Novel adjustable type underreaming drill bit used for well

A bottom-expanding and adjustable technology, which is applied to drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of increasing labor intensity, waste of cost, affecting the work process, etc., so as to increase labor intensity, shorten the work process, and prolong the work. effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

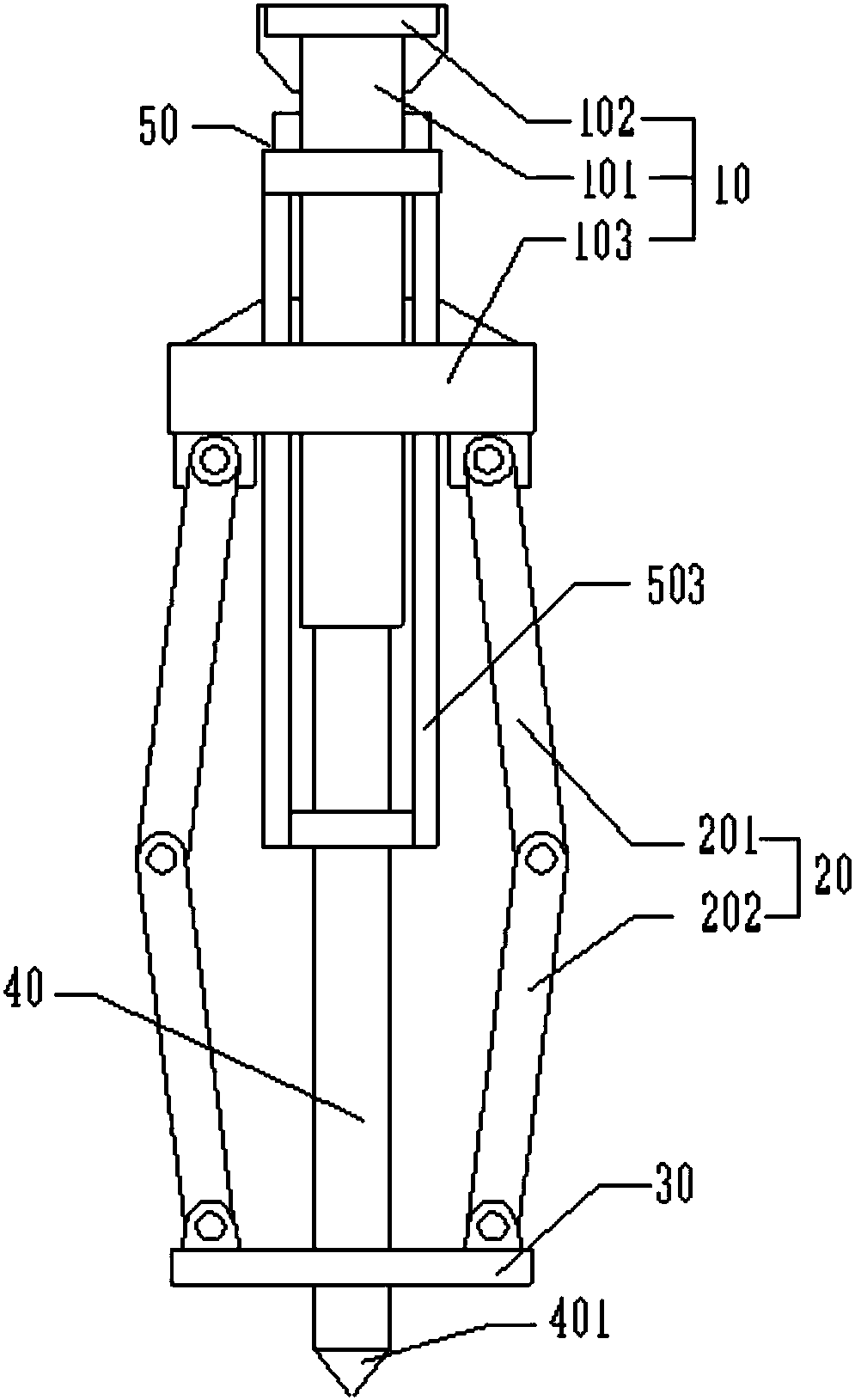

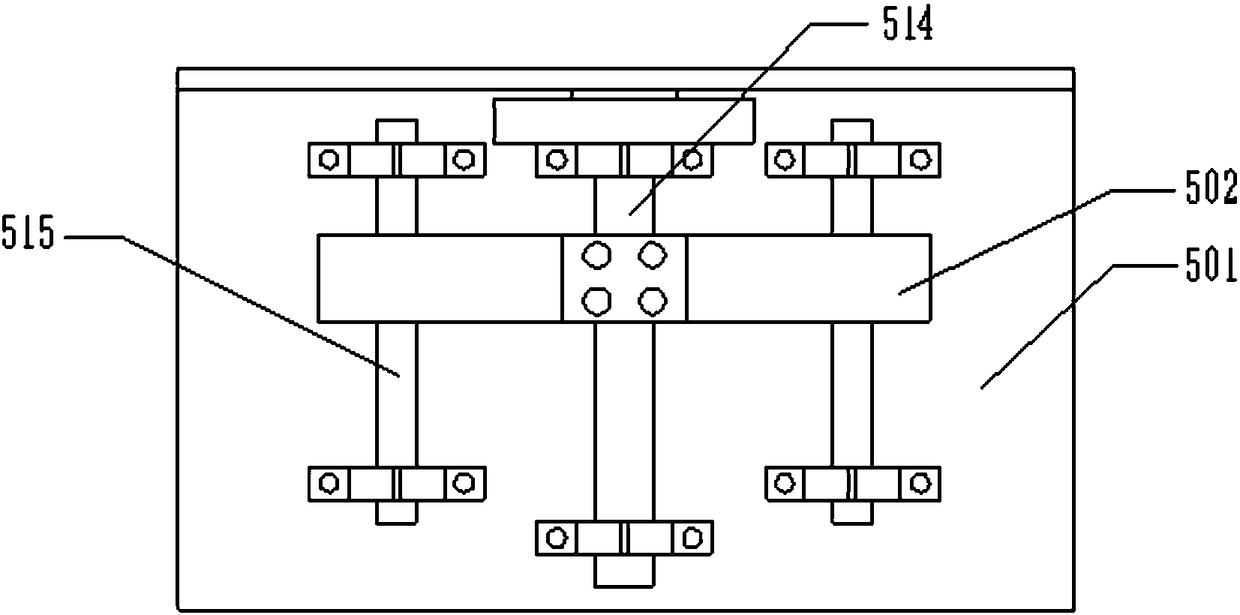

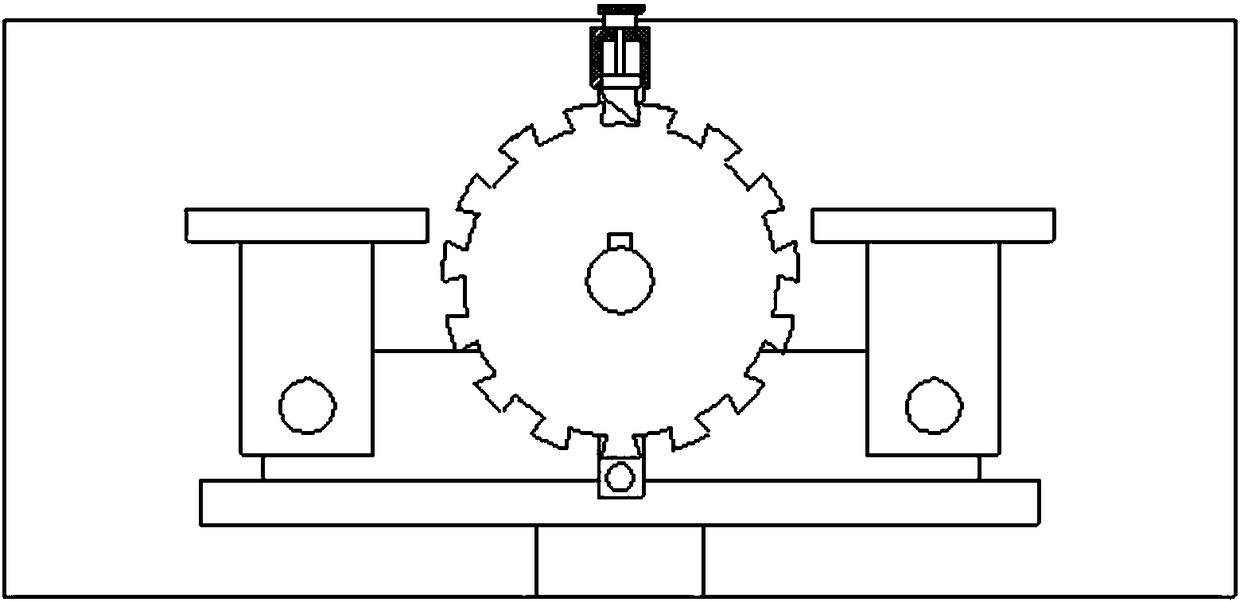

[0030] like Figure 1-Figure 7 As shown, a new type of adjustable bottom expansion drill bit for wells includes a lifting main body 10, a bottom expansion wing main body 20, a bottom plate 30, a central positioning shaft 40 and a limiting main body 50, and the lifting main body 10 is coaxially sleeved on the central positioning shaft 40 and the bottom of the lifting main body 10 is hinged with one end of the bottom expansion wing main body 20, the other end of the bottom expansion wing main body 20 is hinged on the upper surface of the bottom plate 30, and the lower end of the central positioning shaft 40 is vertical and coaxially pierced through the bottom plate 30 , and the lower end of the central positioning shaft 40 is coaxially provided with an insertion tip 401, and the limiter body 50 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com