirring box, the stirring box is provided with a first limit shaft sleeve, the first stirring shaft runs through the first limit shaft sleeve, and the outer circumference of the first stirring shaft is installed The first stirring blade, the second transmission pipe have multiple nozzles in the second cavity, the first box is provided with a second limiting bushing, the first limiting bushing is penetrated with a second stirring shaft, and the second stirring shaft A maple leaf installation shaft is installed on the top, fan blades are installed on the fan blade installation shaft, and a second stirring blade is installed in the first cavity on the second stirring shaft. The invention improves the efficiency and quality of printing and dyeing.

Owner:汪秀英

Mechanical and chemical reaction furnace with good stability

InactiveCN108479655AImprove stabilityEasy to useChemical/physical/physico-chemical processesChemical reactionFixed frame

The invention discloses a mechanical and chemical reaction furnace with good stability. The mechanical and chemical reaction furnace comprises a bottom frame, water pipes, thread rods, sleeve rods, aconvex block and a groove, wherein a limiting body is movably arranged above the bottom frame, and limiting screws are arranged at the left end above the limiting body; universal wheels are arranged under the bottom frame; the water pipes are arranged in the limiting body, and fixed frames are arranged under the left ends of the water pipes; fixing screws are arranged at the left ends above the fixed frames; the thread rods penetrate through the bottom frame, hand wheels are fixedly arranged at the upper ends of the thread rods, and telescopic shafts are arranged at the lower ends of the thread rods; the sleeve rods are arranged at the left end and the right end under the bottom frame; bases are fixedly arranged under the telescopic shafts; the convex block is arranged under the limiting body; the groove is reserved at the upper part of the inner part of the bottom frame. The mechanical and chemical reaction furnace with good stability disclosed by the invention has the advantages thatthe stability is better, the movability can be achieved and the mechanical and chemical reaction furnace can be helped for dissipating heat and the like.

Owner:ZHANGZHOU LONGWEN WEIKE INFORMATION TECH CO LTD

Singular position avoidance method, system, device and computer-readable storage medium

ActiveCN112405525BGuaranteed continuityWarranty limitationsProgramme-controlled manipulatorSimulationComputer vision

Owner:SHENZHEN INOVANCE TECH

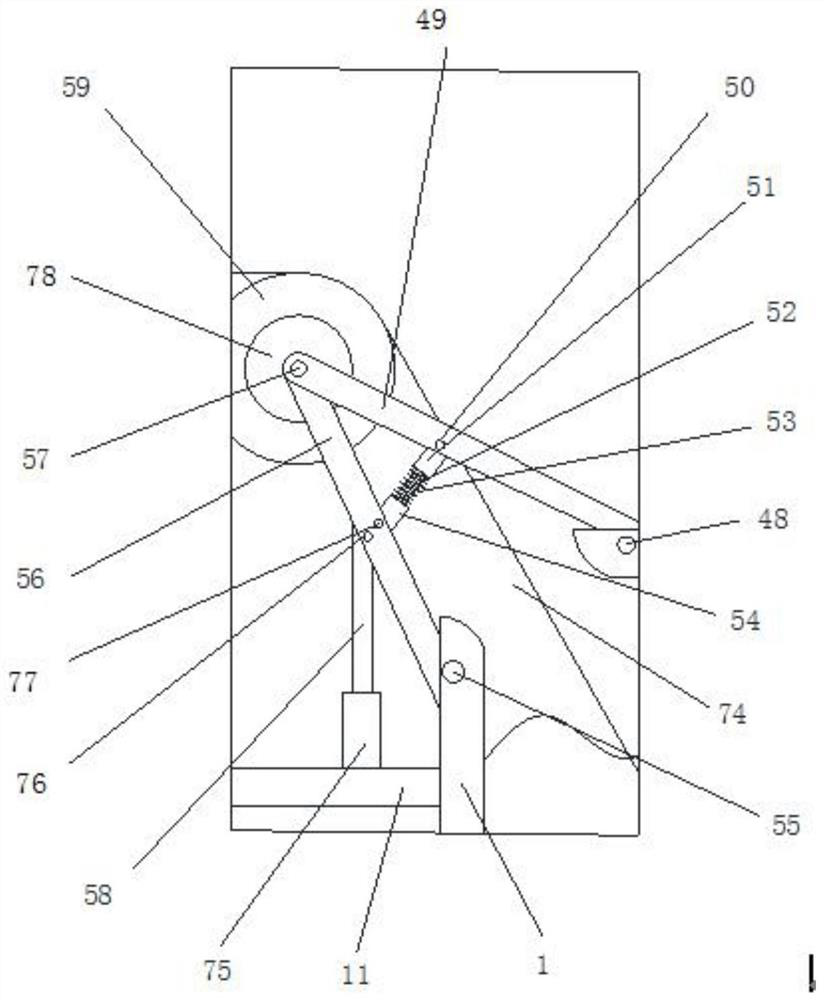

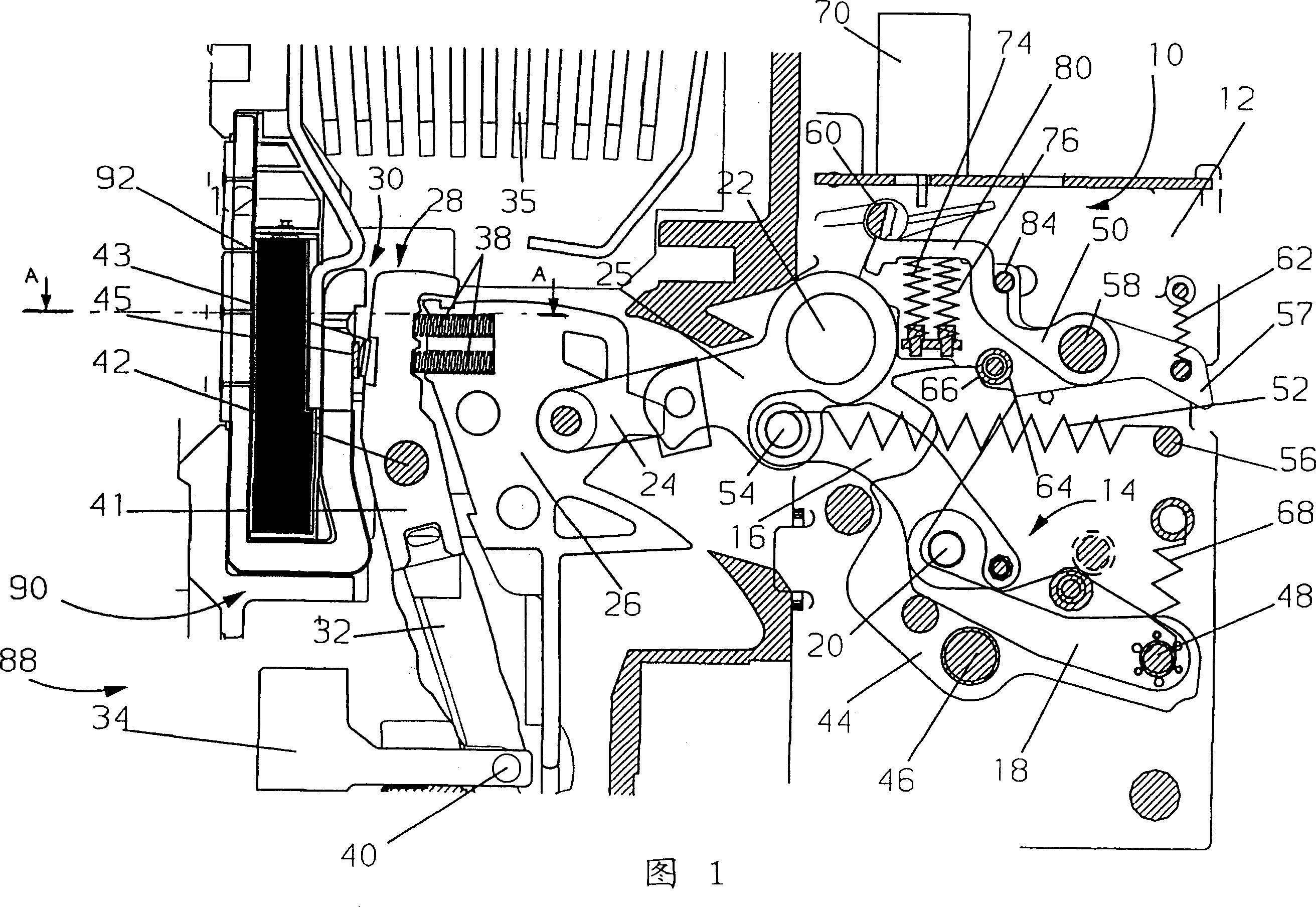

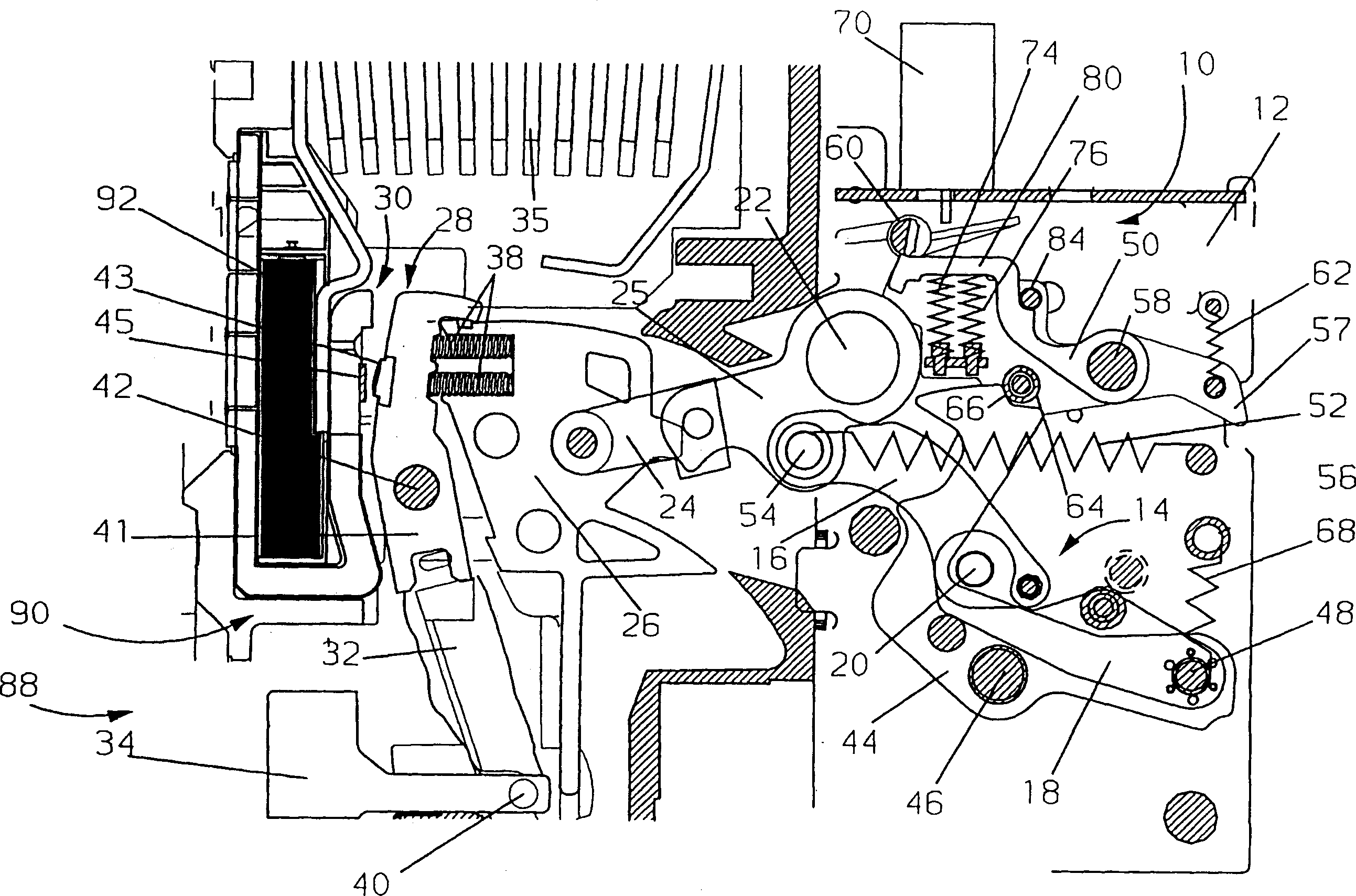

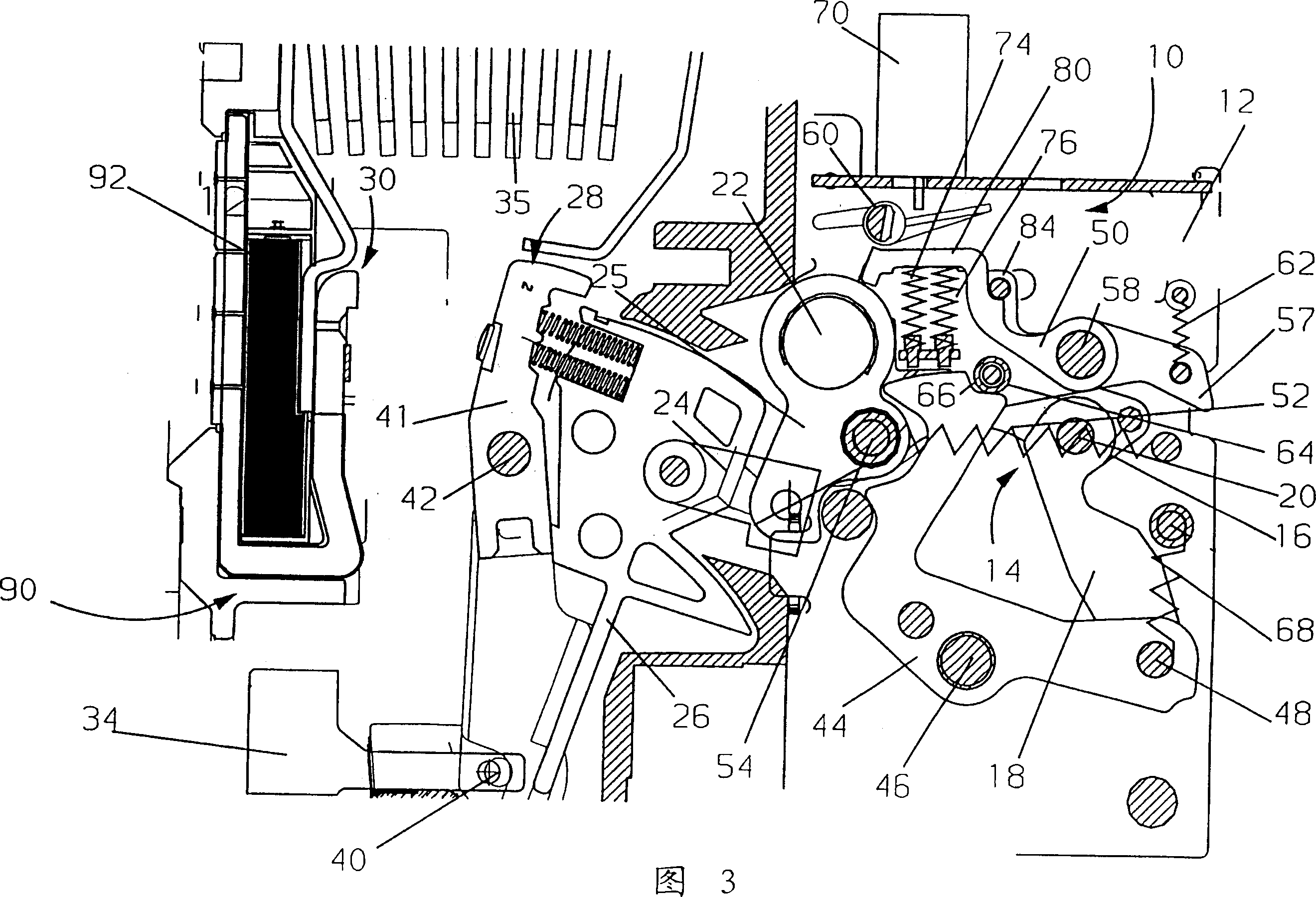

Circuit breaker possessing high power strength and breaking capability

InactiveCN1168114CReduce stressImprove reliabilitySwitch power arrangementsSnap-action arrangementsEngineeringContact position

The circuit breaker pole or poles comprise a movable contact means with a support carrier movable with respect to the frame between an open position and a closed position and one or more contact fingers movable with respect to the support carrier between a contact position and a retracted position. Electromagnetic compensation means are designed to apply electromagnetic forces on the contact finger or fingers tending to keep the contact finger or fingers in contact with the stationary contact means. Electromagnetic limiting means are designed to apply electromagnetic forces on the contact finger or fingers tending to drive the finger or fingers to their retracted position. The electromagnetic compensation means and the electromagnetic limiting means are such that when the current intensity flowing in the movable contact means is under a threshold called the limiting threshold, the finger or fingers are kept in contact with the stationary contact means, and that above said threshold, the finger or fingers are driven to their retracted position. The resultant of the forces applied by the carrier on the kinematic connecting means when the current intensity flowing in the movable contact means reaches the limiting threshold is under the ultrafast opening threshold.

Owner:SCHNEIDER ELECTRIC IND SAS

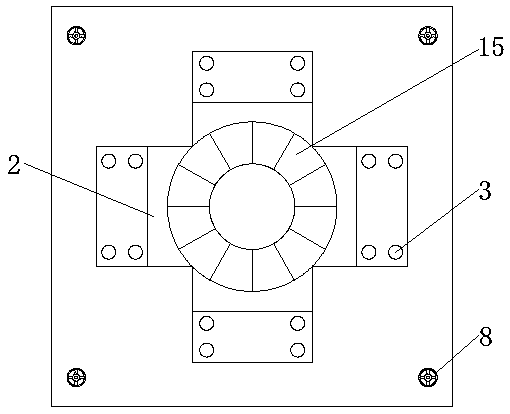

Four-bundle conductor spacer installation assistor

InactiveCN111668789AThere will be no whiplashWon't shakeMaintaining distance between parallel conductorsEngineeringSteel frame

The invention discloses a four-bundle conductor spacer installation assistor, and relates to the field of electric power tools. The assistor comprises a base frame, wherein four lapping rings for fixing sub-conductors are arranged on the base frame; the upper part of the base frame is fixedly connected with a lifting point; the middle part of the base frame is fixedly connected with a cross-shapedcircular steel frame for enhancing the strength of the base frame; and the base frame is a square with the side length of 450mm. The beneficial effects of the invention are that the four sub-conductors are respectively limited in the lapping rings through the four lapping rings, thereby enabling the four sub-conductors not to hit each other, enabling the four sub-conductors not to excessively shake, reducing the work danger degree of a worker, and reducing the damage to equipment.

Owner:国网河北省电力有限公司建设公司 +3

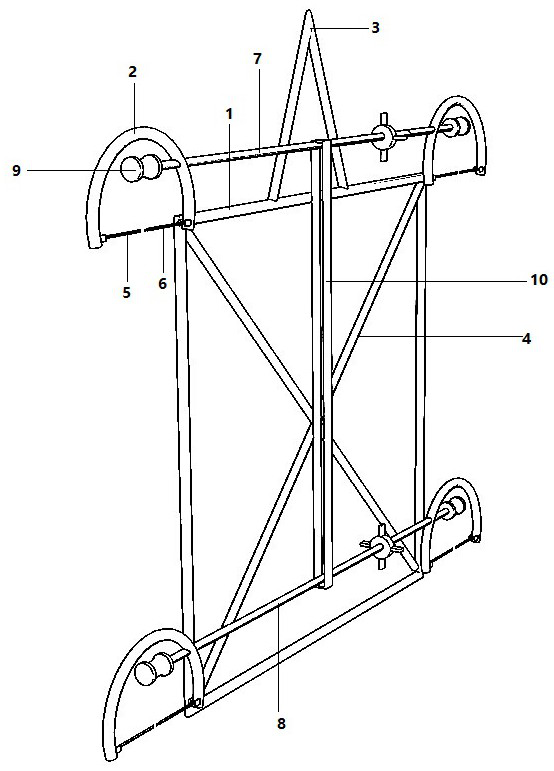

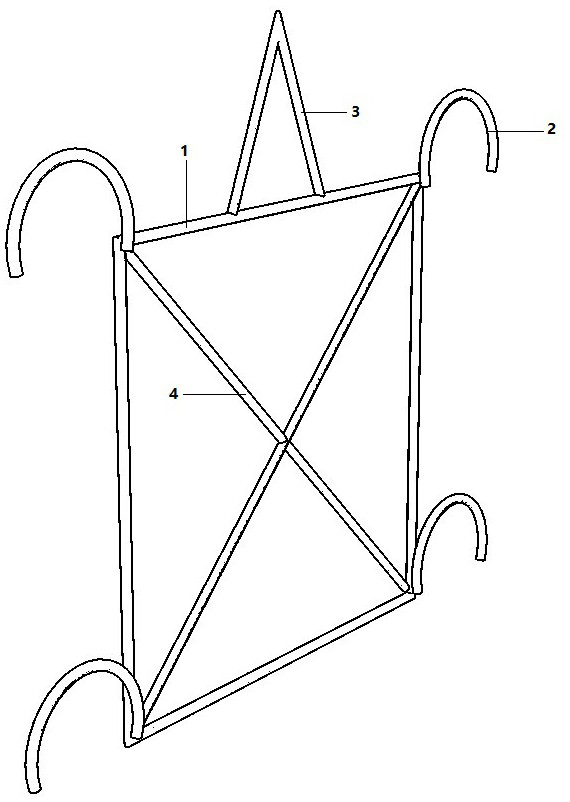

Dynamic lumbar vertebra fixing system

ActiveCN102362816BImprove rigidityIncrease elasticityInternal osteosythesisSpinal columnLumbar vertebrae

The invention discloses a dynamic lumbar vertebra fixing system. The dynamic lumbar vertebra fixing system comprises a dynamic rod (1), and at least two pedicle screws (2) connected to the dynamic rod (1), wherein the upper part of each pedicle screw (2) has a cavity; a screw bolt (3) is arranged in the cavity and is in threaded connection with the pedicle screw (2); the dynamic rod (1) passes through the cavity in the upper part of the pedicle screw (2); the screw bolt (3) in the cavity presses the dynamic rod (1); the dynamic rod (1) is a hollow rod; an elastic core shaft (1-2) is inserted into a hole of the dynamic rod (1); at least one section of lead screw part (1-1) of which the diameter is larger than those of two sides is arranged on an excircle of the dynamic rod (1); and more than one circles of lead threads (1-1-1) are arranged on the lead screw part (1-1). The dynamic lumbar vertebra fixing system can return a lumbar segment to a normal three-dimensional line and keep the normal height of a lumbar disc well, allows the limited movement of a spinal column and well accords with the physiological stability of the spinal column, so that the effects of relieving pains and preventing regression of neighboring segments are achieved.

Owner:瞿玉兴

An electrical automation control system

ActiveCN105867279BRealize real-time monitoringEasy to useProgramme controlComputer controlControl systemMan machine

The invention discloses an electrical automation control system. The electrical automation control system comprises a man-machine operating module, a to-be-controlled equipment operating parameter acquisition module, a central controller, a control command previewing module and a control command optimizing module. Multiple input modes are adopted, great convenience is brought to use, and input of each command carries identity authentication information; on the one hand, limitation of system control authority is guaranteed, and on the other hand, input of each control command has traceability; each control command needs to be previewed before being confirmed to be output, so that output errors of the control commands are well avoided, and each control command has visuality; real-timing monitoring on the operating condition of to-be-controlled equipment is achieved, therefore, output of each control command can achieve optimal parameter adjustment, pertinence is high, and the generation efficiency is improved to a certain degree.

Owner:黑龙江省农业机械工程科学研究院佳木斯农业机械化研究所

Virtual character control method and device, storage medium and electronic device

ActiveCN110134462BImprove control efficiencySolve technical problems of low control efficiencyExecution paradigmsSimulationOperation mode

Owner:TENCENT TECH (SHENZHEN) CO LTD

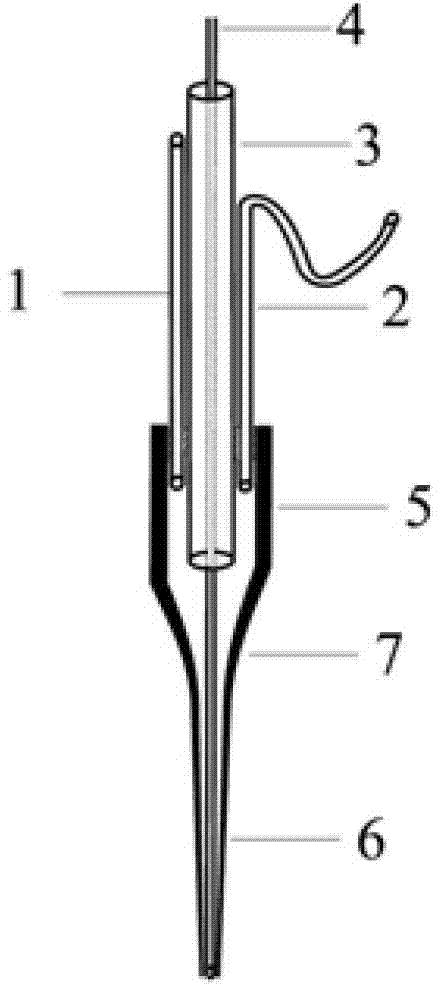

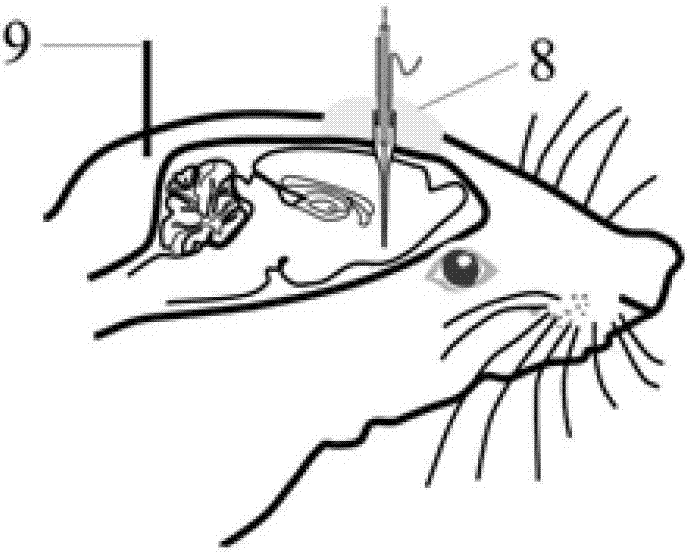

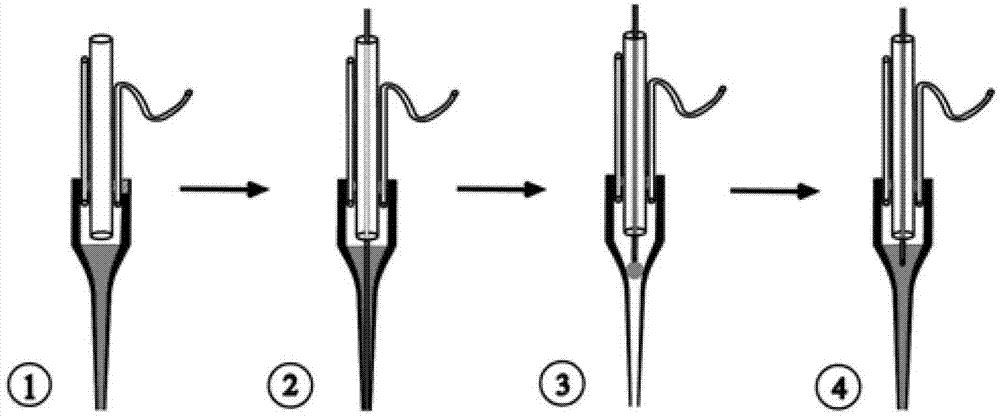

Trace drug delivery and changing device utilizing electroosmosis/pressure technology and application and manufacturing method of trace drug delivery and changing device

InactiveCN103040537BPrecise positioningReduce mistakesVeterinary instrumentsMicroelectrodeGuide tube

The invention relates to a trace drug delivery and changing device utilizing the electroosmosis / pressure technology and an application and manufacturing method of the trace drug delivery and changing device. The device comprises a glass microelectrode, a first PE (polyethylene) tube, a second PE tube and a third PE tube. The glass microelectrode comprises a thick section, a thin section and a neck, wherein the neck is a joint between the thick section and the thin section. The diameters of the first PE tube and the second PE tube are smaller than that of the third PE tube. The first PE tube, the second PE tube and the third PE tube are inserted at openings of the thick section. A gap between the thick section and each of the first PE tube, the second PE tube and the third PE tube is sealed. By the multifunctional trace drug delivery and changing device which is capable of drug delivery and changing, animal anesthesia and supporting of a drug delivery core tube by hands during drug delivery are avoided, positioning errors of traditional drug delivery are avoided, guide tube blocking in traditional drug delivery is eliminated, and trace drug delivery can be performed by selectively utilizing electroosmosis or pressure injection. In addition, the whole device is simple and cheap to manufacture, and more convenient in drug delivery.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

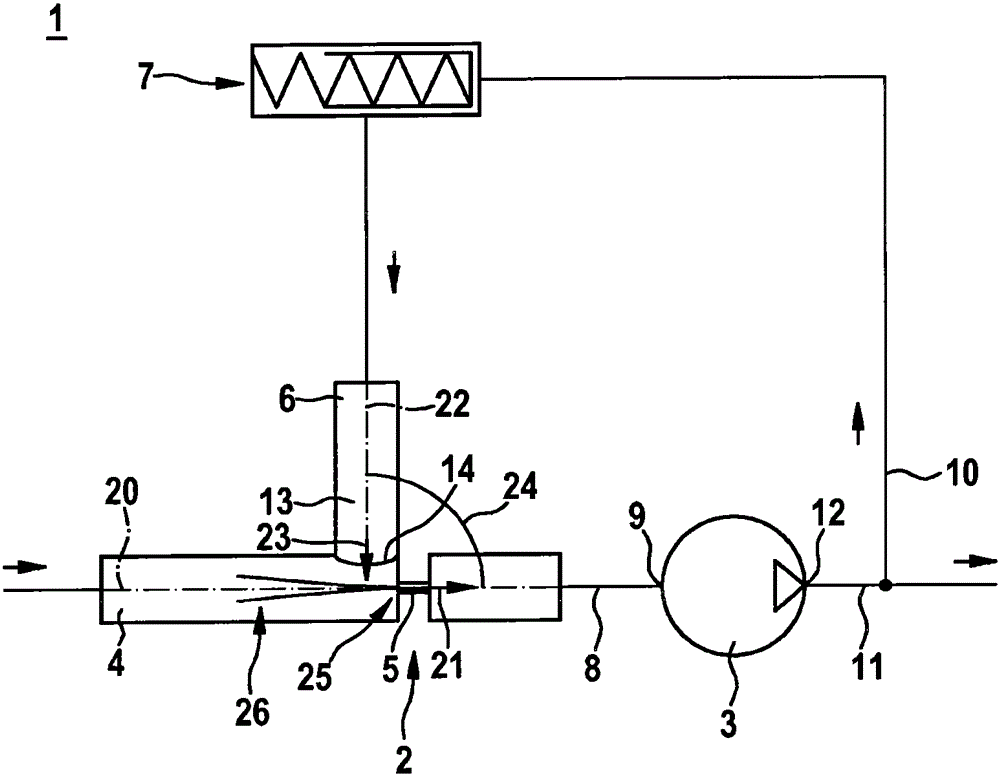

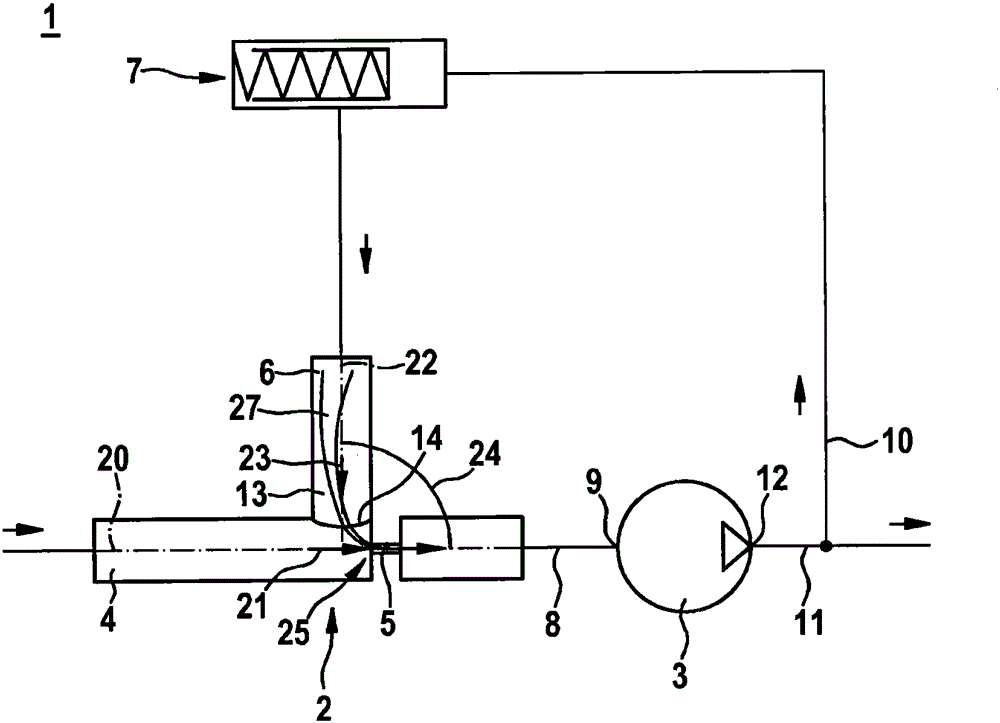

Device for flow restriction on a pump and pump device having such a device

ActiveCN102325996BRelieve stressPrevent or at least reduce pressure riseTurbine/propulsion fuel deliveryJet pumpsCombustionInternal combustion engine

A device (2) for restricting the throughflow quantity at a pump (3), in particular at a suction-throttled delivery pump for fuel injection systems of air-compressing, self-igniting internal combustion engines, has a feed channel (4) on the suction side of the pump (3), which feed channel (4) is connected on an outlet side (8) to an inlet (9) of a pump (3), a cut-off channel (6) which can be connected on its inlet side (10) at least indirectly to an outlet (12) of the pump (3) and which opens on its outlet side (13) laterally at an opening point (14) into the feed channel (4), and a pressure control valve (7) which is arranged in the cut-off channel (6). Furthermore, a throttle (5) is provided which is arranged in the feed channel (4) between the opening point (14) and the outlet side (8) of the feed channel (4). A transverse flow is caused at the opening point (14) by a cut-off quantity which is discharged via the cut-off channel (6), which transverse flow is superimposed with a main flow through the feed channel (4). As a result, a lateral incident flow of the throttle (5) can be achieved, as a result of which the effective throttle diameter is reduced. A given pressure difference at the pump (3) can therefore be reduced. Furthermore, Furthermore, a pump arrangement (1) with the pump (3) and the device (2) for restricting the throughflow quantity is disclosed.

Owner:ROBERT BOSCH GMBH

Energy-saving printing and dyeing device using wind power

ActiveCN109944005AImprove efficiency and qualityImprove printing and dyeing efficiencyLiquid/gas/vapor treatment machines driving mechanismsSucessive textile treatmentsElectric machineryDyeing

The invention discloses an energy-saving printing and dyeing device using wind power. A first cavity is formed in a first box body, a second cavity is formed in a second box body, and a first conveying pipe is connected between the first box body and the second box body; a stirring box is mounted at the upper end of the second box body, a second conveying pipe is connected between the stirring boxand the second box body, a second feeding pipe is mounted at one side of the stirring box, a first motor is mounted on the stirring box, and a first stirring shaft is mounted at the portion, in the stirring box, of the first motor; the stirring box is provided with a first limiting shaft sleeve, the first stirring shaft penetrates through the first limiting shaft sleeve, and first stirring bladesare mounted at the outer periphery of the first stirring shaft; a plurality of nozzles are arranged at the portion, in the second cavity, of the second conveying pipe, the first box body is providedwith a second limiting shaft sleeve, a second stirring shaft penetrates through the interior of the first limiting shaft sleeve, a fan blade mounting shaft is mounted on the second stirring shaft, fanblades are mounted on the fan blade mounting shaft, and second stirring blades are mounted at the portion, in the first cavity, of the second stirring shaft. The energy-saving printing and dyeing device improves the efficiency and quality of printing and dyeing.

Owner:汪秀英

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com