Energy-saving printing and dyeing device using wind power

A wind power and mounting plate technology, applied in liquid/gas/steam processing transmission, textile material processing, continuous processing of textile materials, etc., can solve problems such as increased production costs, and achieve the effect of improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

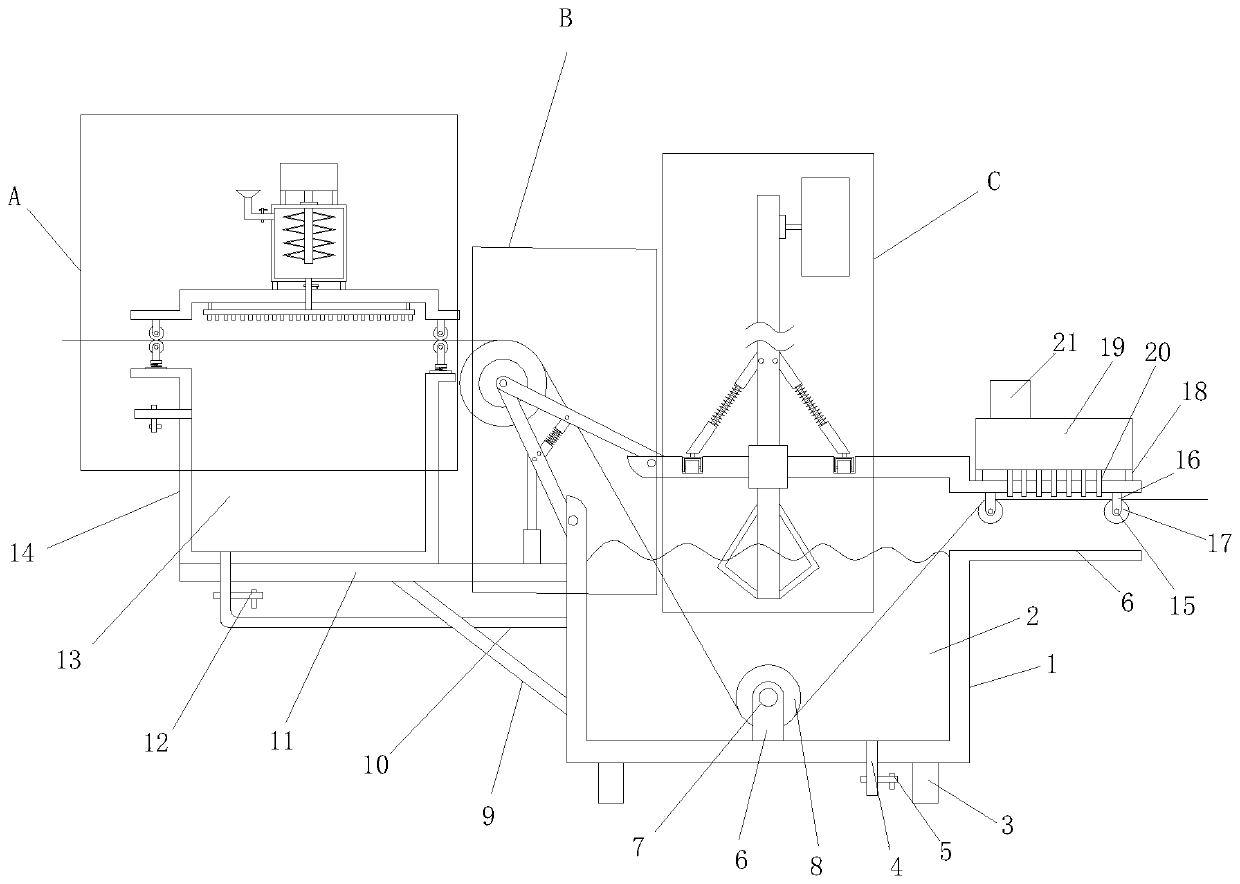

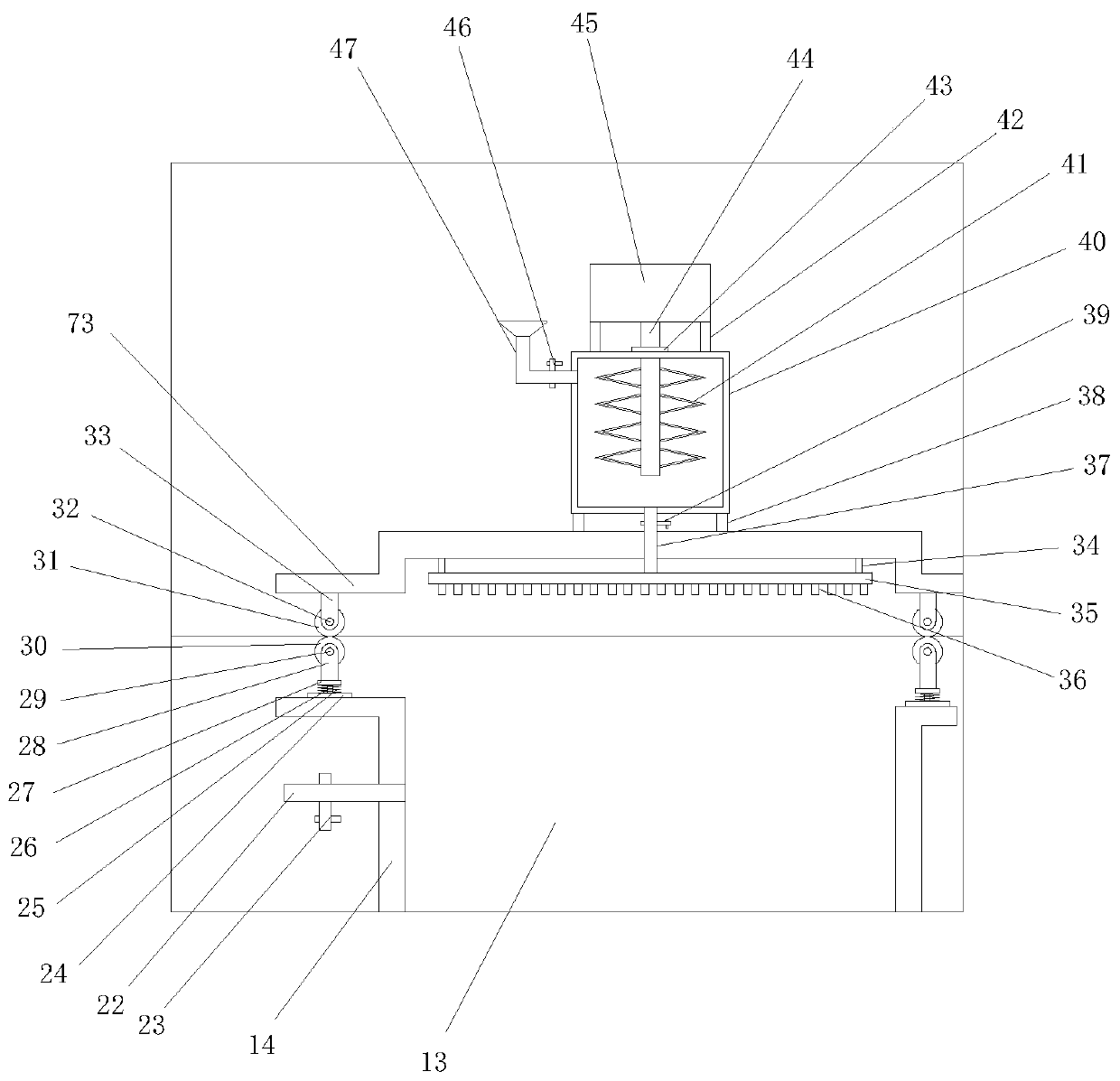

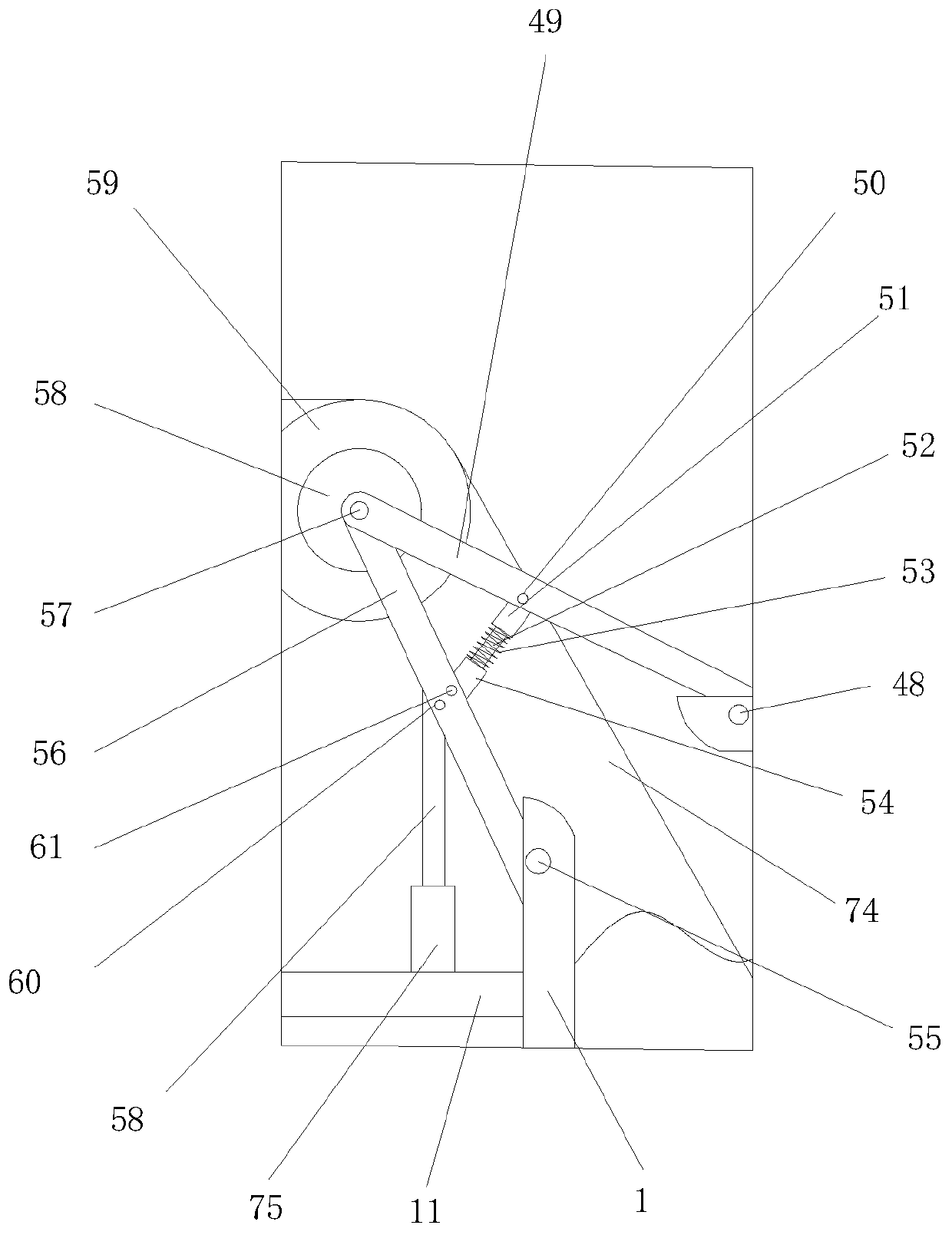

[0024] refer to Figure 1-4 , the present invention proposes an energy-saving printing and dyeing device using wind power, comprising a first box 1 and a second box 14, the first box 1 is provided with a first cavity 2, and the second box 14 is provided with a first Two chambers 13, the lower end of the first box body 1 is equipped with a bracket 3, one side of the first box body 1 is equipped with a second mounting plate 11, the second box body 14 is installed on the upper end of the second mounting plate 11, the first A first transmission pipe 10 is connected between the box body 1 and the second box body 14, a second valve 12 is provided on the first transmission pipe 10, and a first Support rod 9, a cloth output pipeline 6 is installed on one side of the first box body 1, a first mounting plate 6 is installed on the inner bottom of the first cavity 1, a first rotating shaft 7 is installed on the first mounting plate 6, and the first rotating shaft 7 is installed on the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com