Method for packaging white LED locally sprayed with fluorescent powder and fluorescent powder local coating structure

A technology of LED packaging and phosphor powder, which is used in electrical components, electrical solid-state devices, circuits, etc. to achieve uniform light color, increased uniformity, and wide applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

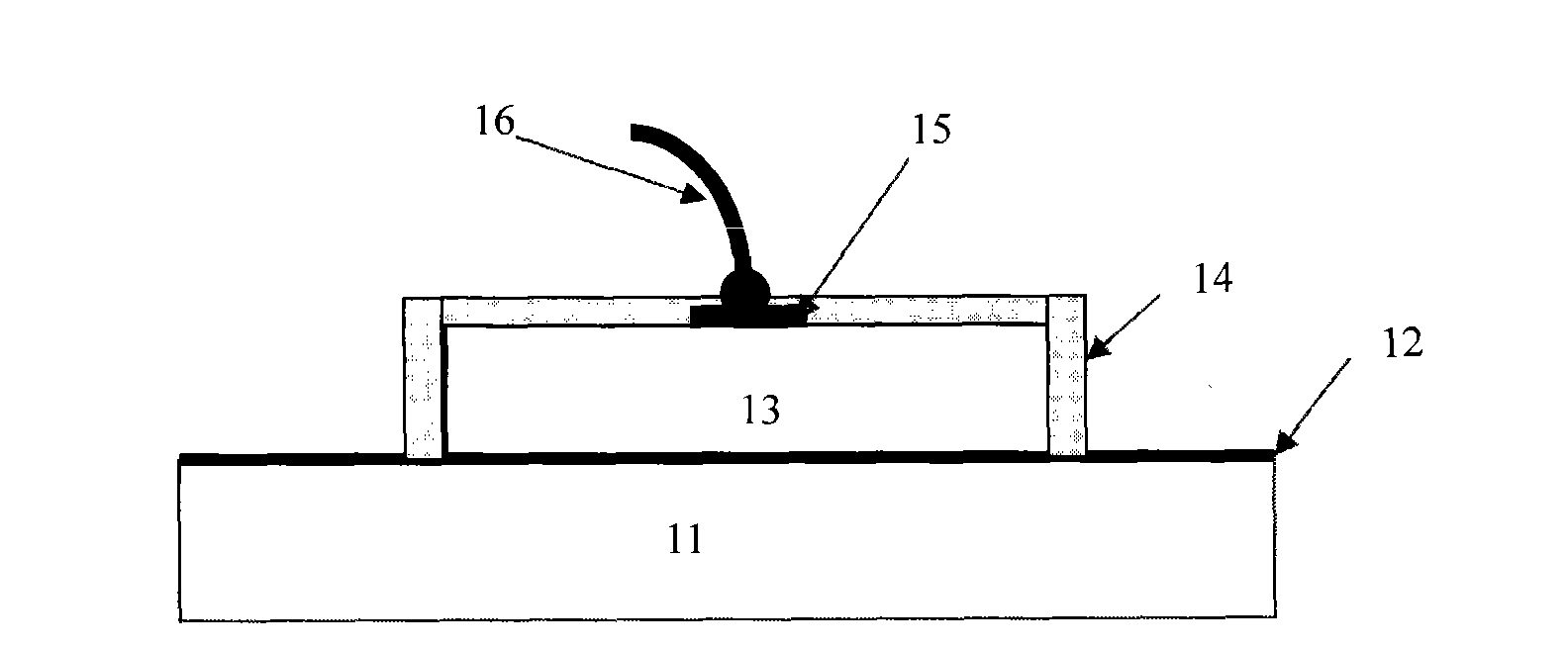

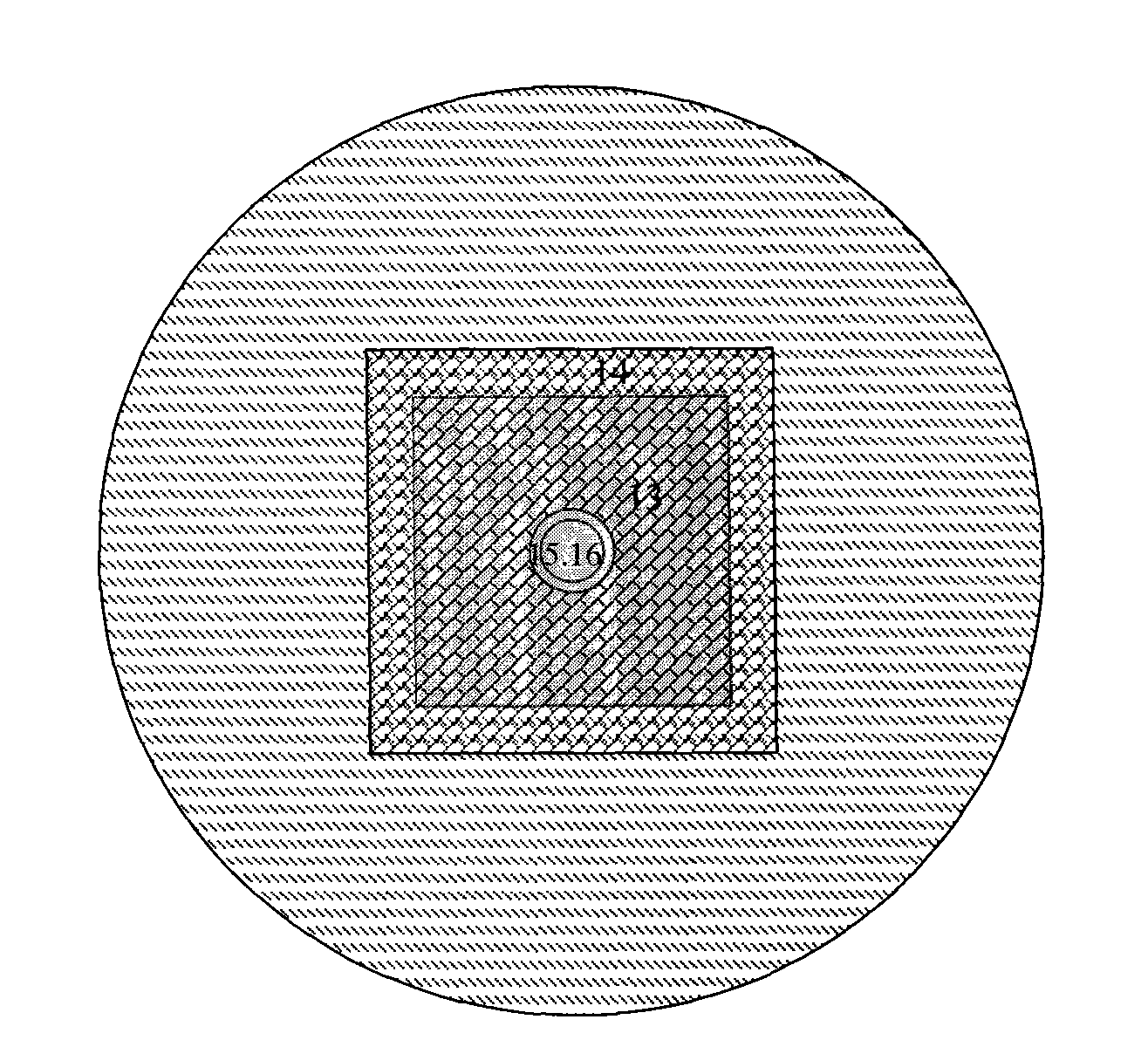

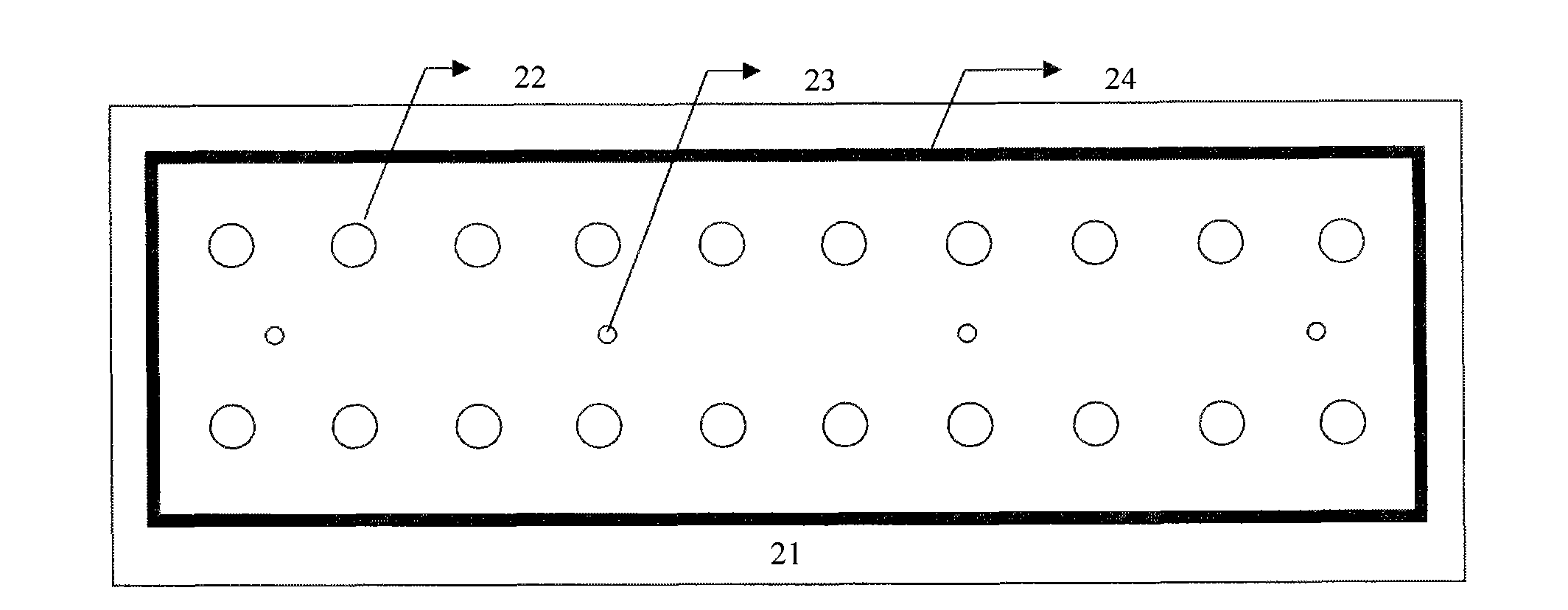

[0052] The invention provides a white light LED packaging method in which fluorescent powder is partially coated on a chip by a spraying method. After the LED chip is solidified and wire-bonded on the power type bracket, the LED bracket is placed in a mold to expose the chip and the edge area. Use the atomizing nozzle of the automatic dispensing machine to atomize the sprayed phosphor colloid, and the fine phosphor powder droplets on the chip surface and side wall are connected to form a film, and on the heat sink of the bracket, because of the special plasma surface During processing, the contact angle between the glue droplets and the heat sink metal is large and mainly gather around the chip. In this way, a uniform film of fluorescent powder colloid is formed around the chip, and after thermal curing or ultraviolet curing, a partial coating of LED fluorescent powder is formed.

[0053] According to the technical solution of the present invention, the structure of the local...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com