A split-level high-speed railway platform door with bottom drive

A platform door, high-speed rail technology, applied in stations, railway car body parts, roads, etc., can solve the problem of not being able to adjust the door opening position for different models, unable to realize the opening of the door in alignment, avoiding physical interference, improving stability, and increasing orientation. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

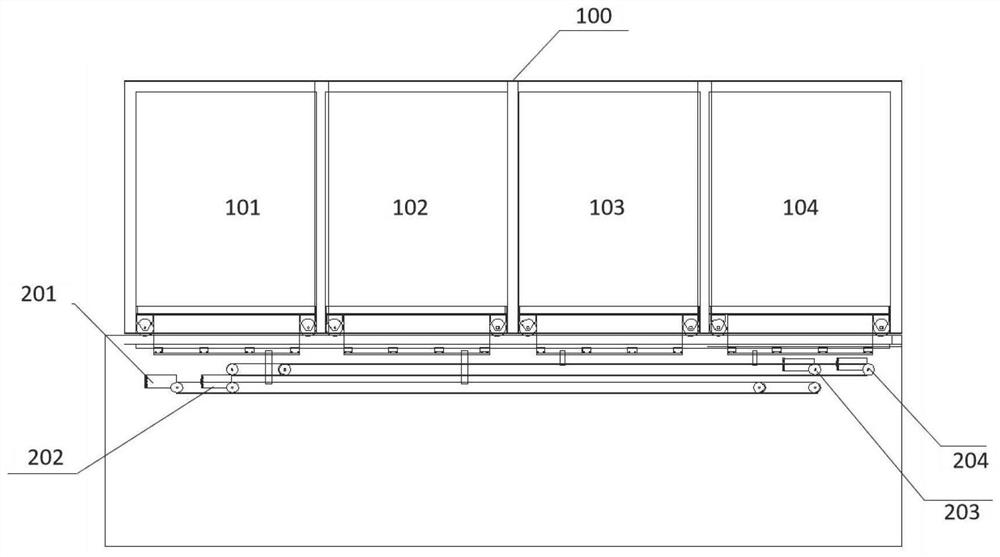

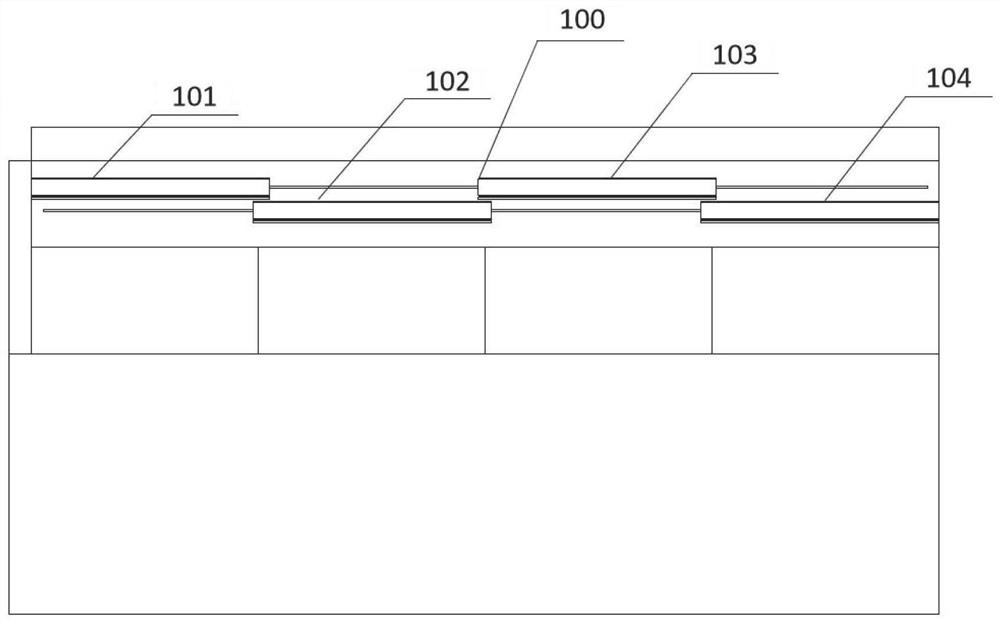

[0037] Embodiment 1 provides a kind of split-level high-speed rail platform door driven by the bottom, such as Figure 1-6 As shown, it includes several movable door unit groups 100 arranged continuously along the direction of the platform, and each movable door unit group 100 includes a first movable door 101, a second movable door 102, a third movable door 103 and a first movable door 103 arranged sequentially in a closed state. Four movable doors 104;

[0038] The first movable door 101 and the third movable door 103 are arranged on the back row, that is, the track side, and the second movable door 102 and the fourth movable door 104 are arranged on the front row, that is, the platform side;

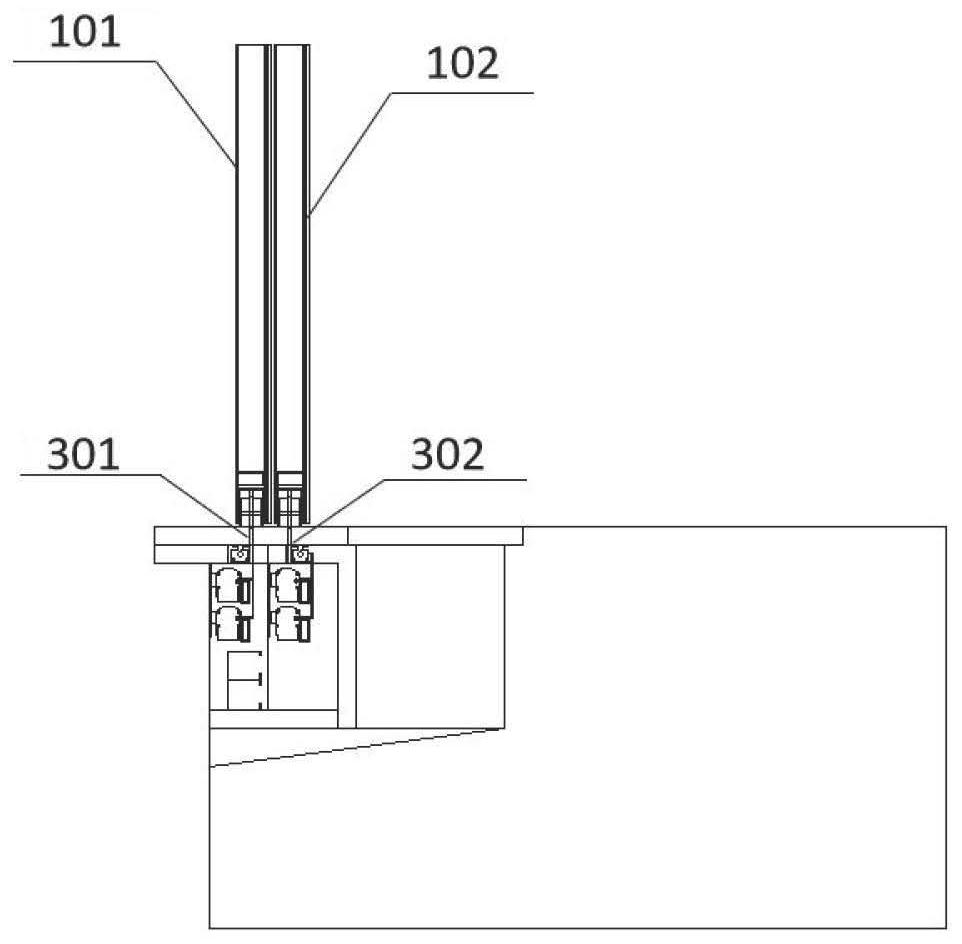

[0039] like Figure 3-4 , the driving device 201 of the first movable door 101 and the driving device 203 of the third movable door 103 are arranged at the bottom of the front row and are staggered up and down, and the driving device 202 of the second movable door 102 and the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com